Dual prestressed beam and construction method thereof

A technology of prestressed beam and construction method, which is applied in the direction of load-bearing elongated structural members, processing of building materials, structural elements, etc., can solve problems such as loss of prestressing of flexible connectors, increase cracking load, save money Cost, Quantity Reduction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

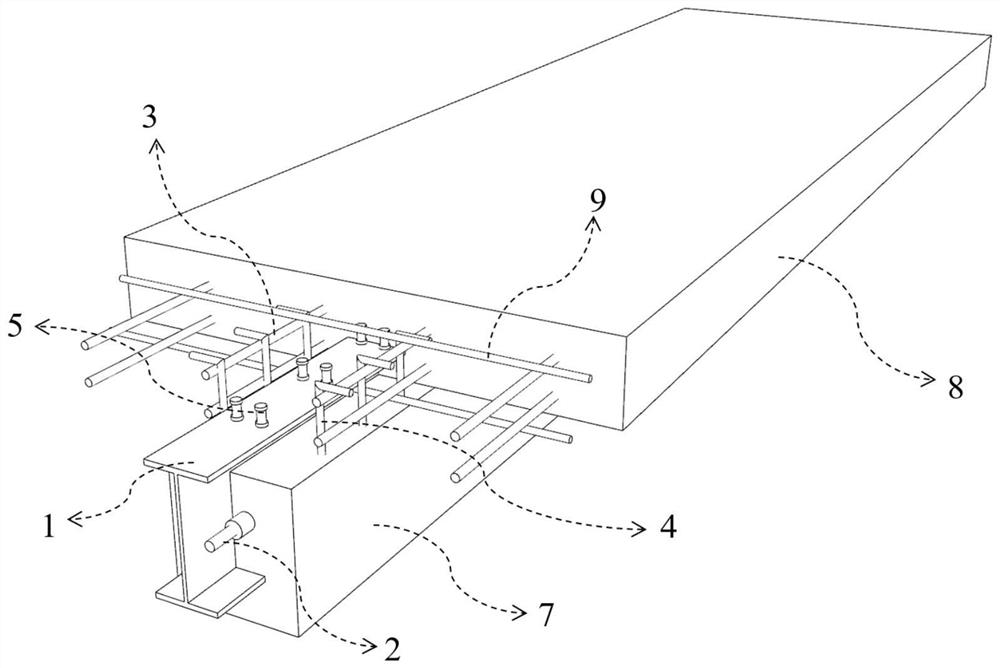

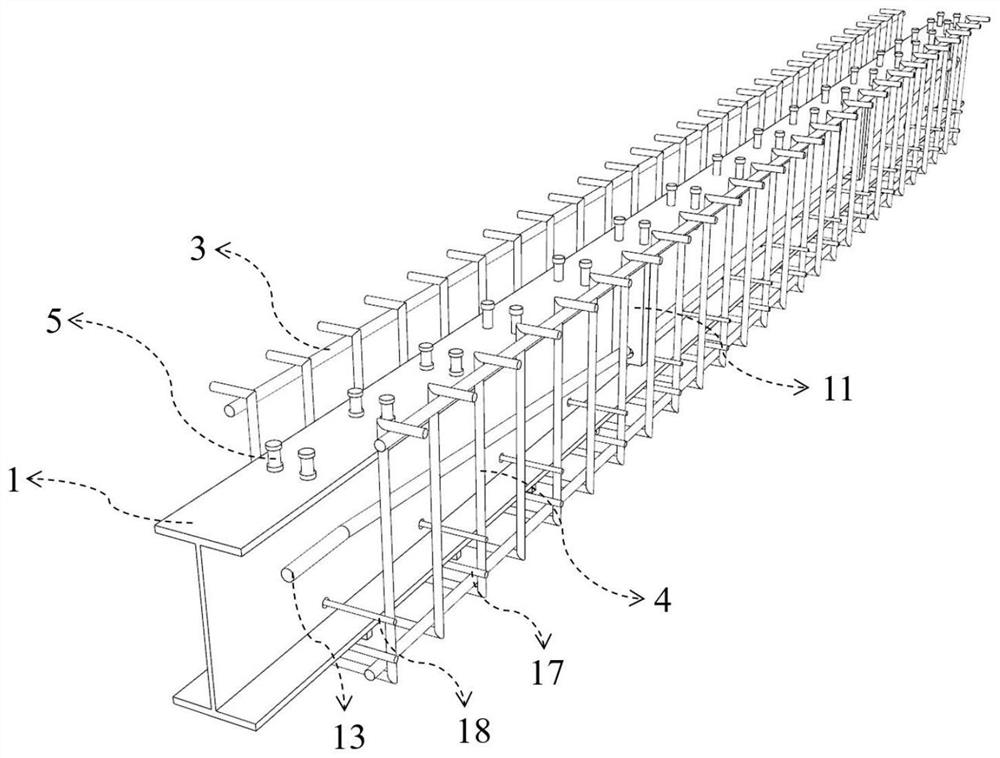

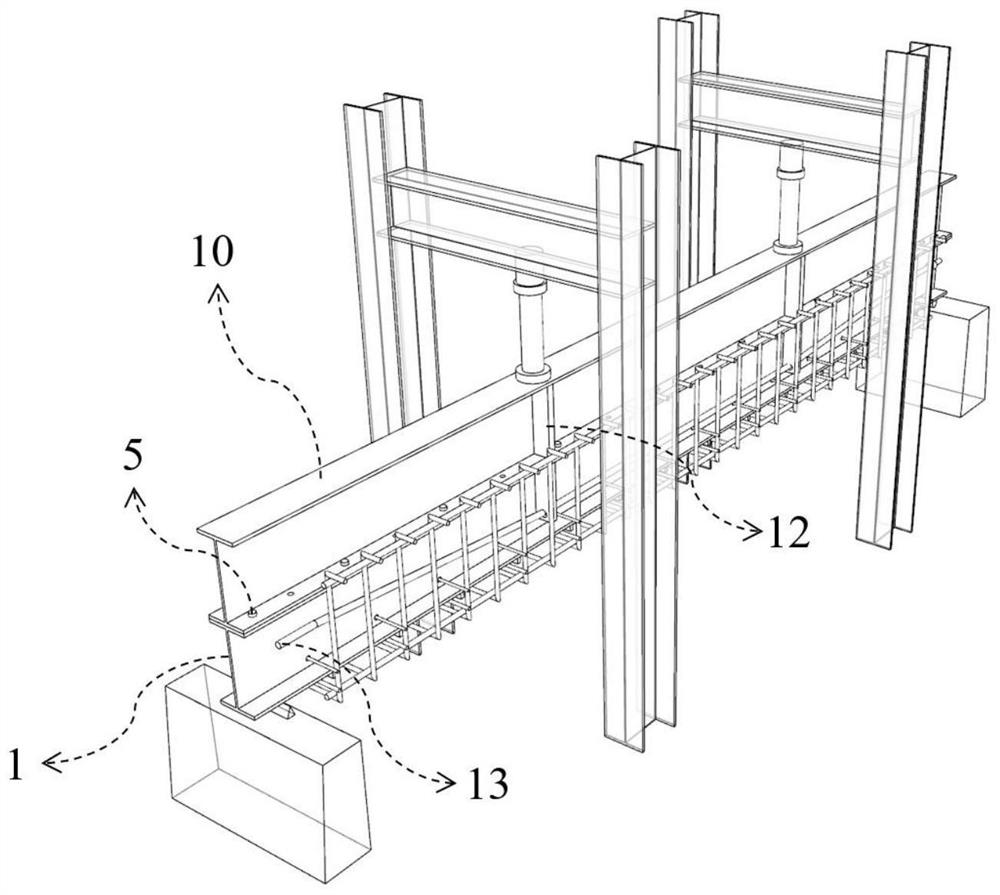

[0039] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

[0040] The invention is a double prestressed beam, which includes a prefabricated part and a cast-in-place part.

[0041] The prefabricated part is finished in the factory, such as Figure 1 to Figure 7As shown, it includes a shaped steel 1, and a number of longitudinal bars 3 and a number of open stirrups 4 are arranged around the shaped steel 1. Wherein, the length direction of the longitudinal bars 3 is parallel to the length direction of the section steel 1 and perpendicular to the plane where each open stirrup 4 is located, and the open stirrups 4 can be arranged at equal intervals along the length direction of the section steel 1 . The open stirrups 4 are opened above the upper flange of the section steel 1 , and the openings are horizontally bent and extended outward for a certain distance, and each open stirrup 4 overlaps with each long...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com