Plastic wound structure wall faucet pipe

A technology for structural walls and sockets, which is applied in the direction of pipes, rigid pipes, and pipe connection arrangements, can solve the problems of troublesome and time-consuming connections between pipes, complicated installation and connection procedures, and cumbersome preparations, and reduce the risk of leakage , pipe connection and installation are convenient, and the effect of reducing installation preparation work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

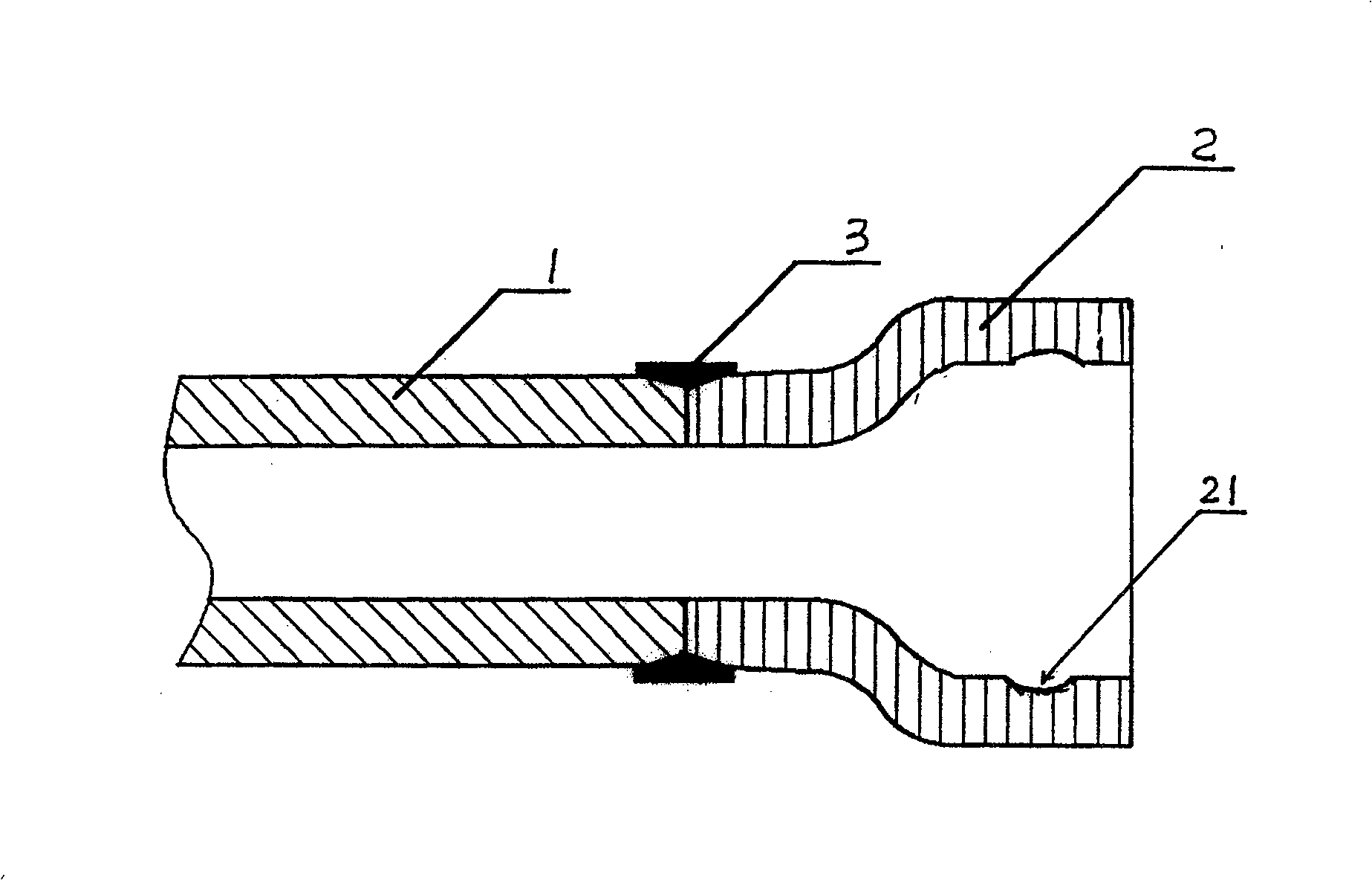

[0017] A plastic winding structural wall pipe with an inner diameter of 294mm and a wall thickness of 6mm is made by extrusion winding molding, and cut into a straight pipe with a length of 5.95m. In addition, a pipe with a total length of 0.295m and a socket joint is made by casting molding. Expand the pipe, and make its inner diameter and wall thickness the same as the inner diameter and wall thickness of the aforementioned straight pipe. Then, the straight pipe port of the winding structure wall and the flared pipe port are melt-welded into a whole by means of electric heating fusion belt welding. Promptly obtain a kind of plastic winding structure wall socket pipe of the present invention.

Embodiment 2

[0019] A plastic winding structure wall pipe with an inner diameter of 195mm and a wall thickness of 5mm is made by extrusion winding molding method, and cut into a straight pipe with a length of 4.95m, and a 0.25m long pipe with a socket joint is made by casting molding method Expand the pipe, and make its inner diameter and wall thickness the same as the inner diameter and wall thickness of the aforementioned straight pipe. Then, the straight pipe port of the winding structure wall and the flared pipe joint are melt-welded into a whole by means of heat-shrinkable tape welding. Promptly obtain a kind of plastic winding structure wall socket pipe of the present invention.

Embodiment 3

[0021] A plastic winding structure wall pipe with an inner diameter of 492mm and a wall thickness of 8mm is made by extrusion winding molding method, and cut into a straight pipe with a length of 3.95m, and a 0.395m long pipe with a socket joint is made by casting molding Expand the pipe, and make its inner diameter and wall thickness the same as the inner diameter and wall thickness of the aforementioned straight pipe. Then, the straight pipe port of the winding structure wall and the flared pipe port are melt-welded into a whole by means of electric heating fusion belt welding. Promptly obtain a kind of plastic winding structure wall socket pipe of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com