Nozzle wind speed measurement system and method suitable for cold state test of pulverized coal burner

A technology of pulverized coal burner and wind speed measurement, which is applied in the direction of measuring fluid speed by pressure difference, can solve the problems of inconvenient maintenance or adjustment, deviation of measurement results, complicated measurement device, etc., to avoid test work, reliability and accuracy. High, improve the effect of operating reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

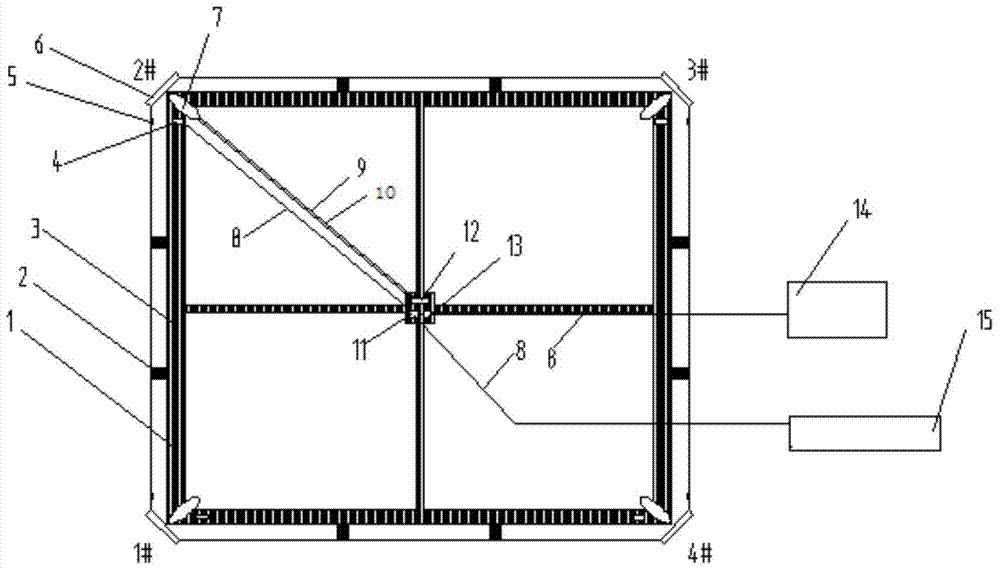

[0062] The #3 boiler in a power plant of Huadian Group is a subcritical, intermediate reheating, forced circulation drum boiler with an evaporation capacity of 1025t / h. The air nozzles are arranged at intervals, and the pulverizing system is a direct blowing type equipped with 6 medium-speed coal mills. The boiler burner adopts the early American CE technology, and the NOx emission concentration is relatively high. In order to meet the latest national pollutant emission standards for thermal power plants, the low-nitrogen burner is modified. The structure and layout of the modified burner are shown in Figure 7 , after the transformation was completed, an intelligent nozzle wind speed measurement system was used during the cold test.

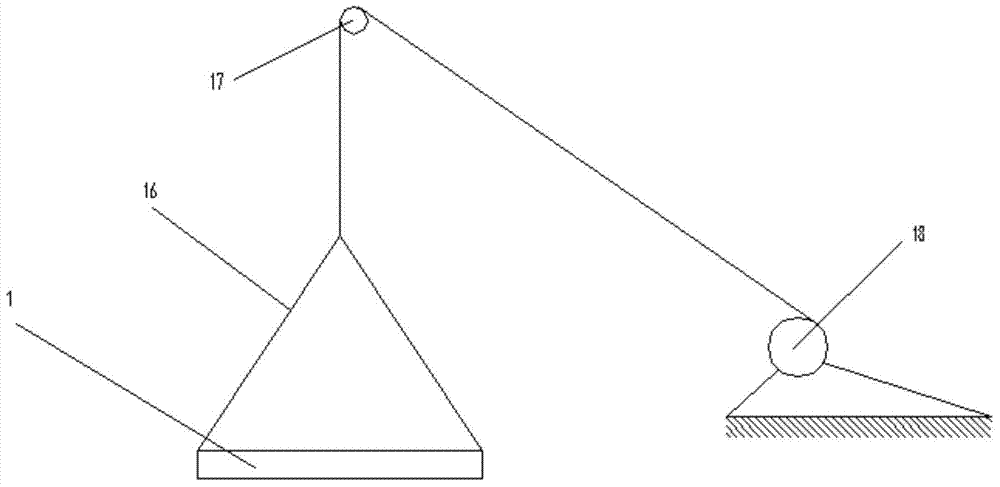

[0063] In the process of boiler overhaul, the power plant adopts the lifting platform 1 to ensure a faster construction progress in the furnace to facilitate the up and down construction in the furnace and to ensure higher construction safety (c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com