System and method for automatically adding anti-vibration strips to gas condenser

A technology of anti-vibration bars and condensers, applied in the field of machinery, can solve problems such as shutdown, leakage, and increased friction of titanium tubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

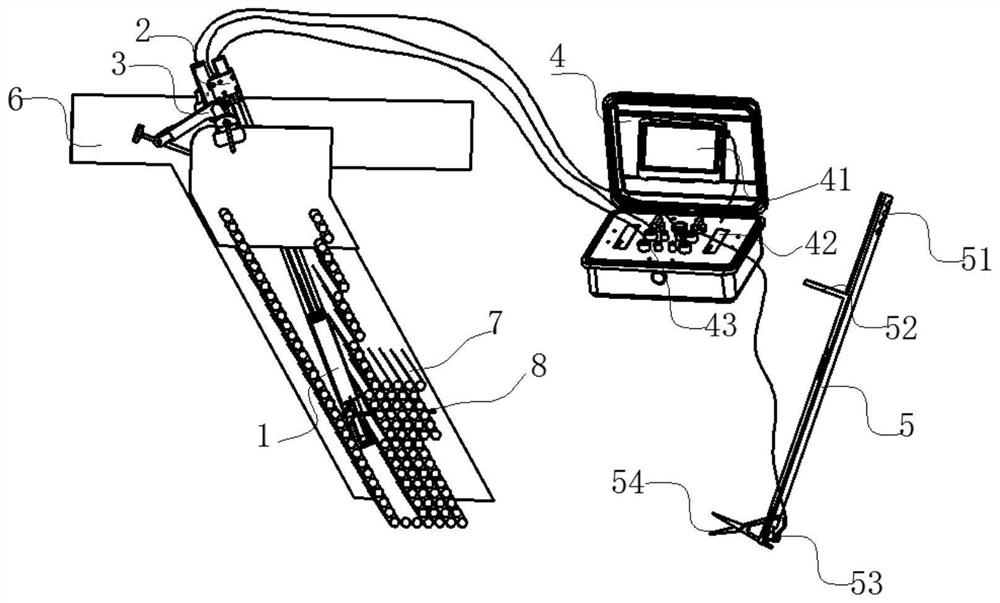

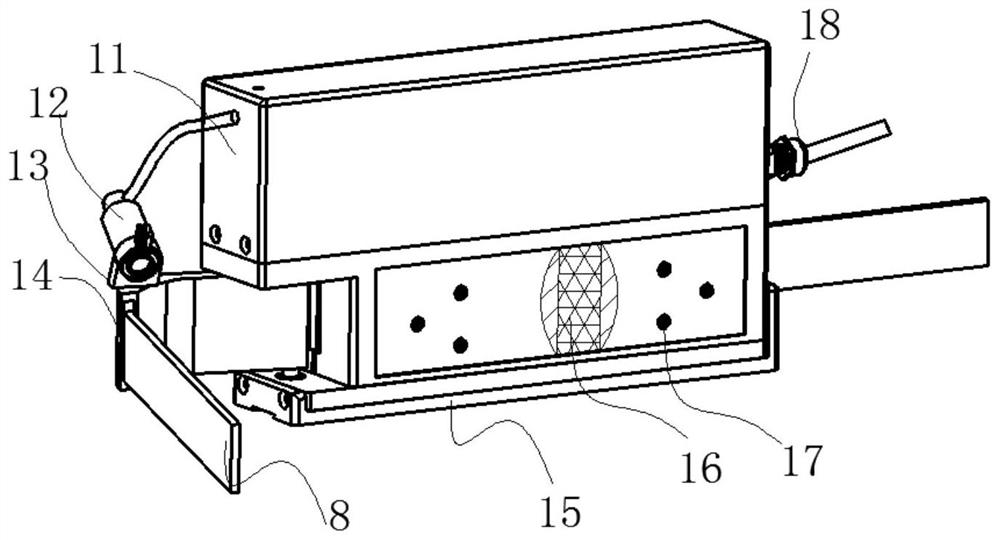

[0043] The core content of this patent is to set the guide rail assembly and the support frame assembly to extend the installation range, and to set the installation body to realize the installation of the anti-vibration strip. The implementation mode will be further described.

[0044] like figure 2 As shown, the embodiment of the present invention provides a system for automatically installing anti-vibration strips in a condenser, the system includes an installation body 1, a guide rail assembly 2, a support frame assembly 3, a control unit 4 and a shearing unit 5, wherein :

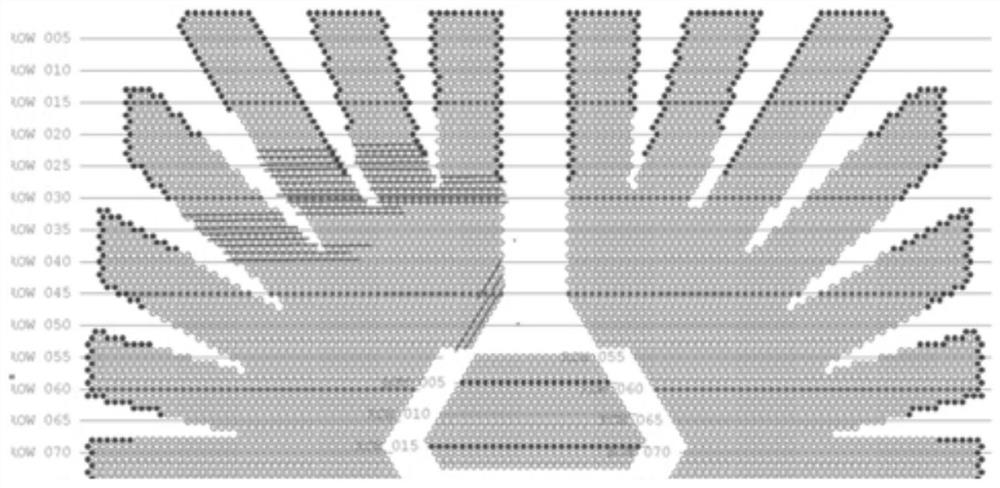

[0045] The installation body 1 is slidably arranged on the guide rail assembly 2, and is used for installing anti-vibration strips between the tube bundles 7 of the condenser to be inserted;

[0046] The guide rail assembly 2 is used to adjust the installation body 1 in the height direction;

[0047] The support frame assembly 3 is used to fix the guide rail assembly 2 and the condenser;

[0048] ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap