Throttle-free sand blasting sliding sleeve

A non-throttle, sliding sleeve technology, used in the production of fluids, wellbore/well components, earth-moving drilling, etc., can solve problems such as the inability to meet the needs of large-scale fracturing construction, reduce erosion damage, and improve safety. , to avoid the effect of traffic restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

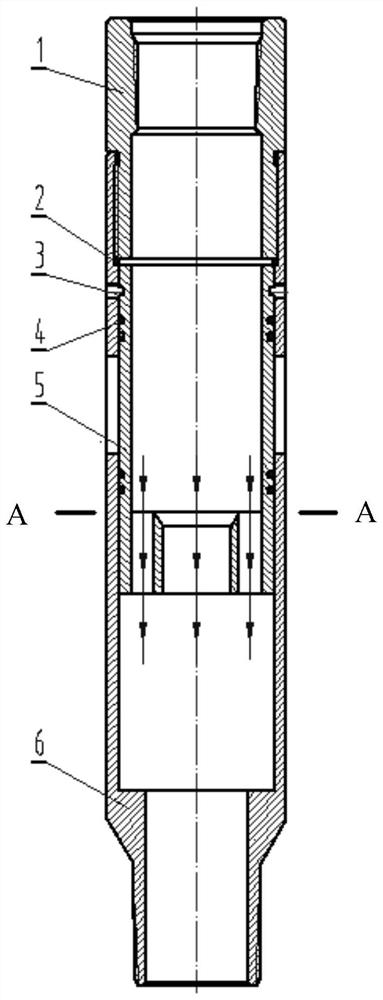

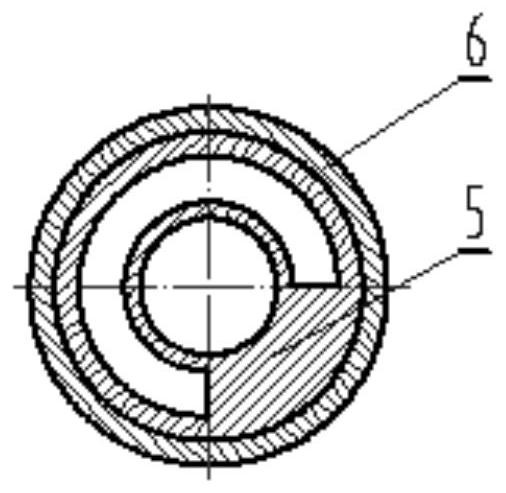

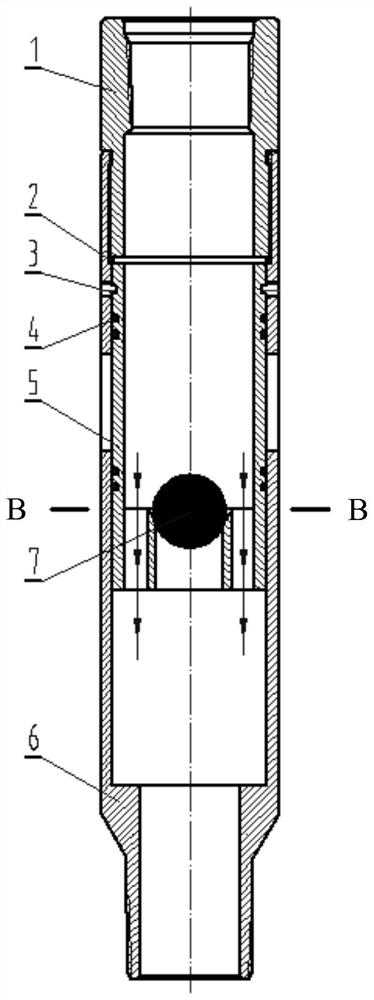

[0031] As shown in FIG. 1( a ) and FIG. 1( b ), the non-throttling sand blaster sliding sleeve includes an upper joint 1 , a non-throttling inner sliding sleeve 5 , a sandblasting sliding sleeve main body 6 and a soluble ball 7 .

[0032] The non-throttle inner sliding sleeve 5 includes an outer cylinder and an inner cylinder. The axial length of the inner cylinder is smaller than that of the outer cylinder, and the inner cylinder is centrally arranged inside the bottom end of the outer cylinder with a gap between the inner cylinder and the outer cylinder. The unrestricted inner sliding sleeve 5 is characterized in that its lower part is a double-layer flow channel structure, including the inner layer ball seat channel formed based on the inner cylinder and based on the gap between the outer cylinder and the inner cylinder. The outer flow complementary channel formed by the annular space of the outer layer, the two channels together form the flow channel.

[0033] The diameter...

Embodiment 2

[0041] Such as Figure 4 Shown is the seven-stage fracturing string formed by using the unrestricted sandblasting sliding sleeve of Example 1 to meet the 7-stage fracturing in the 5-1 / 2" production casing; specifically,

[0042] The seven-stage fracturing string includes a bell mouth A connected sequentially through tubing K from bottom to top, an unrestricted self-service unpacking packer B, a first-stage unrestricted sandblasting sleeve C, an unrestricted self-service Unpacking packer B, second-stage unthrottled sandblasting sleeve D, unthrottled self-unpacking packer B, third-stage unthrottled sandblasting sleeve E, unthrottled self-unpacking B, the fourth-stage unrestricted sandblasting sleeve F, unrestricted self-unpacking packer B, the fifth unrestricted sandblasting sleeve G, unrestricted self-unpacking packer B, the first Six-stage unrestricted sandblasting sliding sleeve H, unrestricted self-service unpacking packer B, sand control hydraulic anchor I and hydraulic saf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com