Buried cylinder needle applied to in-mold burying of screw

A cylinder and screw technology, applied in the field of screw mold embedding, can solve the problems of low product output, easy scrapping, unreasonable embedding method of metal screws, etc., to achieve the effect of low product defect rate and avoid poor matching accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

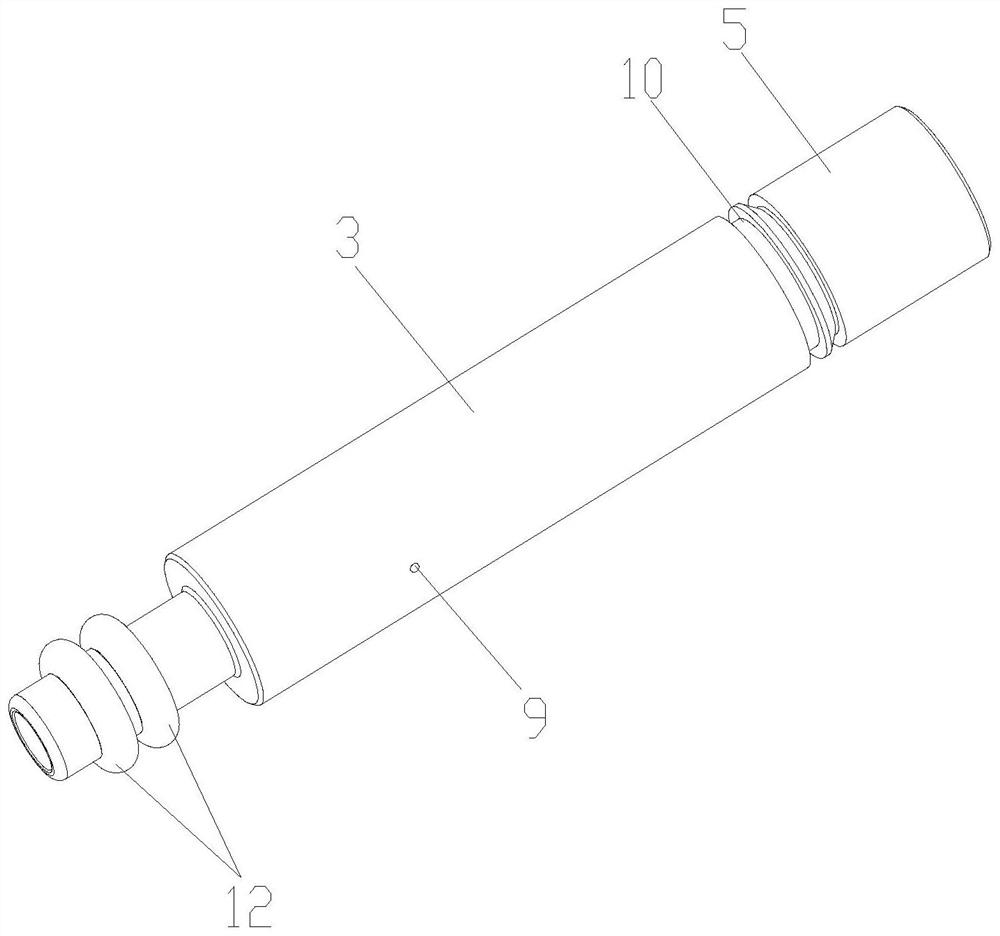

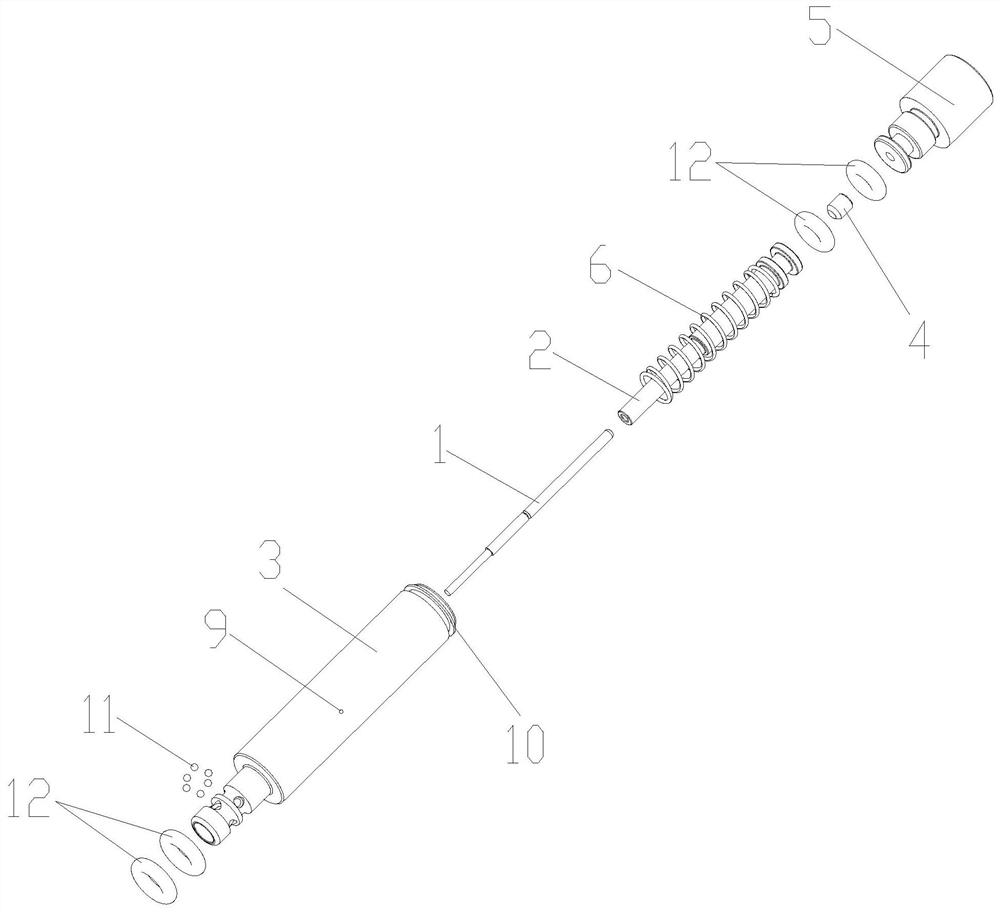

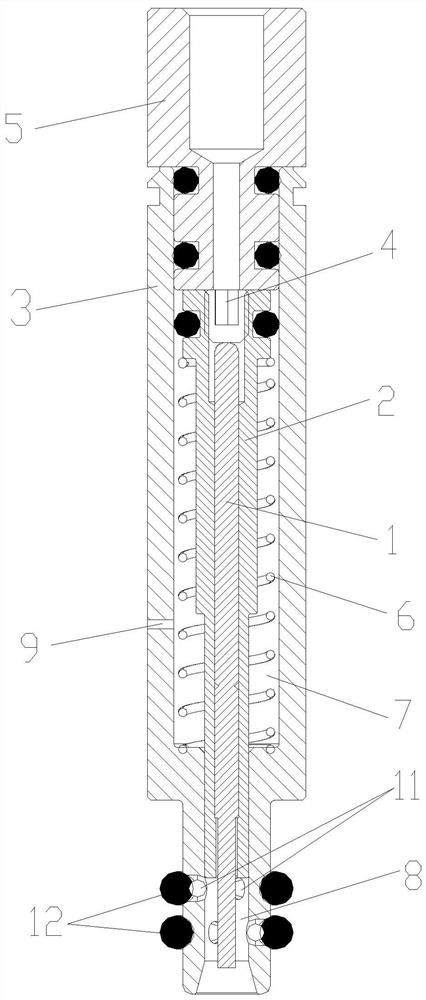

[0028] Such as figure 1 , figure 2 and image 3 As shown, a cylinder embedding needle used for embedding in a screw mold includes a probe 1, a needle shaft 2 and a cylinder body 3 arranged coaxially from the inside to the outside; wherein, the probe 1 is along the axis of the needle shaft 2 The direction is plugged and fixedly fitted, and the end extends to the outside of the needle shaft 2; the needle shaft 2 is plugged and slidably fitted along the central axis of the cylinder body 3, so that the end of the probe 1 extends from the inside of the cylinder body 3 to the outside of the cylinder body 3.

[0029] Such as image 3 As shown, the needle shaft 2 is in the shape of a tubular body with a stepped inner wall. The outer wall of the probe 1 matches the inner wall of the needle shaft 2, including the needle end with a small diameter and the tail end w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com