Servo valve development whole process error prevention system

A servo valve and error prevention technology, applied in the field of quality control in the aerospace servo field, can solve problems such as reducing human errors, inability to predict, prevent and eliminate errors, and increase enterprise production efficiency, achieving control and elimination, and the application implementation effect is remarkable Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

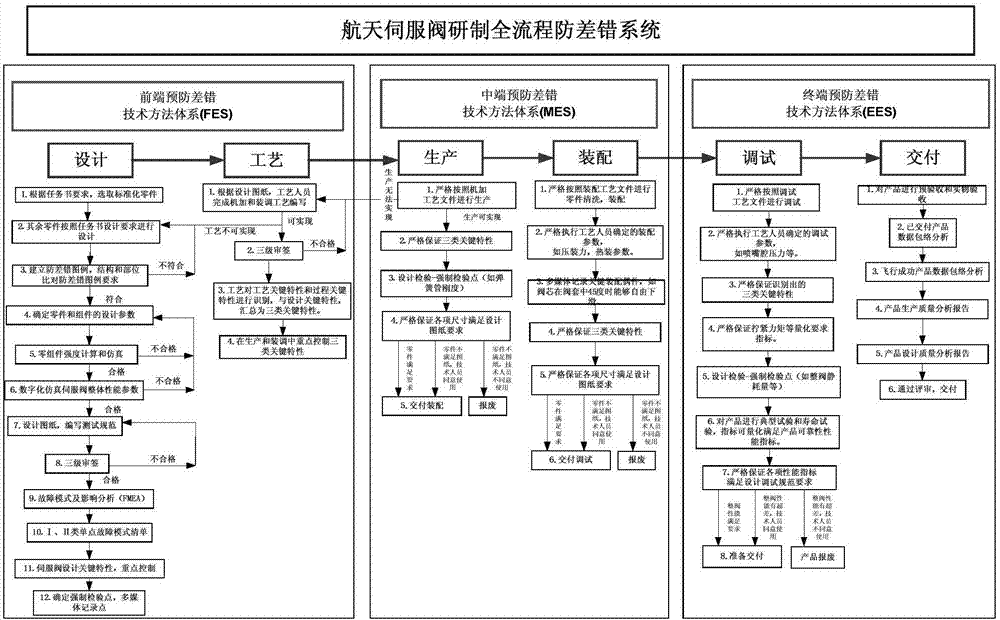

[0050] The present invention will be described in detail below in conjunction with the accompanying drawings and examples. Such as figure 1 Shown:

[0051] Aerospace servo valve development of the whole process error prevention system, according to the development process of aerospace servo valve, including front-end error prevention processing module, middle-end error prevention processing module and terminal error prevention processing module; specifically:

[0052] 1. Front-end error prevention processing module

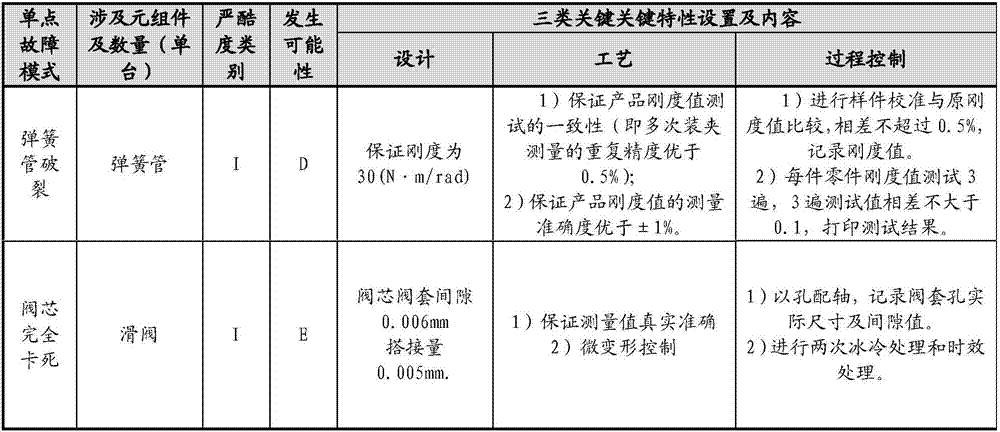

[0053] The front-end error prevention processing module integrates the design and process links of aerospace servo valves, determines the design drawings and test specifications of servo valves that meet the design requirements of the mission statement, compiles machining and assembly debugging processes, and determines the weak links in the whole process of servo valve development Corresponding to the three key characteristics of design key characteristics, pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com