Feeding and blanking gauge with automatic centering and detection

An automatic centering and jig technology, applied in home appliances, other home appliances, household components, etc., can solve the problems of poor work continuity, large space occupation, affecting the quality of molded products, etc., to improve the continuity and efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

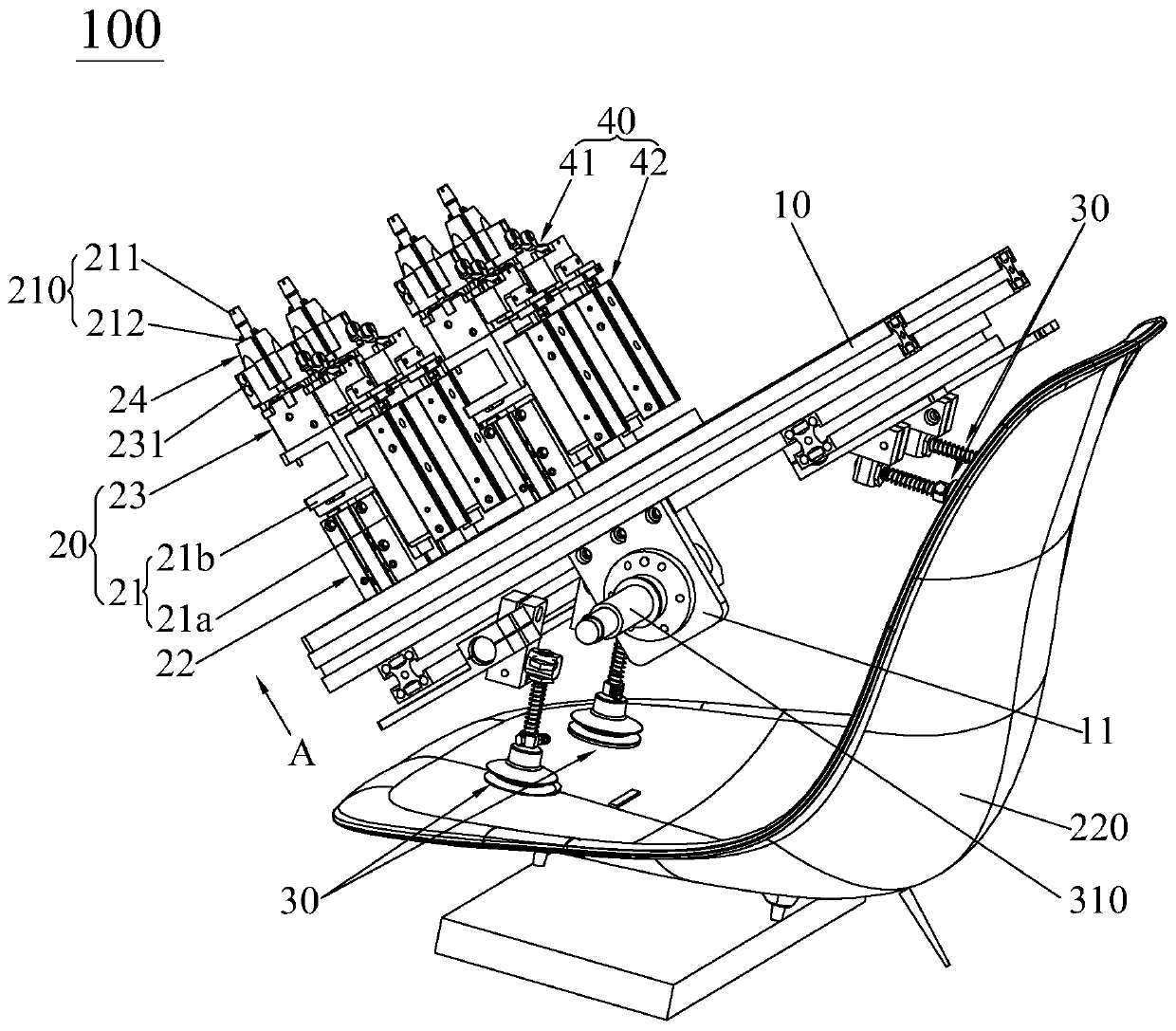

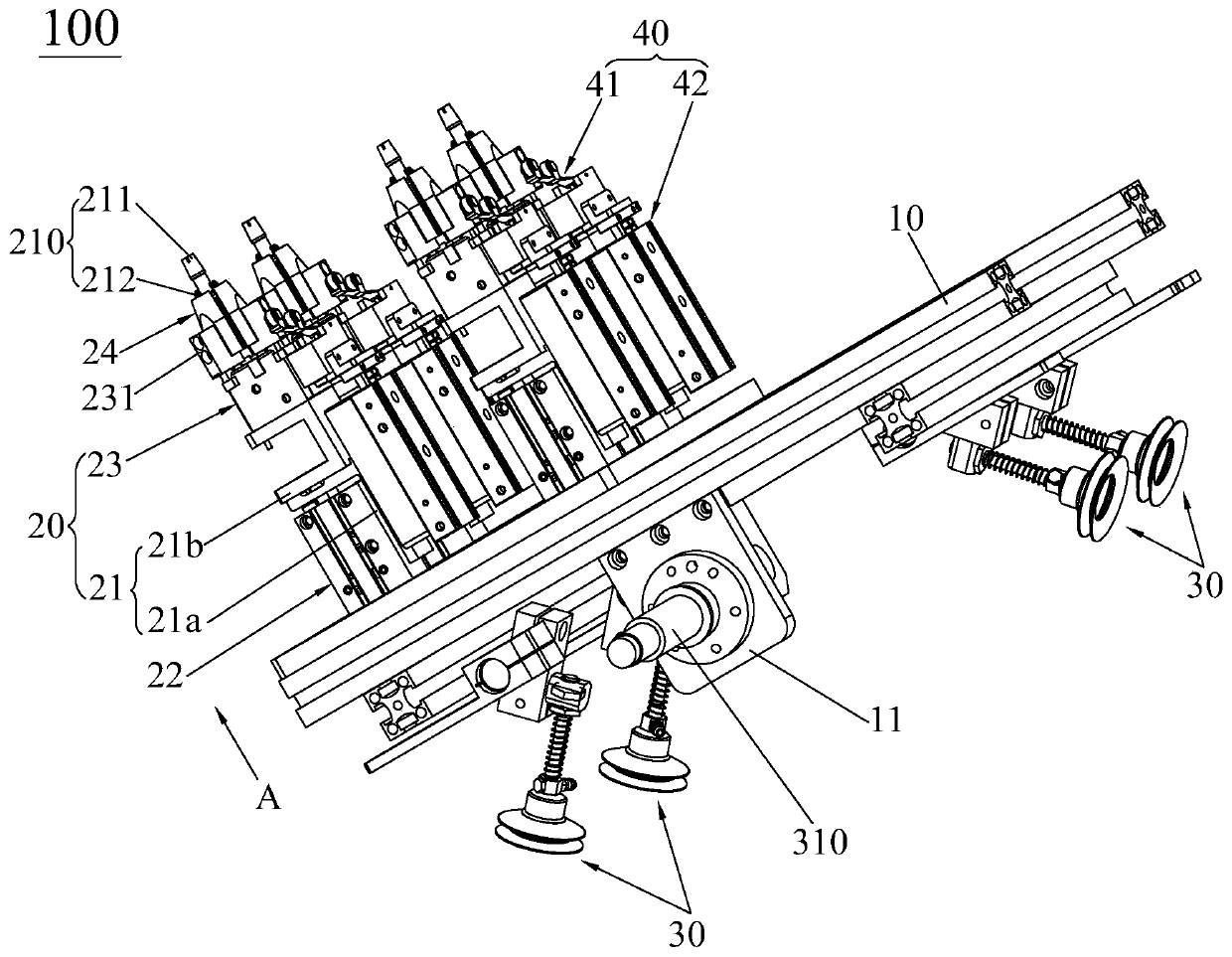

[0025] The preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

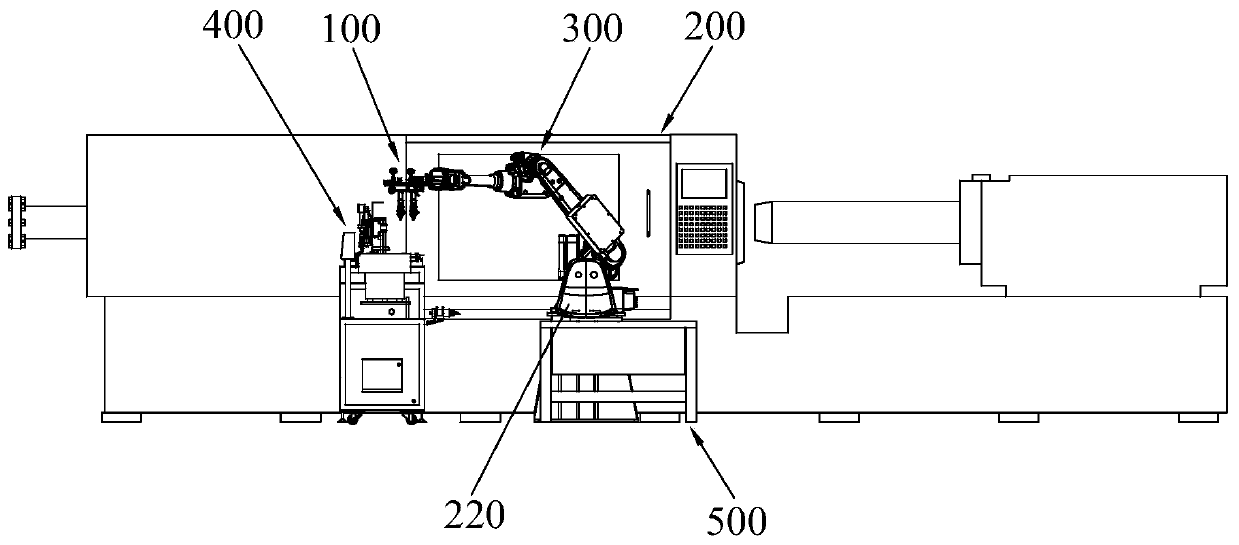

[0026] see figure 1 , the loading and unloading fixture 100 of the present invention is installed on the manipulator 300, and the manipulator 300 drives the loading and unloading fixture 100 of the present invention to perform multi-axis movements, such as horizontal translation, up-down translation and flipping, etc., to meet the requirements of "the present invention" The loading and unloading fixture 100 assembles the assembly 210 formed by the screw 211 and the nut 212 assembled by the screw nut assembly machine 400 (see figure 2 ) to grab and then embed in the injection mold 200, and take away the plastic chair 220 in the injection mold 200 and transfer it to the working inspection table 500 for corresponding processing". At the same time, in the loading and unloading jig of the present invention 100 Before the assembly 210 is embedded in th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com