Automatic embedding equipment for automobile injection molding inserts and control method thereof

An insert and automatic technology, applied in the direction of coating, etc., can solve the problems of increased scrap rate of injection molded parts, skewed nuts, nuts pushed into place, etc., to achieve the effect of improving installation accuracy and increasing yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

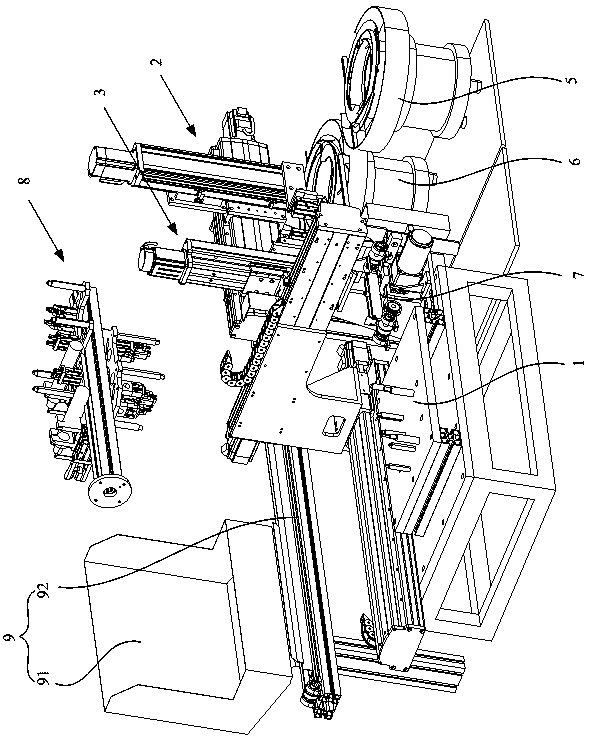

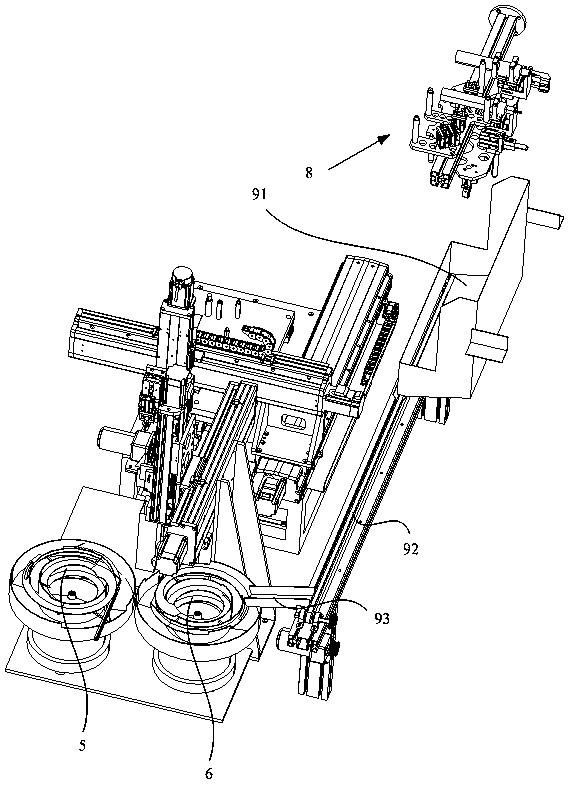

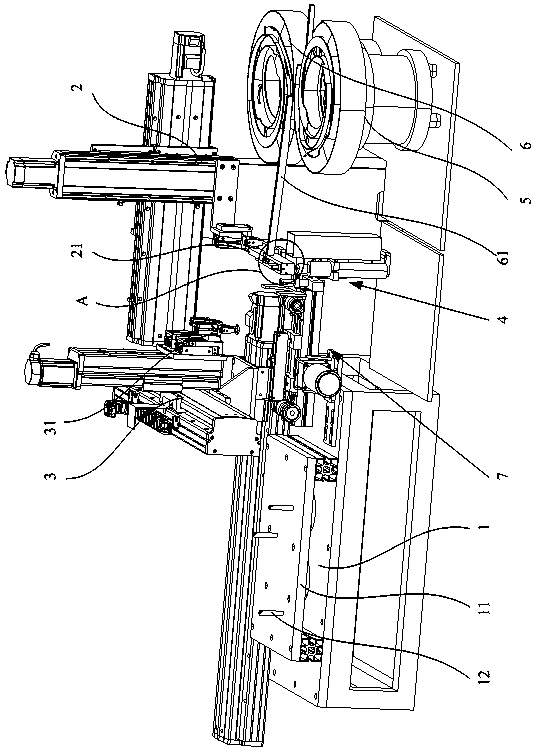

[0031] Such as Figure 1-Figure 9 As shown, the automatic embedding equipment for automobile injection molding inserts in this embodiment includes an installation base 1, a first three-dimensional mobile platform 2, a second three-dimensional mobile platform 3, an assembly mechanism 4, a first vibration screening machine 5 and a second vibration screening machine machine 6; the installation base is provided with a positioning plate 11, and the positioning plate is provided with a plurality of detachable positioning columns 12, and the first three-dimensional mobile platform and the second three-dimensional mobile platform are arranged on the One side of the base is installed, a first jaw 21 is provided on the moving part of the first three-dimensional mobile platform, and a second jaw 31 is provided on the moving part of the second three-dimensional mobile platform;

[0032] The assembly mechanism includes a support frame 41, an assembly chute 42, a sliding block 43, a first t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com