PVC-O pipe fluid blowing-up type bell mouth forming process

A molding process and inflation molding technology, applied in the field of PVC-O pipe production equipment, can solve the problems of reduced strength, toughness and impact resistance, and achieve the effect of improving strength, realizing orientation characteristics and ensuring safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to enable those skilled in the art to better understand the technical solutions of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

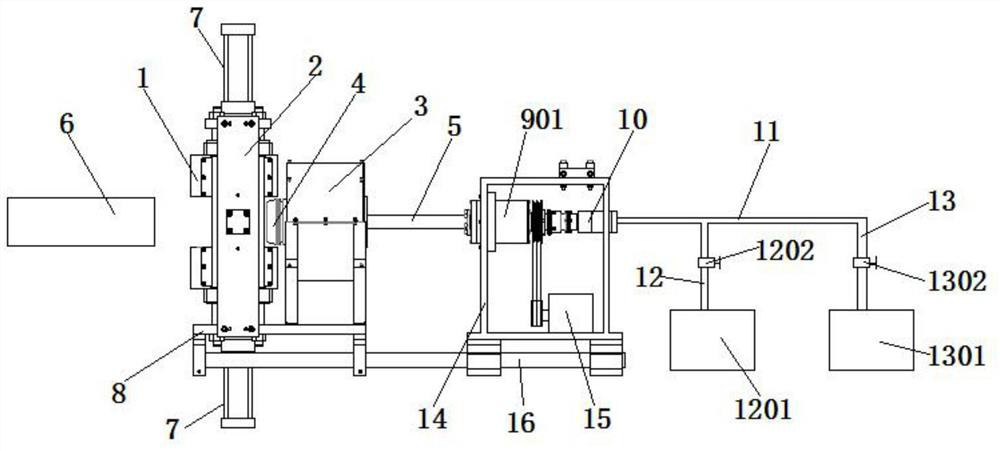

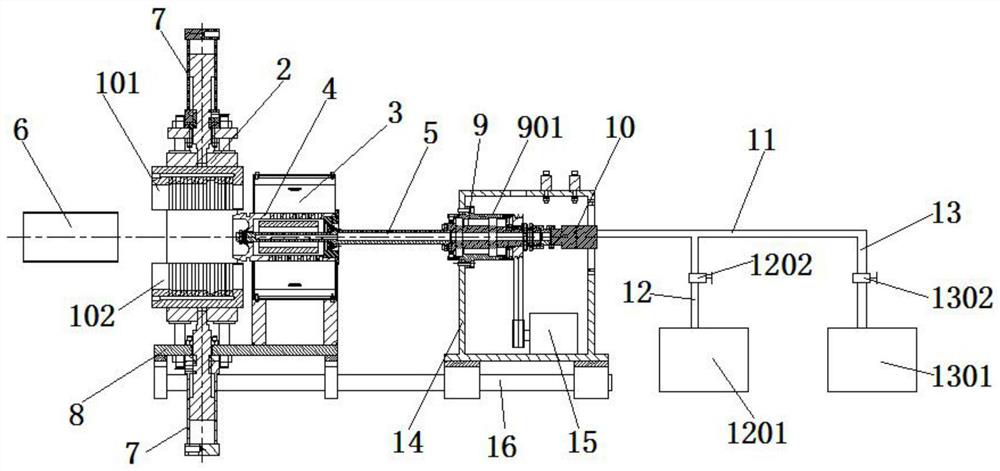

[0035] Such as figure 1 with 2 As shown, a PVC-O pipe fluid inflation type socket forming equipment mainly includes a cavity 1, a cavity frame 2, a heating furnace 3, a mandrel 4, a rotating hollow shaft 5, and a PVC-O pipe 6. The cavity 1, the heating furnace 3 and the mandrel 4 are arranged coaxially in sequence.

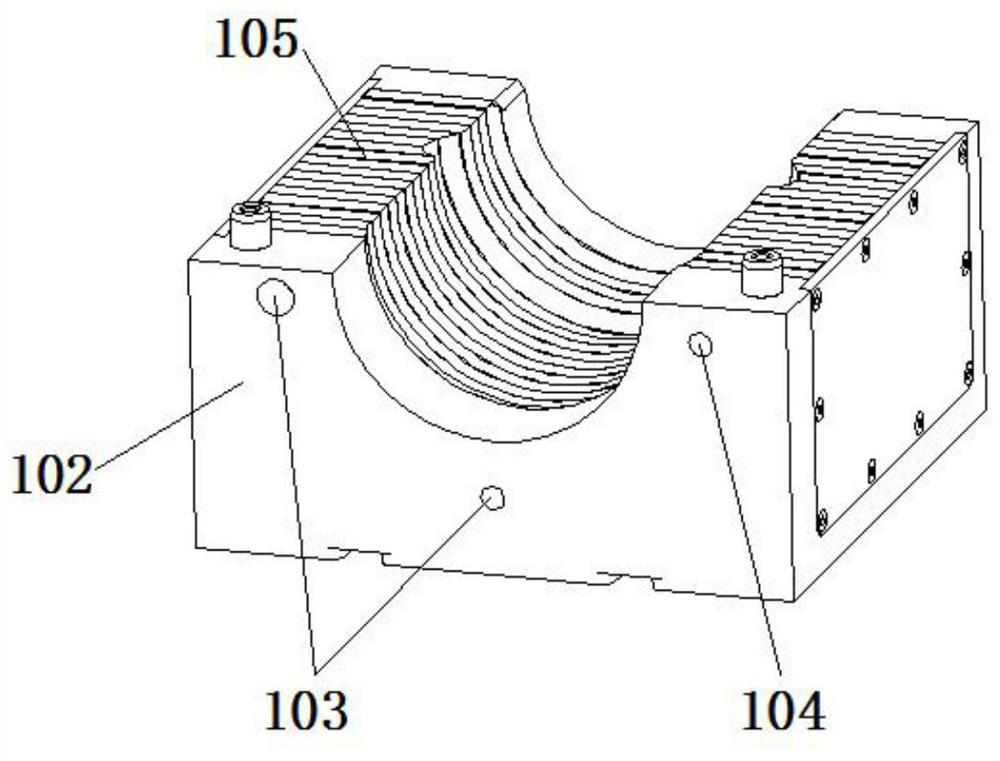

[0036] The cavity 1 includes an upper cavity 101 and a lower cavity 102 . The upper cavity 101 and the lower cavity 102 are located in the cavity frame 2 and are arranged opposite to each other. The upper cavity 101 and the lower cavity 102 are all connected with the driving end of the corresponding hydraulic cylinder 7 installed on the cavity frame 2, and are formed by The hydraulic cylinder 7 drives the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com