Rolling bearing fault identification method based on gaf-cnn-bigru network

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

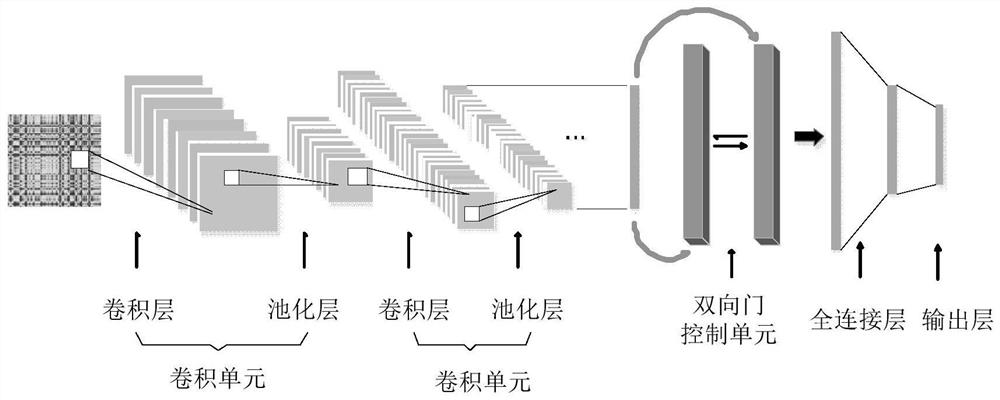

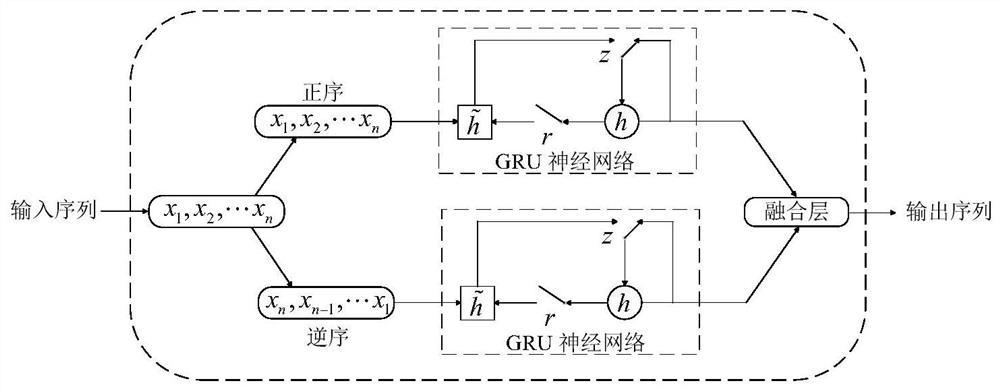

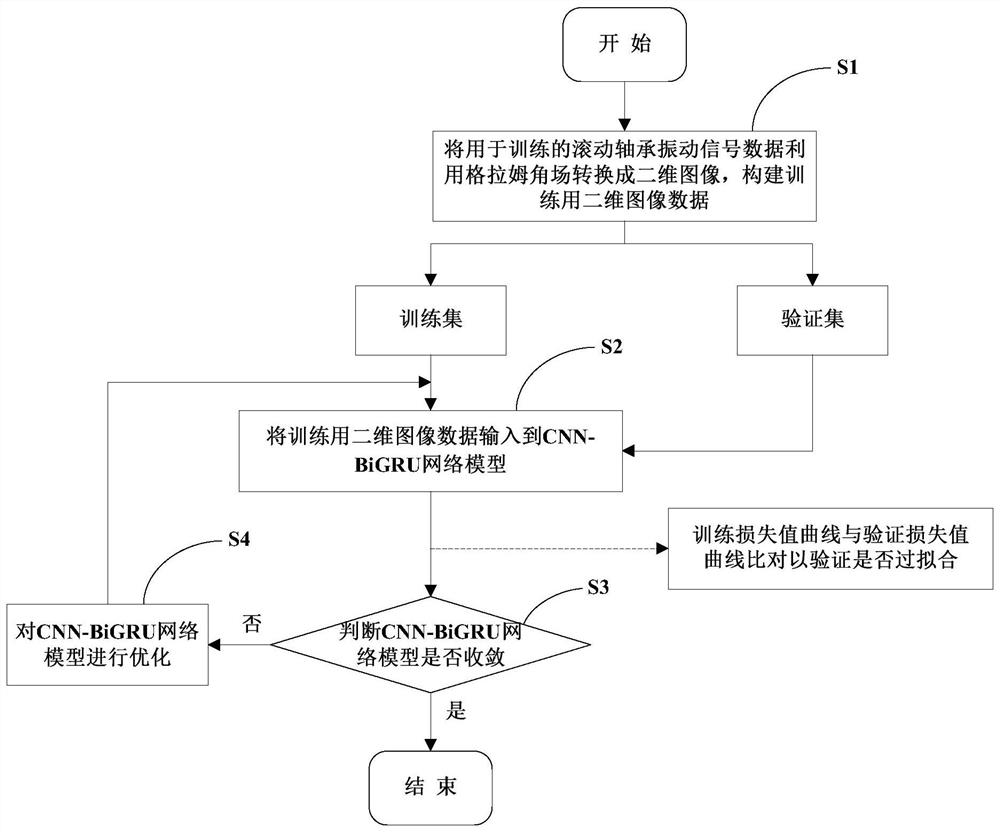

Method used

Image

Examples

Embodiment 1

[0064] In this embodiment, the fault identification method of the rolling bearing based on the GAF-CNN-BiGRU network provided by the present invention is explained in detail with the inner ring fault data.

[0065] In this example, the vibration signals and normal vibration signals of three damage diameters (mild 0.007 inch, moderate 0.014 inch and severe 0.021 inch) at the same fault location of the drive end bearing at the sampling frequency of 12 kHz are selected as the research objects. The length is 864 sampling points, and the data is divided. In order to obtain enough data for training, the data in the collected data set is first enhanced by overlapping samples to expand the number of training samples. Partial overlap, which not only ensures full utilization of the signal, but also further expands the number of samples. In this way, a total of 4000 sample data are obtained to form the original data set.

[0066] In this embodiment, 2400 sample data in the original dat...

Embodiment 2

[0111] In order to further verify the feasibility of the rolling bearing fault identification method based on the GAF-CNN-BiGRU network provided by the present invention, in this embodiment, the sampling frequency of 12 kHz is further selected, and the driving end bearing has three different fault positions (inner ring, rolling element and outer ring) and the vibration signal and normal vibration signal of the same fault degree (damage diameter is 0.014inch) as the research object. According to the same data processing method in Example 1, a training set, a verification set and a test set for model training were obtained. Then, the CNN-BiGRU network model is trained according to the training method of steps S1-S4 provided in Example 1.

[0112] Then use the trained CNN-BiGRU network model to identify the rolling bearing fault on the test set data according to the same identification method as steps L1-L2 in Example 1. The same data set is used for training and testing through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com