Electric vehicle intelligent charging method supporting phase rotation and equipment thereof

An intelligent charging method and technology for electric vehicles, applied in electric vehicle charging technology, electric vehicles, charging stations, etc., can solve the problems of unbalanced three-phase load, affecting the service life of power grid health equipment, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

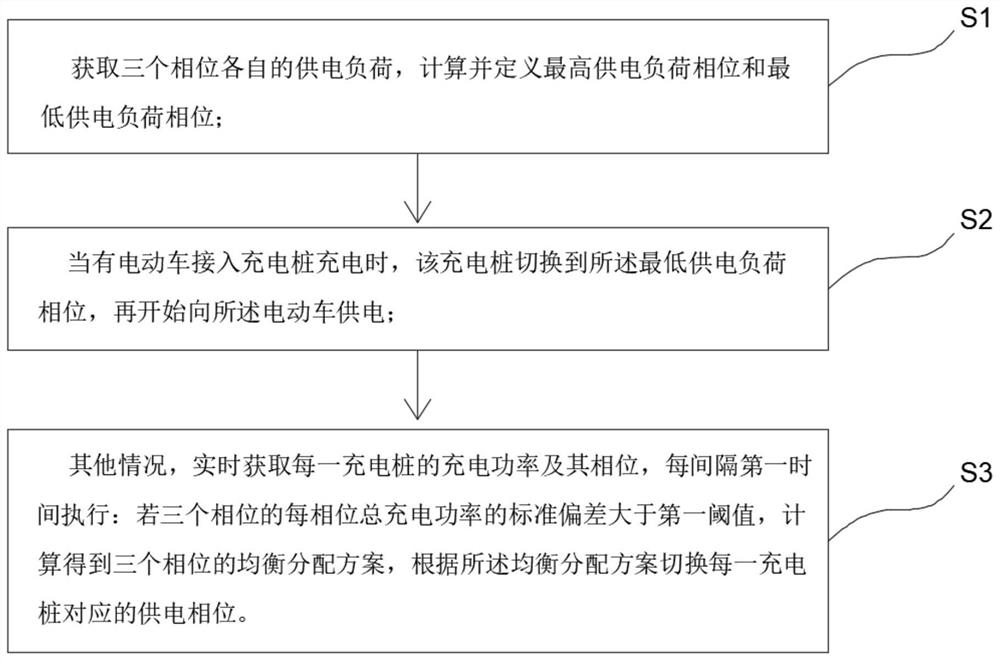

[0035] refer to figure 1 , an electric vehicle intelligent charging method supporting phase rotation, realized by several charging piles, background servers, and phase rotation relay groups, including the following steps:

[0036] S1, obtain the respective power supply loads of the three phases, calculate and define the highest power supply load phase and the lowest power supply load phase;

[0037] Specifically, the background server obtains the power supply loads of the three phases of each charging pile, and obtains the total loads of the three phases after accumulation. Through comparison, the phase with the highest load is defined as the phase with the highest power supply load, and the phase with the highest load Defined as the phase with the highest supply load.

[0038] S2, when an electric vehicle is connected to the charging pile for charging, the charging pile switches to the phase with the lowest power supply load, and then starts to supply power to the electric v...

Embodiment 2

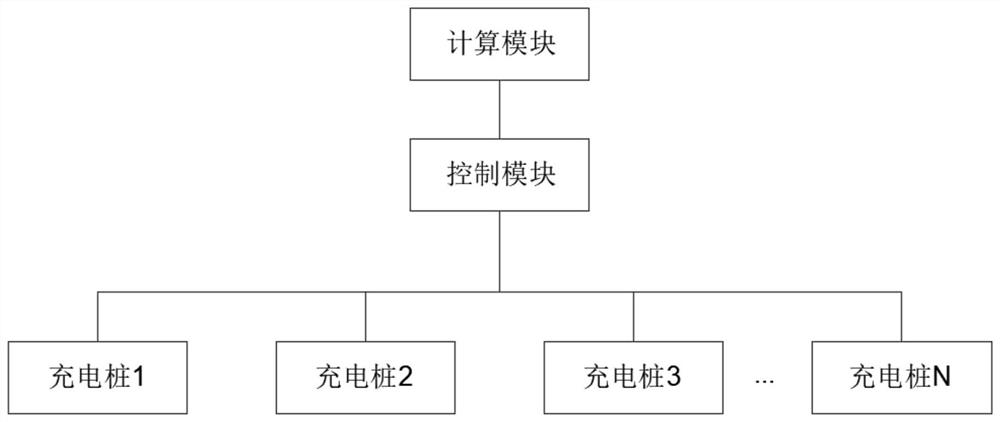

[0053] Further provide an electric vehicle intelligent charging device supporting phase rotation, including:

[0054] refer to figure 2 , a number of charging piles for charging electric vehicles, each of which includes three phase input terminals;

[0055] The calculation module is used for: calculating and defining the highest power supply load phase and the lowest power supply load phase;

[0056] control module for:

[0057] When an electric vehicle is connected to the charging pile for charging, the charging pile switches to the phase of the lowest power supply load, and then starts to supply power to the electric vehicle;

[0058] In other cases, obtain the charging power and its phase of each charging pile in real time, and execute it at the first time every interval: if the standard deviation of the total charging power of each phase of the three phases is greater than the first threshold, calculate the balanced allocation scheme of the three phases , switch the po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com