Chemical detection sampling device capable of realizing batch sampling and use method

A sampling device, a technology that can be batched, applied in the direction of sampling devices, measuring devices, sampling, etc., can solve troublesome, unfavorable sample sampling efficiency, time-consuming and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific operation method steps are as follows

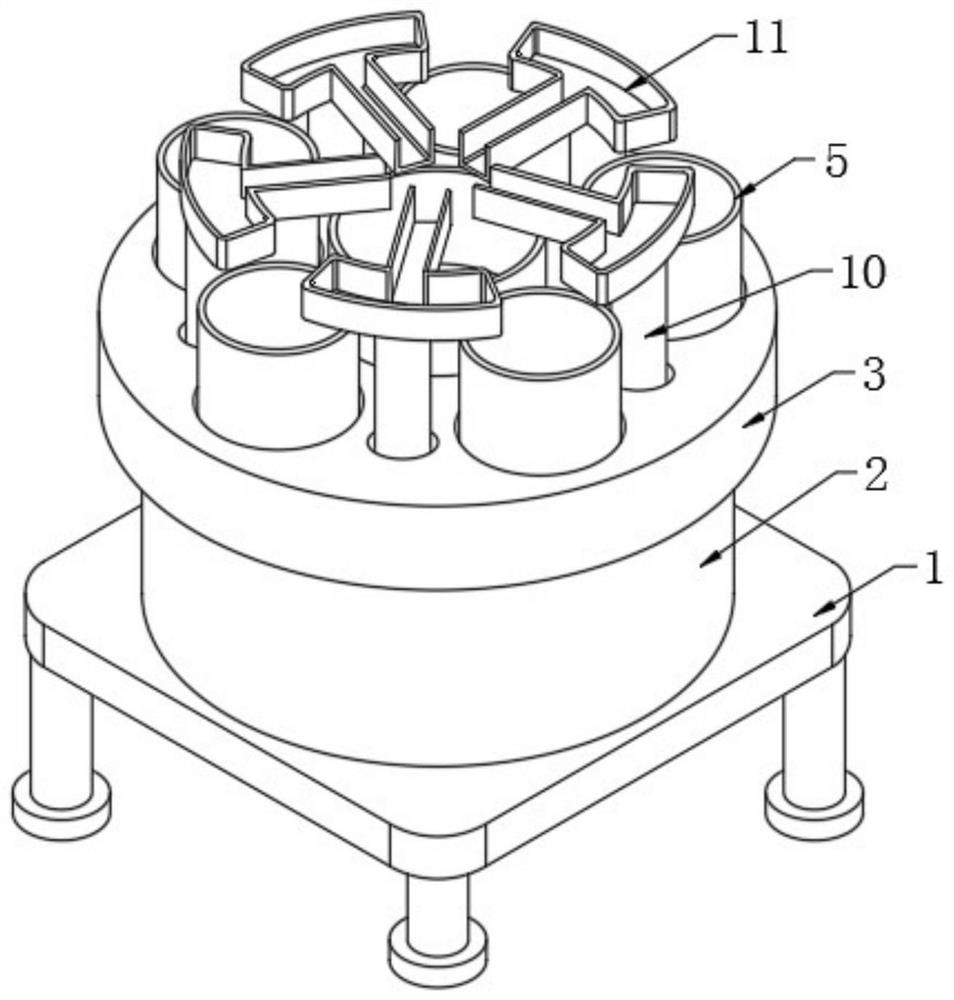

[0039] One of the sampling tanks 5 is placed directly below the sampling tube on the chemical reaction vessel, so that the chemical reagents can flow into the sampling tank 5 automatically.

Embodiment 2

[0041] The specific operation method steps are as follows

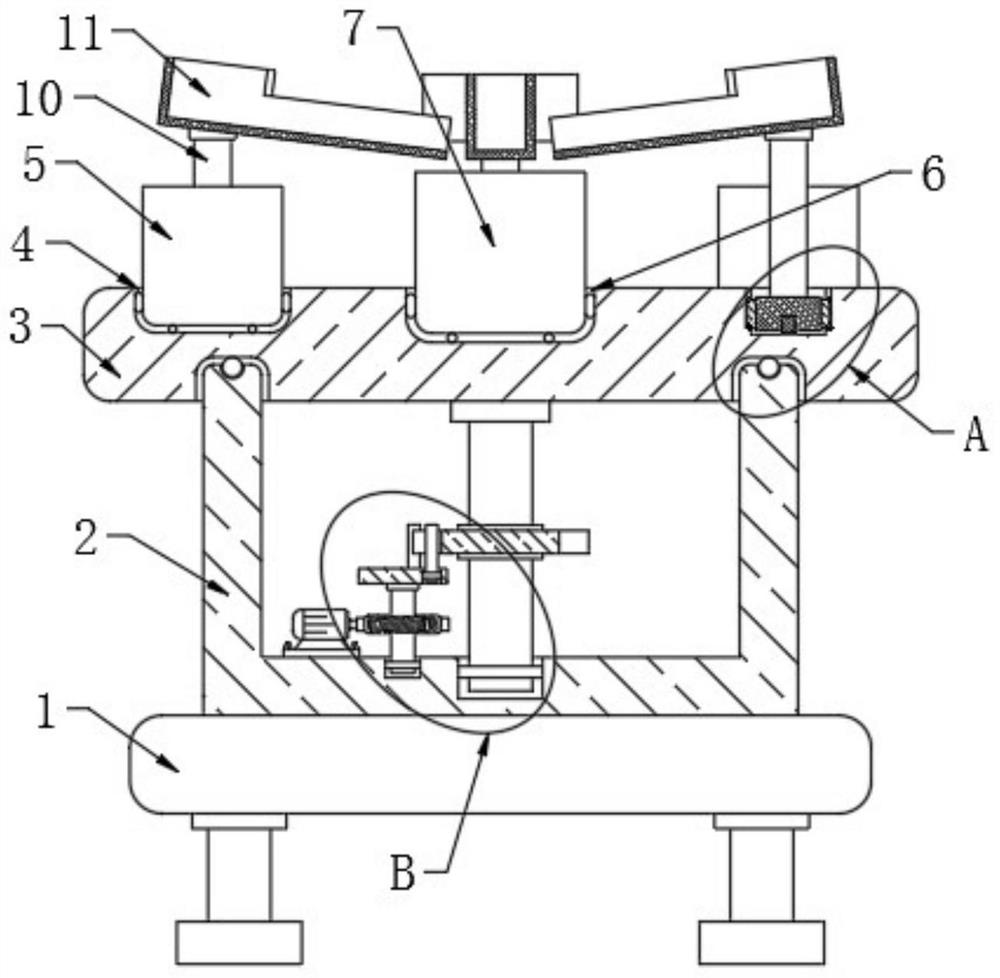

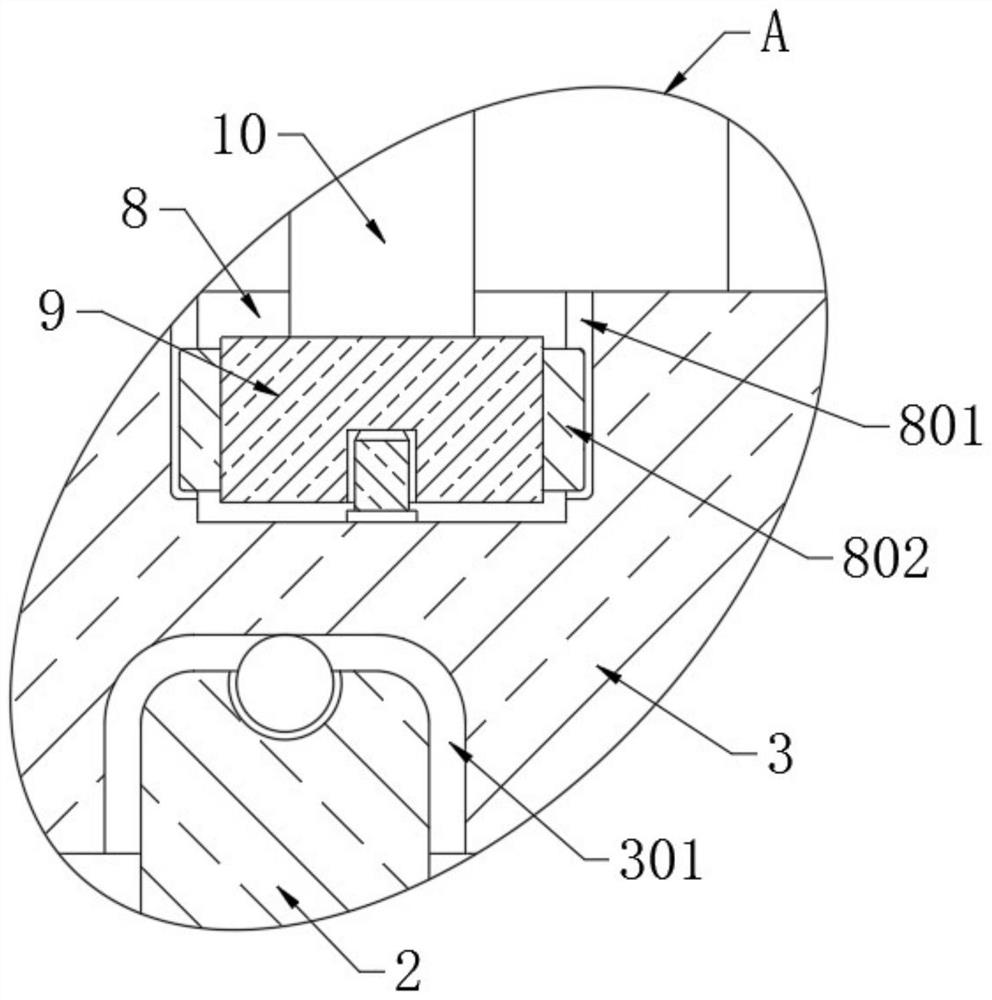

[0042] At the same time start the motor 21, the motor 21 rotates and drives the worm 22 to rotate, the worm 22 drives the worm wheel 20 to rotate, the worm wheel 20 drives the round rod 17 to rotate, the round rod 17 drives the rotating disc 18 to rotate, and the rotating disc 18 drives two Driving rod 19 rotates, and when two driving rods 19 rotate, ring block 14 will be driven to rotate, and when two driving rods 19 all slide out from corresponding guide groove 15, ring block 14 will no longer rotate, and when two When the driving rod 19 entered the corresponding guide groove 15 respectively, the ring block 14 would rotate again, so that the rotating disc 18 could drive the ring block 14 to rotate intermittently through the two driving rods 19, and the ring block 14 could thus drive the The rotating column 13 rotates intermittently, and the rotating column 13 drives the circular plate 3 to rotate intermittently.

Embodiment 3

[0044] The specific operation method steps are as follows

[0045] When the sampling tank 5 was full of chemical reagents soon, the circular plate 3 would rotate once, so that the circular plate 3 would drive the sampling tank 5 full of chemical reagents to spin away from the bottom of the sampling tube, and the empty sampling tank 5 would rotate to the same time. Directly below the sampling tube, when the two sampling tanks 5 rotate past the top of the sampling tube, the chemical reagents flowing out of the sampling tube will flow into the corresponding liquid guiding groove 11, and the chemical reagents that finally enter the liquid guiding groove 11 will flow Into the waste tank 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com