Flux field plate

A flow field plate and flow field technology, applied in separation methods, electrochemical generators, and dispersed particle separation, can solve problems such as heat loss, lower fuel cell system efficiency, and operational stability, and achieve improved flow guidance and improved The effect of the suction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

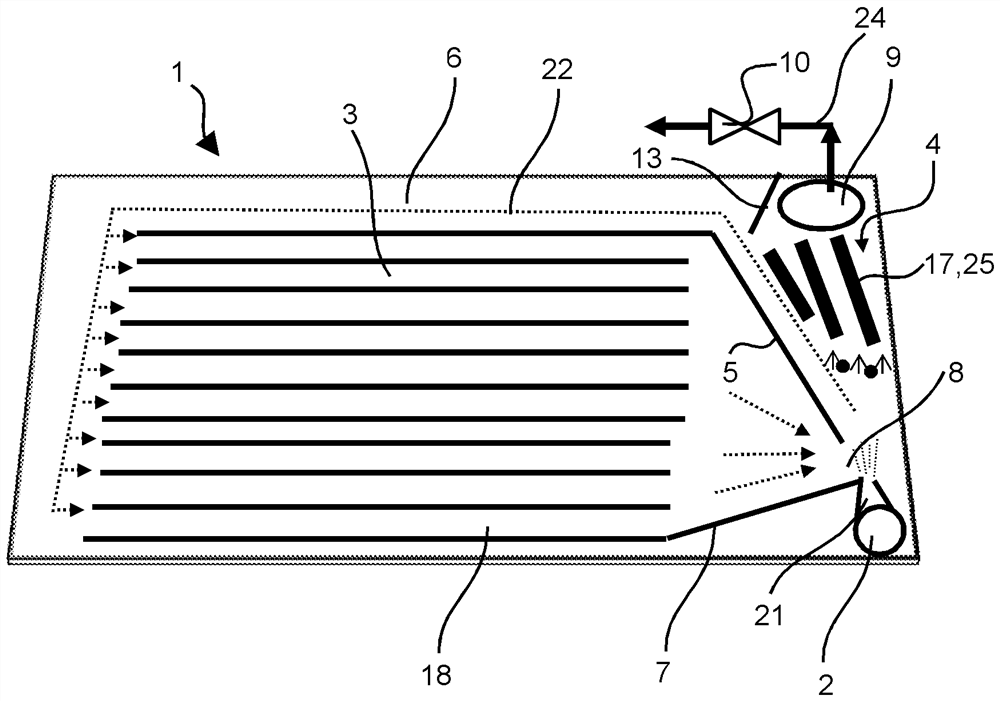

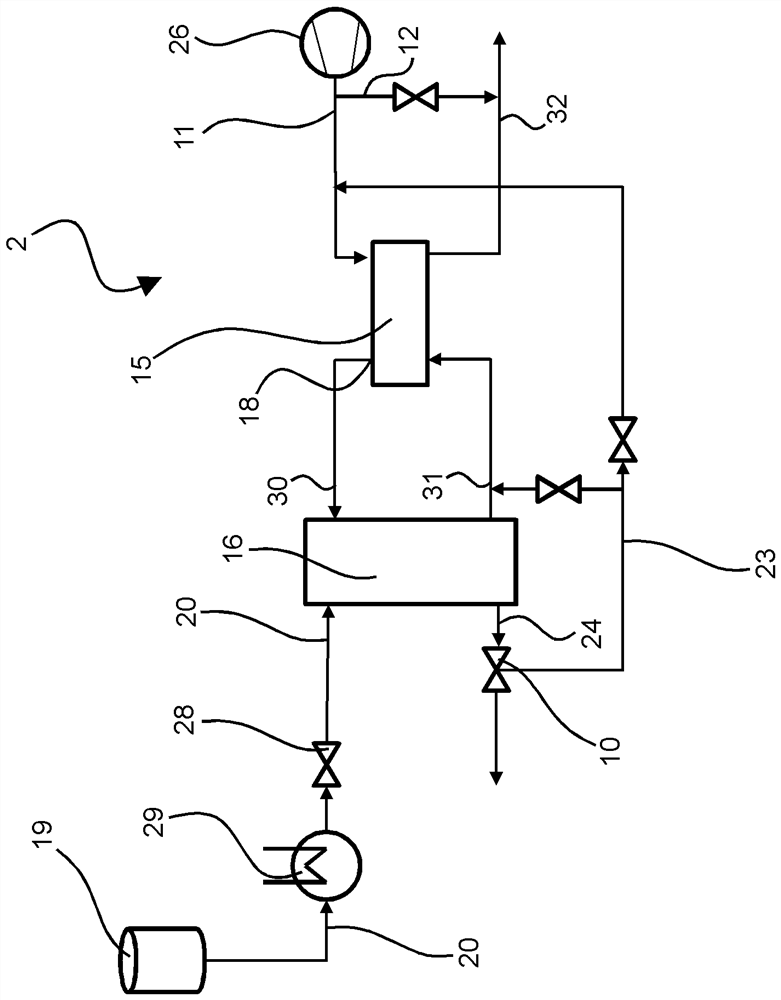

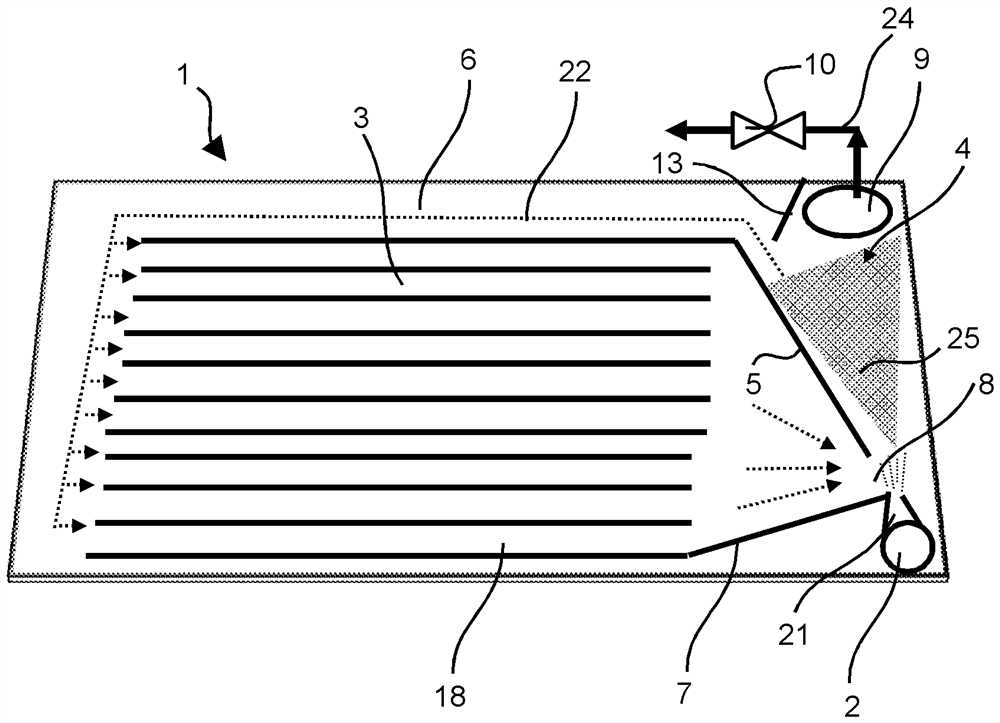

[0023] figure 1 Shown is a flow field plate 1 with gas inlets 2 for distributing reactants to electrodes or gas diffusion layers of a fuel cell. A plurality of channels 3 defining a flow field are arranged on the flow field plate 1 , wherein there is a pressure drop between the gas inlet 2 and the flow field in the flow-through state. This pressure drop causes exhaust gas flowing in channel 3 to be sucked in in the direction of gas inlet 2 . A water-gas separator 4 is additionally arranged on the flow field plate 1 for separating liquid water and / or water vapor from gas, especially waste gas, wherein the water-gas separator 4 is flow-mechanically connected to the flow field in order to The gas separated in the moisture separator 4 is supplied to the flow field again. In other words, the flow field plate 1 enables efficient anode recirculation integrated into the fuel cell or within the fuel cell. Due to the pressure drop, exhaust gas is drawn from the channel 3 of the flow ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com