Mechanical water meter calibration method and device based on laser sensor

A laser sensor and verification device technology, applied in the field of metrology, can solve problems such as inaccurate verification, and achieve the effects of enhancing resistance to light changes, low cost, and avoiding signal loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

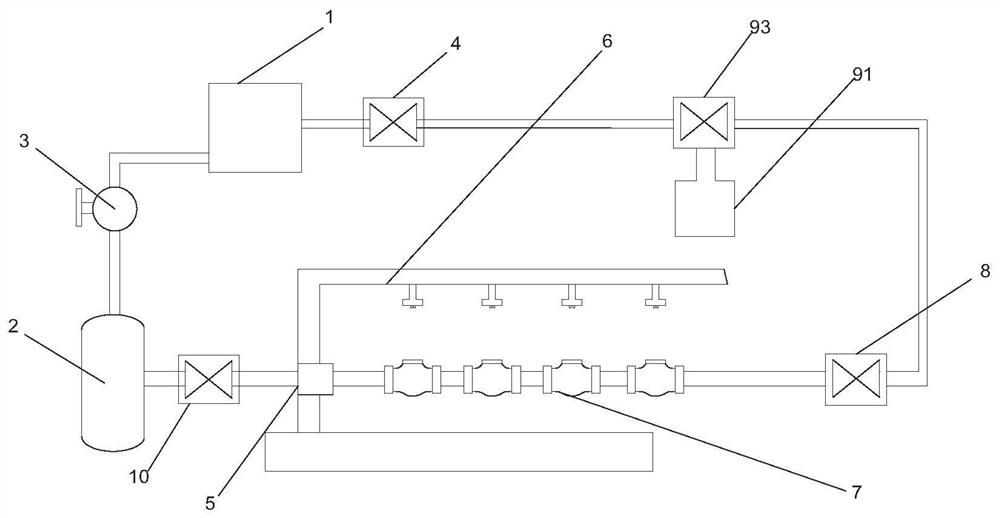

Embodiment 1

[0053] A mechanical water meter verification method based on a laser sensor, comprising the following steps: the water meters to be verified are sequentially connected in series and placed on a detection platform through a meter clamp, and the flow collection device is adjusted so that the light sources of the main laser sensor and the auxiliary laser sensor emit to the test station. Any fixed point in the circular area swept by the last pointer of the water meter rotates a circle and remains stable;

[0054] The controller controls the water pump, the water inlet valve, the water outlet valve, and the flow monitor to work at the same time. The flow monitor detects the state of the water flow. When the water flow is stable to the verification flow point, the controller controls the main laser sensor and the auxiliary laser sensor to start working;

[0055] The final pointer of the water meter to be verified rotates. When the last pointer reaches the fixed point, the main laser ...

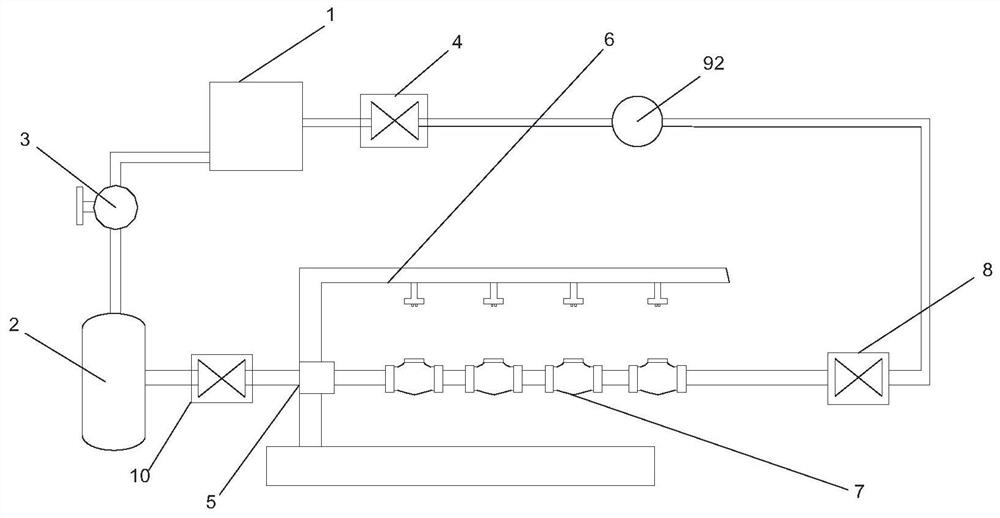

Embodiment 2

[0063] Such as figure 2 As shown, the structure of embodiment 2 is substantially the same as that of embodiment 1, except that the flow standard device is a standard flow meter 92, and the standard flow meter 92 is set between the water inlet valve 4 and the flow monitor 8 through the water delivery pipe.

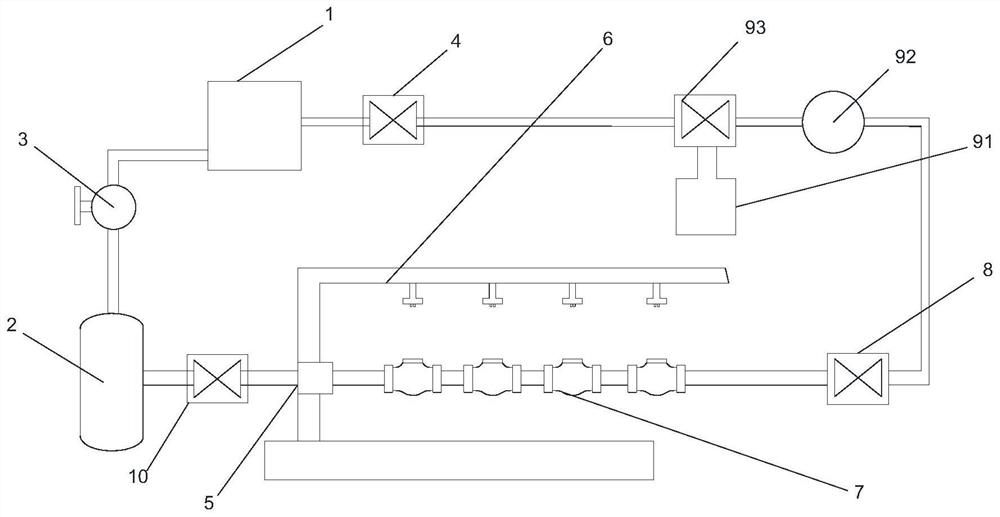

Embodiment 3

[0065] Such as image 3 As shown, the structure of embodiment 3 is substantially the same as that of embodiment 1, the difference being that the flow standard device is a combination of an electronic capacity scale 91 and a standard flow meter 92, the electronic capacity scale 91 is matched with a reversing valve 93, and the standard flow meter 92 is set between the reversing valve 93 and the flow monitor 8 through the water delivery pipe, one water outlet of the reversing valve 93 is connected to the water inlet valve 4 through the water delivery pipe, and the other water outlet is connected to the water inlet of the electronic capacity scale 91 In one case, the set time T is used as the verification time. When the verification time reaches the set time, the verification process stops, and the average value of the unit time T water flow of the electronic capacity scale 91 and the standard flow meter 92 is taken as the unit verification. The standard value of the water flow wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com