A rotary tower limestone stacking device

A limestone and tower technology, applied in the field of rotary tower limestone stacking device, can solve the problems of poor stacking environment, easy lifting of limestone, increase production cost, etc., and achieve the effect of slowing down dust.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

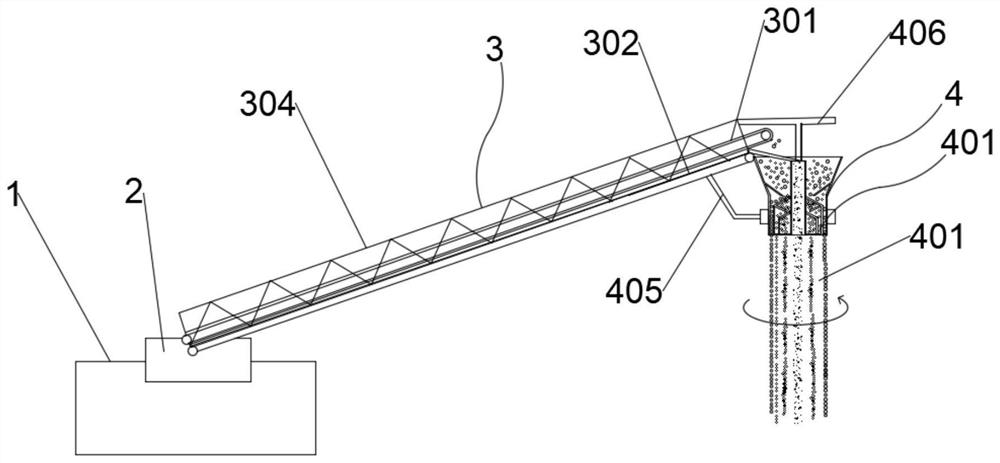

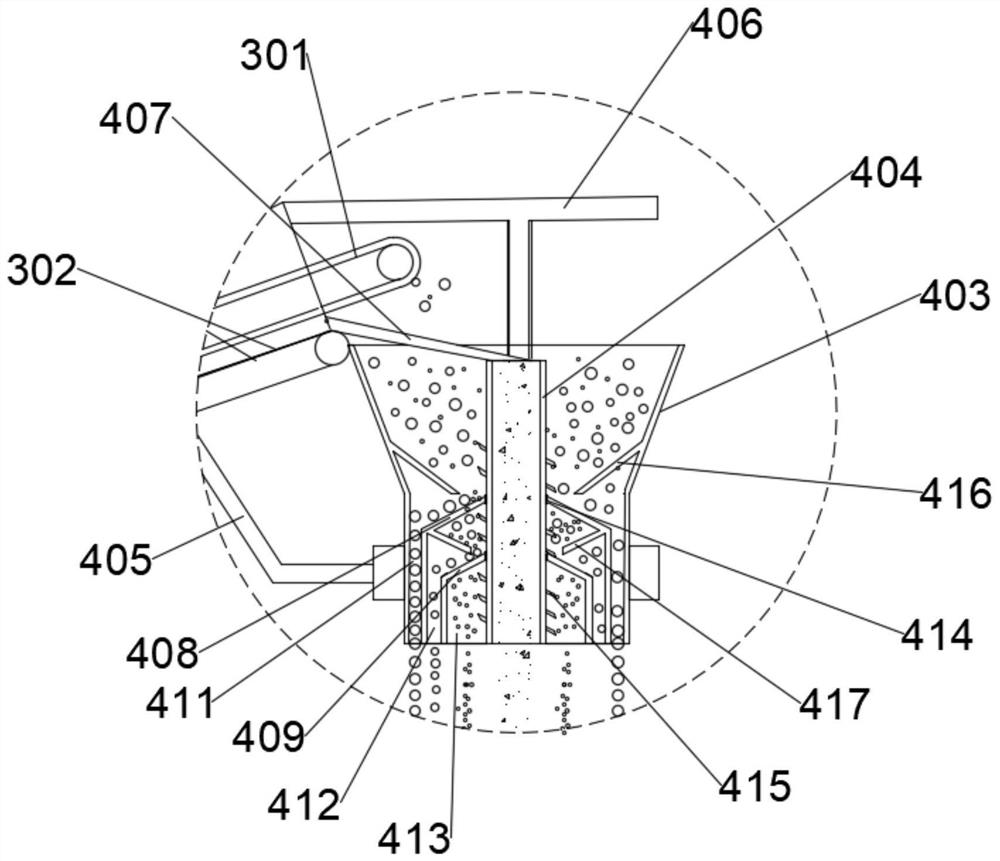

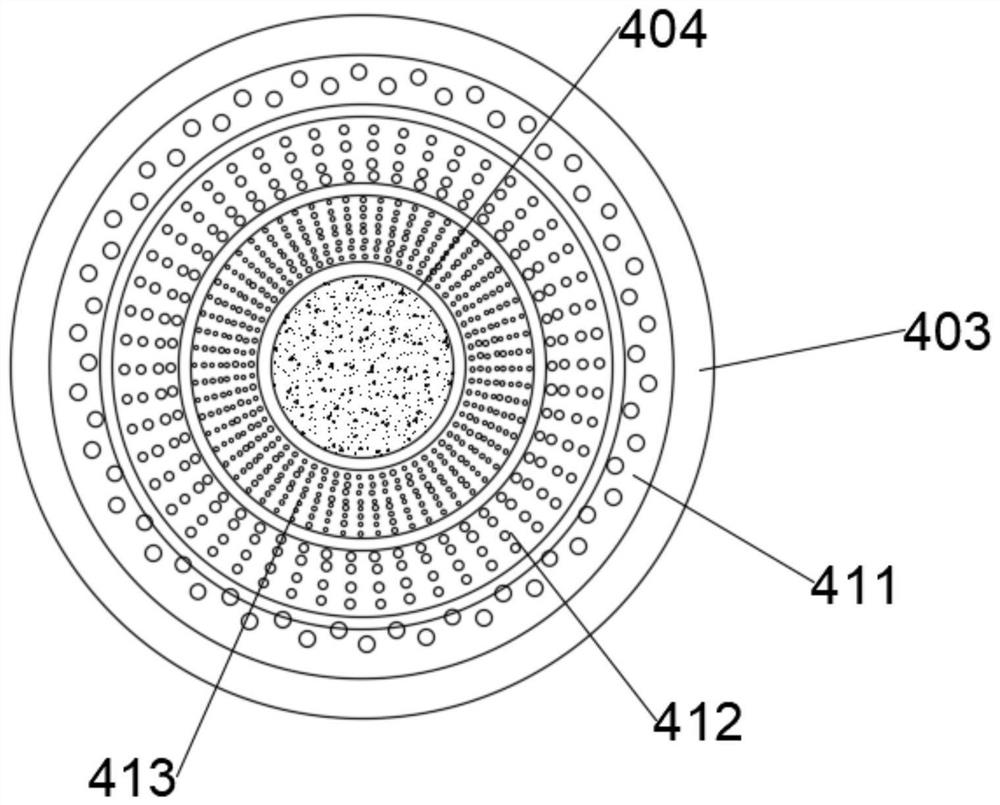

[0026] Such as Figure 1 to Figure 4 As shown, the present invention provides a rotary tower limestone stacking device. The restricted falling area surrounded by coarse materials forms a windproof barrier for the internal fine materials, and the fine materials containing limestone dust directly fall to the stacking area, which can slow down the stacking time Dust phenomenon in the material process. specific:

[0027] The stacking device includes a tower body 1, a slewing mechanism 2, a boom conveying mechanism 3 and a discharge mechanism 4, and the slewing mechanism 2 is rotatably installed above the tower body 1;

[0028] Wherein, the boom conveying mechanism 3 is installed on the slewing mechanism 2 for conveying stone materials, including a c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com