Patents

Literature

71results about How to "Reduce dust phenomenon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

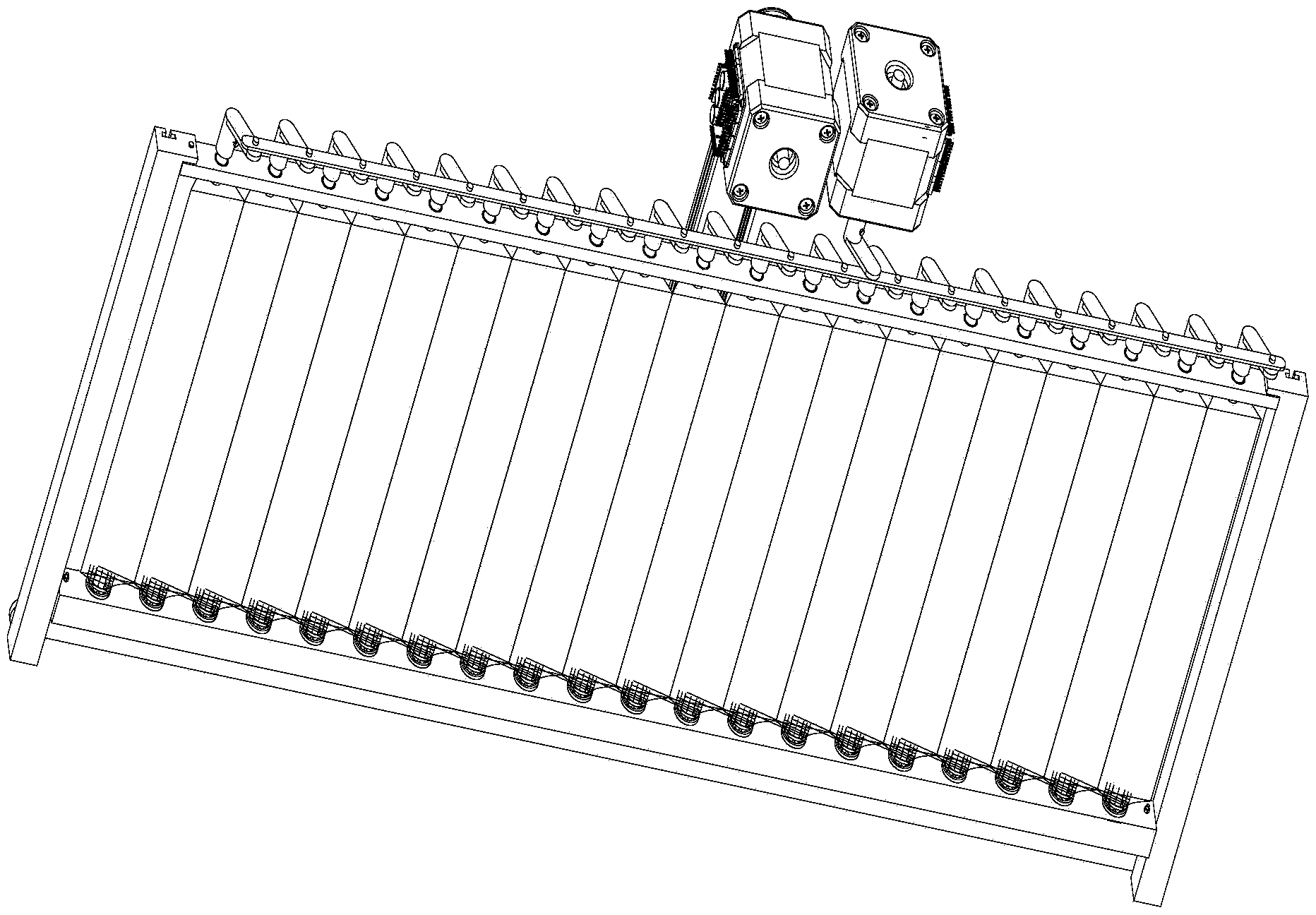

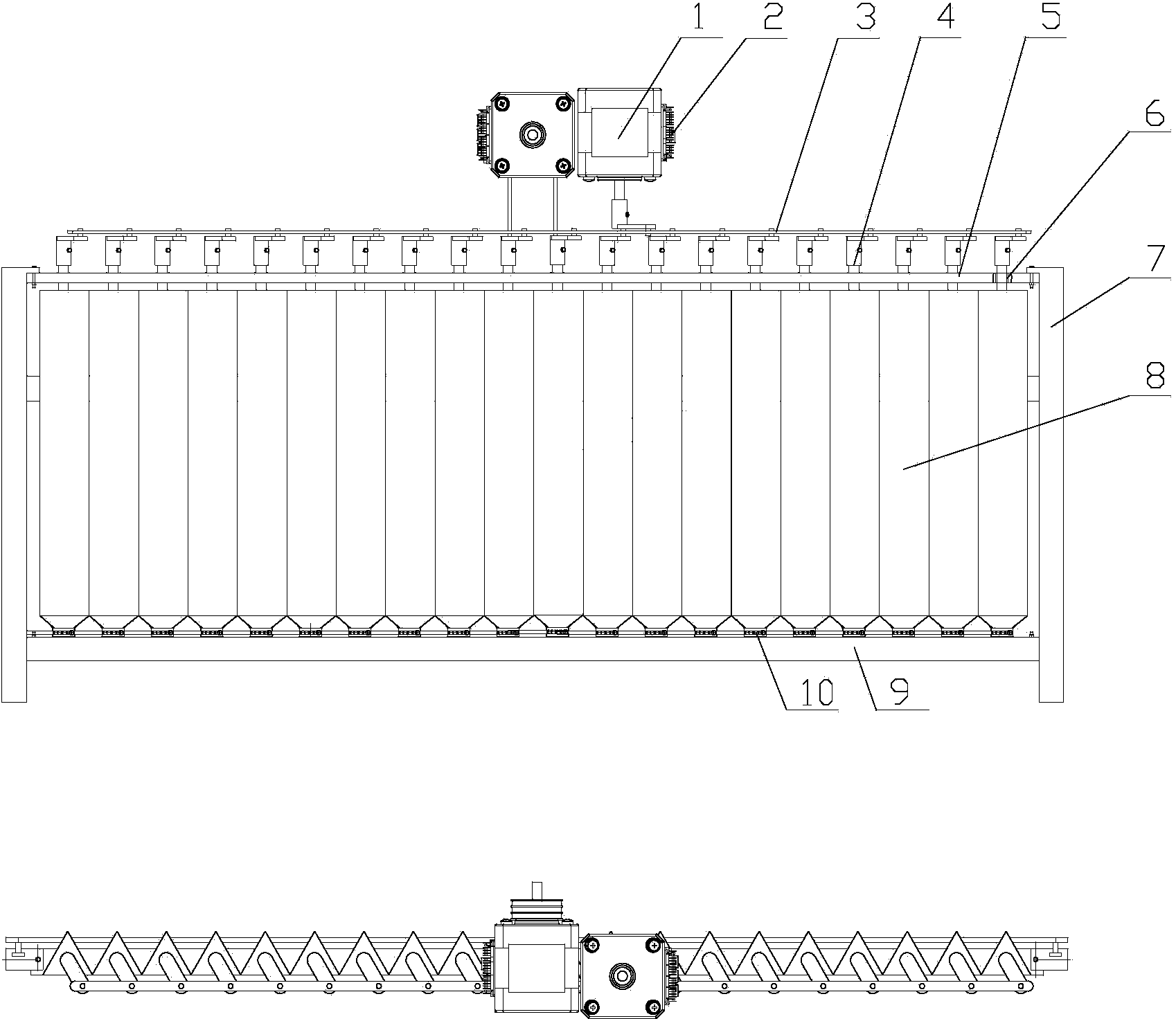

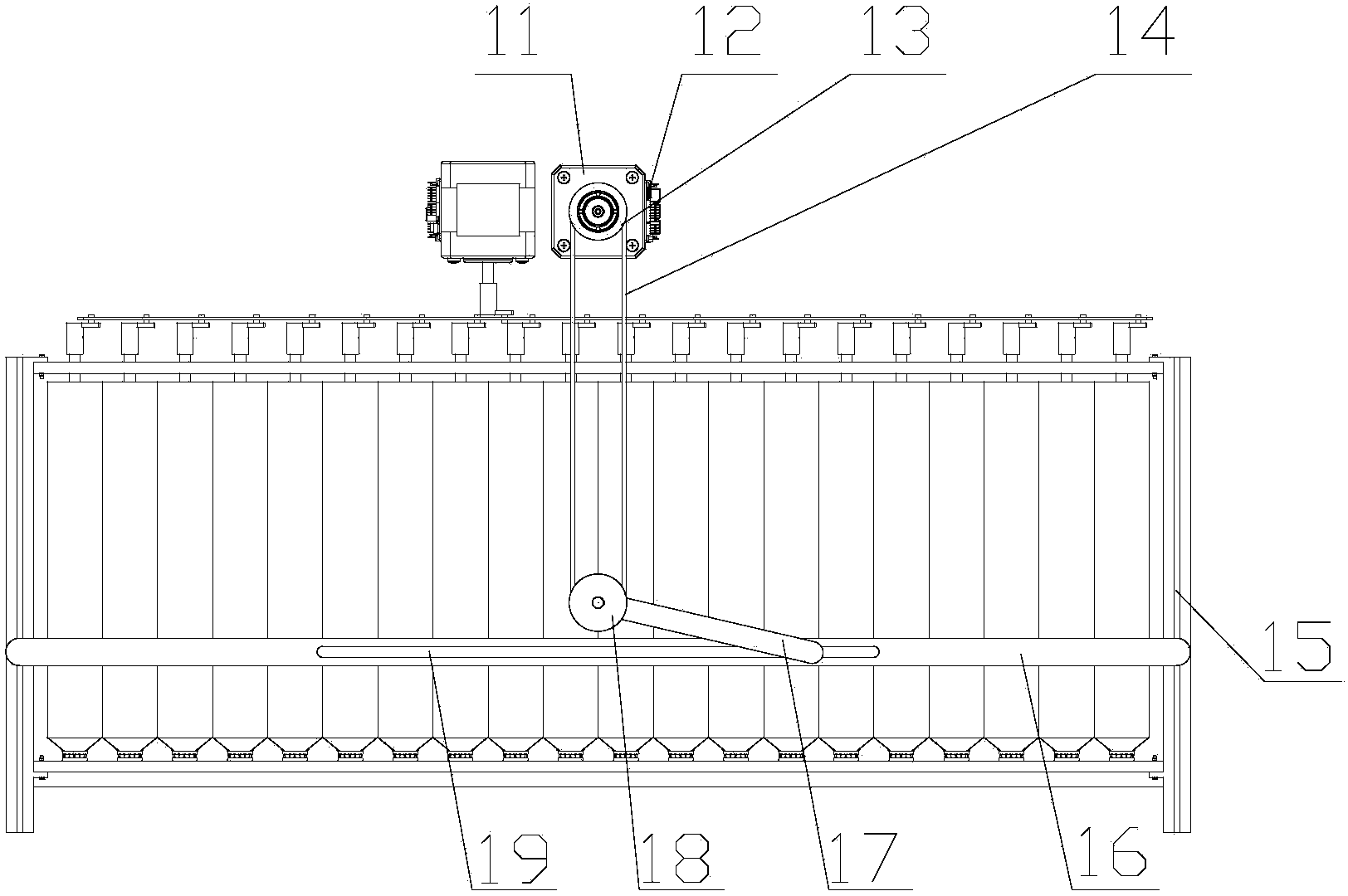

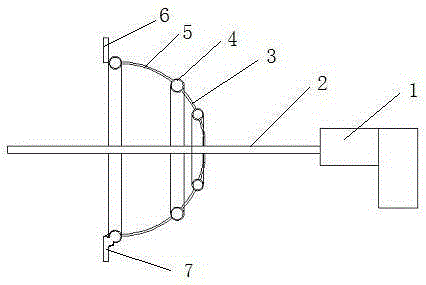

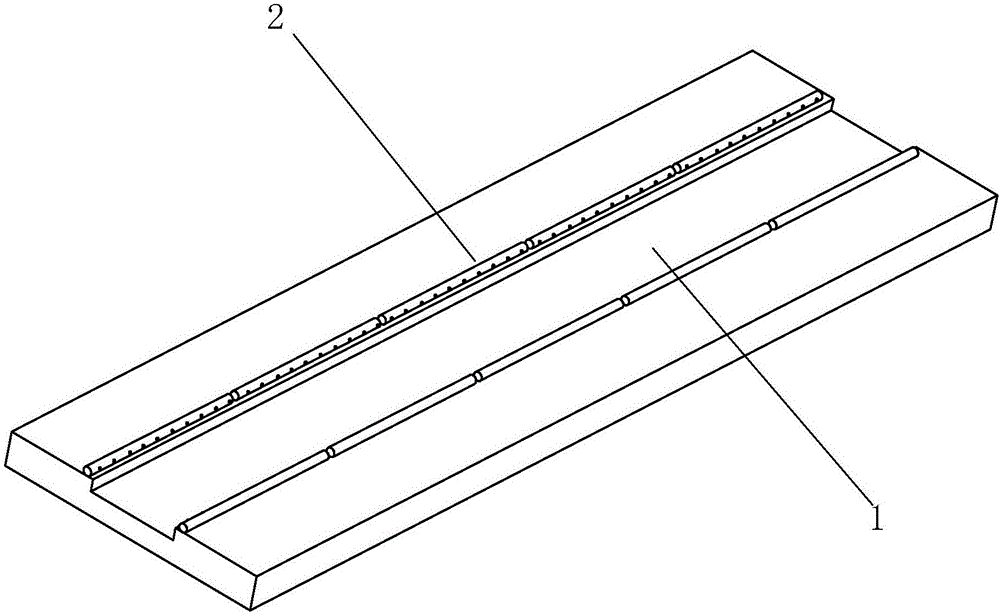

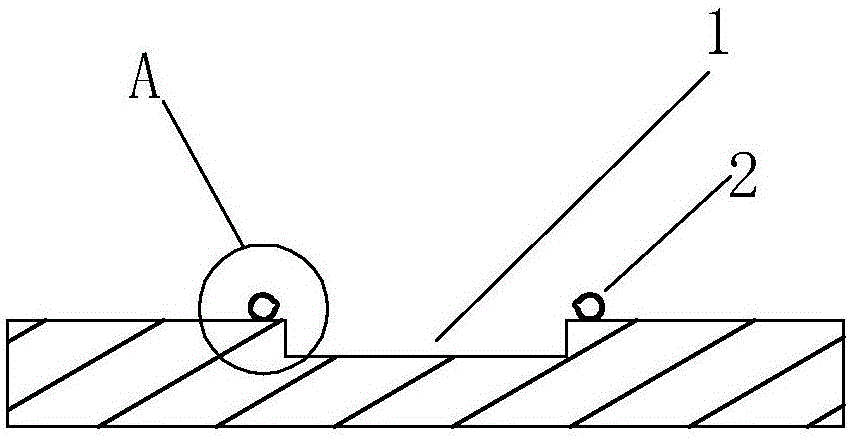

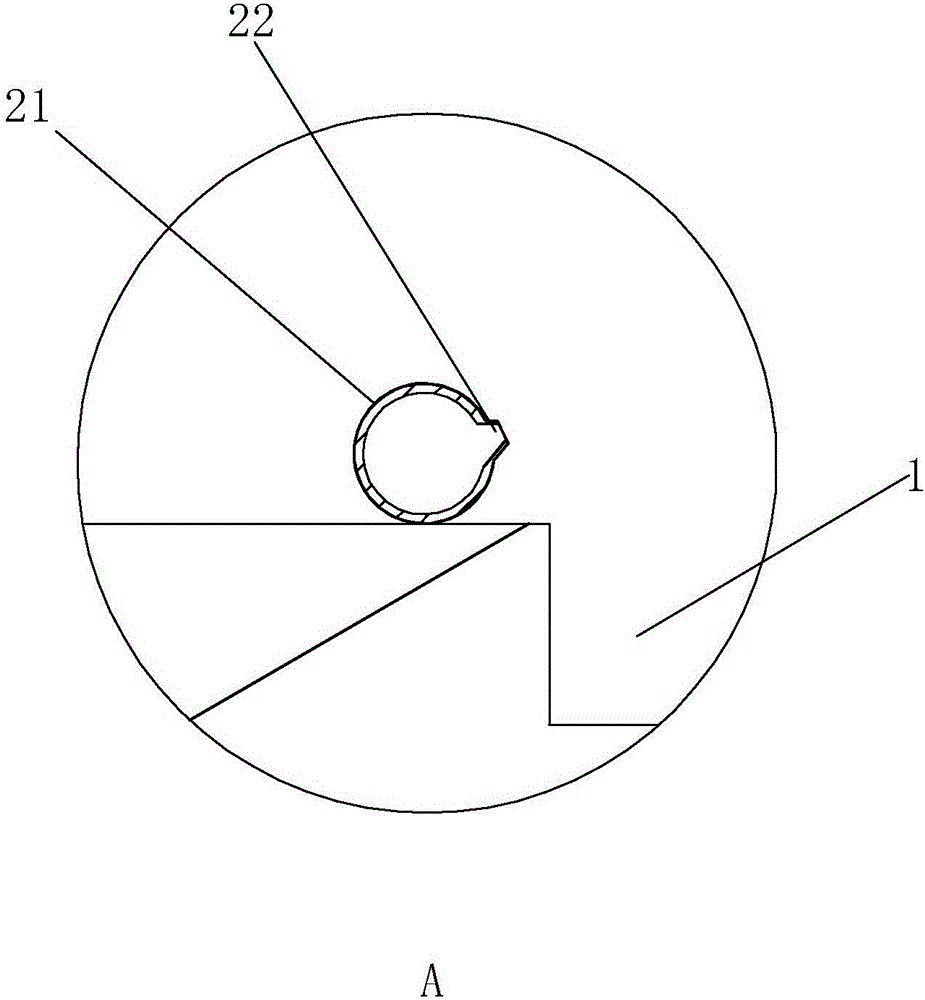

Novel three-side-reversible blackboard

InactiveCN103625173AIncrease the usable areaRealize synchronous rotationWriting boardsMotor controllerEngineering

Owner:ANHUI UNIV OF SCI & TECH

Molten iron desulphurization slag pre-processing method, slag-iron separating method and application of by-products

InactiveCN103627830AReduce equipment stressIncrease productivityRecycling and recovery technologiesSlagPre treatment

The invention discloses a molten iron desulphurization slag pre-processing method, a slag-iron separating method and application of by-products, and belongs to the metallurgy field. The first technical problem that the invention aims to solve is to provide the molten iron desulphurization slag pre-processing method which can control dust and is environment-friendly, and the second technical problem that the invention aims to solve is to provide the slag-iron separating method and application of molten iron desulphurization slag pre-processed by adopting the pre-processing method. The technical scheme adopted by the invention is that the desulphurization slag is subjected to tank-watering, hot disintegration, striking and smashing, screening, grinding, and magnetic separation for recycling iron from the molten iron desulphurization slag; while recycling the metallic iron from the molten iron desulphurization slag, keeping the MFe in tailings smaller than 1%, so that the tailings can be used in cement production.

Owner:PANZHIHUA GANGCHENG GROUP

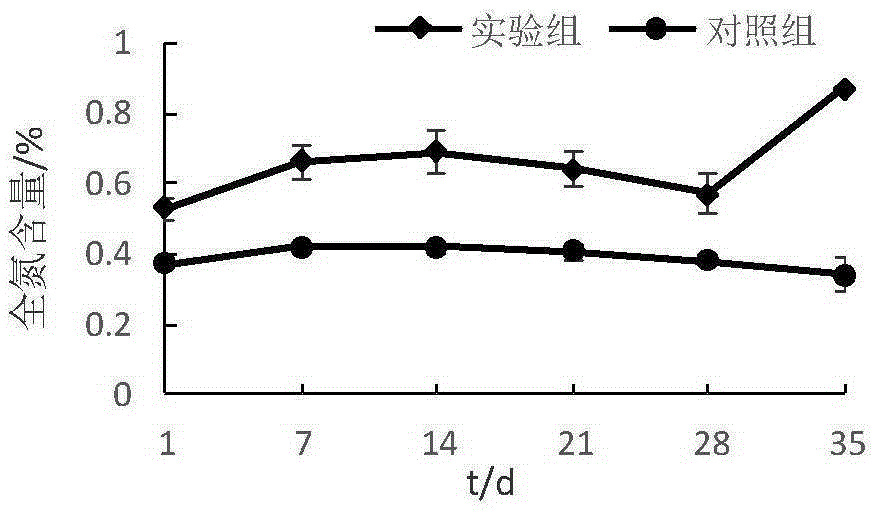

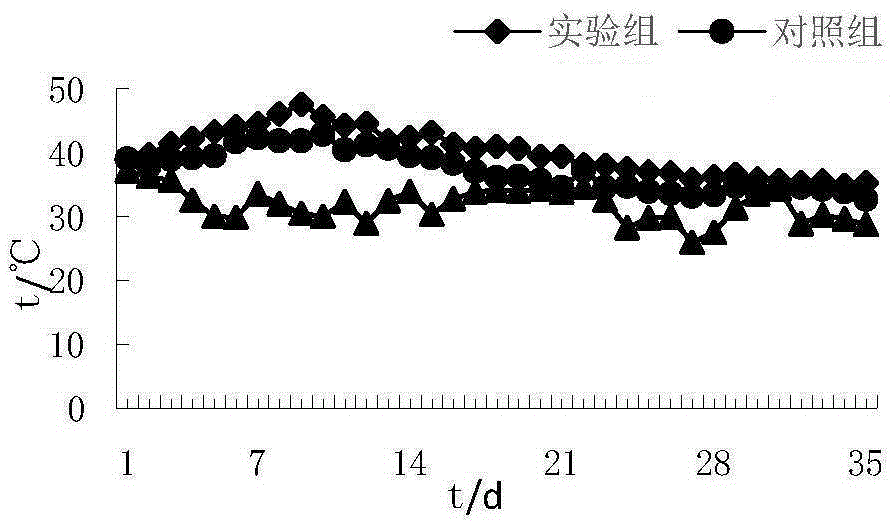

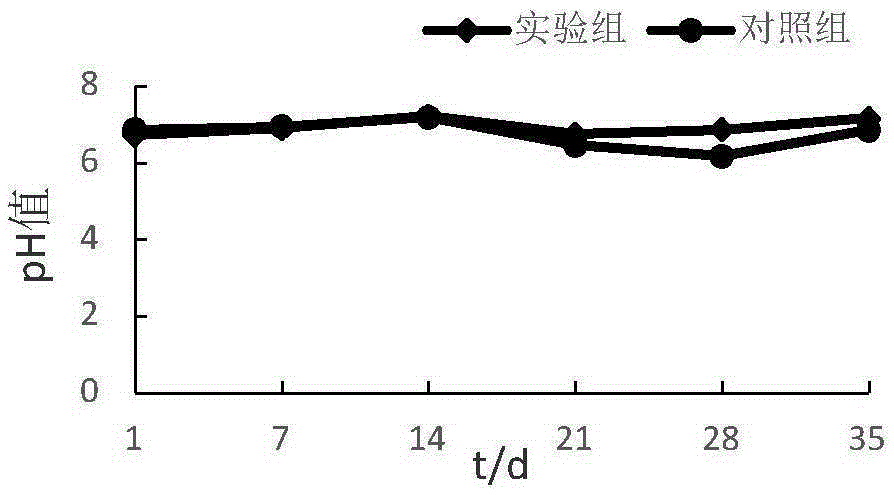

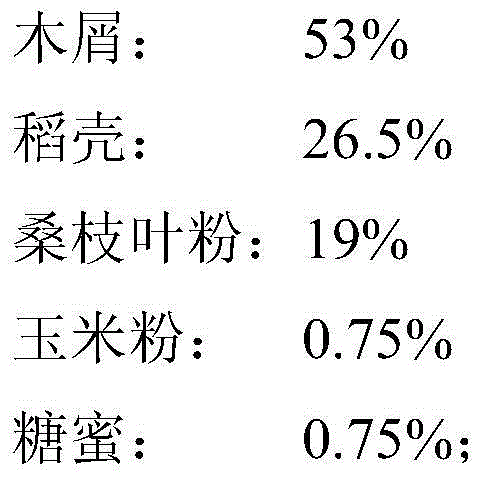

Composite microbial preparation and poultry fermentation bed padding material

ActiveCN105255767AExtended use timeReduce labor costsFungiBacteriaBacillus licheniformisAdditive ingredient

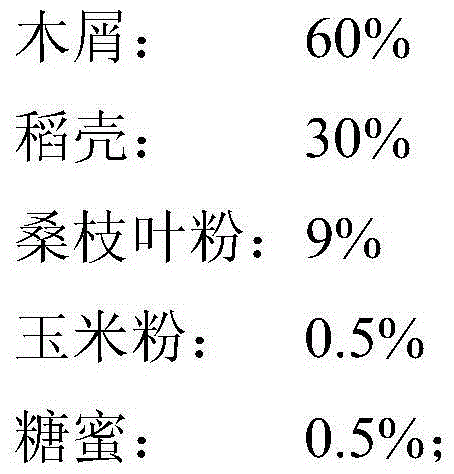

The invention discloses a composite microbial preparation, which is prepared from bacillus subtilis liquid, bacillus licheniformis liquid, saccharomyces cerevisiae liquid, lactobacillus acidophilus liquid and rhodopseudomonas palustris liquid according to a mass part ratio being (0.8 to 1.2):(0.8 to 1.2):(0.8 to 1.2): (0.8 to 1.2): (0.8 to 1.2). The invention also discloses a poultry fermentation bed padding material. Per cubic meter of padding material is prepared from the following ingredients including 120 to 160kg of wood shavings, 60 to 80kg of rice husk, 30 to 40kg of mulberry branch powder, 1.5 to 2.0kg of corn powder, 1.5 to 2.0kg of molasses, 40 to 50g of brown sugar, 10 to 12L of compound micro-organisms preparations and 200 to 300kg of water. The padding material is applicable to poultry culture, has the effects of effectively reducing the occurrence of poultry epidemic disease, reducing the use of medicine and improving the poultry meat quality, and is suitable for being used in high-temperature and high-humidity environment in southern areas.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI

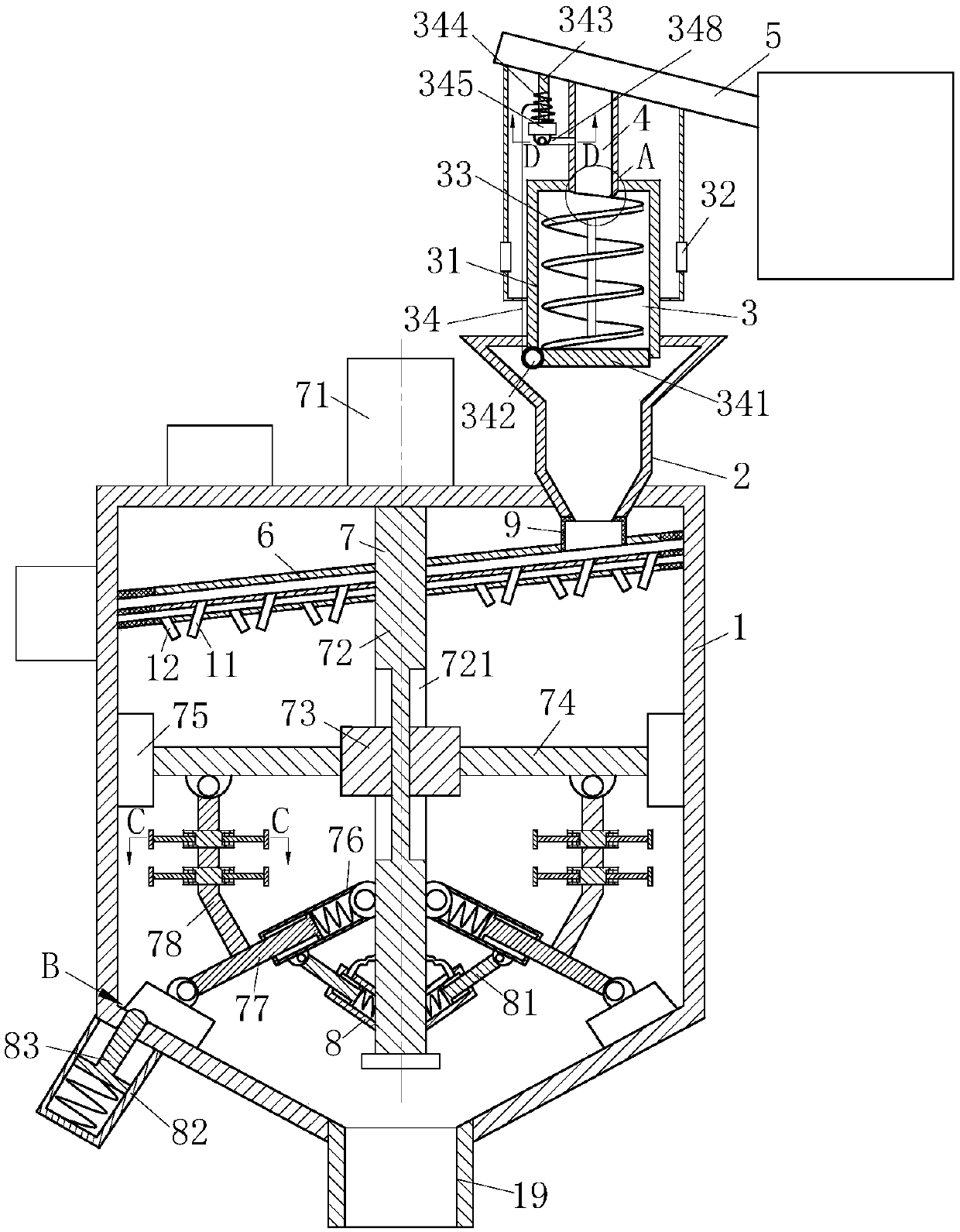

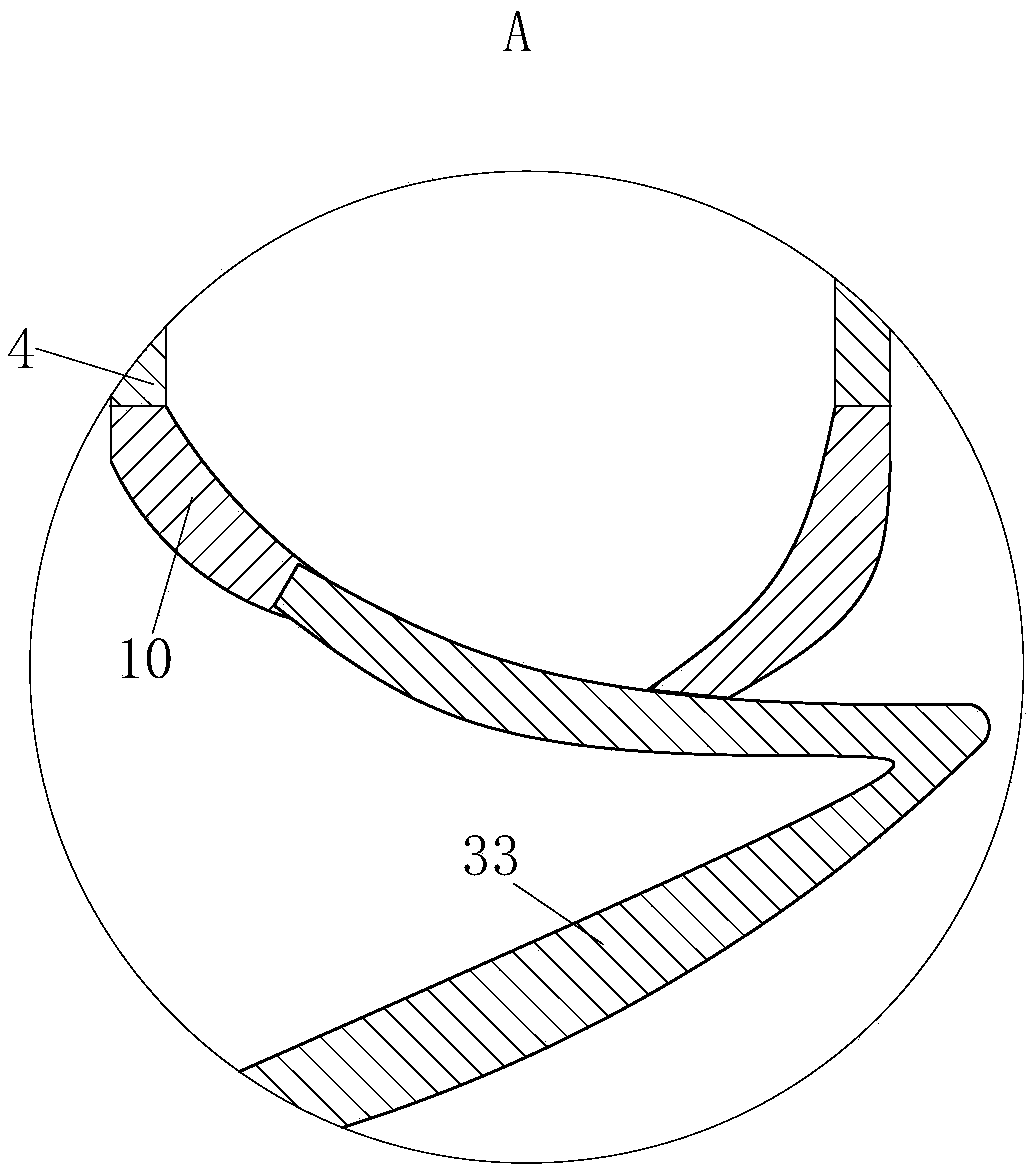

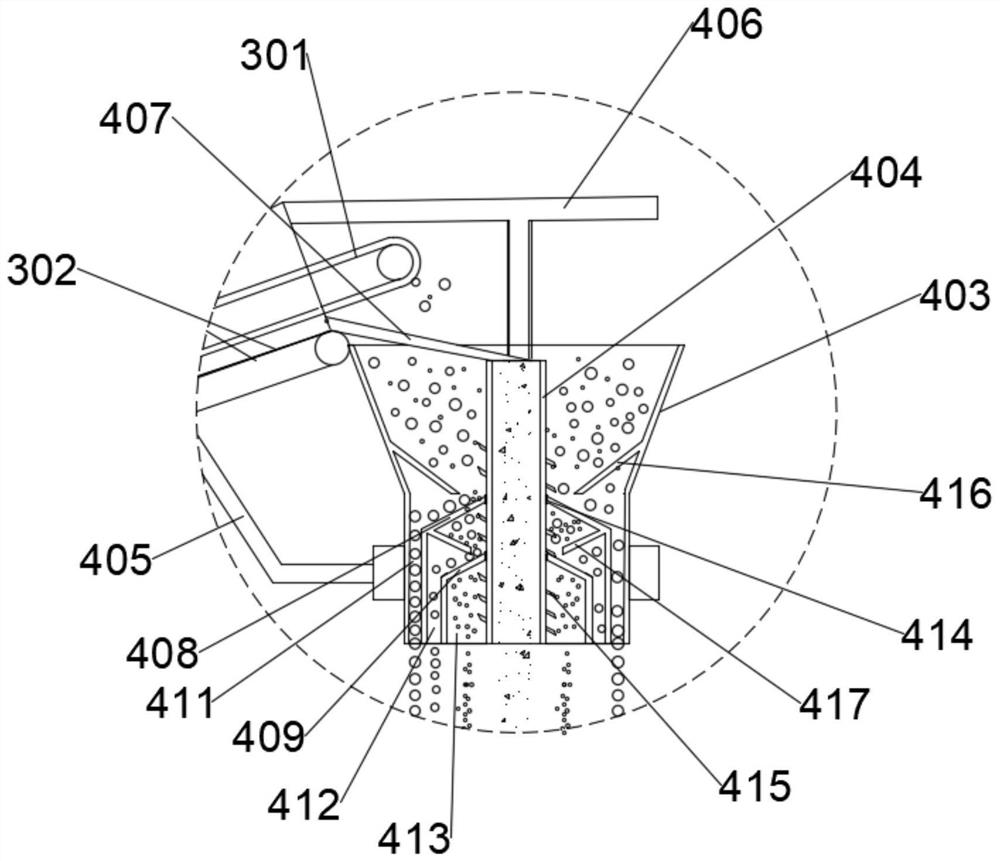

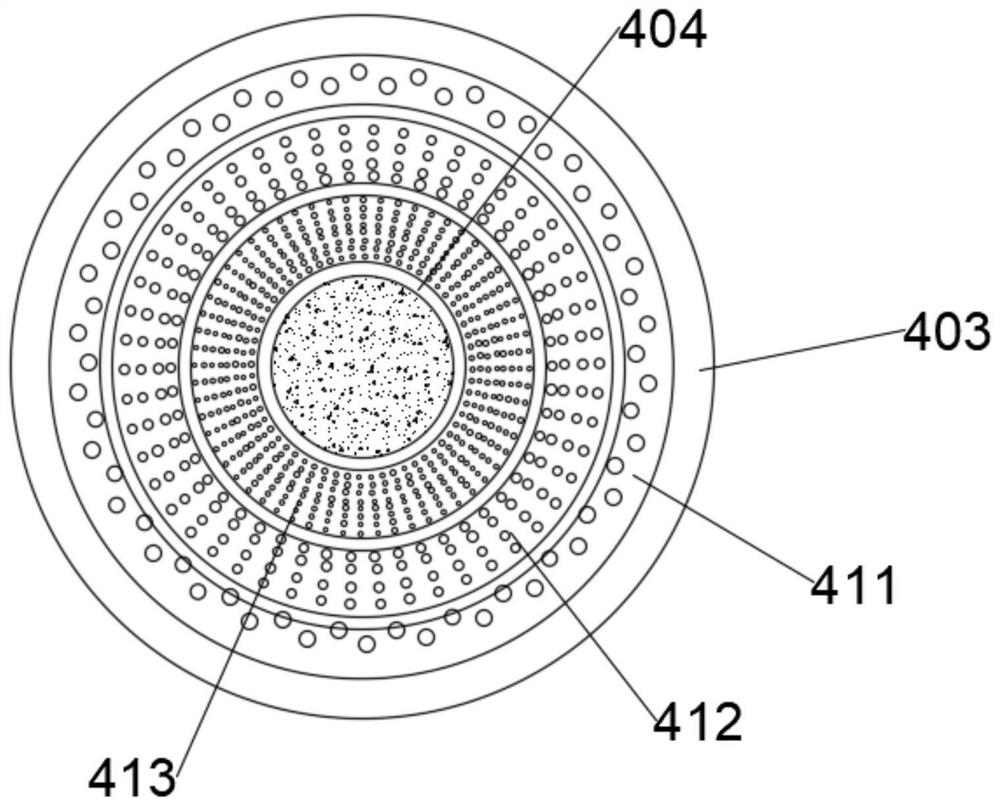

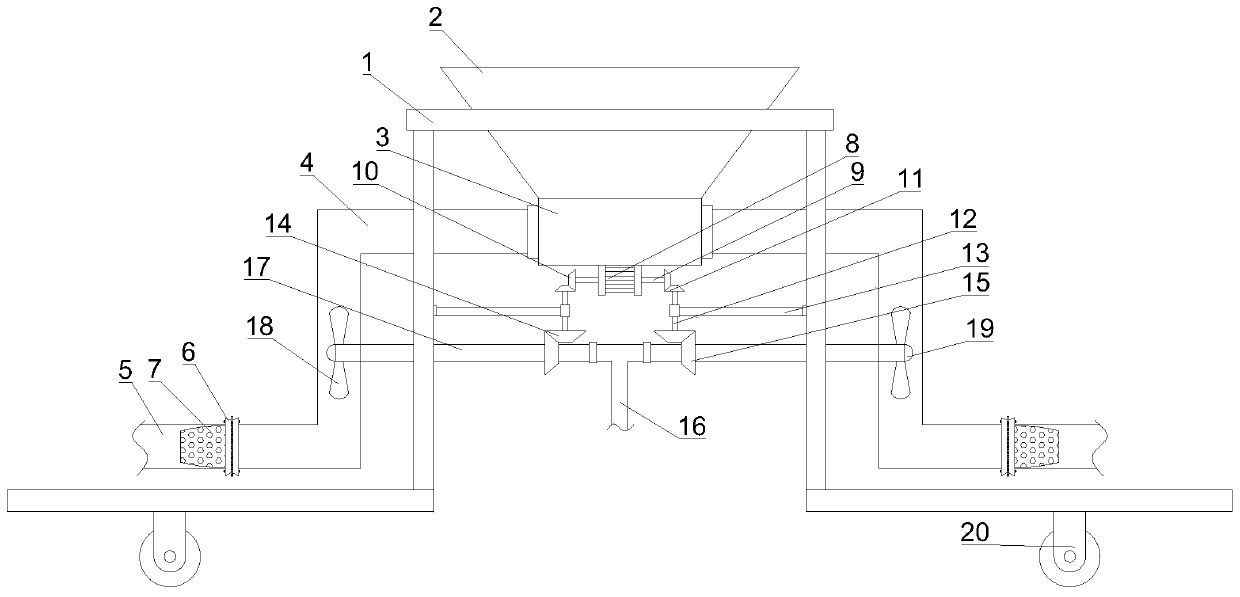

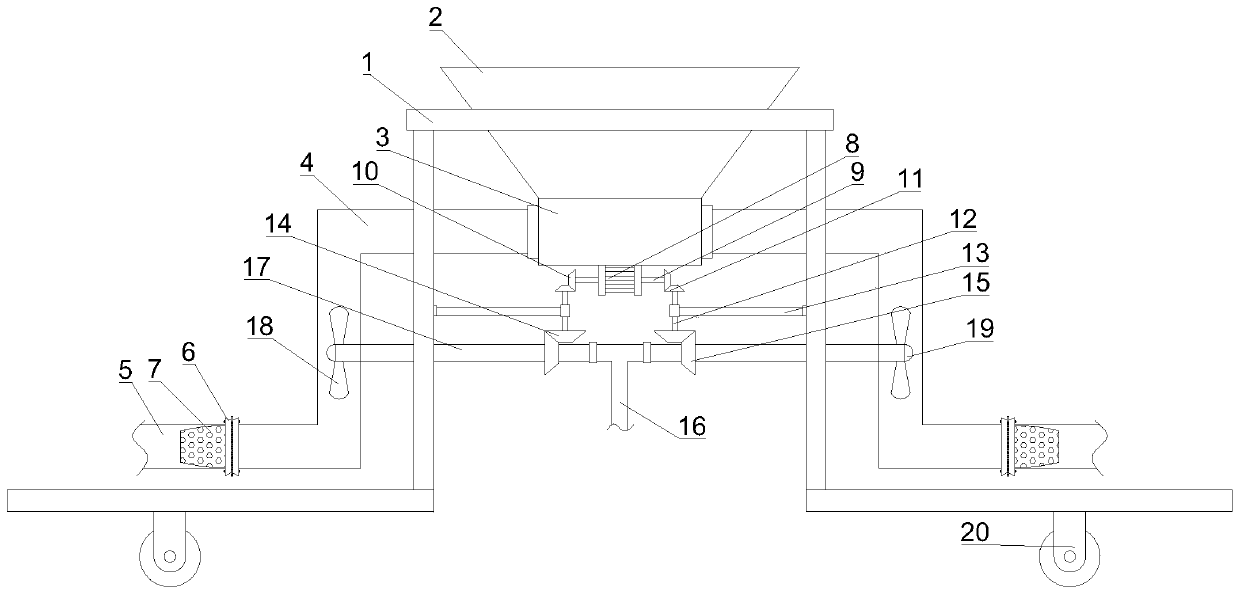

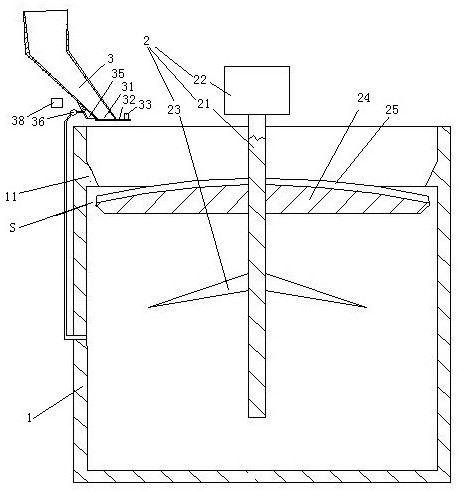

Concrete production device with automatic material control function

ActiveCN109624089AAvoid dustDust effectMixing operation control apparatusPretreatment controlControl functionWater pipe

The invention belongs to the technical field of concrete production equipment, and particularly relates to a concrete production device with an automatic material control function. The concrete production device comprises an outer shell. A blanking hopper is arranged at the top end of the outer shell. A powder material control unit is arranged at the top end of the blanking hopper. A powder material input port is formed in the upper end of the powder material control unit. A powder material conveyor is connected to the top end of the powder material input port and is connected with a powder material storage bin. A material guiding pipe is arranged at the top end of the interior of the outer shell and is connected with the blanking hopper through a rubber hose. A water conveying pipe is arranged in the material guiding pipe. A stirring unit is arranged in the outer shell. A discharging hole is formed in the bottom end of the outer shell. The powder material control unit is used for controlling the usage amount of powder materials, so that the proportions of the balance weights of water and the powder materials can be accurately controlled, and the proportions of the materials for concrete are more uniform, and quality indexes such as concrete strength are better. The water conveying pipe is arranged in the material guiding pipe, so that the phenomenon that dust flies in the outer shell is avoided.

Owner:湖南郴建集团泰湘新型材料有限公司

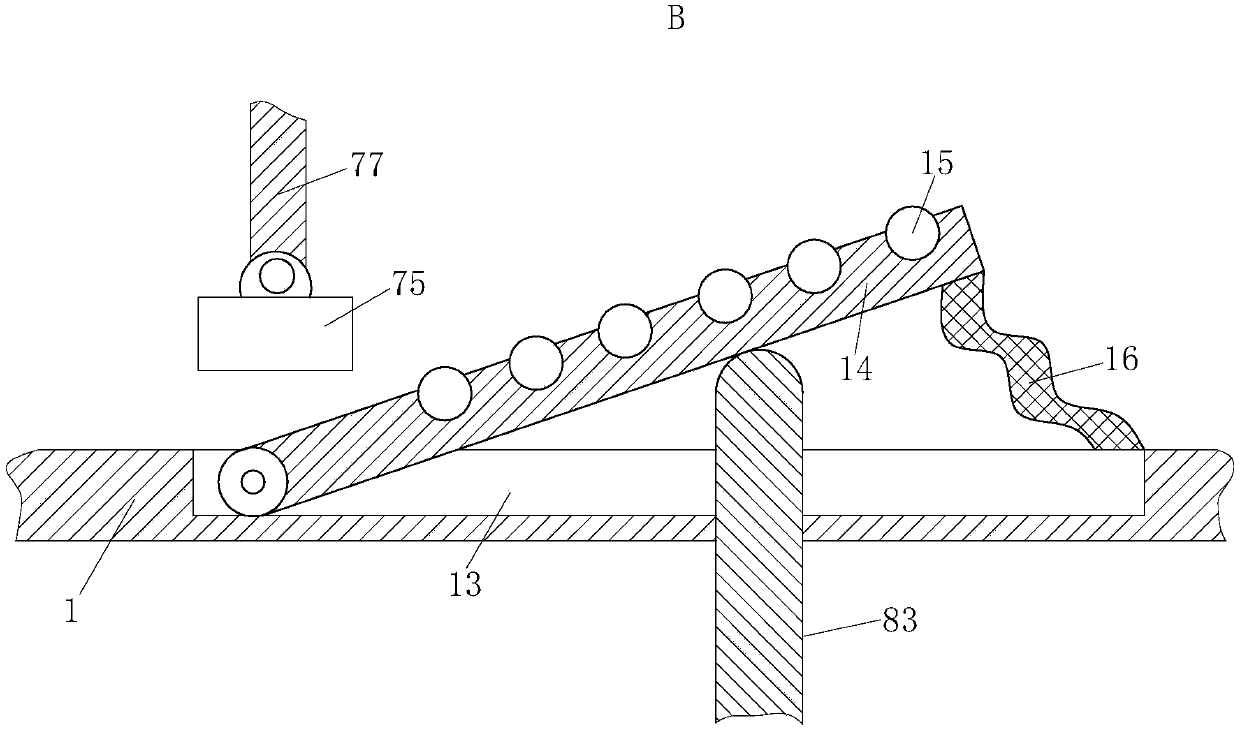

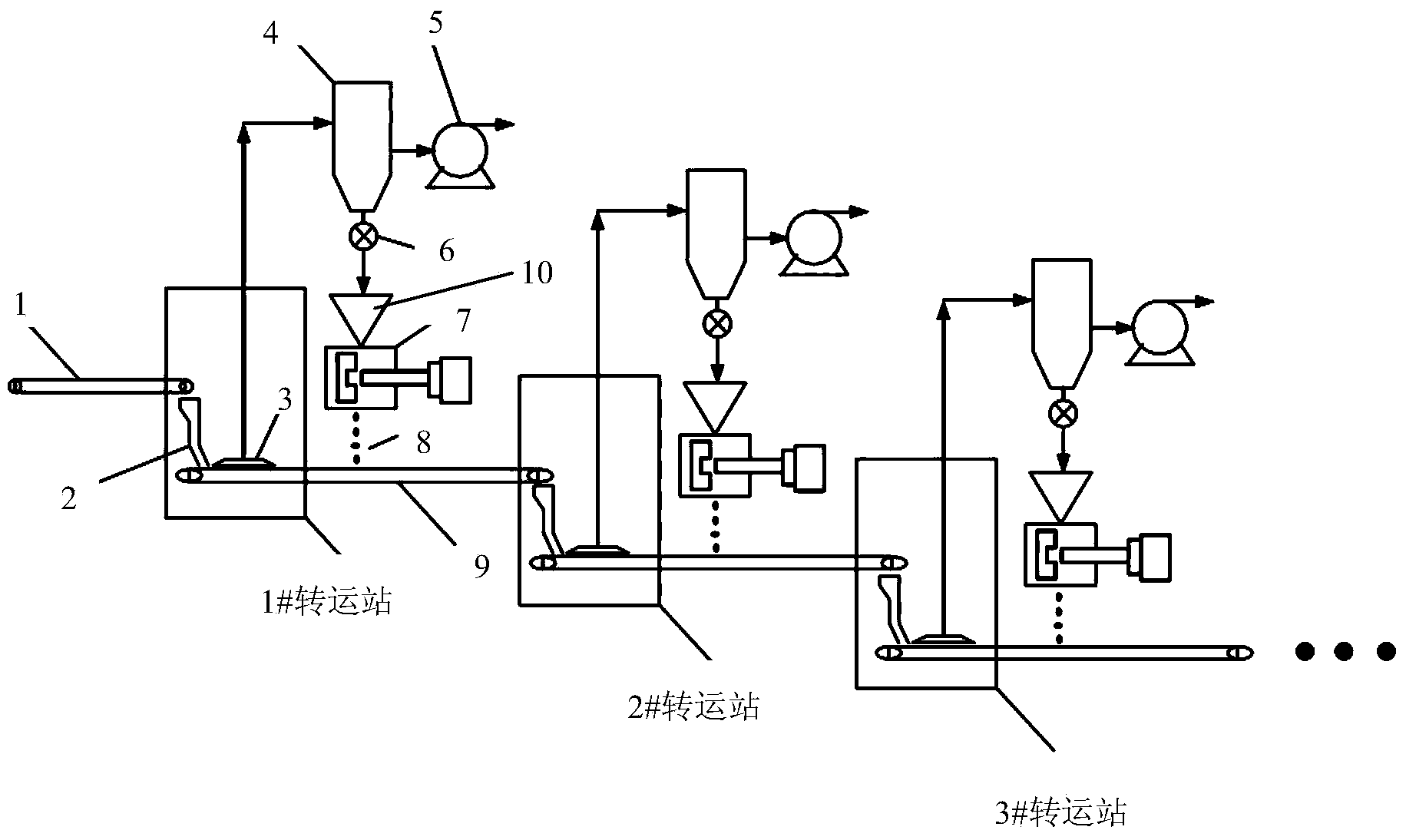

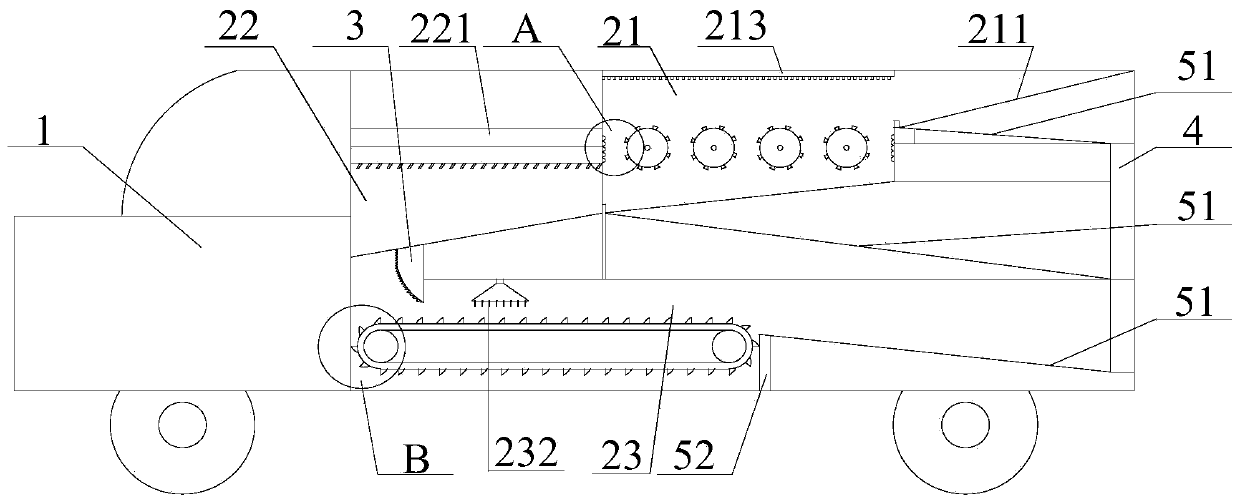

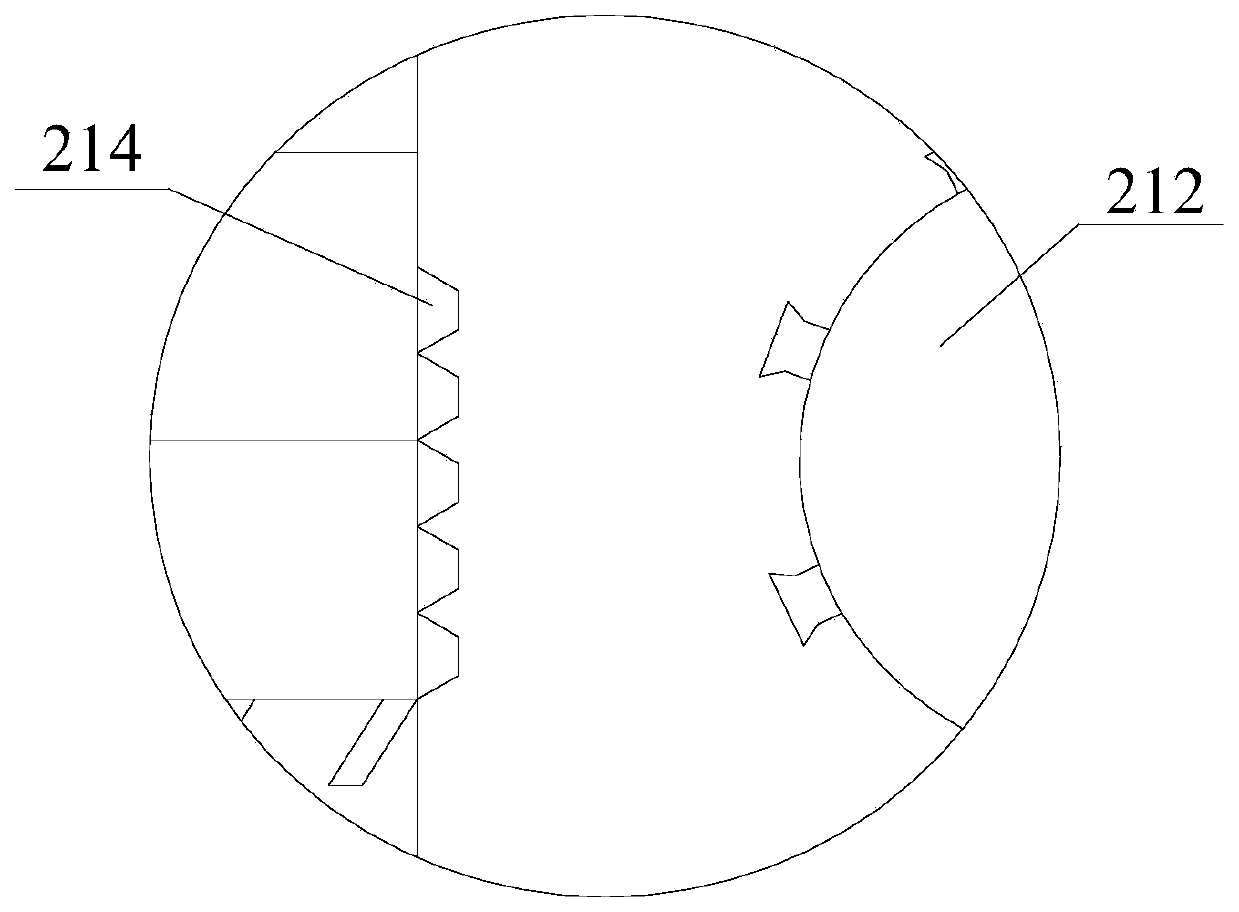

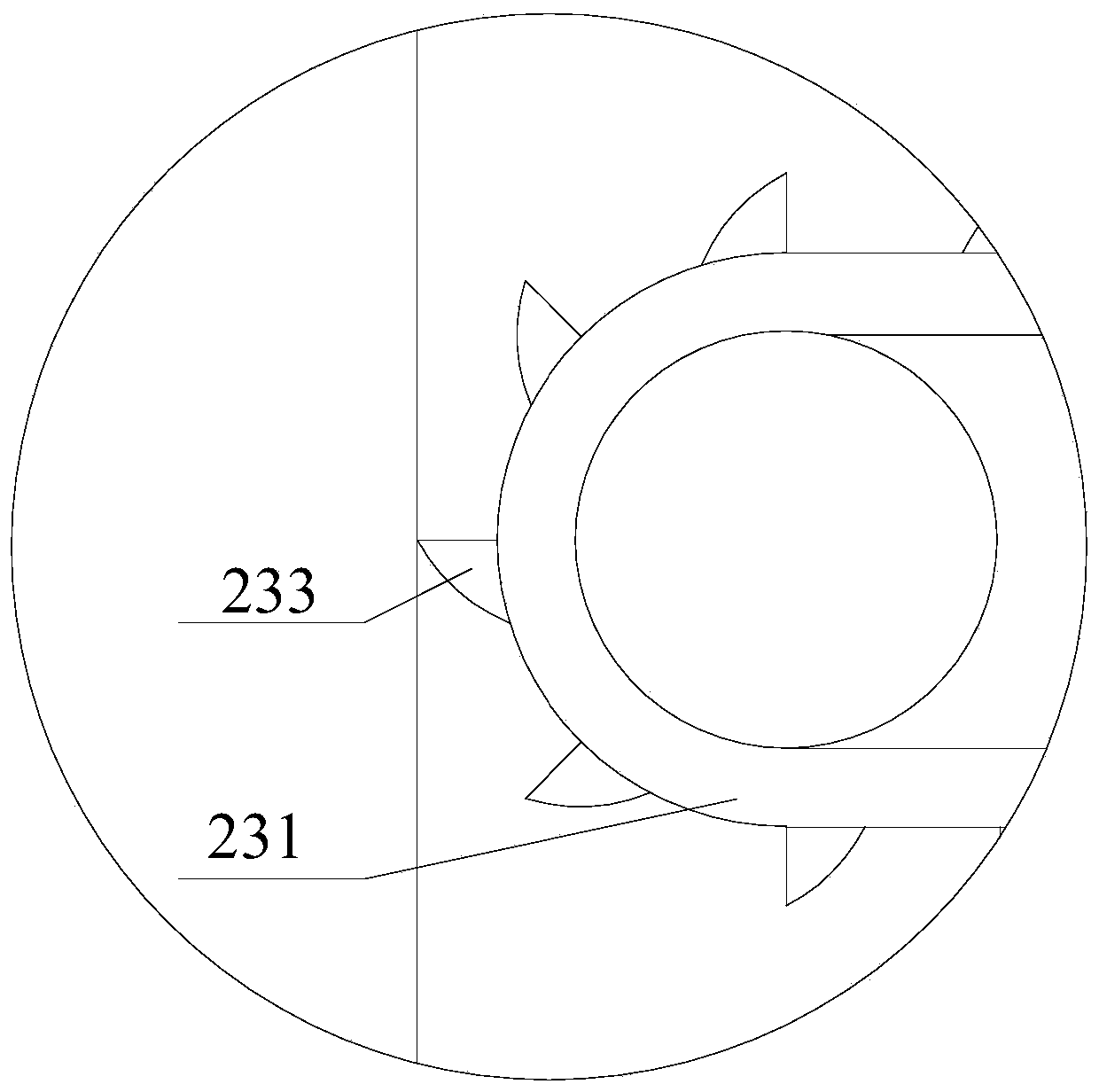

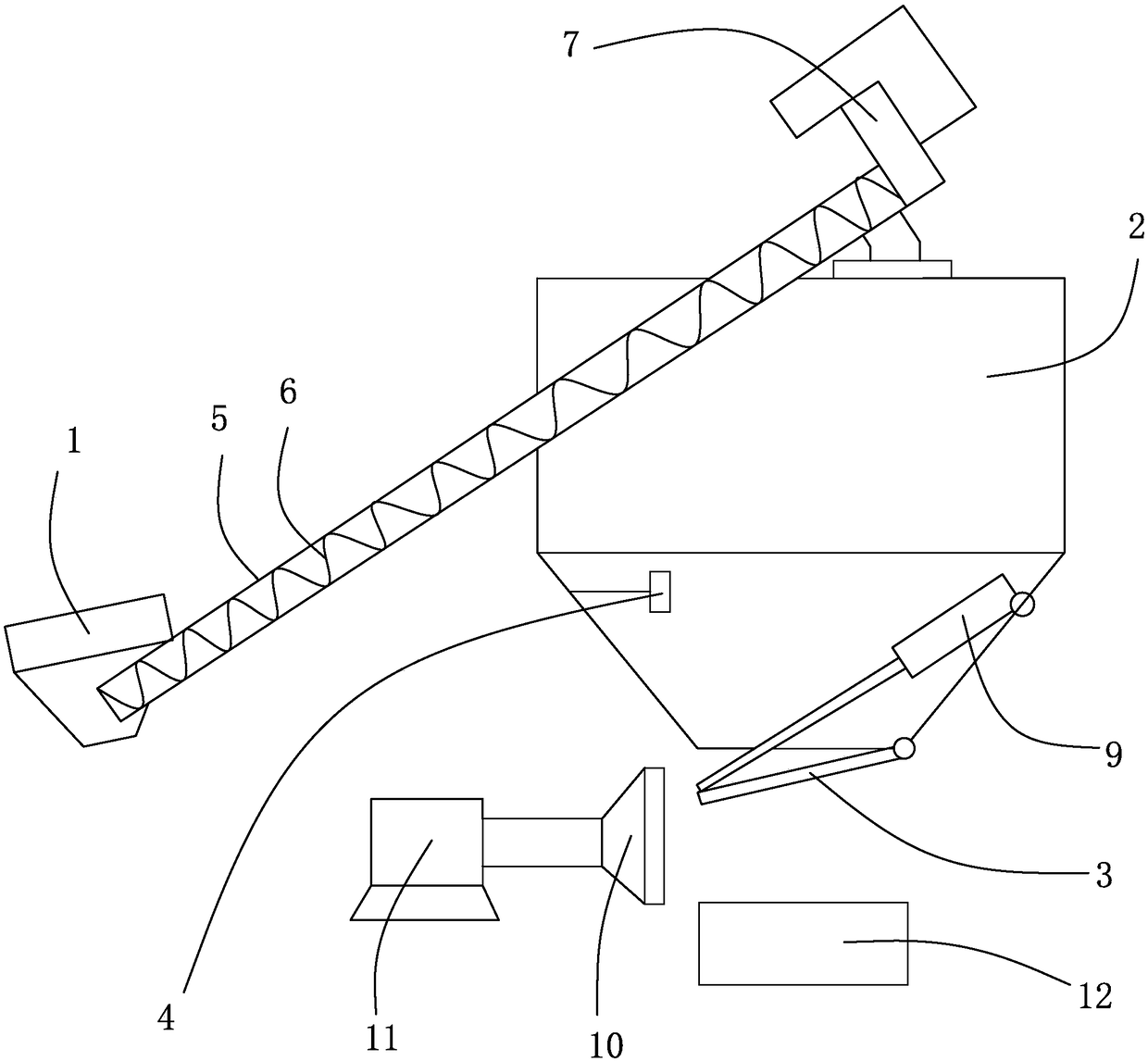

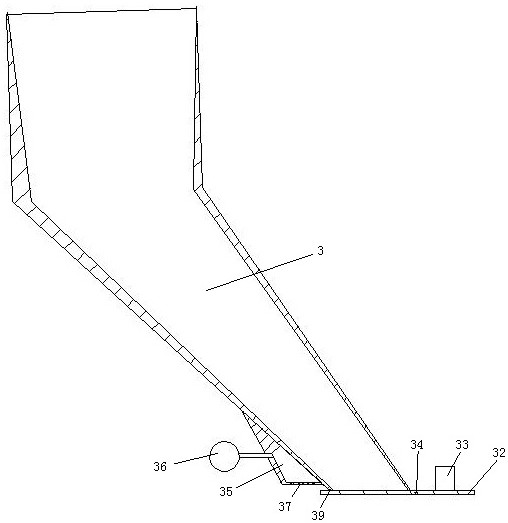

Dedusting delivery system and method for bulk materials

InactiveCN103754597AReduce dust phenomenonPrevent spontaneous combustionCleaningMechanical conveyorsEngineeringMechanical engineering

The invention provides a dedusting delivery system and method for bulk materials. The dedusting delivery system comprises at least one material conveying unit, wherein all the material conveying units are arranged in sequence along a material conveying path. Each material conveying unit comprises a first conveyor, a second conveyor, a closed transfer station, a dust extraction mechanism and a forming machine, wherein the first conveyor is provided with a first feed end and a first discharge end; the second conveyor is communicated with the first conveyor and is provided with a second feed end used for receiving the materials from the first conveyor and a second discharge end used for discharging the materials out of the material conveying unit; the first discharge end of the first conveyor and the second feed end of the second conveyor extend into the transfer station, and the first discharge end transfers the materials to the second feed end of the second conveyor in the transfer station; the dust extraction mechanism is communicated with the inside of the transfer station so as to draw raised material dust out of the transfer station; the forming machine is communicated with the dust extraction mechanism so as to receive and form the dust extracted by the dust extraction mechanism into profile materials, and the forming machine is communicated with the second conveyor or an independent profile material conveying device outside the transfer station so as to further convey the profile materials.

Owner:INNER MONGOLIA DATANG INT XILINHOT LIGNITE INTEGRATION DEV

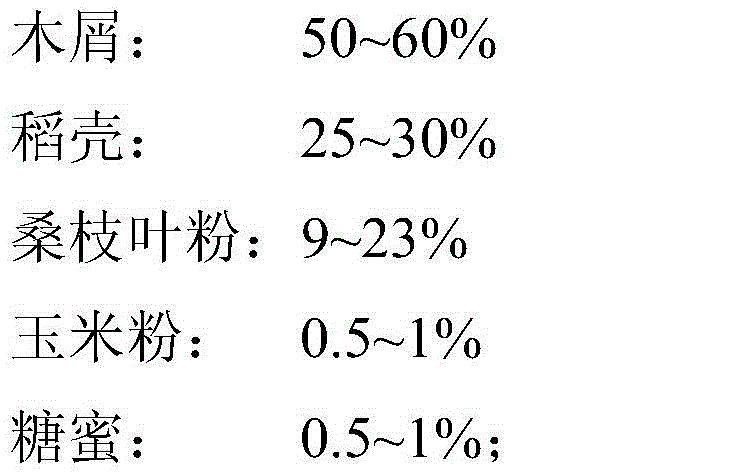

Southern area fermentation bed padding for birds and preparation method and purpose thereof

The invention discloses a southern area fermentation bed padding for birds and a preparation method and purpose thereof. The fermentation bed padding for the birds is composed of a padding raw material, a fermentative bacteria agent and water. The padding raw material is composed of 50% to 60% of wood sawdust, 25% to 30% of rice husks, 9% to 23% of mulberry branch powder, 0.5% to 1% of corn flour and 0.5% to 1% of molasses. The mass ratio of the wood sawdust to the rice husks is 2:1. The fermentative bacteria agent is EM bacteria liquid, and the using amount of the fermentative bacteria agent accounts for 2% to 5% of the padding raw material by mass. The using amount of the water accounts for 35% to 40% of the padding raw material by mass. According to the southern area fermentation bed padding for the birds, the conversion effect of microorganisms in the padding is utilized for decomposing feces of the birds, organic matter and inorganic matter are decomposed and utilized by the microorganisms, the surface of the padding can be wetted by the water, the dust raising phenomenon is reduced, odor is reduced, and the breeding environment is remarkably improved.

Owner:SERICULTURE & AGRI FOOD RES INST GUANGDONG ACAD OF AGRI SCI +1

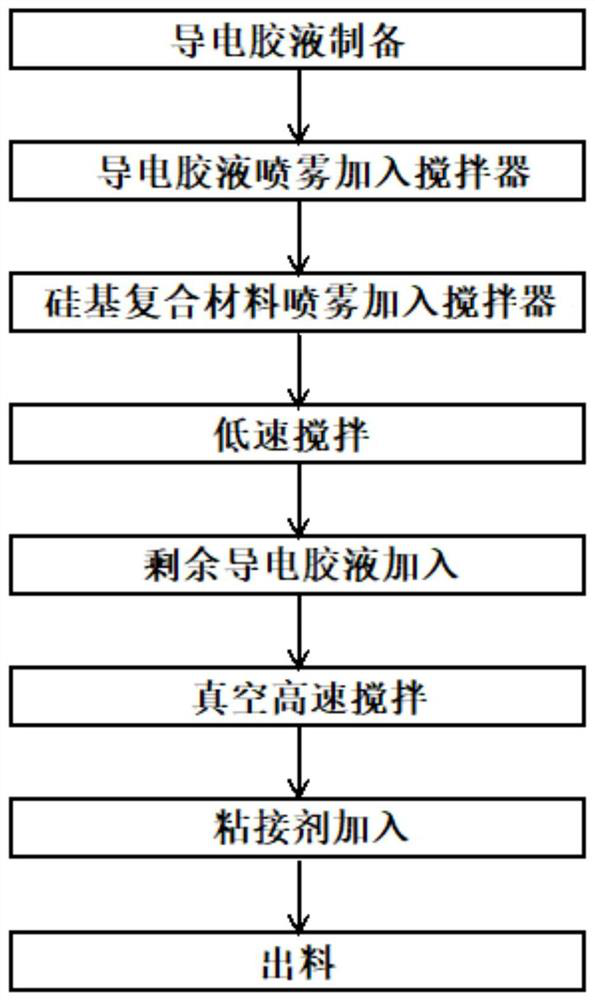

Preparation method of silicon-based negative electrode slurry

ActiveCN113380973AShort manufacturing timeReduce dustElectrode manufacturing processesSecondary cellsSlurryElectrically conductive adhesive

The invention discloses a preparation method of silicon-based negative electrode slurry. The preparation method comprises the following steps OF: stirring a solvent, a thickening agent and a conductive agent in a glue preparation tank to obtain a conductive glue solution; uniformly mixing a silicon active material and a carbon active material to obtain a silicon-based composite material; uniformly stirring the silicon-based composite material and the conductive adhesive solution in a stirrer at a low speed, then completely adding the rest conductive adhesive solution into the stirrer, and performing uniform stirring and mixing under a high-speed vacuum condition to obtain mixed slurry; and adding an adhesive into the mixed slurry, continuing vacuum high-speed stirring, and finally discharging the negative electrode slurry. In the preparation process of the negative electrode slurry, the conductive glue solution and the silicon-based composite material are added in a spraying manner at the same time, so that the contact probability of the surfaces of active material particles in the silicon-based composite material and the conductive glue solution is greatly increased, the infiltration process of the glue solution on the surfaces of the active material particles is promoted, the dispersion efficiency of the active material particles is improved, the preparation time of theslurry is effectively shortened, and 20% of stirring time can be saved.

Owner:DONGGUAN MIYEAR BATTERY CO LTD

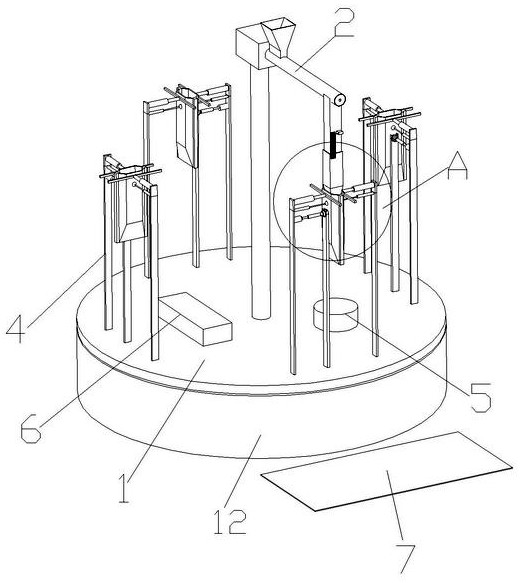

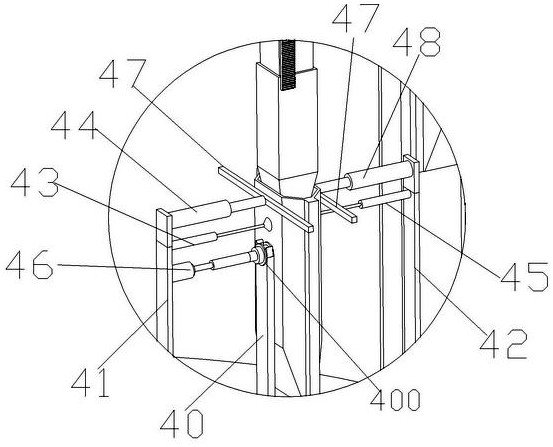

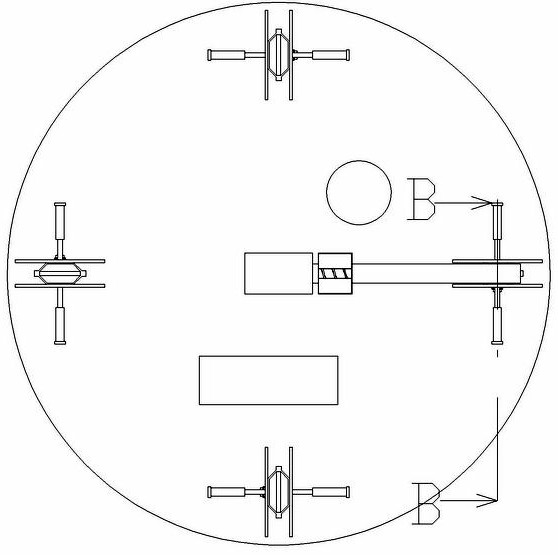

Dry powder filling gradual detection device and method

ActiveCN112849448AIncrease productivityLower relative altitudeWrapper twisting/gatheringSolid materialCircular discGear wheel

The invention discloses a dry powder filling gradual detection device and method. The dry powder filling gradual detection device comprises a rotary base, a filling mechanism, a powder weighing mechanism, multiple groups of supporting and detecting assemblies and a control device, wherein the filling mechanism comprises a supporting rod, a first servo motor and the like; the supporting rod penetrates through a rotating disc and is fixedly connected to a support base, a stator of the first servo motor is fixedly connected to the upper end of the supporting rod, a rotor of the first servo motor is coaxially and fixedly connected to a worm, the worm is sleeved with a charging barrel, and the head end of the charging barrel is fixedly connected to the stator of the first servo motor; the tail end of the charging barrel is rotatably connected to the worm; a feeding bin and a discharging bin are arranged at the upper end and the lower end of the charging barrel respectively, a storage bin is slidably connected to the lower end of the discharging bin, a rack is fixedly connected to the side wall of the storage bin, a second servo motor is fixedly connected to the side wall of the discharging bin, a rotor of the second servo motor is meshed with the rack through a gear, and a powder weighing mechanism is hinged to an opening in the lower end of the storage bin. Through cooperation of the rotating base and the multiple groups of supporting and detecting assemblies, the whole continuous production mode of filling, sealing and detecting can be guaranteed.

Owner:吉林省富生医疗器械有限公司

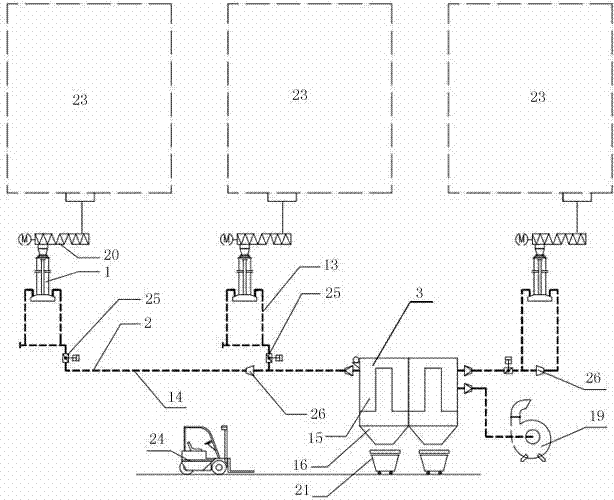

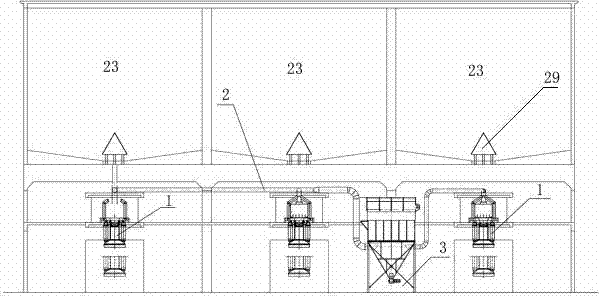

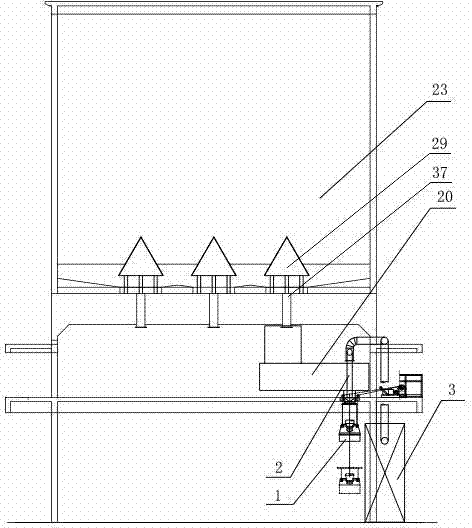

Dust suppression system for dust silo

The invention discloses a dust suppression system for a dust silo. The dust suppression system comprises a dust hood device 1, a negative-pressure pipe network system 2 and a dust catching and collecting device 3, wherein the dust hood device 1 is set with a telescopic structure; one end of the negative-pressure pipe network system 2 is connected with the dust hood device 1; the other end of the negative-pressure pipe network system 2 is connected with the dust catching and collecting device 3. Overall design of the dust suppression system for one or more dust silos can be performed according to the characteristics of different dust samples, dust produced in a discharging process is controlled, water vapor produced by contact of hot ash with stirring water is controlled, the distance between a discharging hole and the bottom of a carriage is adjustable, and dust and water vapor can be collected and treated concentrically, so that the problem of raise dust on a double-shaft stirrer in a power plant dust silo is solved, and environmental sanitation and working personnel health in a power plant dust silo region are realized. The dust suppression system has good reference and guidance significance to the cultured production design of future dust silo regions and the design of similar discharging regions such as residue siloes.

Owner:SOUTHWEST ELECTRIC POWER DESIGN INST OF CHINA POWER ENG CONSULTING GROUP CORP

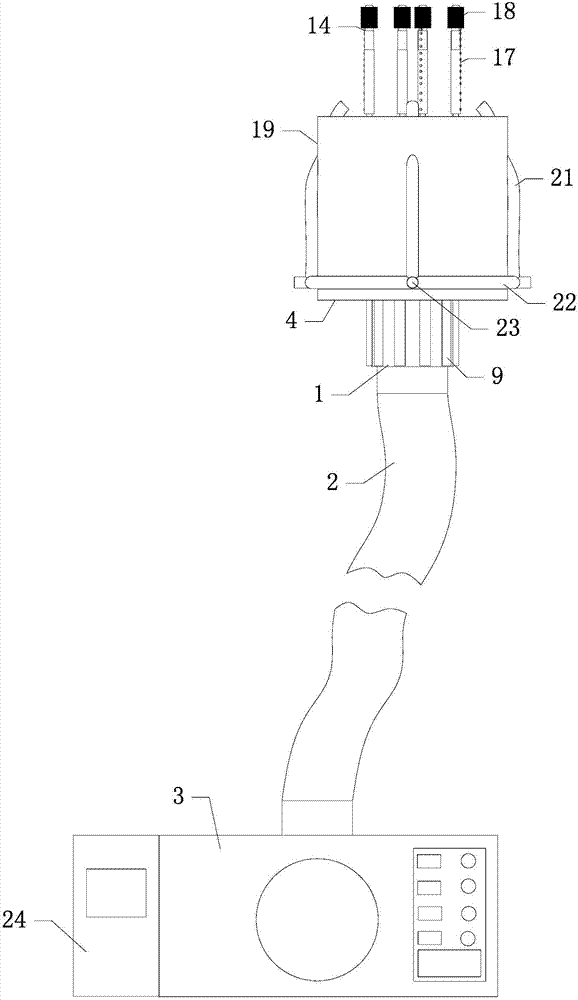

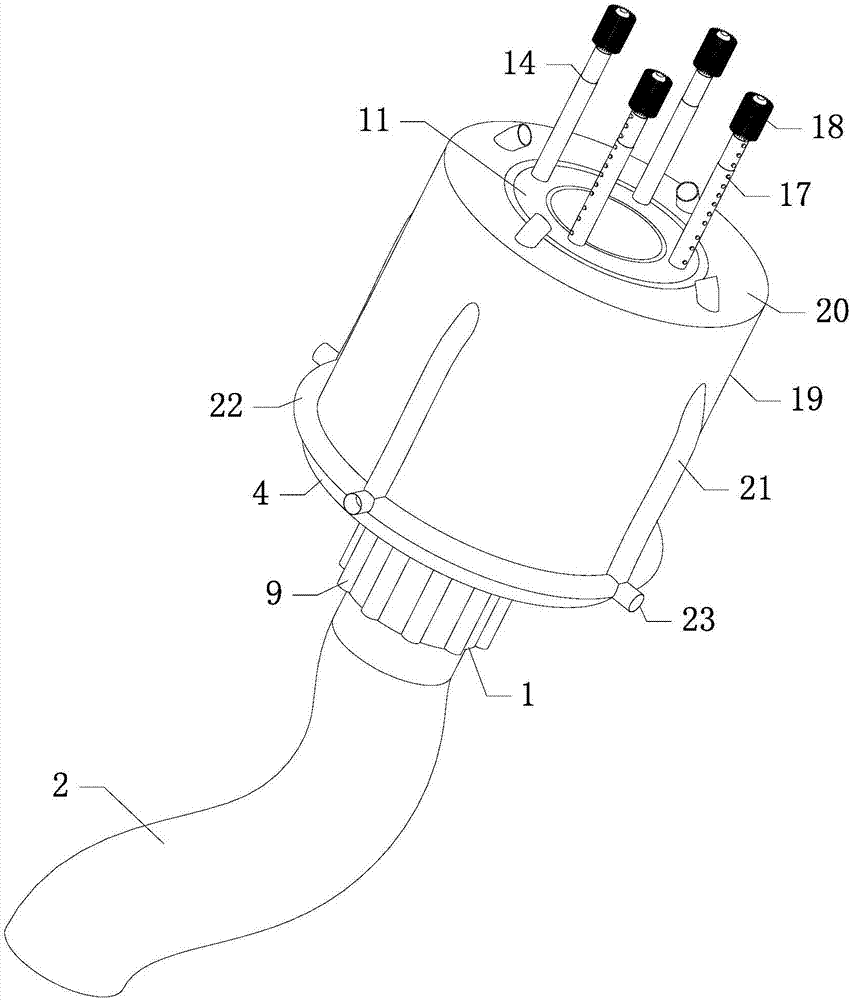

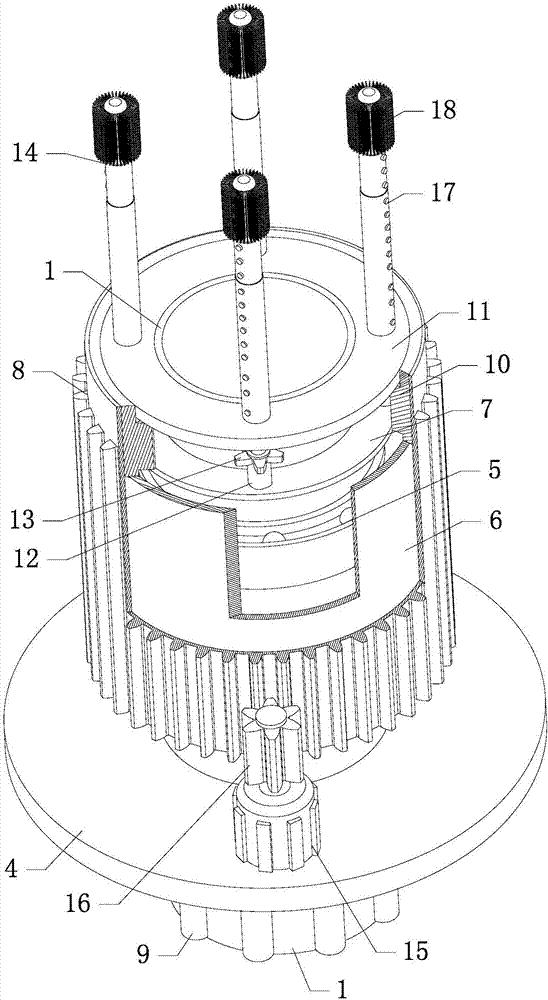

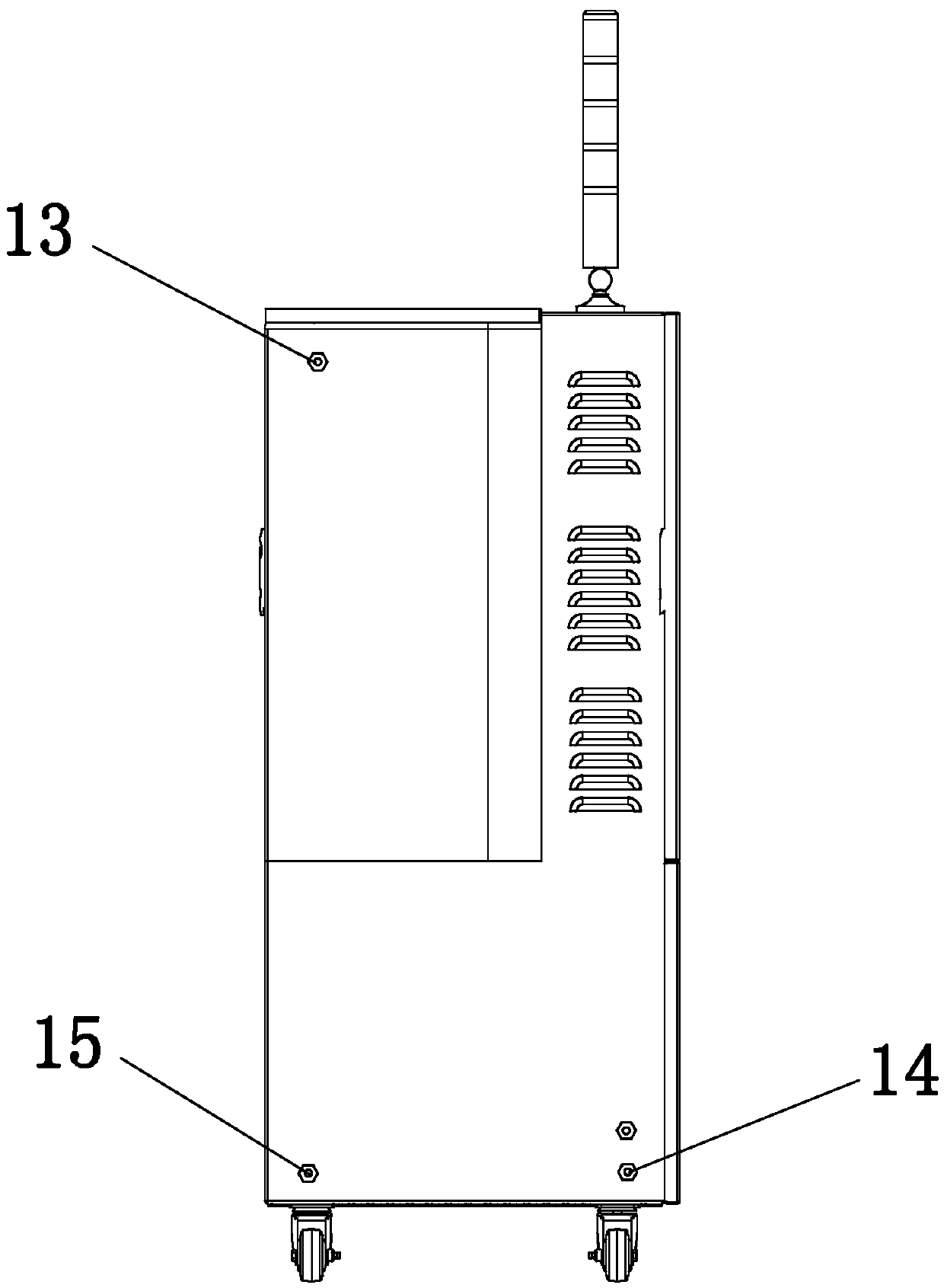

Dust sweeping and treatment device utilized in high-voltage electrical equipment

ActiveCN107225121AFast centralized collectionFast and effective centralized collectionHuman health protectionCasings/cabinets/drawers detailsEngineeringHigh pressure

The invention relates to the field of cleaning devices of electrical equipment, particularly to a dust sweeping and treatment device utilized in high-voltage electrical equipment. The dust sweeping and treatment device comprises a dust suction device, and the dust suction device comprises a central dust suction pipe; the lower end of the central dust suction pipe communicates with a control device with a dust suction fan arranged inside through a dust suction connecting pipe; the outer side of the lower part of the central dust suction pipe is in threaded connection with a locating circular plate; a sweeping device is arranged on the outer side of the central dust suction pipe above the locating circular plate; and a high-voltage cleaning device is fixedly connected above the locating circular plate on the outer side of the sweeping device. According to the dust sweeping and treatment device, the structure is simple, the design is reasonable, cleaning can be carried out through the high-voltage cleaning device, the surface of the electrical equipment can be swept through the sweeping device, cleaned dust can be quickly and effectively gathered and collected through the dust suction device during the cleaning process, requirements of people are met more effectively, and problems in the prior art are solved.

Owner:山东鲁昂电气有限公司

Pig fermentation bed padding reducing dust

InactiveCN106106201AIncrease appetiteIncrease feed intakeFood processingAnimal feeding stuffBiotechnologyN-Butyl Alcohol

The invention discloses a pig fermentation bed padding reducing dusts. The pig fermentation bed padding is made of raw materials in the following parts by weight: 34-38 parts of fresh phragmites communis, 5-7 parts of groundsel, 1.6-2.0 parts of edible salt, 20-22 parts of seaweed, 26-28 parts of garden soil, 0.3-0.4 parts of n-butyl alcohol, 1.8-2.2 parts of carboxymethylcellulose, 34-36 parts of maize straws, 25-28 parts of beer yeast paste, 1-2 parts of a proteinase preparation, 0.9-1.1 parts of cysteine hydrochloride, 1.5-1.7 parts of thiamine, 24-25 parts of vanilla planifolia pods, appropriate 45% ethanol solution, and appropriate water. The fermentation bed padding is combined by multi-layer structures, and a high porosity structure is formed in the fermentation bed padding. Cooperated with use of the carboxymethylcellulose on an upper layer, high adsorbability, high water-absorbing property, and high moisture retention of the padding are realized. The padding can preferably adsorb dusts in air, reduce stink and dust phenomenon, and culture environment is obviously improved.

Owner:ANHUI WANLI ECOLOGICAL LANDSCAPE

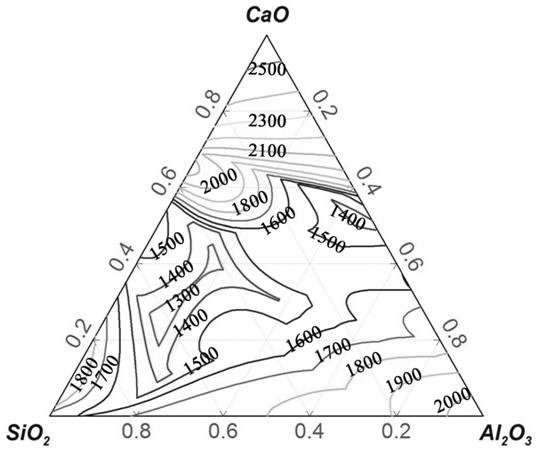

Method for recycling aluminum ash as steelmaking deoxidation slag former

InactiveCN113234891AStable ingredient rangeQuality improvementProcess efficiency improvementSteelmakingAluminium electrolysis

The invention discloses a method for recycling aluminum ash as a steelmaking deoxidation slag former. The aluminum ash is scum generated in an aluminum electrolysis process, the air-dried aluminum ash is added with limestone and then ground into fine particles, the fine particles are uniformly stirred with a binder and water, and the deoxidation slag former is prepared after extrusion forming by using a mold and drying treatment. In the tapping process, a deoxidizing slag former is added in batches, slag is formed quickly by utilizing dynamic conditions during tapping, and the oxygen content in steel is reduced. According to the method, molten steel is deoxidized and slagging is performed by using metal aluminum and oxides thereof in the aluminum ash so that the burden of the aluminum manufacturing industry can be reduced, the economic benefit of a steel mill can be improved, the ecological environment can be improved, and the method has important practical significance.

Owner:INST OF RES OF IRON & STEEL JIANGSU PROVINCE +1

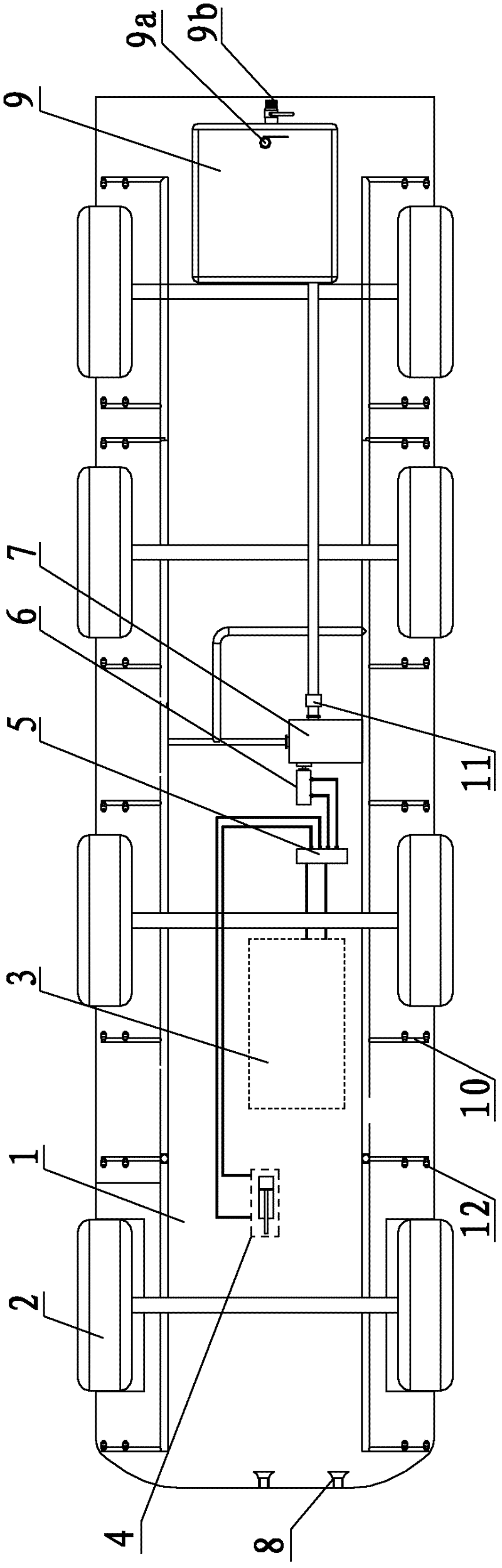

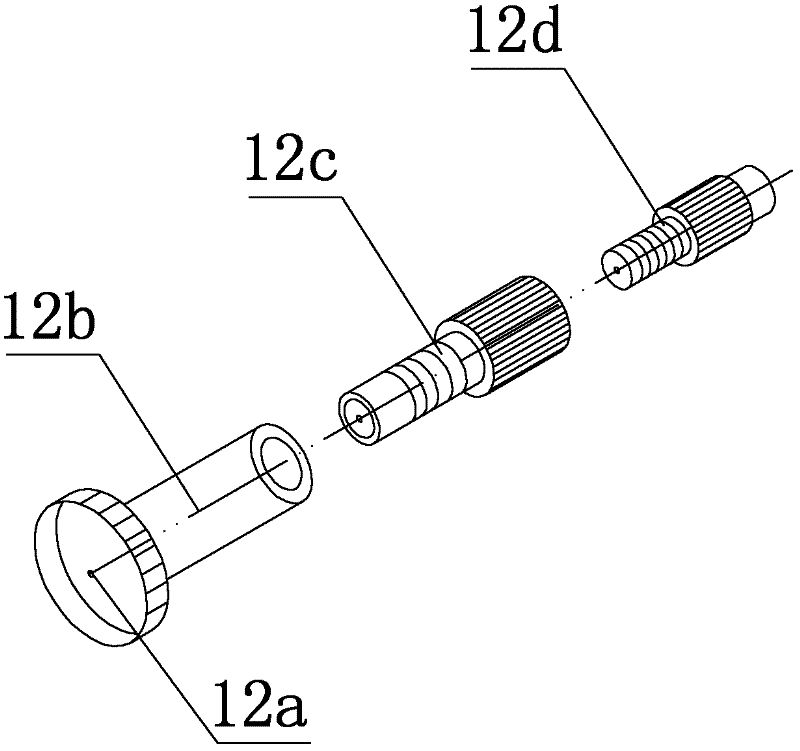

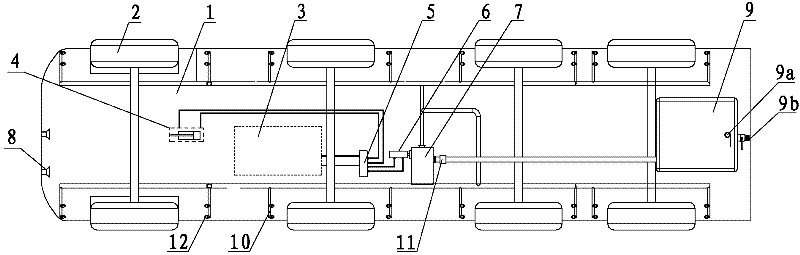

Dumper with travel spray dust suppression device

InactiveCN102390333AWeight increaseAccurate targetRoad cleaningElectric/fluid circuitHydraulic motorHigh pressure

The invention discloses a dumper with a travel spray dust suppression device belonging to the technical field of dumper. The technical point is that: a dumper body is included and wheels are arranged on the bottom part of the dumper body. A power transmission box is arranged on the bottom part of the dumper body. A power transmission box pipeline is connected with a dump arm assembly, wherein an oil path distributor is arranged on the pipeline between the power transmission box and the dump arm assembly. An oil path distributor pipeline is connected with a hydraulic motor and a power output shaft of the hydraulic motor is connected with a high-pressure pump. An oil path distributor circuit is connected with a hydraulic motor control button; a water inlet pipeline of the high-pressure pump is connected with a water tank; and the water tank is arranged on the dumper body. A water outlet pipeline of the high-pressure pump is connected with a plurality of atomizers; and these atomizers are arranged on the front and rear sides of each wheel, respectively. The invention is aimed to provide the spray dust suppression device on the dumper and provide a dumper with a travel spray dust suppression device, which has compact structure, good dust suppression effect and convenient use, and is capable of automatically suppressing the dust when walking to the dumper.

Owner:广东风华环保设备股份有限公司

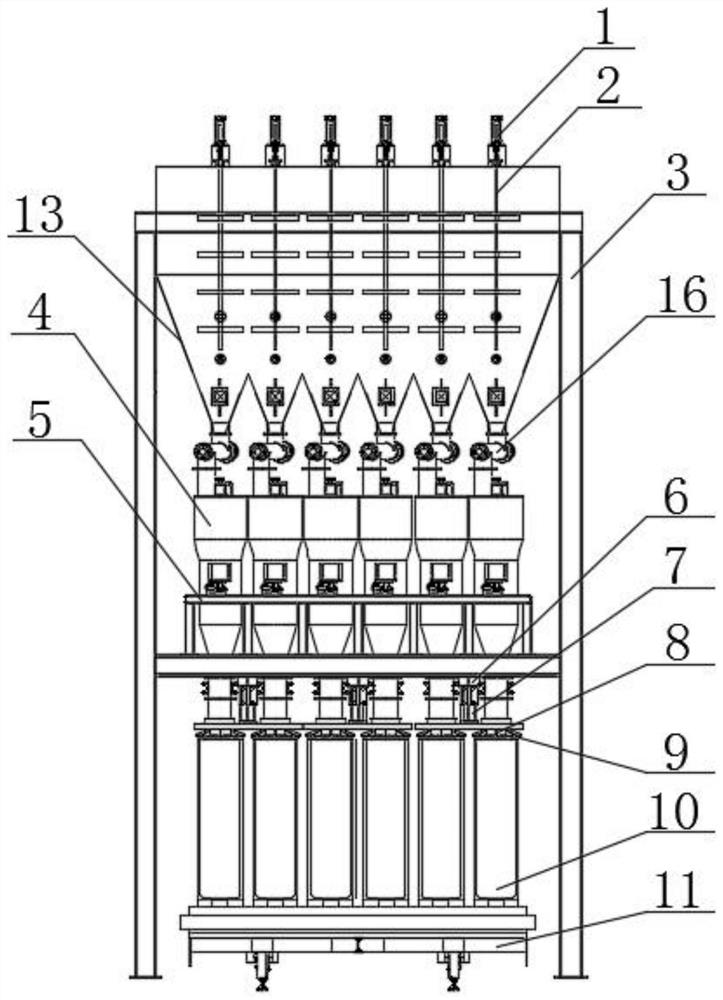

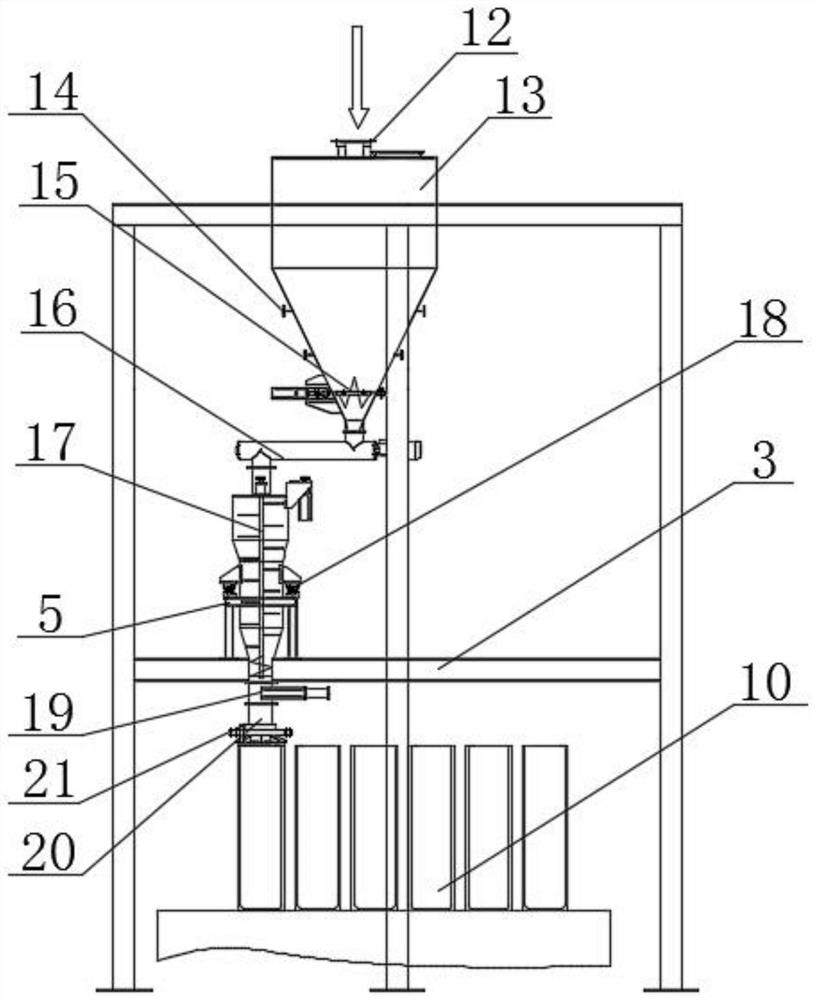

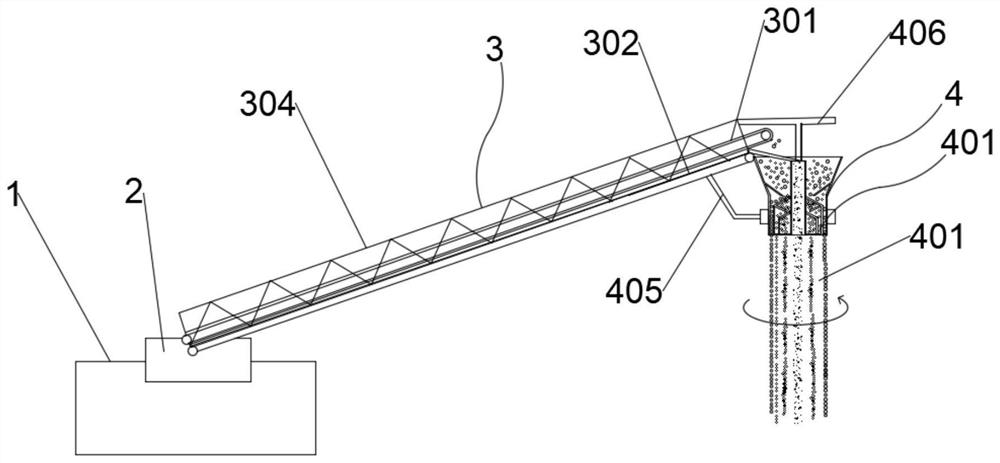

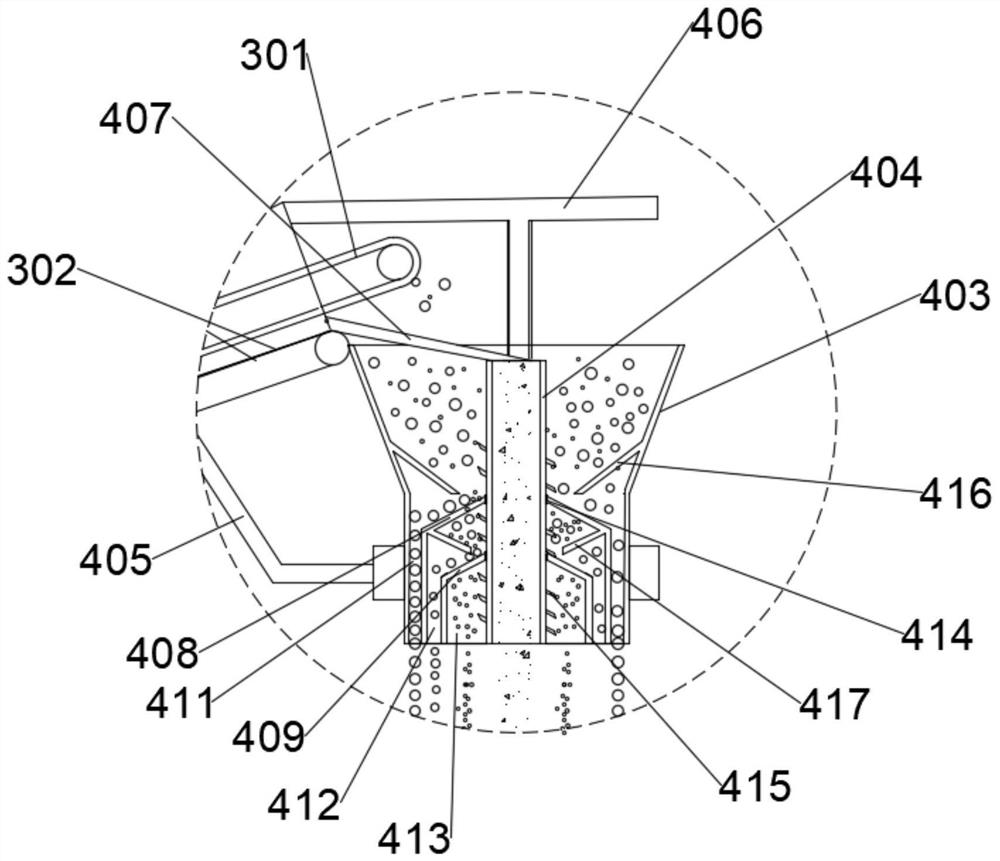

Graphite cathode material crucible automatic charging system

PendingCN114394342AReduce labor intensityIncrease productivityLarge containersControl devices for conveyorsCrucibleGraphite

The graphite cathode material crucible automatic charging system comprises a multi-layer frame, a small frame and a crucible, the small frame is fixedly connected to the middle of the multi-layer frame, a stock bin is erected at the top end of the multi-layer frame, a charging opening is formed in the upper portion of the stock bin, and an arch breaking lifting air cylinder is fixedly installed on the upper portion of the stock bin; and an arch breaking pull rod is installed at the lower output end of the arch breaking lifting air cylinder and located in the stock bin, a plurality of compressed air ports are formed in the side wall of the stock bin, and an arch breaking stirring device used for stirring the graphite negative electrode material is installed on the stock bin. The blanking smoothness of the graphite negative electrode material is effectively improved, and blanking blockage of the material is prevented; the feeding amount of the graphite cathode material filled in the crucible can be accurately controlled, and the feeding matching precision is high; the charging process of the graphite negative electrode material is totally closed, so that the dust raising phenomenon caused by manual charging is greatly reduced, and the production safety is guaranteed; and the crucible charging efficiency is improved, and the labor intensity of workers is reduced.

Owner:ANYANG JIAHE MACHINERY

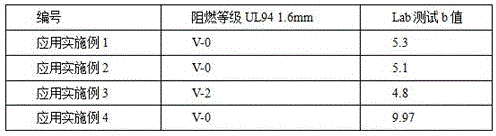

A kind of manufacture method of large particle size melamine cyanurate

The invention discloses a preparation method of large-particle size melamine cyanurate. The preparation method comprises the following steps: (1) uniformly mixing melamine and cyanuric acid, adding water, heating, keeping temperature, and removing moisture; (2) carrying out prepolymerization reaction on caprolactam and a catalyst, then adding a cocatalyst, and uniformly mixing; and (3) adding a prepolymer obtained from the step (2) to a system obtained from the step (1) for polymerization reaction, after the polymerization reaction is finished, cooling, and discharging. MCA prepared through the method disclosed by the invention has large particle size, is coated with nylon 6 on a surface and can be used for improving the problem of poor compatibility of the MCA and a matrix when applied to plastic modification and nylon modification especially. The preparation method disclosed by the invention is green and environment-friendly. The MCA can reduce the phenomenon of dust reduction by being taken as a raw material of downstream plastic processing.

Owner:PRESAFER QINGYUAN PHOSPHOR CHEM

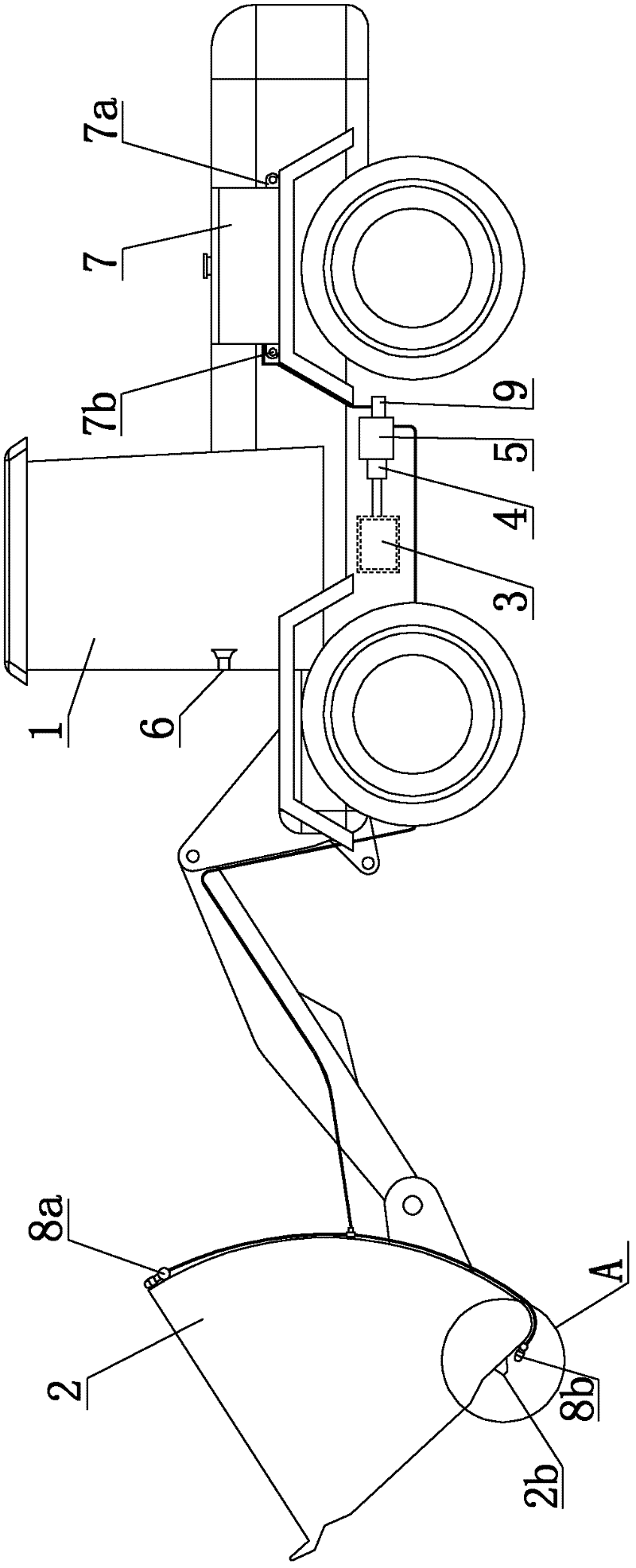

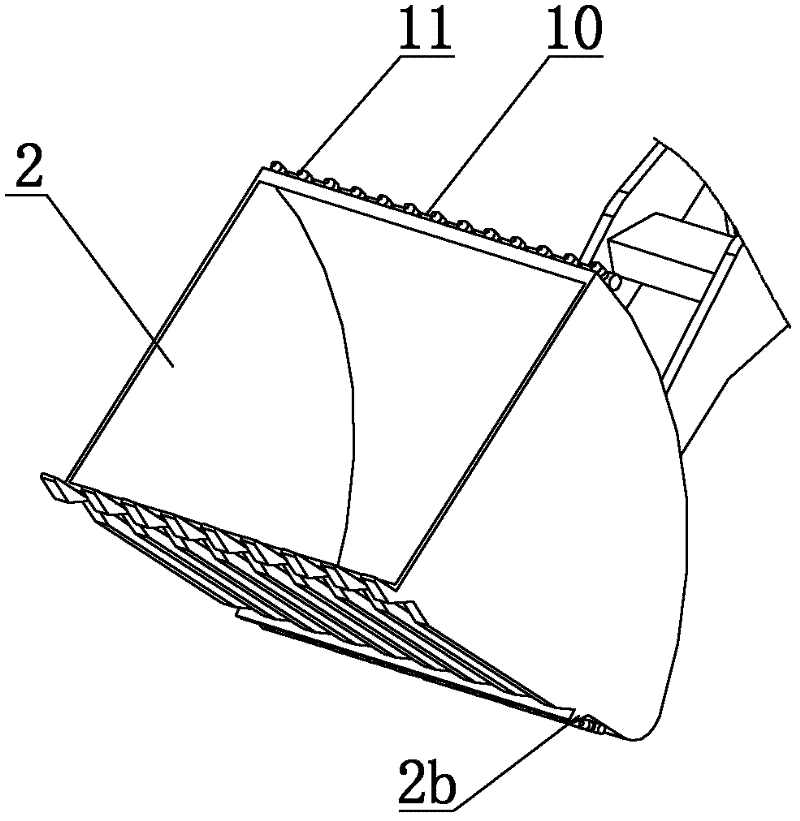

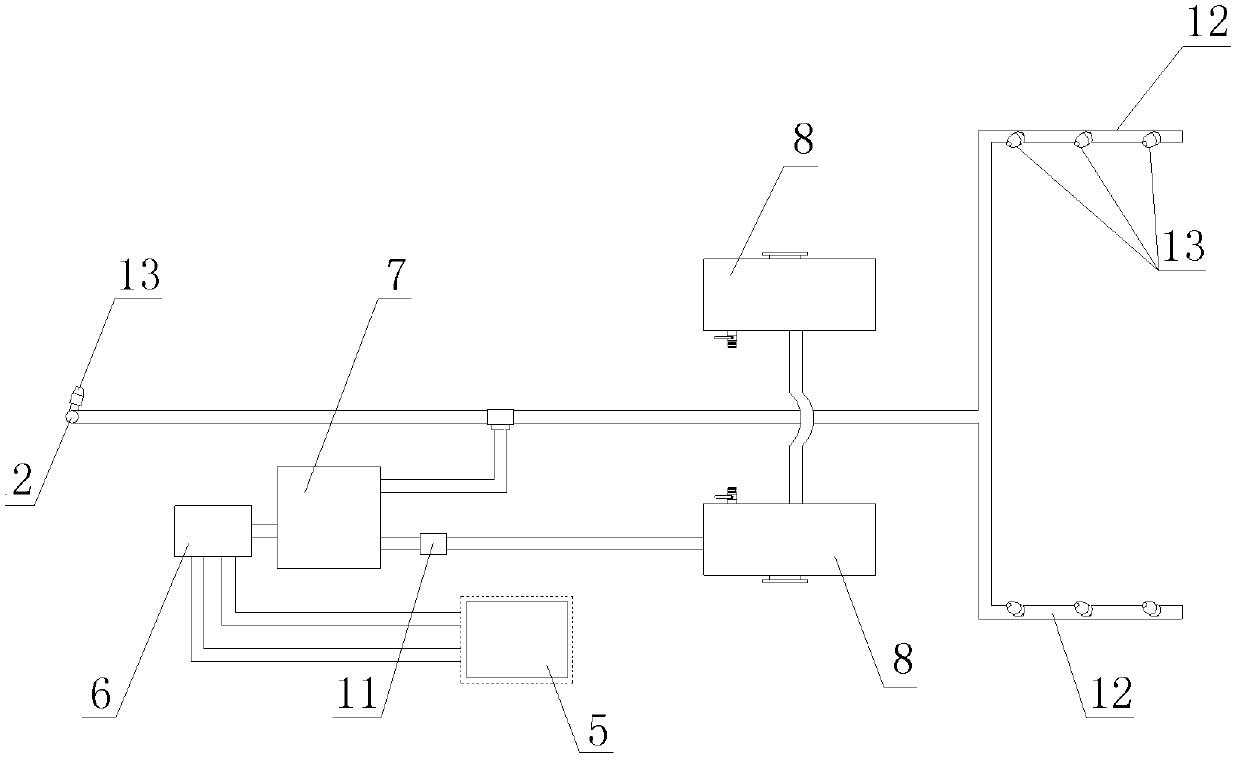

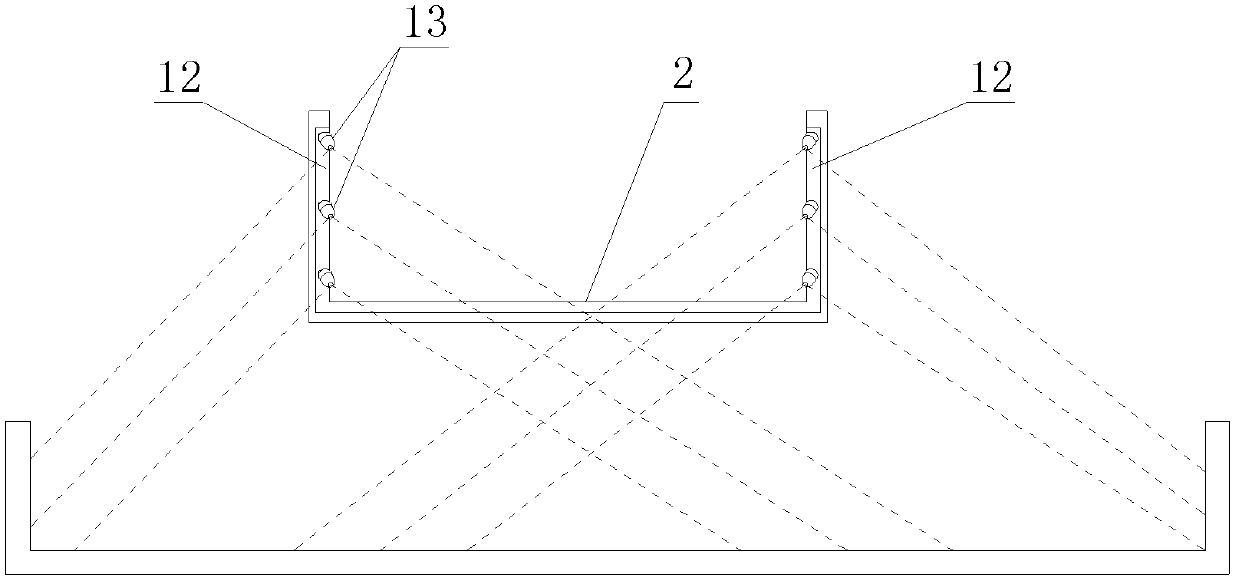

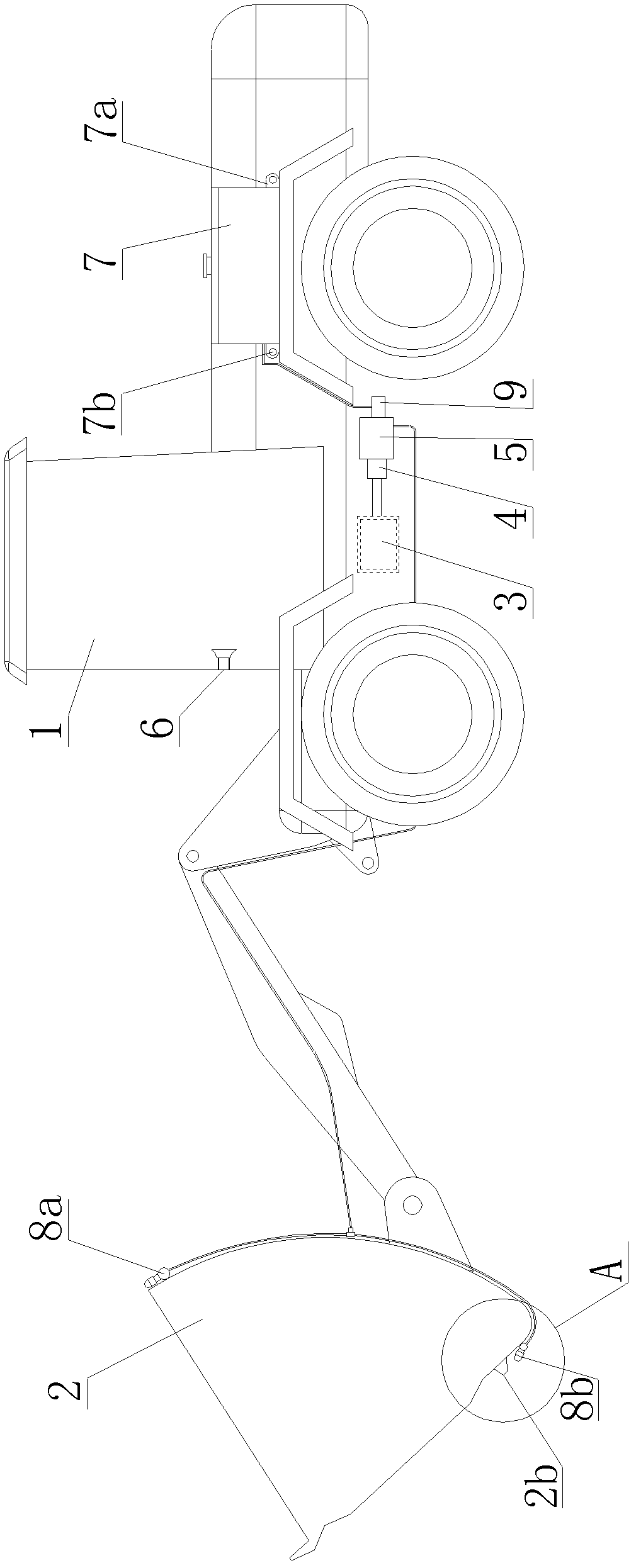

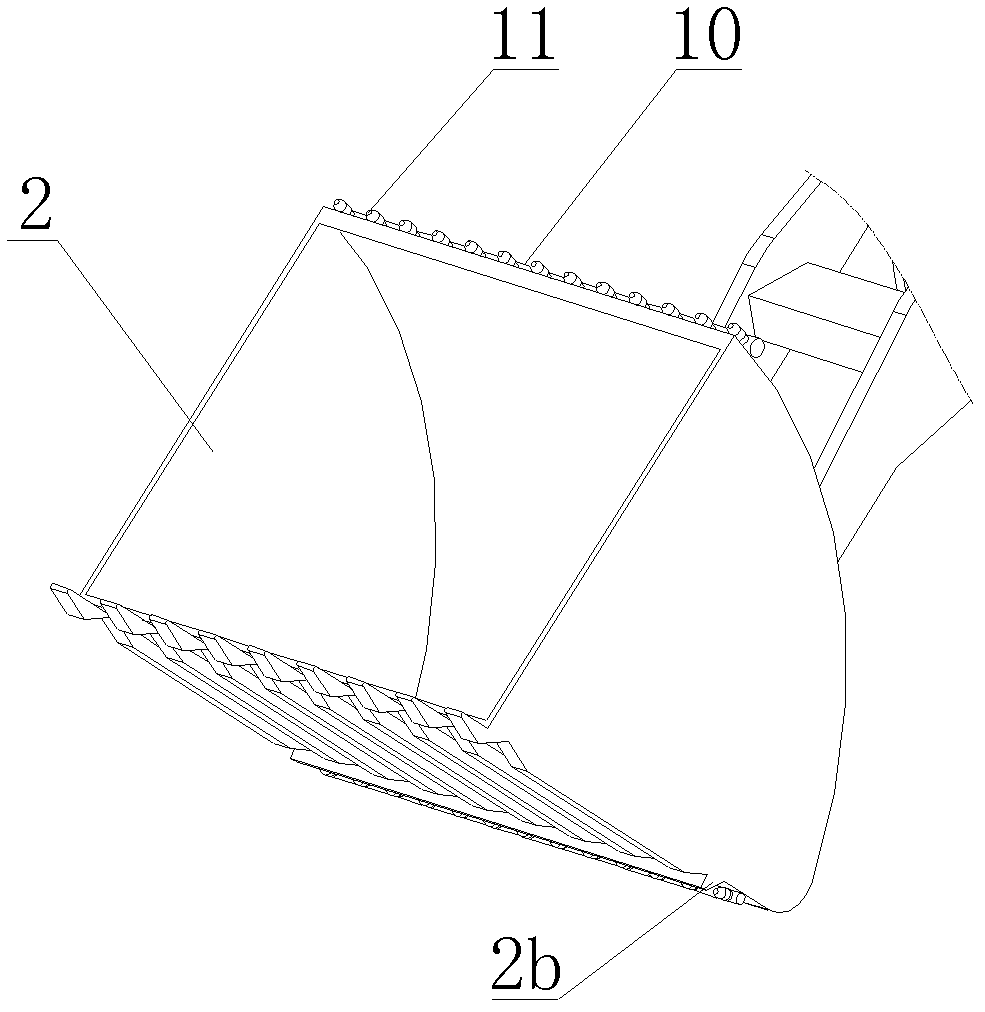

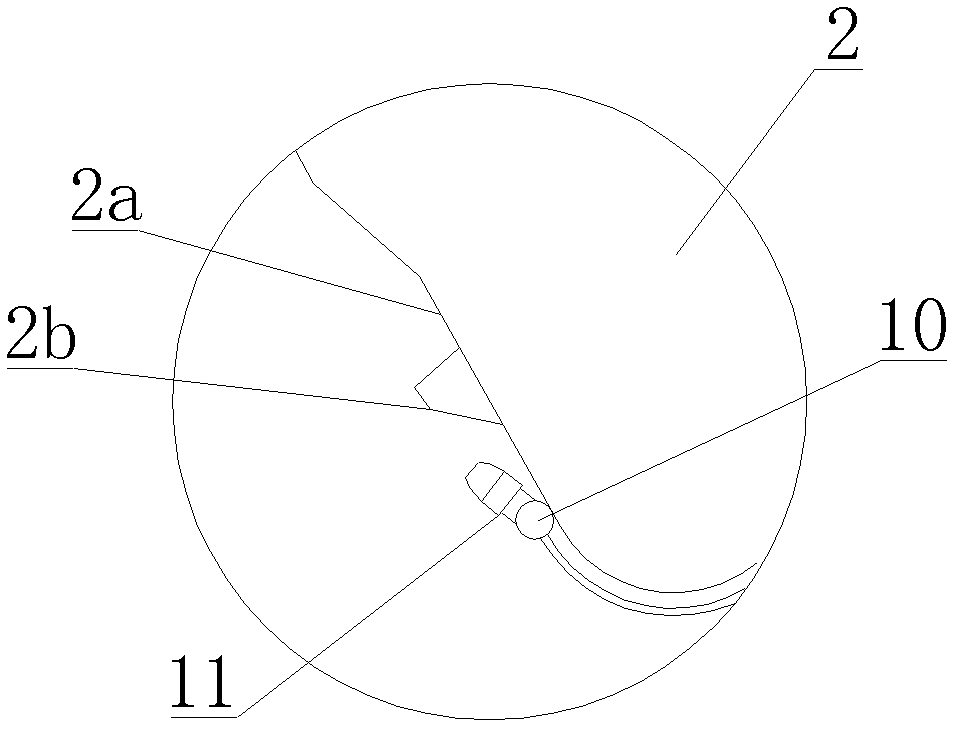

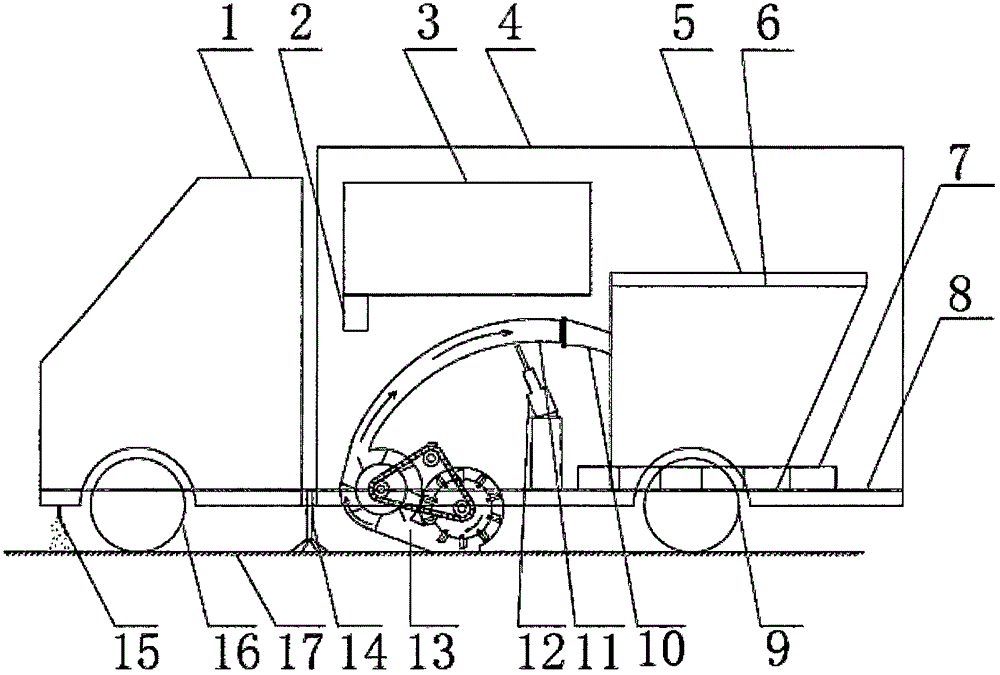

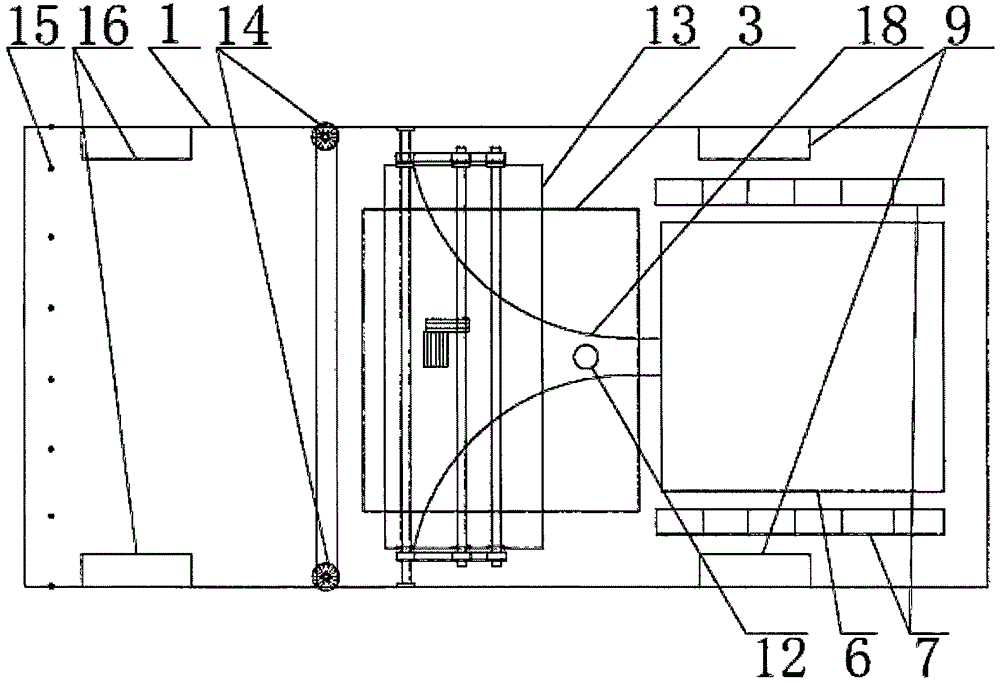

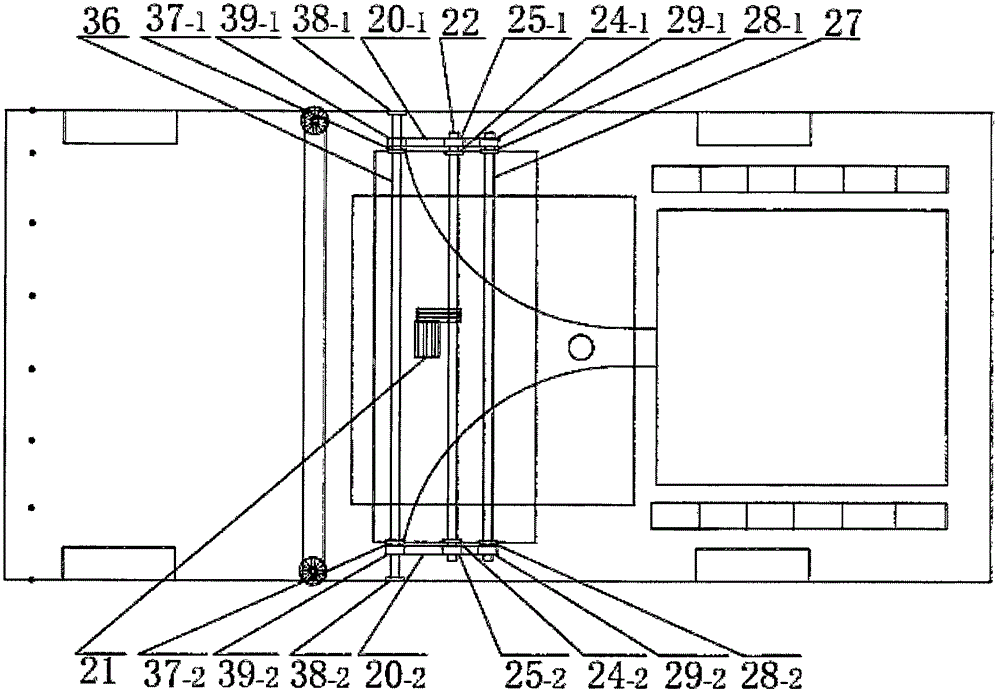

Loader with water mist dust suppressor

ActiveCN102505714AEffective coverageAccurate targetMechanical machines/dredgersUsing liquid separation agentHydraulic motorSuppressor

The invention discloses a loader with a water mist dust suppressor, belonging to the technical field of loaders. The loader is characterized by comprising a vehicle body; a hopper is arranged at the front part of the vehicle body; a power transmission box is arranged at the bottom of the vehicle body, wherein a hydraulic distributor is connected to a pipeline of the power transmission box; a hydraulic motor is connected to the pipeline of the hydraulic distributor; a high-pressure liquid pump is connected to a power output shaft of the hydraulic motor; a hydraulic motor control button is connected to a circuit of the hydraulic distributor; a water tank is connected to a water inlet pipeline of the high-pressure liquid pump; the water tank is arranged on the vehicle body; a plurality of atomizers are connected to a water outlet pipeline of the high-pressure liquid pump, and each atomizer is respectively arranged at the outer side of the hopper along a circumferential direction. The invention aims at providing the loader with the water mist dust suppressor; and the loader has the advantages of rational structure, convenience for use and capability of automatically suppressing dust and is used for loading materials.

Owner:广东风华环保设备股份有限公司

Aggregate smashing trolley for civil engineering

ActiveCN110270428AReduce volumeVolume changeCleaning using liquidsGrain treatmentsRadianCivil engineering

The invention is applicable to the technical field of civil engineering and provides an aggregate smashing trolley for civil engineering. A transporting trolley and a multi-smashing device are included; the multi-smashing device comprises a shell, a first smashing bin, a cleaning bin and a second smashing bin; the first smashing bin comprises an inclined plate and a plurality of smashing rollers, and the adjacent smashing rollers are opposite in rotating direction; the cleaning bin comprises a gas sucking device and a cleaning part located below the gas sucking device; the second smashing bin comprises a conveying device and a smashing hammer located above the conveying device; a plurality of baffles are uniformly distributed on the conveying device; the smashing hammer is provided with a plurality of smashing thorns; a material guiding device is arranged on one side of the second smashing bin, and comprises a power wheel and a material guiding plate in abutting connection with the power wheel; one end of the material guiding plate is movably connected with the shell, and the other end of the material guiding plate is connected with a supporting base through an arc-shaped plate; and the power wheel is provided with a plurality of ejecting blocks, and the ejecting blocks have a radian. Thus, the aggregate smashing trolley for the civil engineering can be used for effectively performing smashing and transporting on materials, and improves the smashing quality and the transporting efficiency.

Owner:WEIFANG UNIVERSITY

Mining waste treatment system

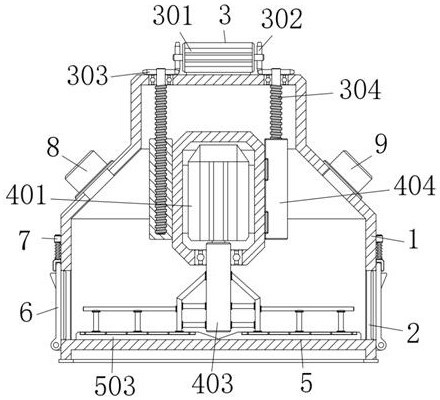

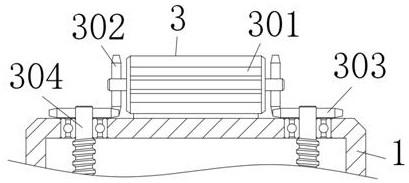

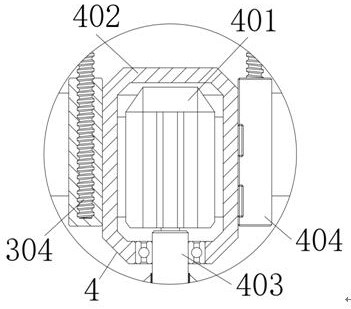

InactiveCN111872062AImprove mixing efficiencyEffective agglomerationSolid waste disposalTransportation and packagingGear wheelElectric machinery

The invention discloses a mining waste treatment system. The mining waste treatment system comprises a shell; discharging outlets are formed in the bottom ends of the left side and the right side of the shell correspondingly; a lifting mechanism is fixedly connected with the top end of the shell, the bottom end of a first motor is fixedly connected with the top end of the shell, and first gears are arranged on the left side and the right side of the first motor correspondingly; second gears are arranged below the two first gears correspondingly, and the two second gears are engaged with the two first gears correspondingly; threaded rods are arranged below the two second gears correspondingly, and the top ends of the two threaded rods are fixedly connected with the two second gears correspondingly; and the top ends of the outer walls of the threaded rods are movably connected with the shell through bearings. According to the mining waste treatment system, powdery mining waste can be effectively agglomerated, thus the phenomenon of dust flying is effectively reduced, the mixing efficiency of the powdery mining waste and an adhesive solution can be improved under the action of a disturbance mechanism, thus the overall working efficiency is improved, the practicability is high, and promotion is convenient.

Owner:陈爱华

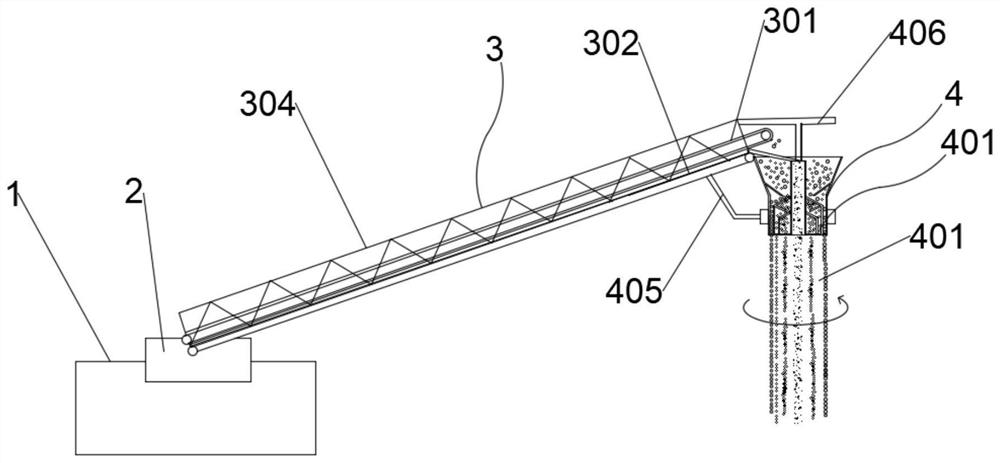

Rotary tower type limestone stacking device

The invention discloses a rotary tower type limestone stacking device. The device comprises a tower type machine body, a rotation mechanism, a cantilever conveying mechanism and a discharging mechanism, the rotation mechanism is arranged on the tower type machine body, the cantilever conveying mechanism is arranged on the rotation mechanism and comprises a coarse material conveying belt and a finematerial conveying belt distributed in a vertical manner, a plurality of uniformly distributed screen holes are formed in the surface of the coarse material conveying belt, stone is fed to the coarsematerial conveying belt, fine materials in the stone conveyed by the coarse material conveying belt fall onto the fine material conveying belt through the screen holes, the discharging mechanism is arranged at the feeding tail end of the arm cantilever conveying mechanism and comprises a guiding mechanism used for performing blanking on coarse materials conveyed on the coarse material conveying belt to form a peripherally-closed limiting blanking area, the conveying tail end of the fine material conveying belt is aligned with the interior of the limiting blanking area, and the limiting blanking area defined by coarse materials forms a wind-proof barrier for the internal fine materials. According to the device, the wind-proof barrier for the internal fine materials is formed in the blanking limiting area defined by the coarse materials, and the phenomenon of dust raising in the stacking process can be relieved.

Owner:安徽省恒金矿业有限公司

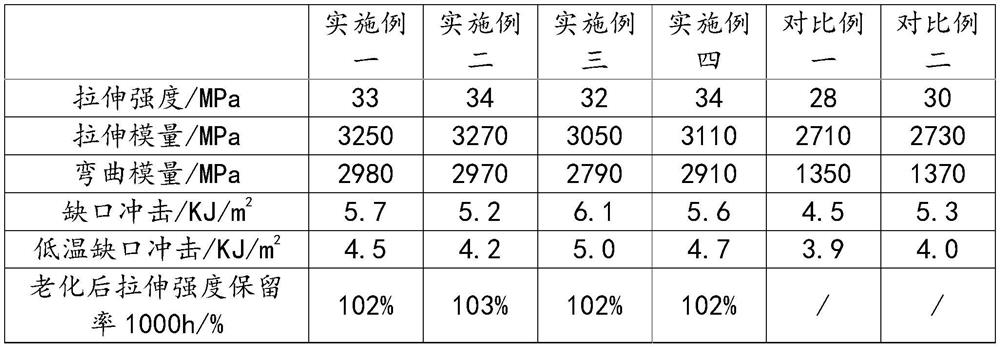

Mineral modified polypropylene composite material for vehicles and preparation method of mineral modified polypropylene composite material

The invention discloses a mineral modified polypropylene composite material for vehicles and a preparation method thereof, and provides the following technical scheme aiming at the problems of the existing PP modified material: the mineral modified polypropylene composite material is prepared from the following raw materials in parts by weight: 50-90 parts of polypropylene (PP), 10-40 parts of talc master batch, 3-10 parts of flexibilizer, 0.1-0.5 part of stabilizer, 0.1-0.5 part of lubricant and 0.2-1 part of other auxiliaries. The preparation method comprises the following steps: material preparation, material premixing and mixing. The mineral modified polypropylene composite material for vehicles provided by the invention has good mechanical properties and excellent aging resistance, and also has good processability and product appearance, and the preparation method of the material provided by the invention is simple and has high comprehensive benefits.

Owner:SUZHOU SUNWAY POLYMER

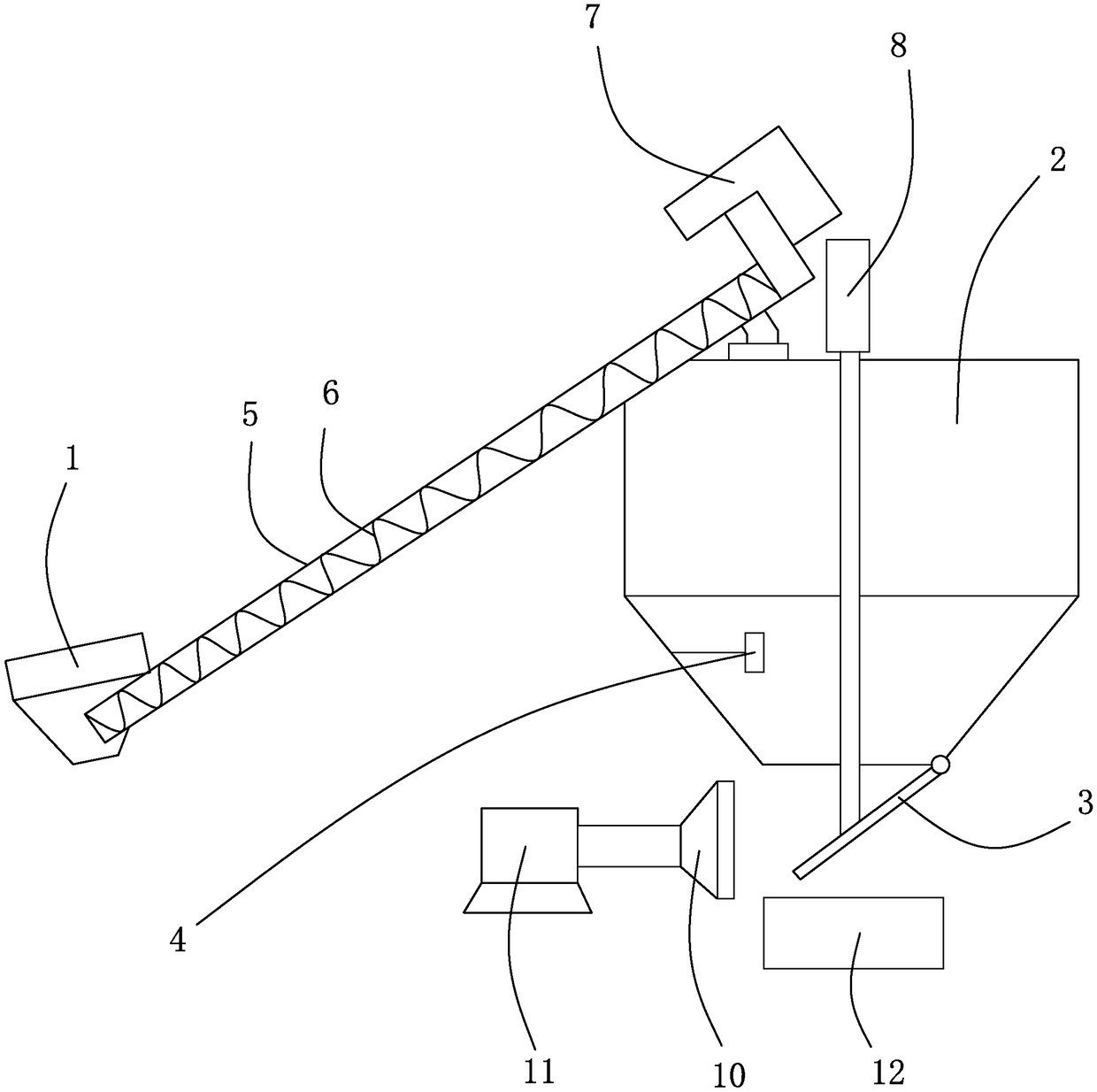

Powder type feeding device

PendingCN109178969AReduce labor intensityReduce dust phenomenonPackagingLoading/unloadingLevel sensorEngineering

The invention discloses a powder type feeding device. The powder type feeding device comprises a feeding hopper, a screw conveying mechanism, a stock bin and a control unit; the feeding hopper is arranged at the front end of the stock bin; materials are conveyed into the stock bin through the screw conveying mechanism; the bottom of the stock bin is provided with a discharging port; a bin door ishinged to one end of the discharging port; the stock bin is provided with a bin door opening mechanism which is used for controlling opening and closing of the bin door; a material level sensor is arranged in the stock bin and transmits signal to the control unit; the control unit controls the work of the bin door opening mechanism; and a dust removing mechanism is arranged on one side of the discharging port. The powder type feeding device can relieve the dust raise phenomenon occurring when the materials are carried, and the labor intensity of workers is lowered.

Owner:广东贝尤安新材料科技有限公司

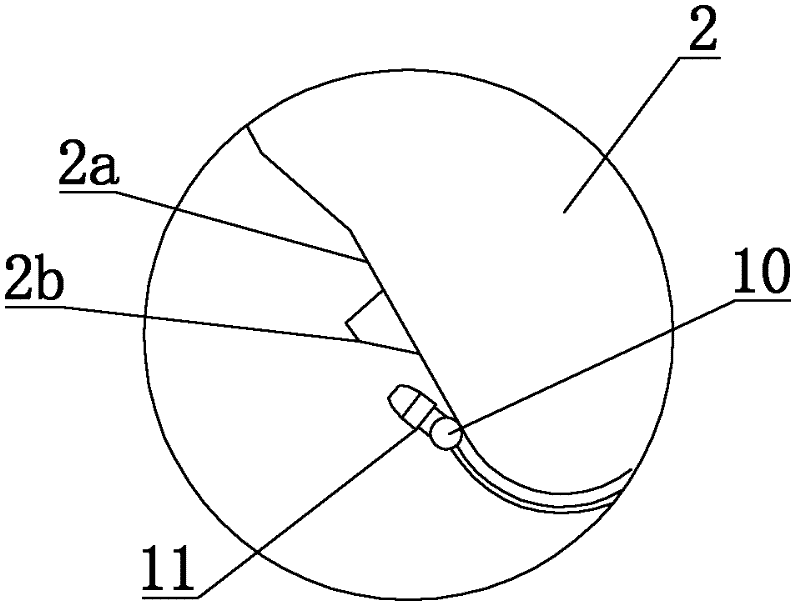

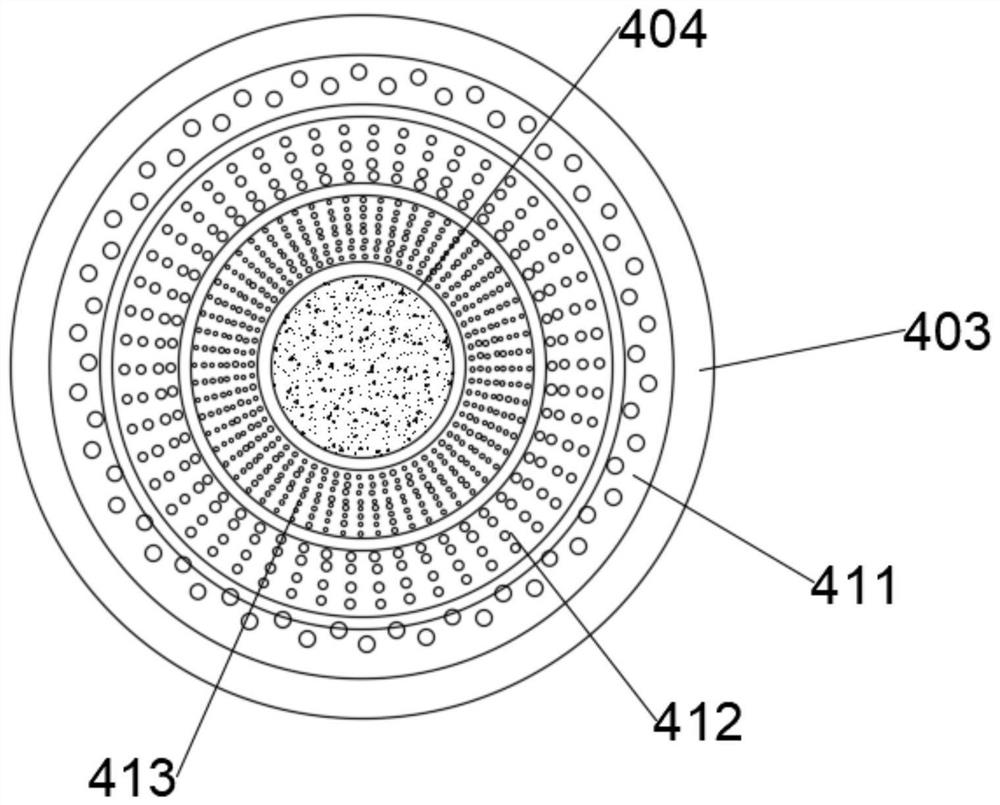

Downhole drilling anti-dust device

A downhole drilling anti-dust device belongs to the field of accessory equipment of coal mine excavation. The anti-dust device is semispherical and comprises a hitch device, a water inlet pipe, annular mist spray water pipes and connecting parts, wherein the hitch device is installed on the outer circle of the anti-dust device and can be firmly installed on an excavation face; the multiple annular mist spray water pipes are disposed and annularly and uniformly arranged on cross sections with different radiuses; a mist spray device is disposed on the annular mist spray water pipe; and the connecting parts are uniformly distributed along the radial direction of the semispherical shape and perpendicular to the mist spray water pipes. The downhole drilling anti-dust device is characterized in that the device can effectively reduce generation of raised dust during drilling of a coal mine excavation working face, will not influence other surrounding construction work and saves water resources.

Owner:DENGFENG JUNXIN COAL IND

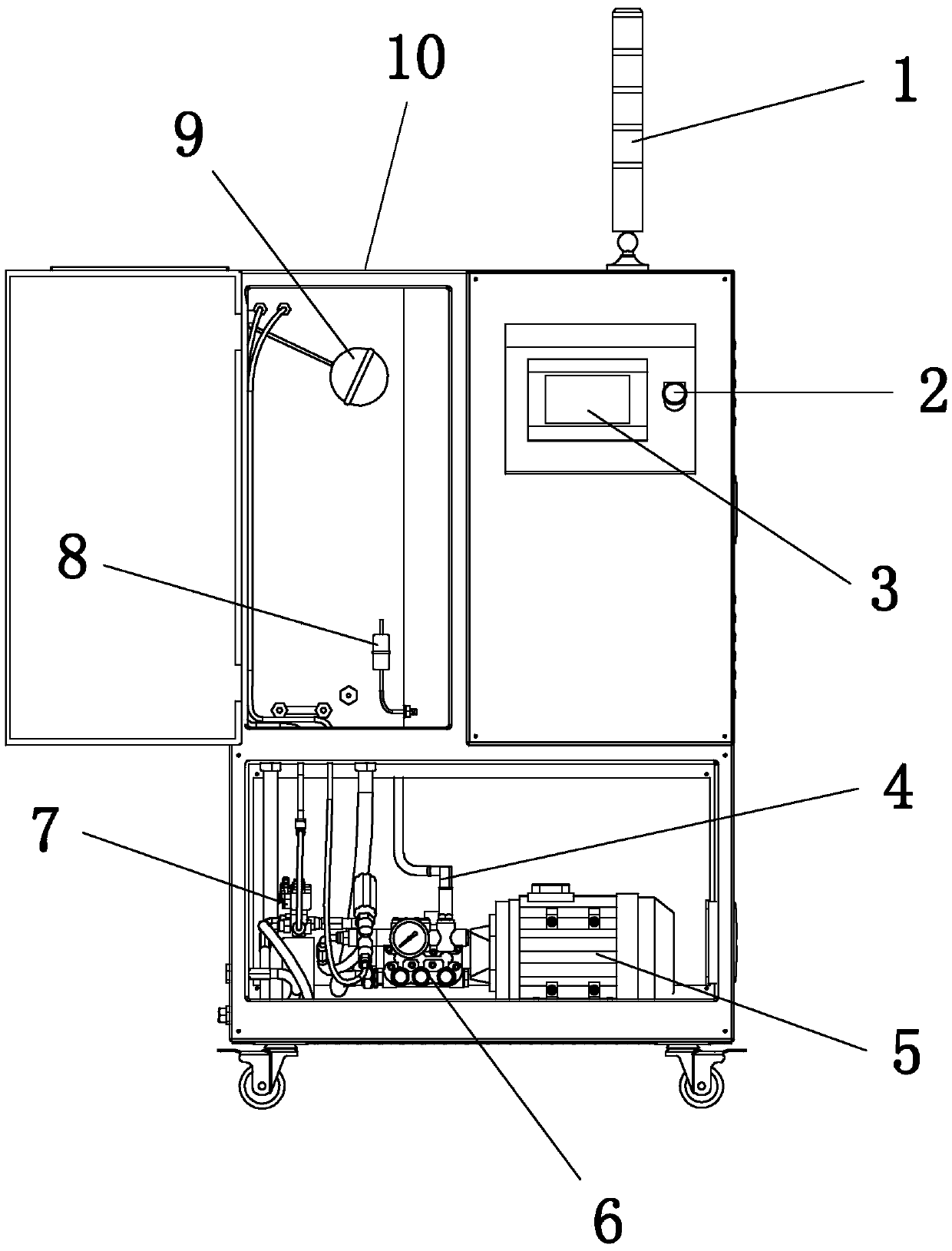

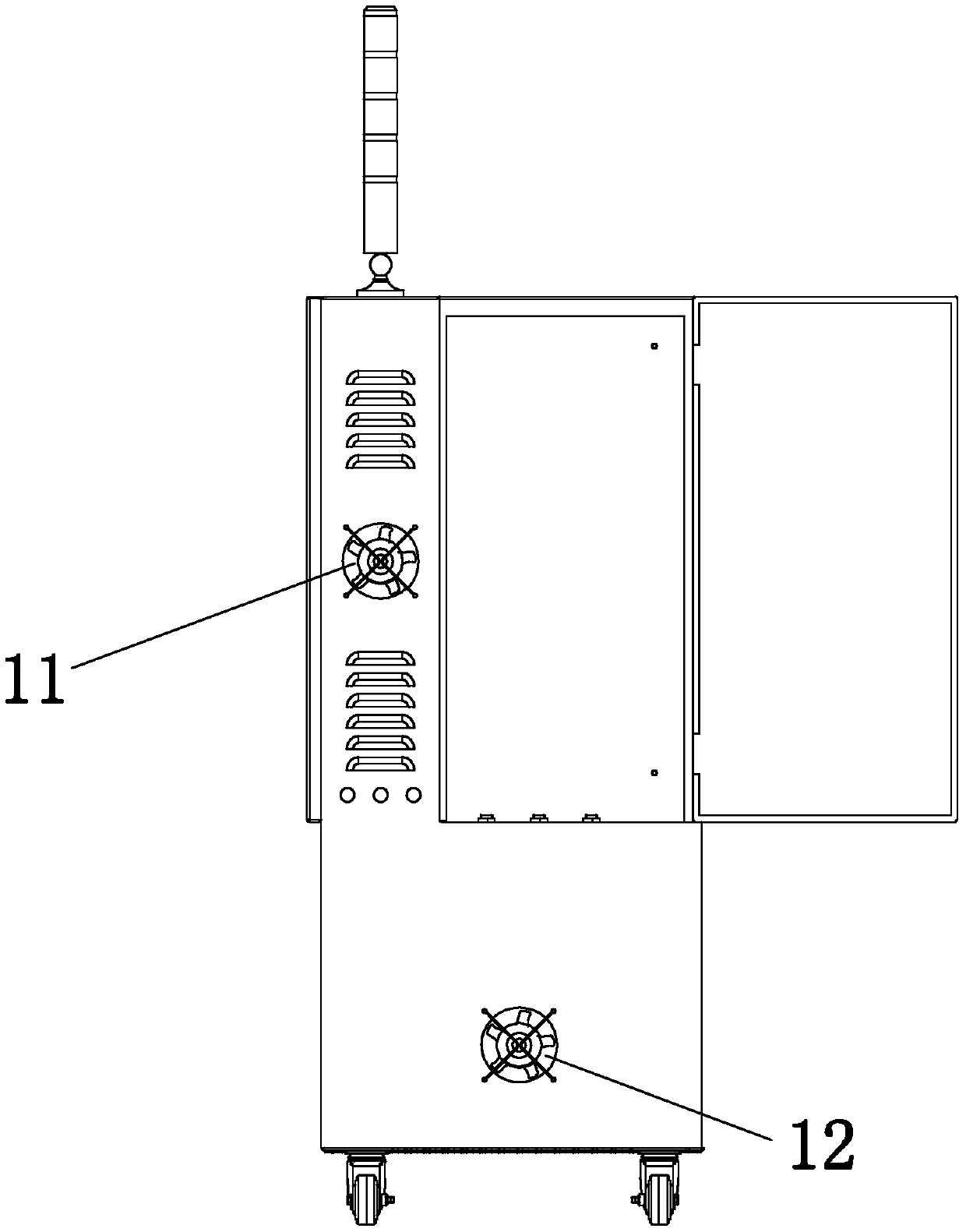

Tobacco high-pressure micro fog humidification system

InactiveCN105495669AUniform humidification effectReduced humidity conditionsTobacco preparationBall valveHuman–machine interface

The invention discloses a tobacco high-pressure micro fog humidification system. The system comprises a shell, a PLC control system, a pressure transmitter and a heating device. The shell comprises a left cavity, a right cavity and a lower cavity; a water inflow floating ball valve is arranged on the top left of the rear of the left cavity; a floating ball limiting switch is arranged on the lower left of the front of the left cavity; the heating device is arranged at the bottom of the left cavity; the PLC control system is arranged in the right cavity; a human-computer interface touch screen is arranged on the front side face, corresponding to the PLC control system, of the shell; a high-voltage motor is arranged in the lower cavity; a high-pressure pump, a pressure regulating valve and an electromagnetic valve are sequentially arranged at the left end of the high-voltage motor; the pressure transmitter is installed at the upper end of the high-pressure pump. Water fog particles sprayed out of the system are thin and are not prone to forming condensate water, the humidification effect is more uniform, the temperature and humidity condition needed for tobacco preparation and storage can be achieved, the floating dust phenomenon is substantially reduced, and the tobacco quality and the production effectiveness are improved.

Owner:NANTONG WUJING HIGH PRESSURE PUMP

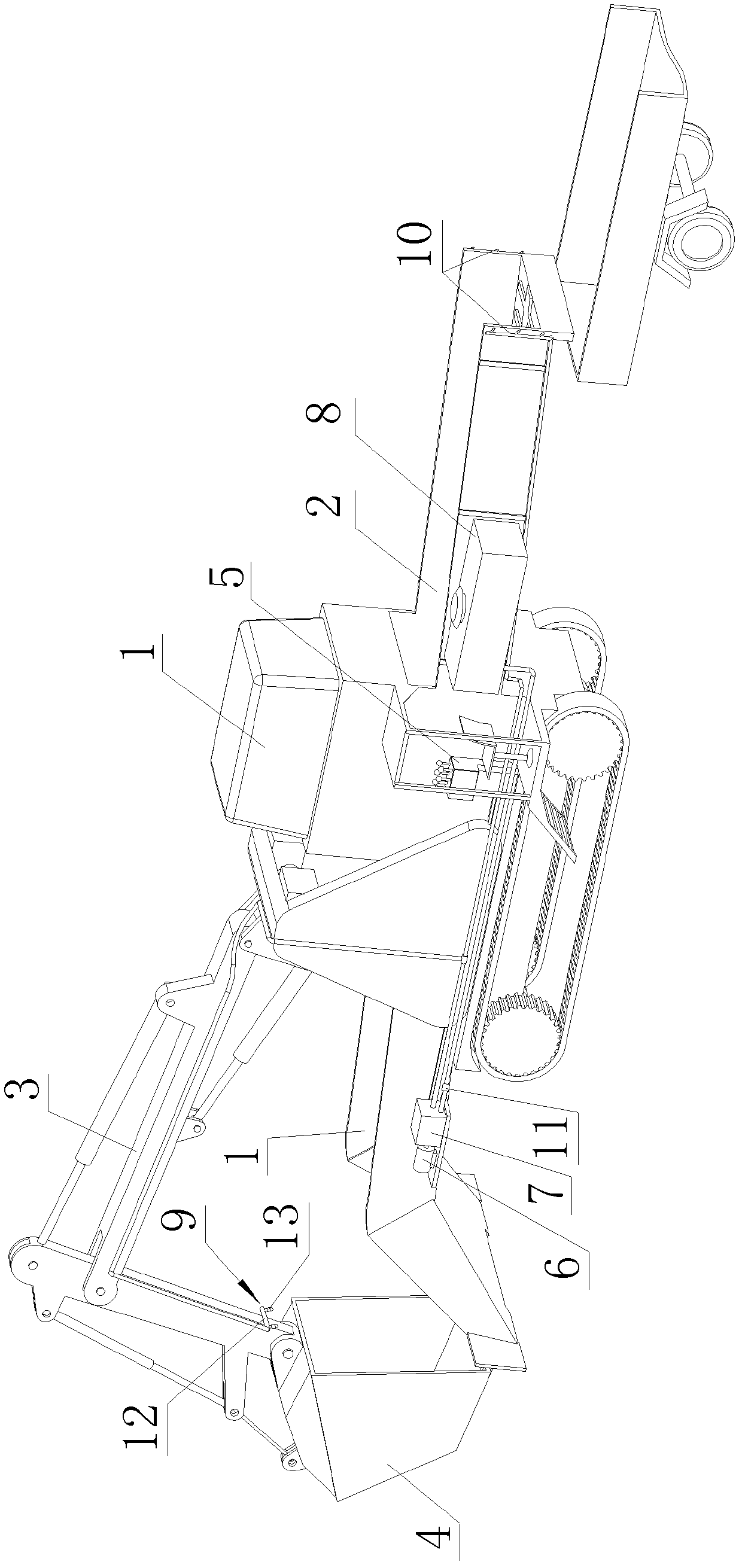

Slag skimming machine with automatic water mist dust suppression device

ActiveCN102505715BSimple structureFirmly connectedUsing liquid separation agentDust removalHydraulic motorHydraulic cylinder

The invention discloses a slag removal machine with an automatic water mist dust suppression device, which belongs to the technical field of slag removal machines, and its technical points include a machine body, on which a chain conveying groove is arranged, and a slag removal arm is arranged on the front part of the machine body , the free end of the slag removal arm is provided with a hopper corresponding to the feed port of the chain conveying trough, and a hydraulic distributor is provided on the machine body, which is connected with the hydraulic cylinder pipeline on the slag removal arm, wherein the hydraulic distributor There is also a hydraulic motor connected to the pipeline, the power output shaft of the hydraulic motor is connected to a high-pressure liquid pump, the water inlet pipeline of the high-pressure liquid pump is connected to a water tank, the water tank is arranged on the body, and the water outlets of the high-pressure liquid pump are respectively connected to a water tank. A slag atomizer and a falling material atomizer; the slag removing atomizer is arranged at the front of the slag removing arm, and the liquid outlet of the slag removing atomizer is opposite to the opening of the hopper; the material removing atomizer It is arranged on the discharge end of the chain conveying trough; the present invention aims to provide a slag removal machine with reasonable structure and convenient use; it is used for slag removal and charging.

Owner:广东风华环保设备股份有限公司

Cold in-place recycling construction method

The invention discloses a cold in-place recycling construction method. The method is characterized by comprising the following steps that S1, construction preparation is conducted, specifically, a to-be-treated old pavement is pretreated, a plurality of atomizing devices are arranged on the two sides of the to-be-treated pavement at equal intervals at the same time, the atomizing devices on the two sides of a road are opposite directly, every two directly opposite atomizing devices conduct injection towards the oblique upward sides, and intersections of injection tracks exist over the to-be-treated pavement; S2, cement is evenly paved and spread on the pretreated pavement, and after the cement is paved for a certain distance, the atomizing devices within the range conduct atomizing operation; S3, water is added into the old pavement where the cement is paved and spread, milling and stirring are conducted to obtain a mixture, and the mixture is evenly flattened on the pavement; and S4, rolling and shaping are conducted. Through collision of two streams of water mist, the water mist can be evenly sprinkled on the cement, the flying dust phenomenon of the cement can be suppressed to a certain degree, the environment pollution is reduced, and the situation that the water is insufficient for actual use is prevented.

Owner:JIANGSU SITONG ROAD & BRIDGE ENG

Vacuum drawing type dust removal hopper

InactiveCN110015572AReduce dust phenomenonImprove dust removal efficiencyConveyorsLoading/unloadingEngineeringExhaust pipe

The invention discloses a vacuum drawing type dust removal hopper. The vacuum drawing type dust removal hopper comprises a support, a hopper body and a dust removal device. The hopper body is arrangedon a rack, the hopper body is connected with the dust removal device, a connecting box is arranged on the hopper body, and communicates with the hopper body, discharging ends on the two sides of theconnecting box communicate with the feeding end of a connecting pipe, the discharging end of the connecting pipe is connected with the feeding end of an exhaust pipe through a connecting flange, a filter bag is arranged at the connecting position of the discharging end of the connecting pipe and the feeding end of the exhaust pipe, a dual-shaft motor is arranged on the bottom of the connecting box, the output end of the dual-shaft motor is connected with a rotating shaft, the rotating shaft is connected with two sets of rotating rods through two sets of transmission parts, and one ends of therotating rods penetrate through the connecting pipe and are rotatably connected with the connecting pipe, and are further connected with fan blades. According to the vacuum drawing type dust removal hopper, through filter separation, environment-friendly clean air is obtained, and is exhausted into the atmosphere, the raised dust during hopper work can be greatly reduced, and the dust removal efficiency is effectively improved.

Owner:JIANGSU ZISHI MACHINERY MFG

Loader with water mist dust suppressor

ActiveCN102505714BEffective coverageAccurate targetMechanical machines/dredgersUsing liquid separation agentHydraulic motorEngineering

The invention discloses a loader with a water mist dust suppressor, belonging to the technical field of loaders. The loader is characterized by comprising a vehicle body; a hopper is arranged at the front part of the vehicle body; a power transmission box is arranged at the bottom of the vehicle body, wherein a hydraulic distributor is connected to a pipeline of the power transmission box; a hydraulic motor is connected to the pipeline of the hydraulic distributor; a high-pressure liquid pump is connected to a power output shaft of the hydraulic motor; a hydraulic motor control button is connected to a circuit of the hydraulic distributor; a water tank is connected to a water inlet pipeline of the high-pressure liquid pump; the water tank is arranged on the vehicle body; a plurality of atomizers are connected to a water outlet pipeline of the high-pressure liquid pump, and each atomizer is respectively arranged at the outer side of the hopper along a circumferential direction. The invention aims at providing the loader with the water mist dust suppressor; and the loader has the advantages of rational structure, convenience for use and capability of automatically suppressing dust and is used for loading materials.

Owner:广东风华环保设备股份有限公司

Dust-raising-preventing and liquid-splashing-preventing stirrer

InactiveCN111603971AReduce spillageReduce dust phenomenonRotary stirring mixersTransportation and packagingElectric machineryEngineering

The invention relates to a stirrer. The utility model discloses a stirrer capable of preventing flying dust and splashing liquid. The device comprises a circular container, a liquid conveying pump, afeeding pipe located above the container and a stirring mechanism. The stirring mechanism comprises a vertical rotating shaft, a motor for driving the vertical rotating shaft to rotate, and a stirringpaddle connected to the vertical rotating shaft and positioned in the container; the feeding pipe is provided with a water distribution cavity; a liquid spraying hole is formed in the water distribution cavity; the liquid conveying pump is used for driving liquid to enter the liquid preparation cavity and then be sprayed out through the water spraying holes to humidify materials conveyed out of the feeding pipe, and the vertical rotating shaft is sleeved with a material receiving cover in a liftable mode, wherein the material receiving cover rotates along with the vertical rotating shaft, islocated above the stirring paddle and can float on the liquid in the container. The stirrer capable of preventing flying dust and splashing liquid can effectively prevent water from splashing out whensolid materials enter a container and reduce the flying dust phenomenon, and the problems that when solid materials are fed into the container, water splashing out and flying dust are likely to happen in an existing stirrer are solved.

Owner:HANGZHOU GENCE TECH CO LTD

A rotary tower limestone stacking device

Owner:安徽省恒金矿业有限公司

Electric Double Roller Garbage Sweeper

The invention relates to an electric double-roller garbage sweeper, which belongs to the technical field of environmental sanitation machinery manufacturing. The middle and lower parts of the vehicle frame are equipped with cleaning mechanisms, the middle and upper parts are equipped with water tanks, the rear is equipped with battery packs and garbage dust collection boxes, motors and wheel axles. connected. The driving wheel and driven wheel of the cleaning mechanism are installed on the support frame through the transmission shaft, and the transmission shaft I is installed in the bearing seats on both sides of the chassis of the vehicle frame. The air-delivered garbage channel at the upper end of the outer cover is connected with the electro-hydraulic oil rod fixed on the chassis of the vehicle frame. The broom brush is installed on the cleaning roller, the air-delivered blade is installed on the air-delivered roller, and the water pump and water nozzle are installed under the water tank. An oblique vertical broom round brush is installed on both sides of the vehicle frame chassis in front of the cleaning mechanism. The invention provides a new-energy high-efficiency cleaning device which integrates garbage cleaning, recycling and transportation, has a simple and compact structure, and has a wide cleaning range.

Owner:YANGXIAN GUANGDA NEW ENERGY MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com