Dry powder filling gradual detection device and method

A dry powder and powder weighing technology, applied in the field of medical devices, can solve the problems of only sampling inspection, waste, and high cost, and achieve the effects of ensuring product quality, shortening relative height, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

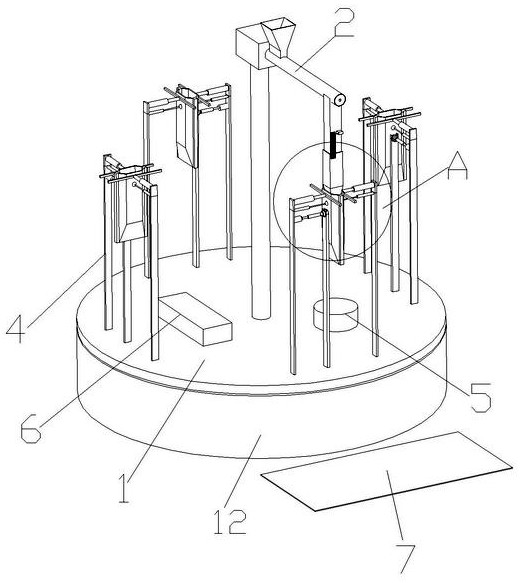

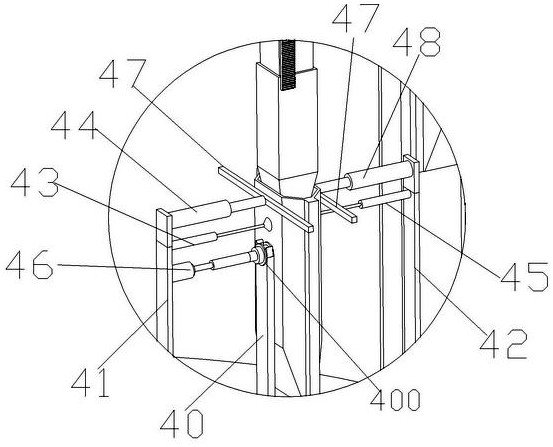

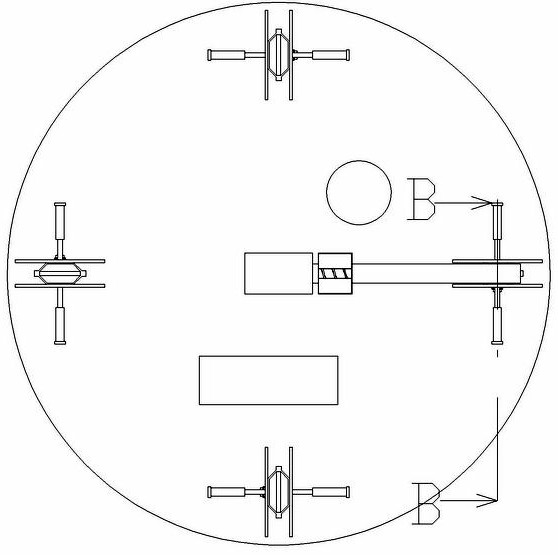

[0037] see Figure 1 to Figure 12 As shown, a dry powder filling inspection device includes a rotating base 1, a filling mechanism 2, a powder weighing mechanism 3, multiple sets of support and detection components 4 and a control device 5;

[0038] The rotating base 1 includes a first motor 10, a rotating disc 11 and a support 12, the stator shell of the first motor 10 is fixedly connected with the support 12, and the rotor of the first motor 10 is fixedly connected with the lower end of the rotating disc 11 through a pinion. The large gear 110 is meshed and connected, and the supporting part at the lower end of the rotating disc 11 is rotatably connected with the support 12 through the bearing 13;

[0039]The filling mechanism 2 includes a support rod 20, a first servo motor 21, a worm screw 22, a material barrel 23, a feed bin 24, a discharge bin 25 and a storage bin 26, and the support rod 20 runs through the rotating disk 11 and is fixed to the support 12. connection, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com