Concrete production device with automatic material control function

A production device and concrete technology, applied in the control device, clay preparation device, mixed operation control device, etc., can solve the problems of dust, waste of raw materials, weight deviation, etc., and achieve the effect of preventing dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

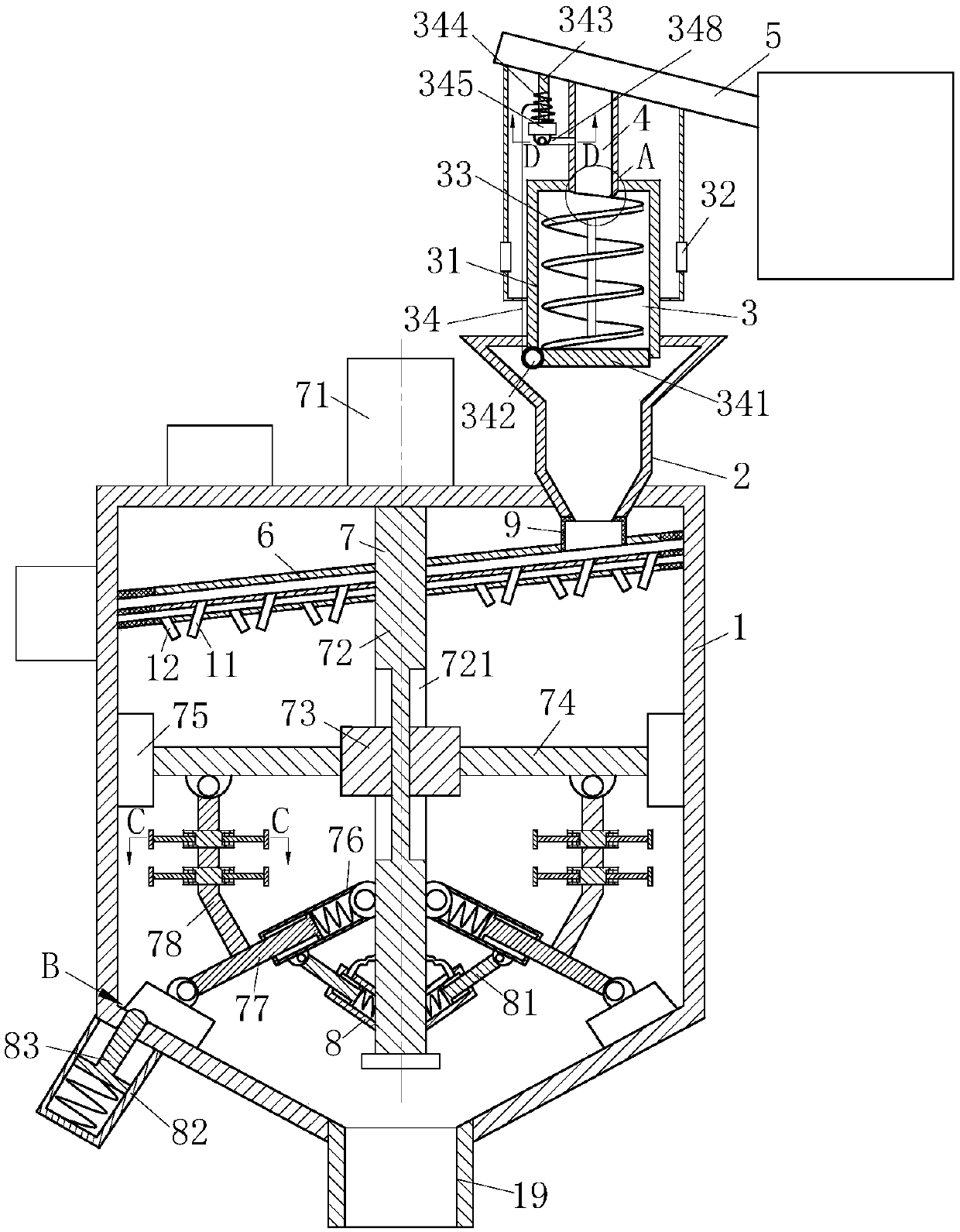

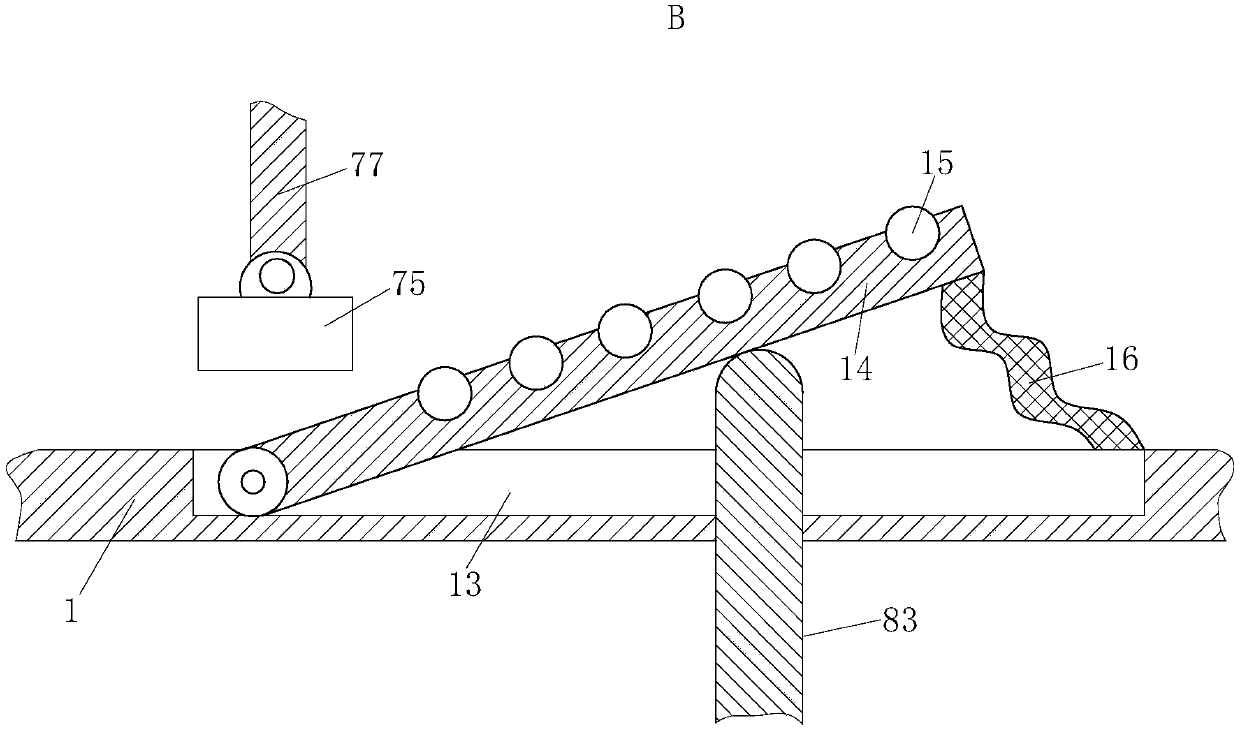

[0031] As an embodiment of the present invention, the stirring unit 7 includes a driving motor 71, a stirring shaft 72, a sliding block 73, a stirring rod 74, a scraper 75, a first cylinder 76, a first telescopic rod 77, a soft connecting rod 78. The second cylinder 8, the second telescopic rod 81, the third cylinder 82, and the third telescopic rod 83; the driving motor 71 is arranged on the top of the casing, and the output end of the driving motor 71 passes through the casing 1 and is connected to a stirring Shaft 72; said stirring shaft 72 is symmetrically provided with sliding groove 721, and sliding block 73 is arranged in sliding groove 721; described sliding block 73 is provided with stirring rod 74, and the end of stirring rod 74 is provided with scraper 75; the first cylinder 76 is symmetrically hinged on the stirring shaft 72, and the first cylinder 76 is provided with a first telescopic rod 77, and the end of the first telescopic rod 77 is provided with a scraper 75...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com