Patents

Literature

31results about How to "Fall into easy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

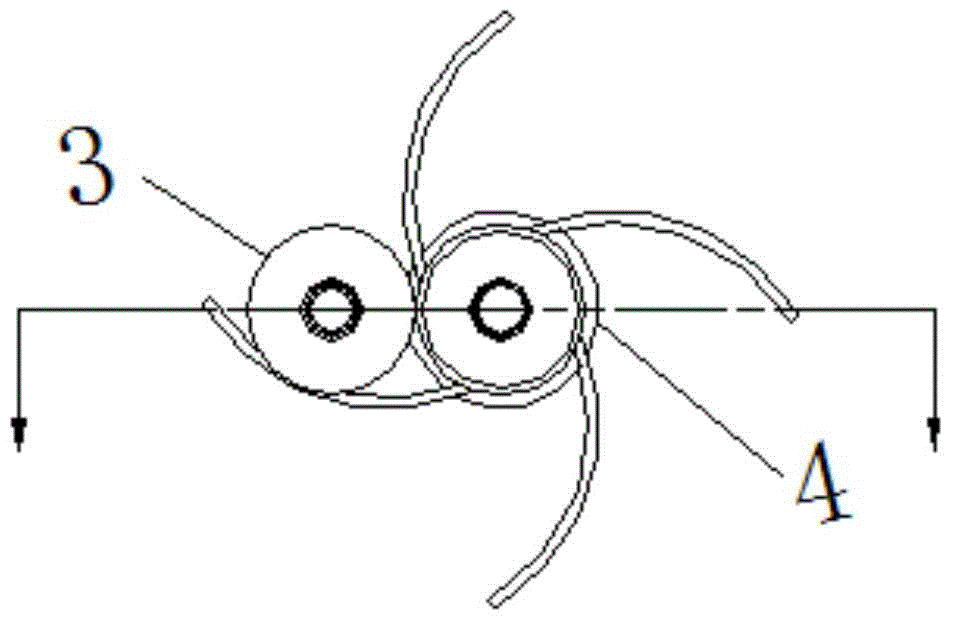

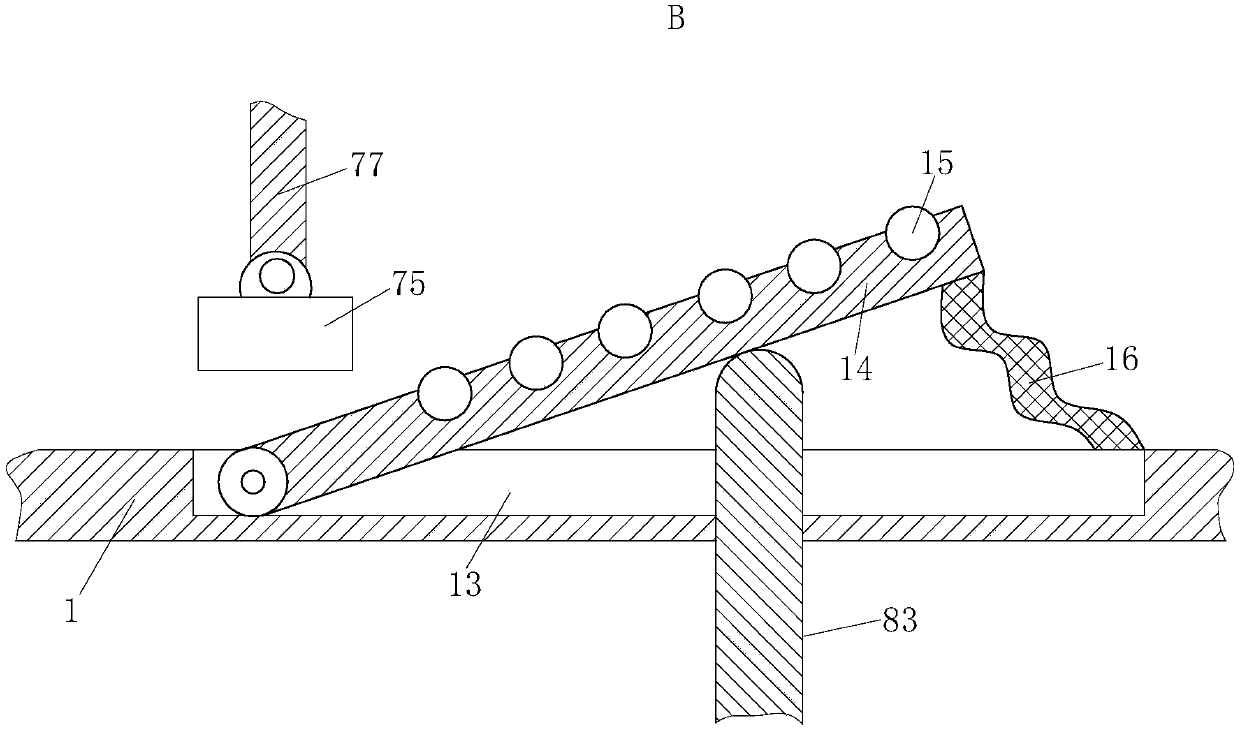

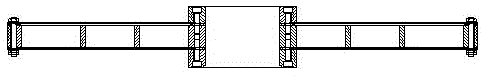

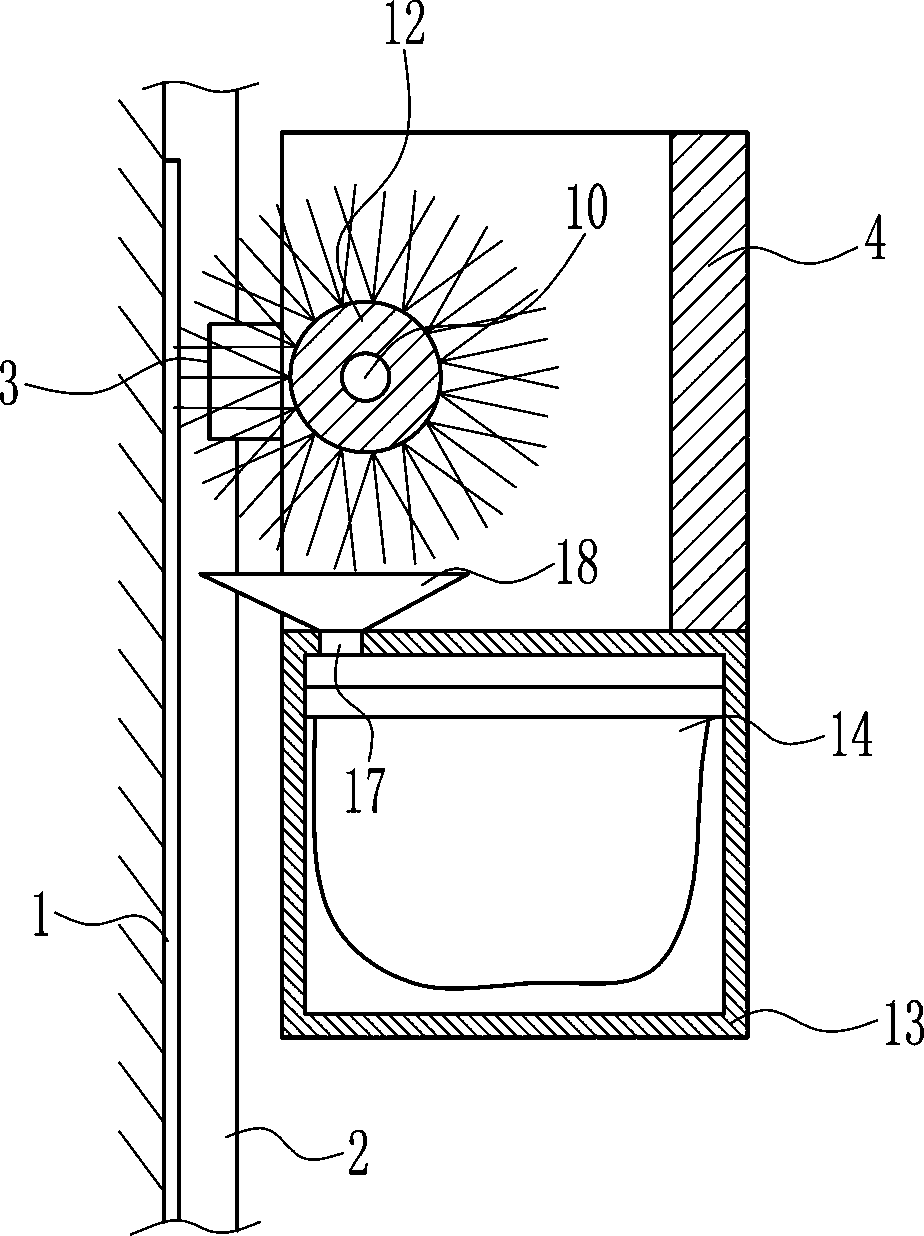

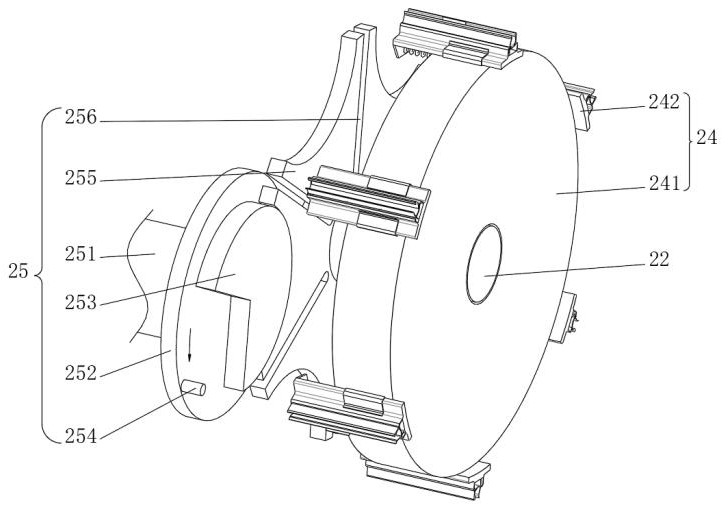

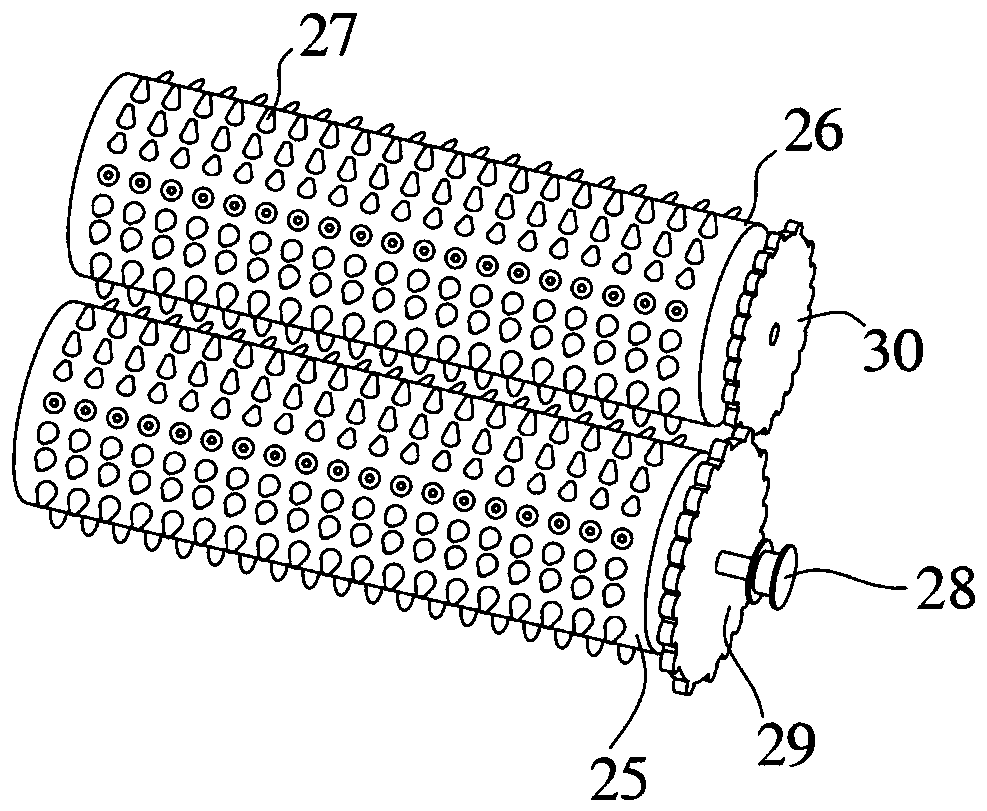

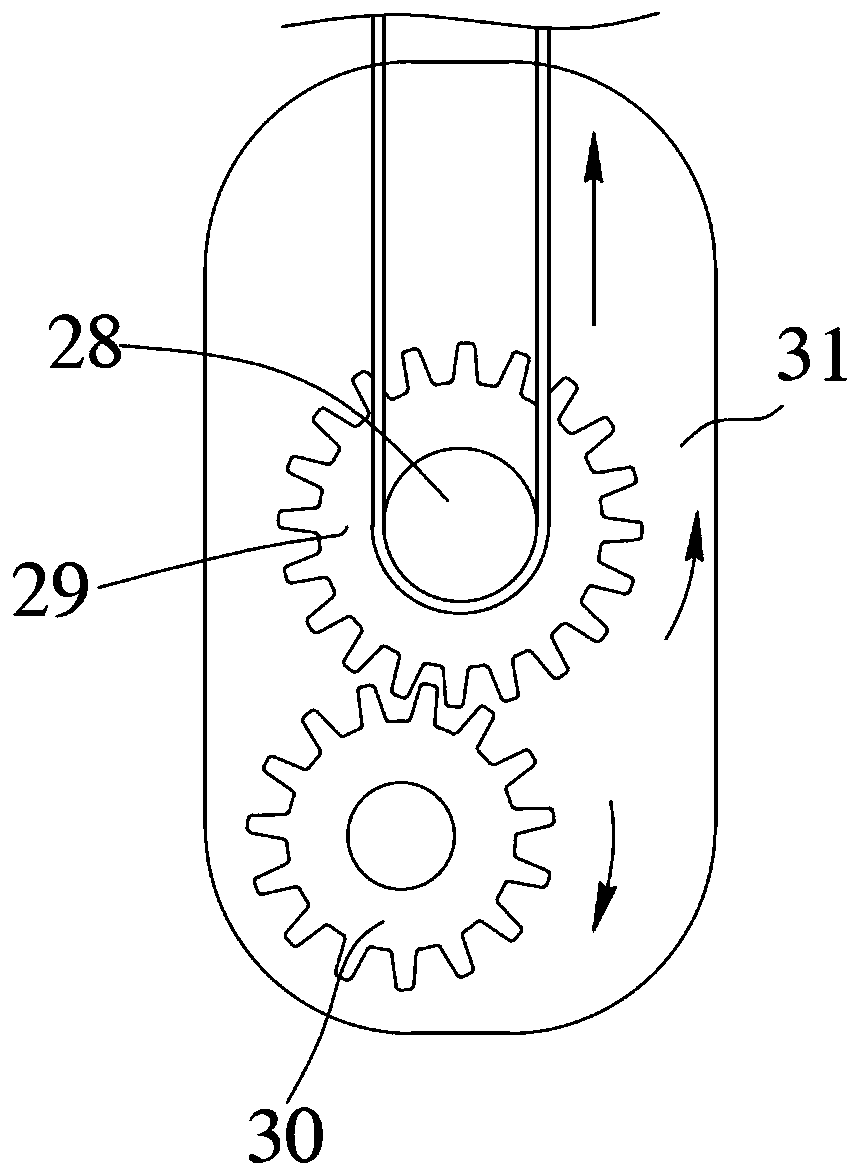

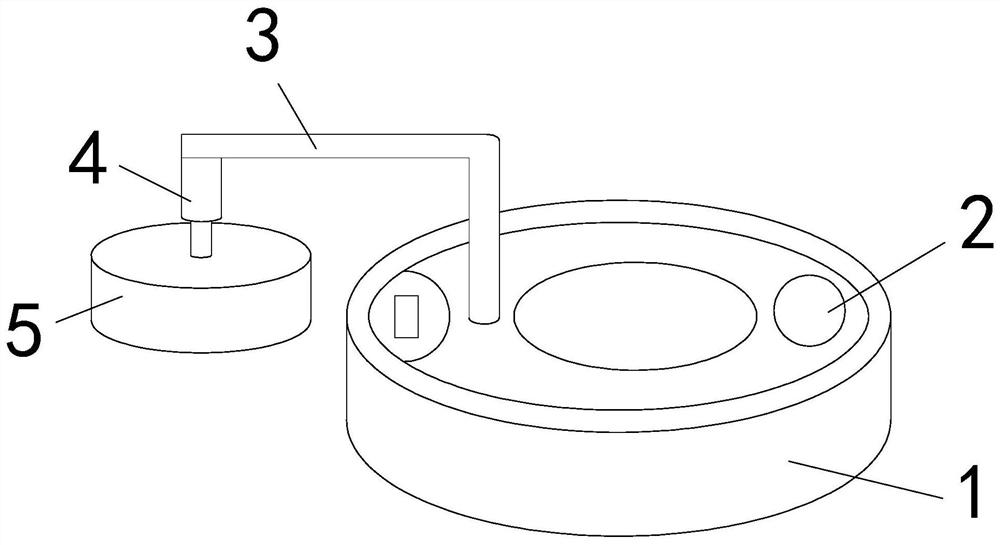

Rolling wheel assembly and paper money storage device

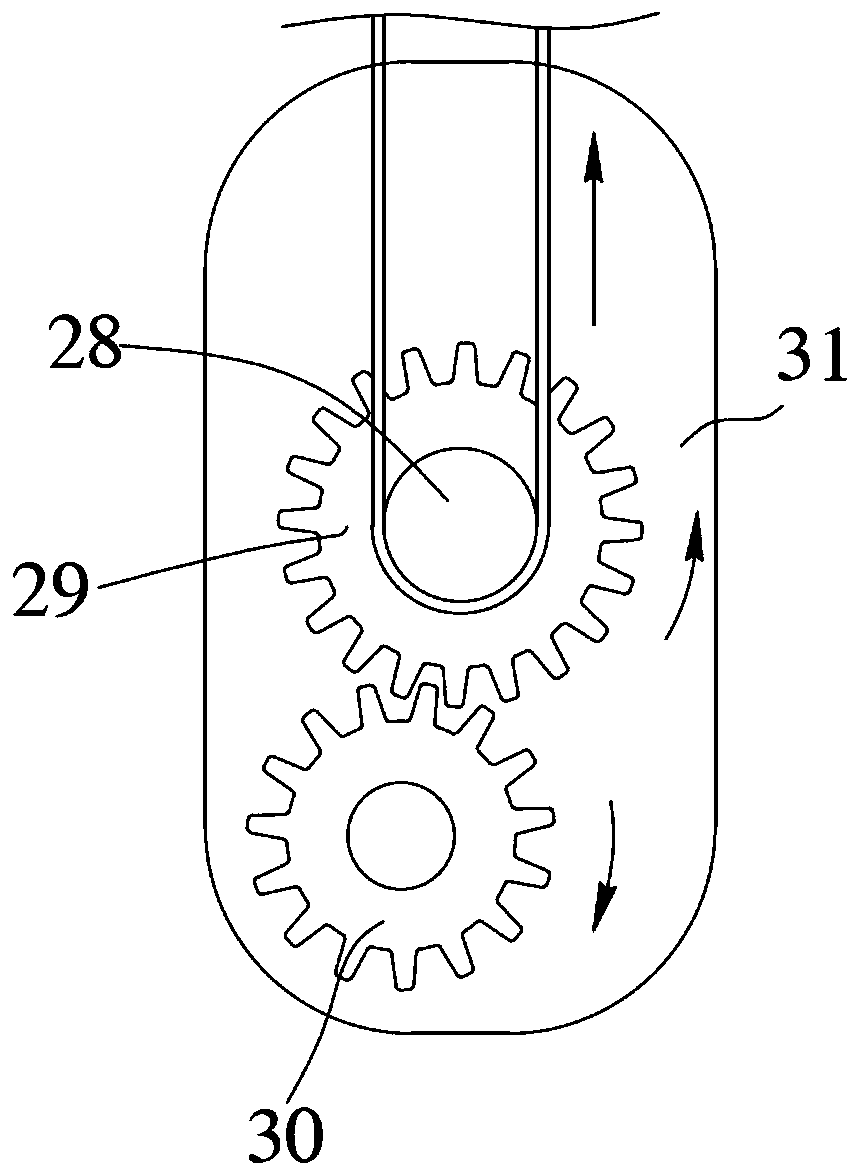

InactiveCN104809806AIncrease stiffnessAvoid overlappingCoin/currency accepting devicesPile receiversImpellerDrive wheel

The embodiment of the invention provides a rolling wheel assembly. Paper money in a highly-curled state can be smoothly recovered and folded. According to the technical scheme, the rolling wheel assembly provided by the embodiment of the invention comprises a driven roller assembly and a driving roller assembly, wherein the driven roller assembly comprises a driven shaft and a plurality of driven wheels positioned on the driven shaft; the driving roller assembly comprises a driving shaft and a plurality of driving wheels positioned on the driving shaft; the driven shaft is parallel to the driving shaft; the driven wheels are in one-to-one correspondence to the driving wheels; an impeller is arranged between every two driving wheels; the impellers and the driving shaft rotate together. The embodiment of the invention further provides a paper money storage device.

Owner:GRG BAKING EQUIP CO LTD

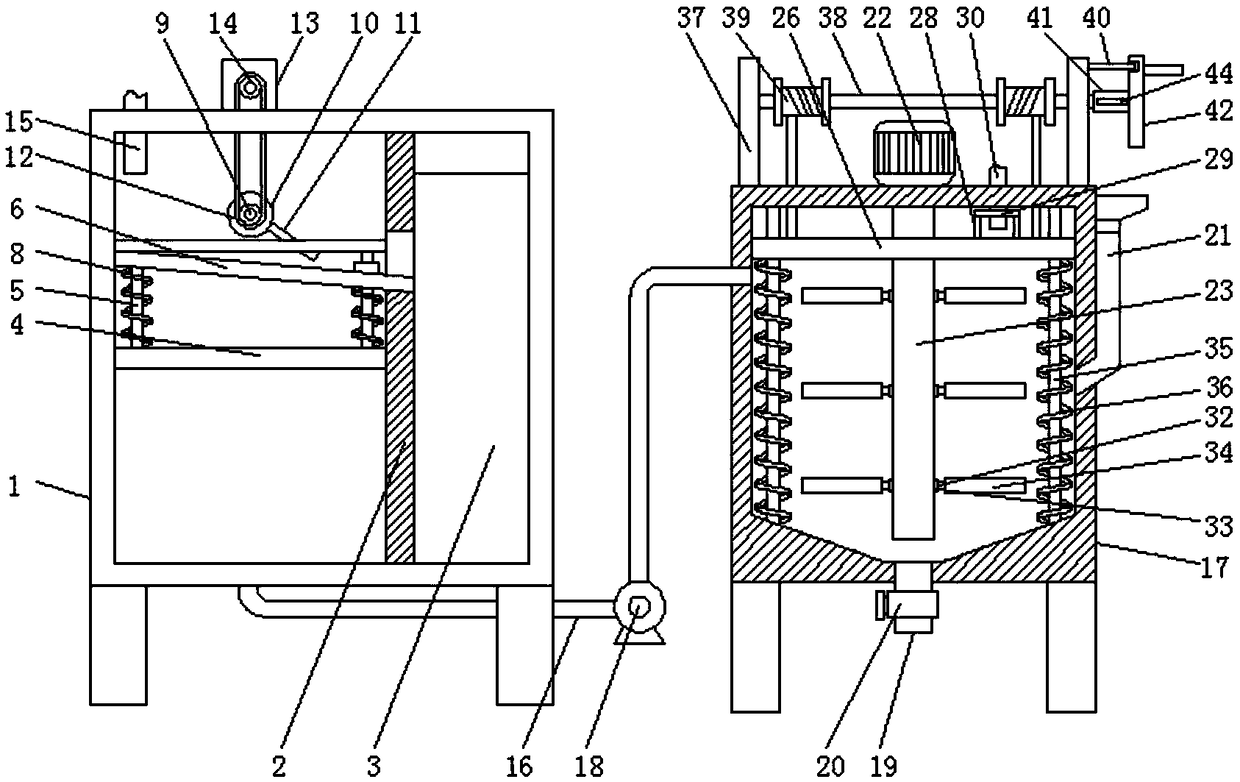

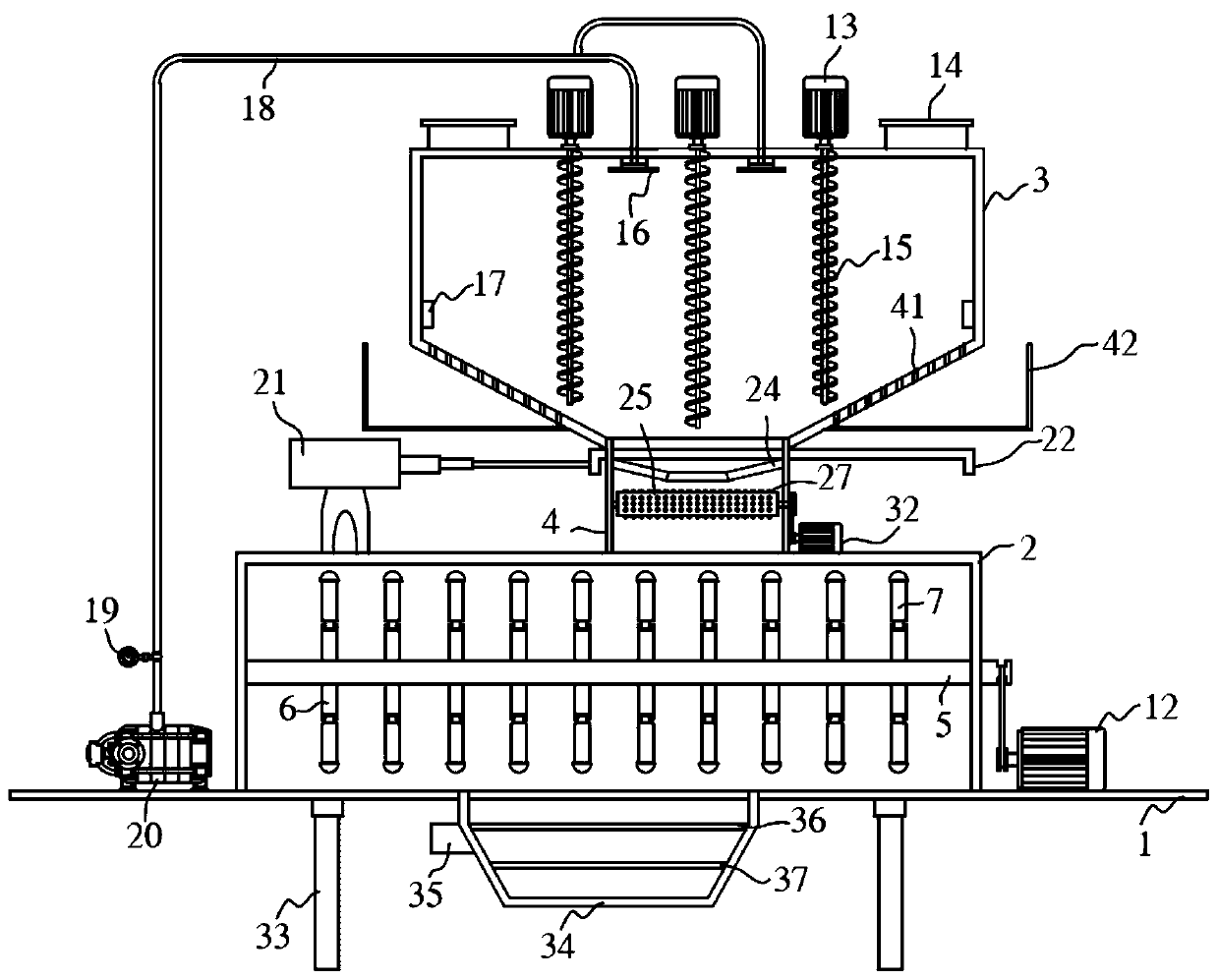

Coal mine wastewater purification treatment equipment

InactiveCN108715492AImprove filtration efficiencyImprove efficiencyWaste water treatment from quariesWater/sewage treatmentSlagCoal

The invention relates to the technical field of wastewater treatment equipment and discloses coal mine wastewater purification treatment equipment. The equipment comprises a filter tank, wherein a partition plate is fixedly arranged on one side inside the filter box in a sleeving manner; a blow-down tank positioned on one side of the partition plate is fixedly arranged at the bottom of an inner cavity of the filter tank; and four positioning rods are fixedly connected to the top of the side face of the partition plate. According to the coal mine wastewater purification treatment equipment, coal mine wastewater passes through a first filtering net on a positioning frame and then drops into the bottom of the filter tank by virtue of the first filtering net. Meanwhile, one end of the adjusting rod is frequently contacted with the top of the positioning frame by utilizing a rotating disc, and the elastic force effect of the spring is matched, so that the first filtering net shakes at a certain frequency, and pulverized coal, slag and other sludge in the coal mine wastewater can conveniently drop into the blow-down tank. During filtration of the coal mine wastewater, the first filteringnet is not blocked by the pulverized coal, slag and other sludge, so that the filtering efficiency of the coal mine wastewater is improved.

Owner:贾中全

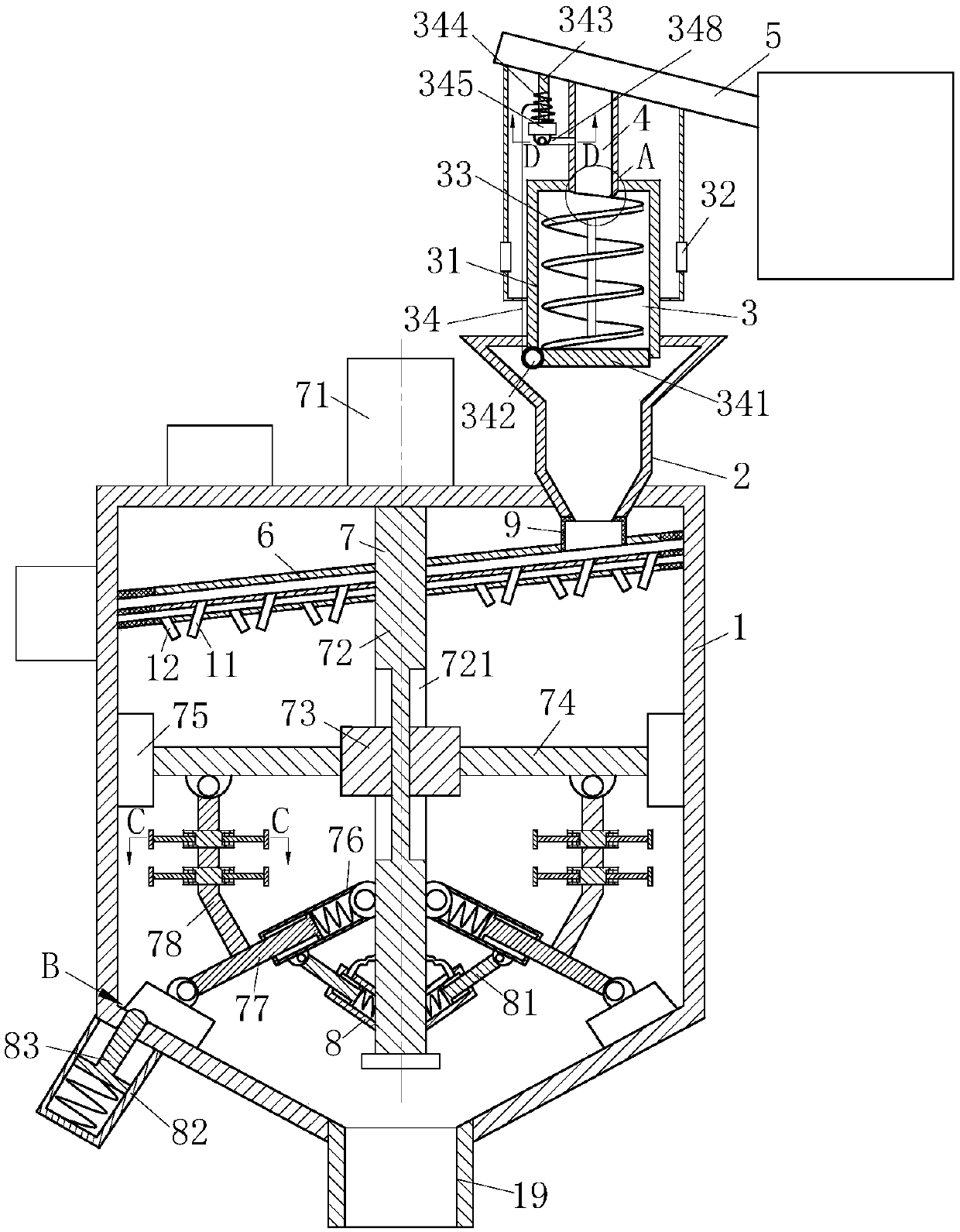

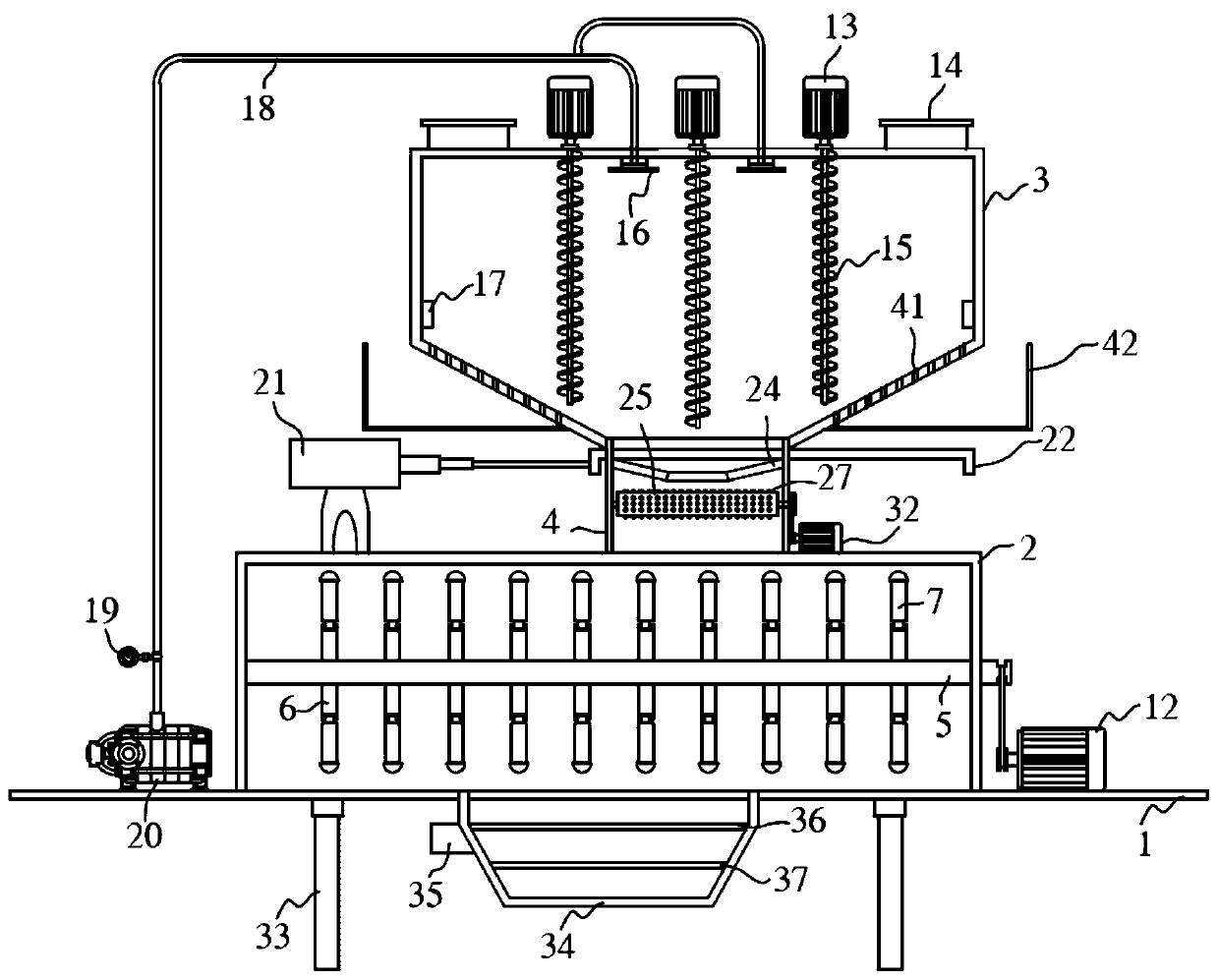

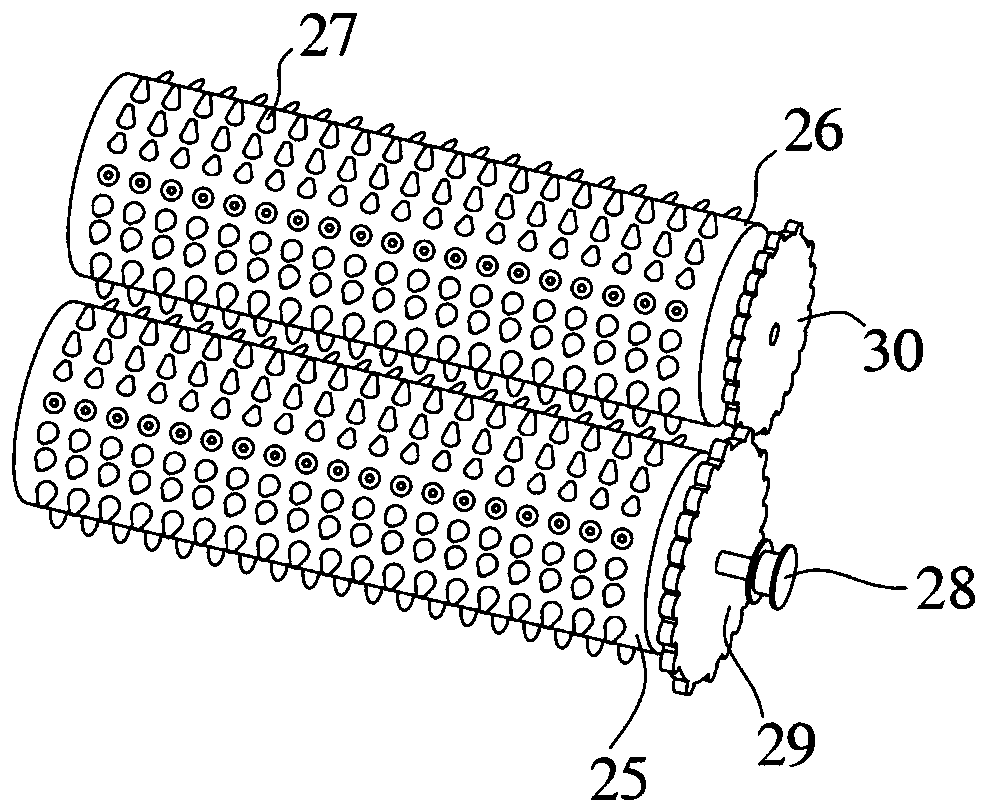

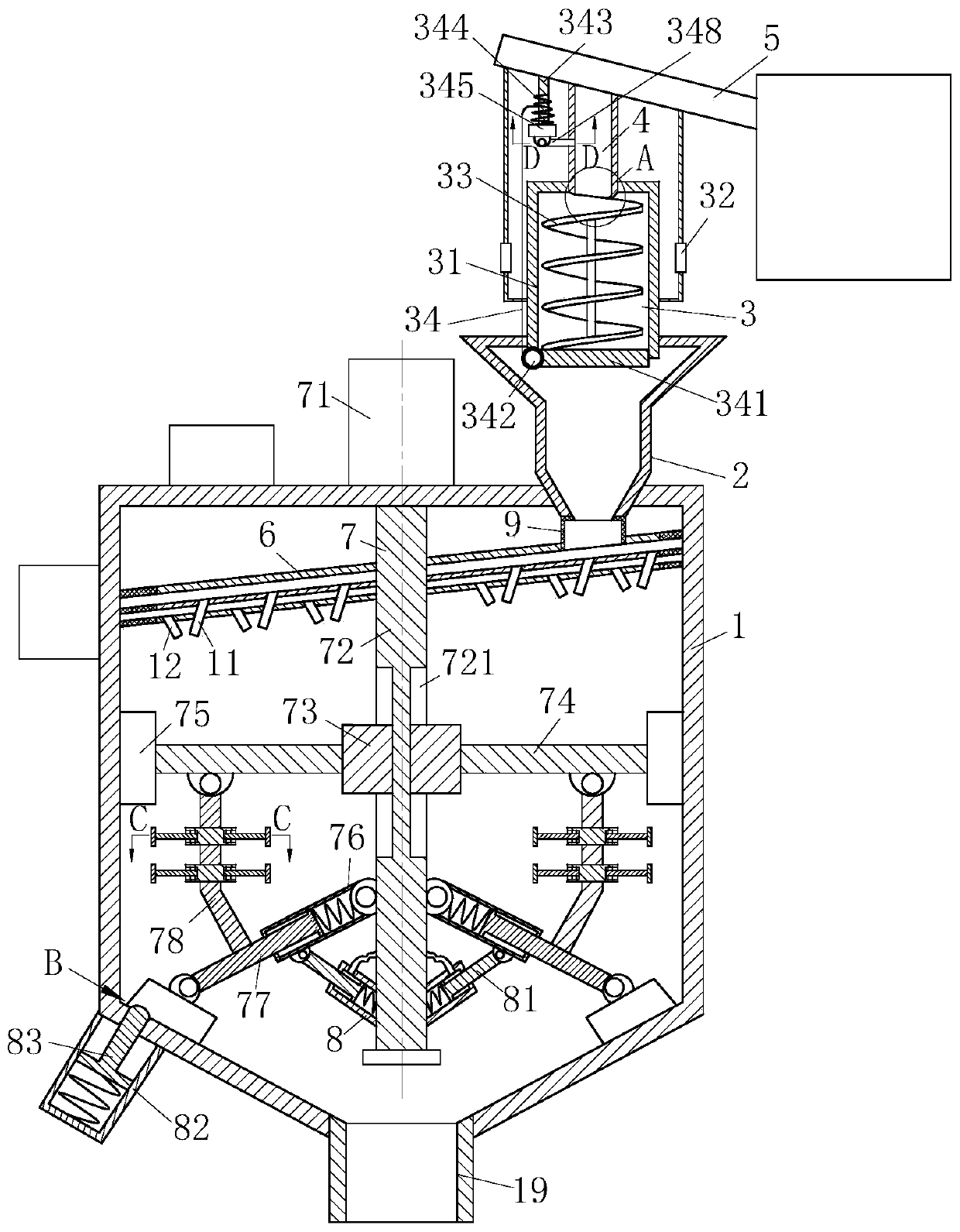

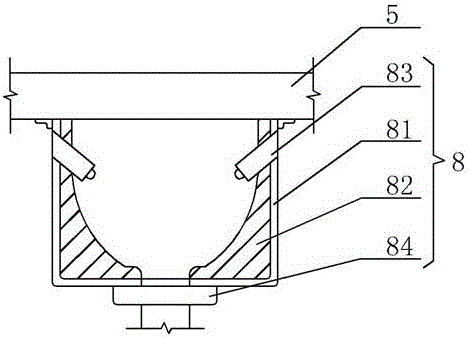

Concrete production device with automatic material control function

ActiveCN109624089AAvoid dustDust effectMixing operation control apparatusPretreatment controlControl functionWater pipe

The invention belongs to the technical field of concrete production equipment, and particularly relates to a concrete production device with an automatic material control function. The concrete production device comprises an outer shell. A blanking hopper is arranged at the top end of the outer shell. A powder material control unit is arranged at the top end of the blanking hopper. A powder material input port is formed in the upper end of the powder material control unit. A powder material conveyor is connected to the top end of the powder material input port and is connected with a powder material storage bin. A material guiding pipe is arranged at the top end of the interior of the outer shell and is connected with the blanking hopper through a rubber hose. A water conveying pipe is arranged in the material guiding pipe. A stirring unit is arranged in the outer shell. A discharging hole is formed in the bottom end of the outer shell. The powder material control unit is used for controlling the usage amount of powder materials, so that the proportions of the balance weights of water and the powder materials can be accurately controlled, and the proportions of the materials for concrete are more uniform, and quality indexes such as concrete strength are better. The water conveying pipe is arranged in the material guiding pipe, so that the phenomenon that dust flies in the outer shell is avoided.

Owner:湖南郴建集团泰湘新型材料有限公司

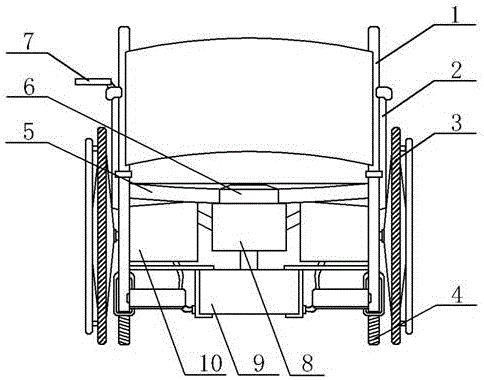

Duck coop cleaning device

ActiveCN105994009AEasy to separateEasy to dropSeparation devicesBird housingsEngineeringDrinking habits

The invention discloses a duck coop cleaning device, comprising a drinker and a separation plate for breeding; below the separation plate, a water receiving bucket is arranged by corresponding to the drinker, the bottom of the water receiving bucket is connected with one end of a drain pipe, the other end of the drain pipe is connected with a waste water collection device, the lower side of the water receiving bucket is connected with a support, and the upper side face of the water receiving bucket is connected with a filter plate; the bottom of the water receiving bucket is provided with a through hole, and the through hole is connected with the drain pipe. The duck coop cleaning device has the beneficial effects that sundries with bigger sizes are separated by the filter plate, and liquid falls into the water receiving bucket below, and is discharged through the drain pipe, so that the drain pipe can adopt a pipeline with a smaller pipe diameter, subsequent pipeline erection is facilitated, overall space is saved, and subsequent wastewater treatment difficulty is reduced; a shaking mechanism more facilitates the falling of the sundries, and an air drying mechanism contributes to the air drying of the sundries, so that the problem that in meat duck breeding, the environment is wet and gets worsened due to the drinking habit of meat ducks, and thus the bred ducks get ill is solved; the device is driven by one motor, and is low in overall power consumption.

Owner:NEW HOPE LIUHE

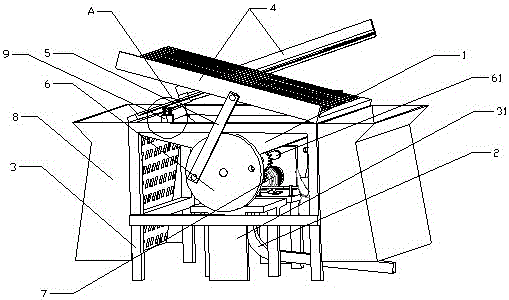

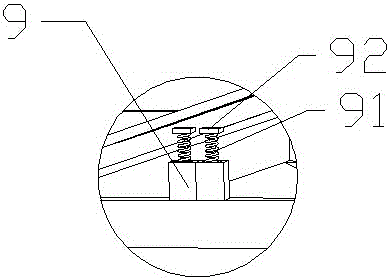

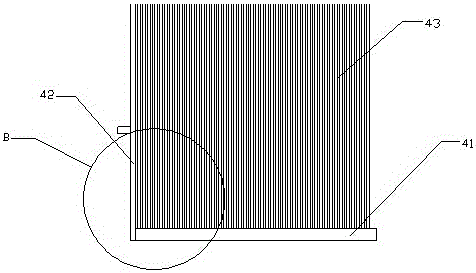

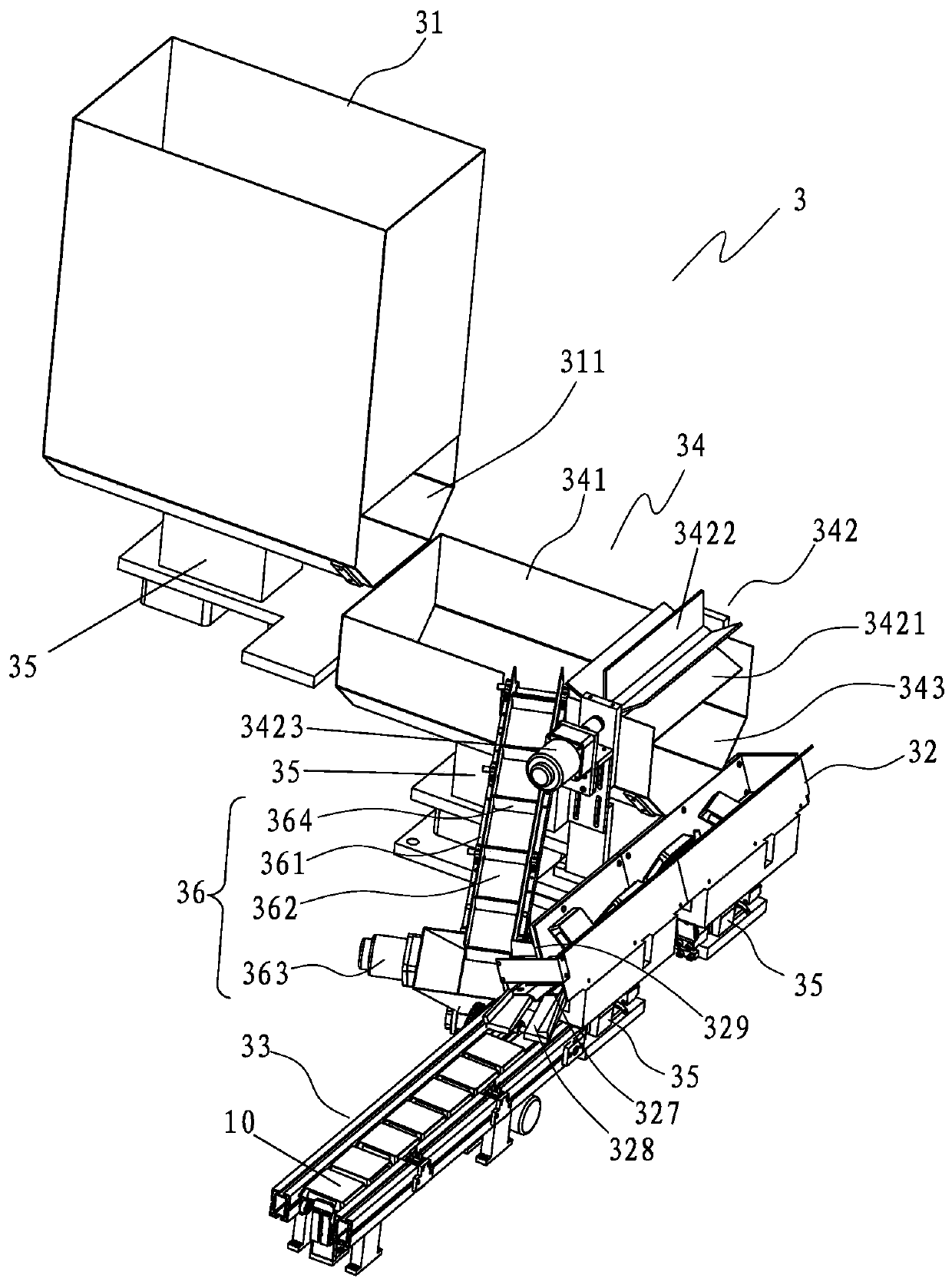

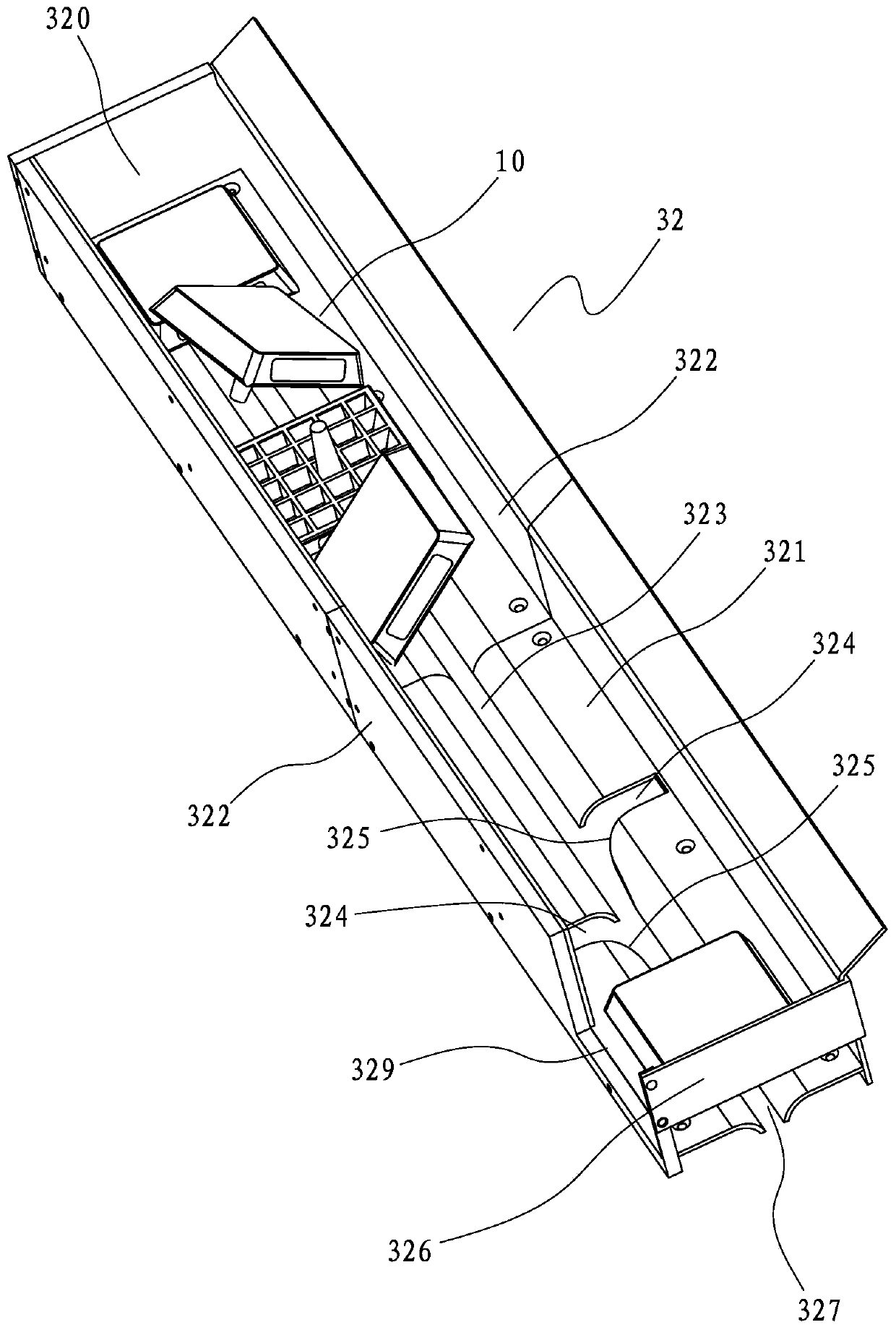

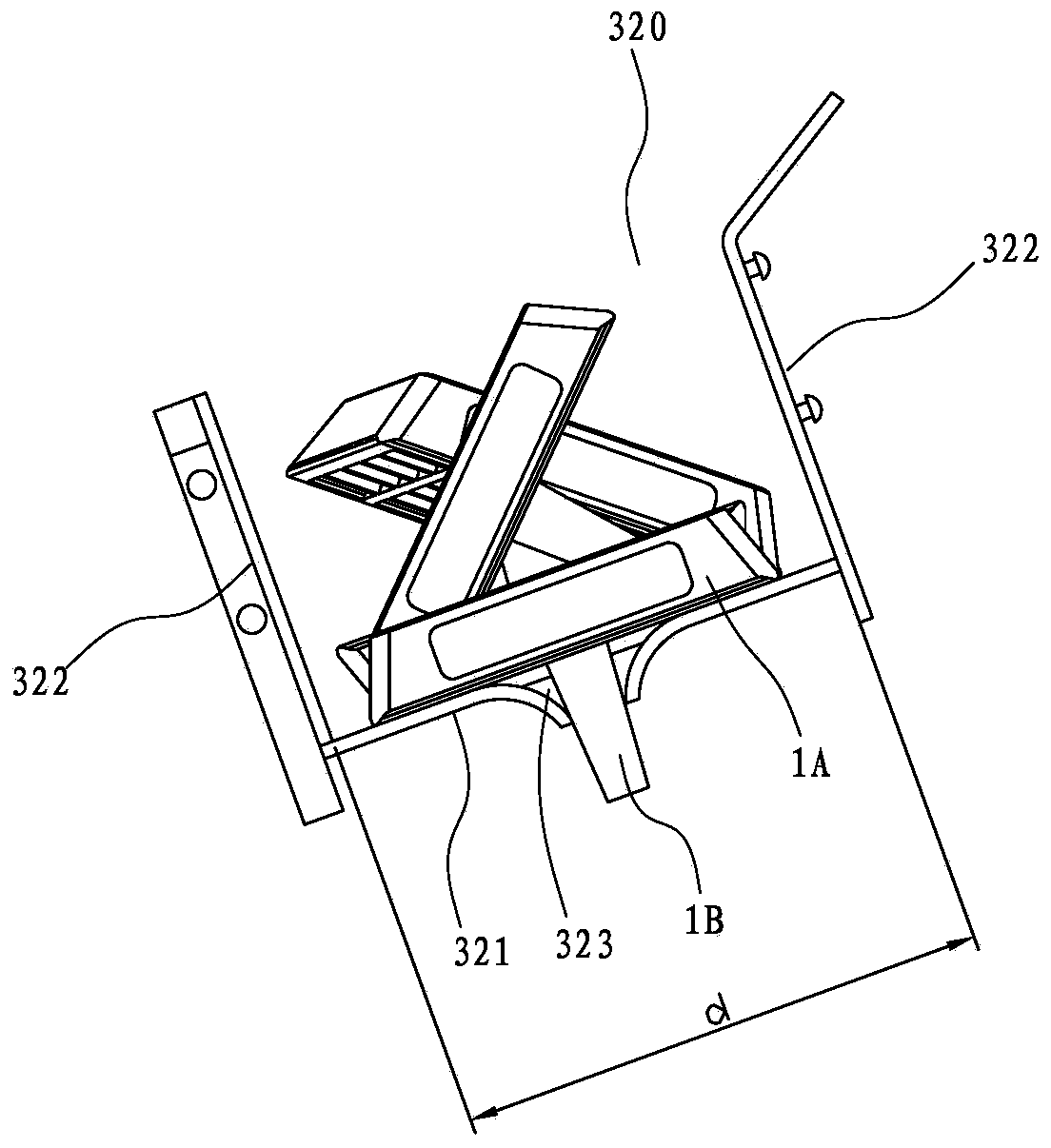

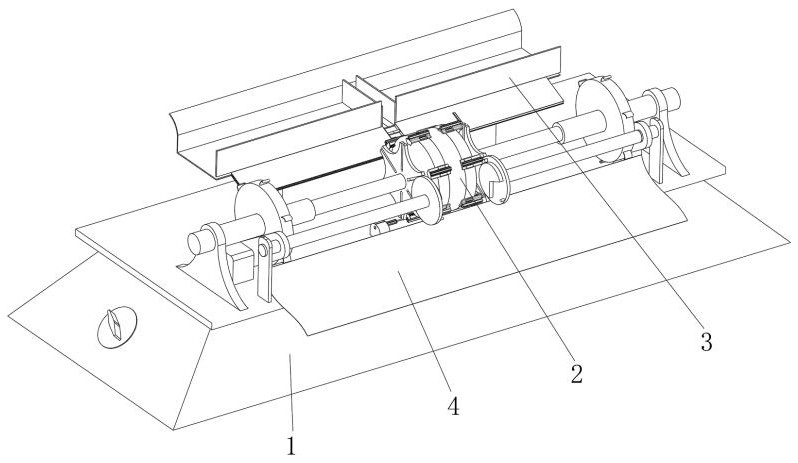

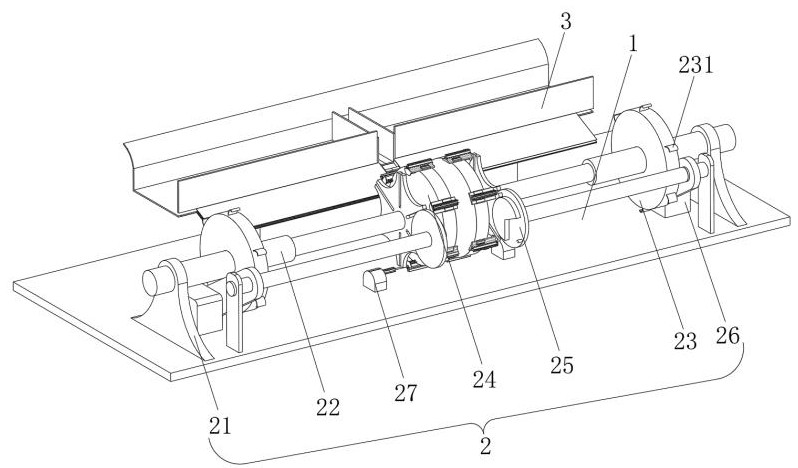

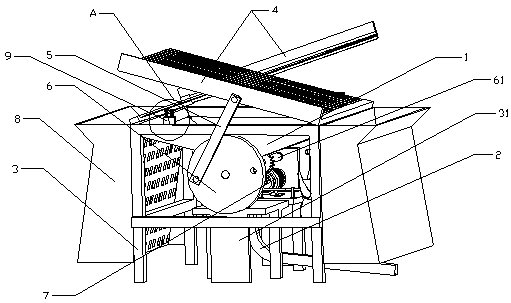

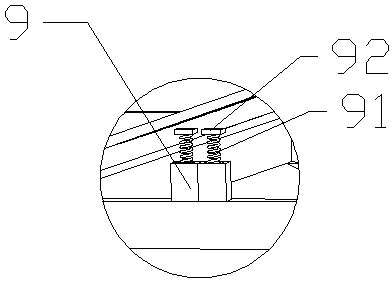

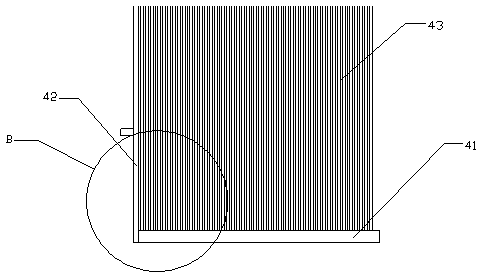

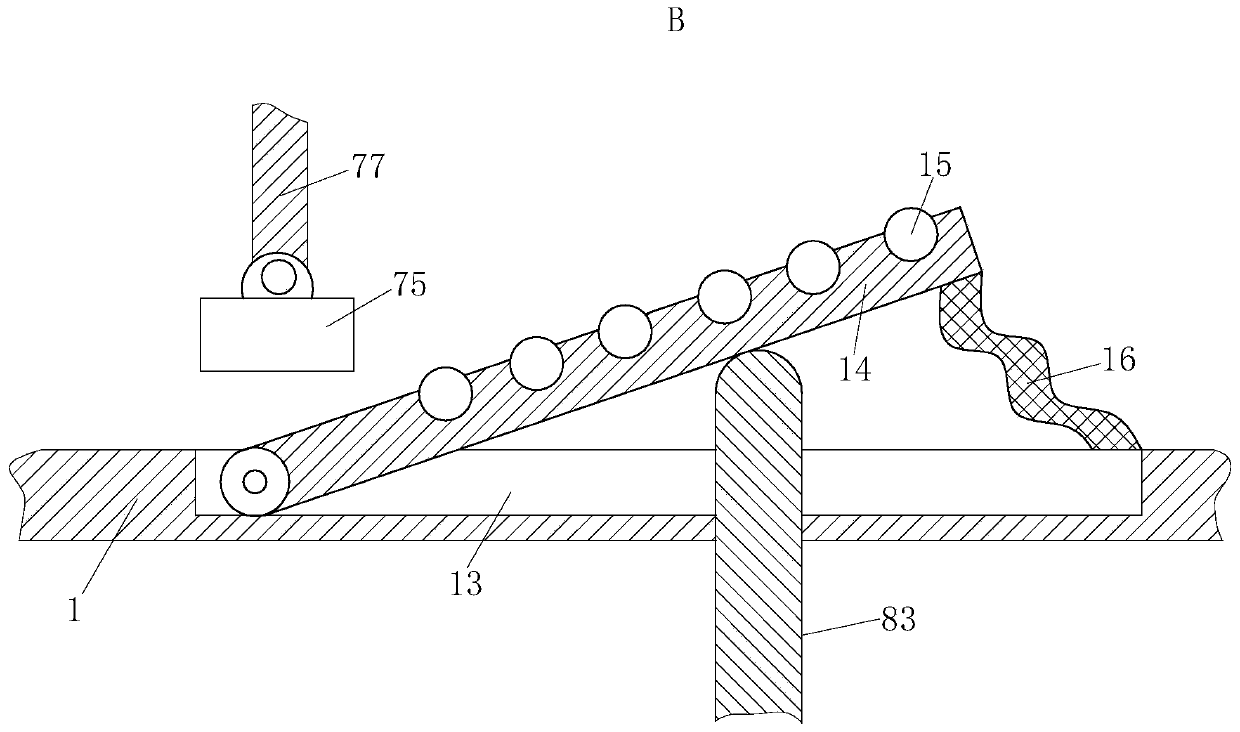

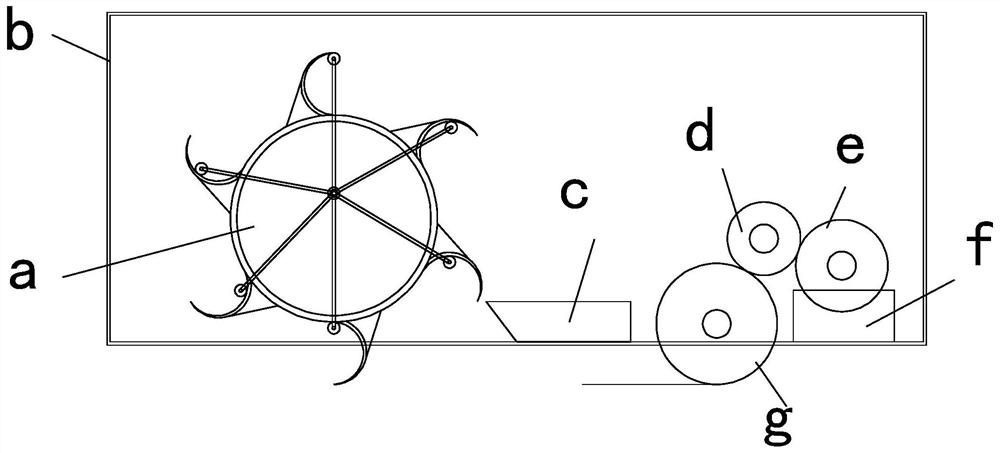

Safe spike sequencing and conveying mechanism

PendingCN111153161AFall into easyRealize the first time sortingConveyor partsEngineeringStructural engineering

The invention discloses a safe spike sequencing and conveying mechanism. The safe spike sequencing and conveying mechanism comprises a storage hopper, a transferring device, a material arranging railand a conveying device, wherein safe spikes flow out of the storage hopper and flow into the material arranging rail through the transferring device, the material arranging rail is driven to vibrate and feed through a direct vibrator, the material arranging rail comprises an inclined bottom plate and two side plates, a spike rod groove for a spike rod to fall into is formed in the middle of the inclined bottom plate, the positions, on the two sides of the spike rod groove, of the inclined bottom plate are respectively provided with a rod falling groove communicating with the spike rod groove,the rod falling grooves are provided with guide corners, spike rods on the inclined bottom plate fall into the rod falling grooves, the guide corners guide the spike rods into the spike rod groove, the tail end of the material arranging rail is provided with a baffle and a screening port, the screening port is used for guiding safe spikes with indicating caps hung on the inclined bottom plate to pass through and be input into the conveying device for sequencing after being guided by a guide rail, a sliding outlet is arranged on the side plate positioned on the lower side of the inclined bottomplate, and the safe spikes blocked by the baffle slide out of the sliding outlet and return to the storage hopper or the transferring device through a material returning device.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

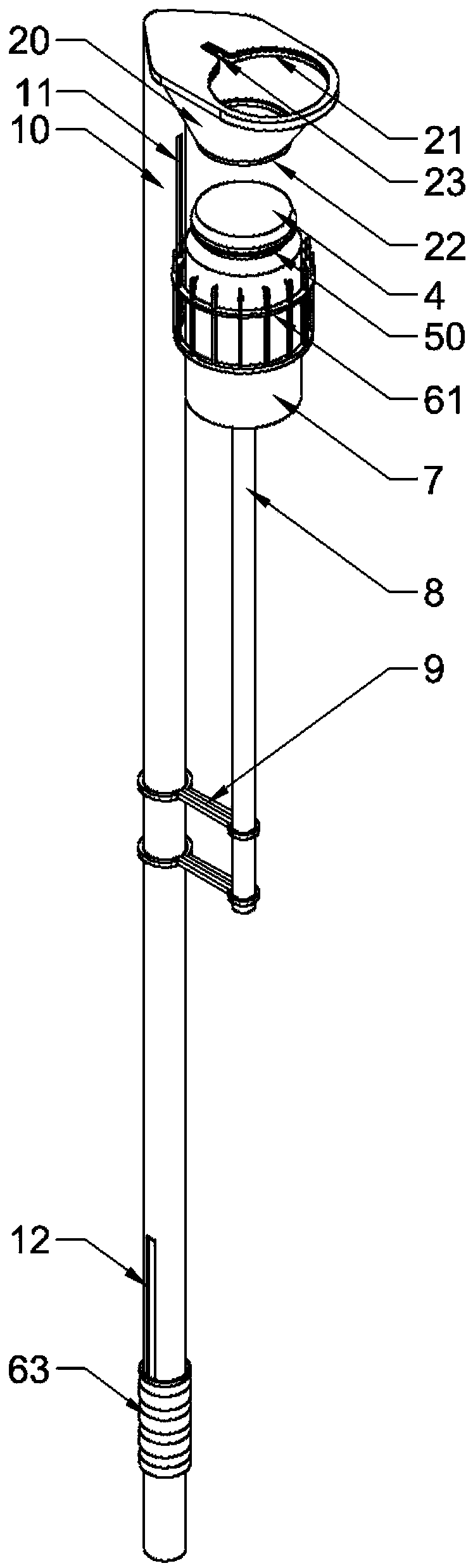

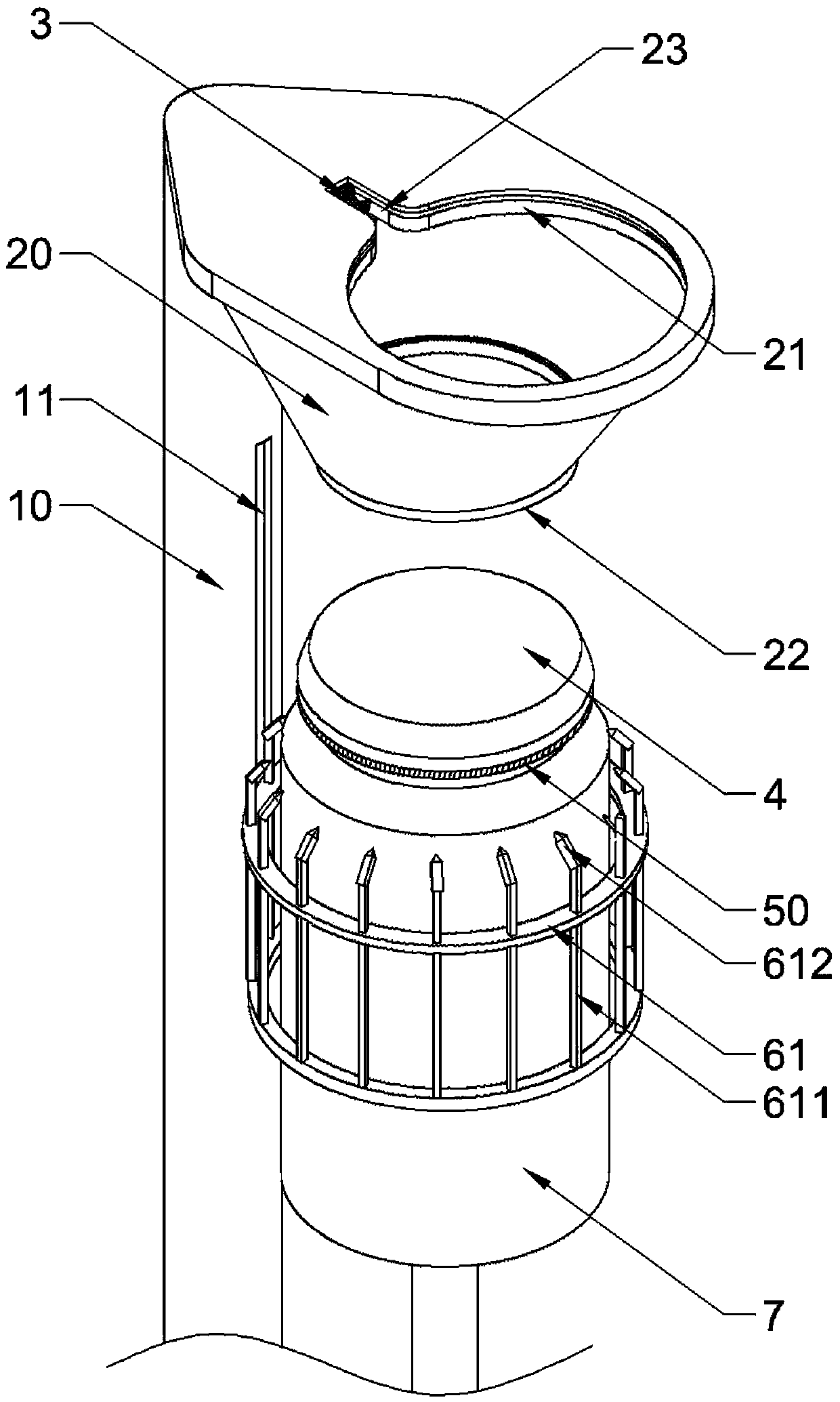

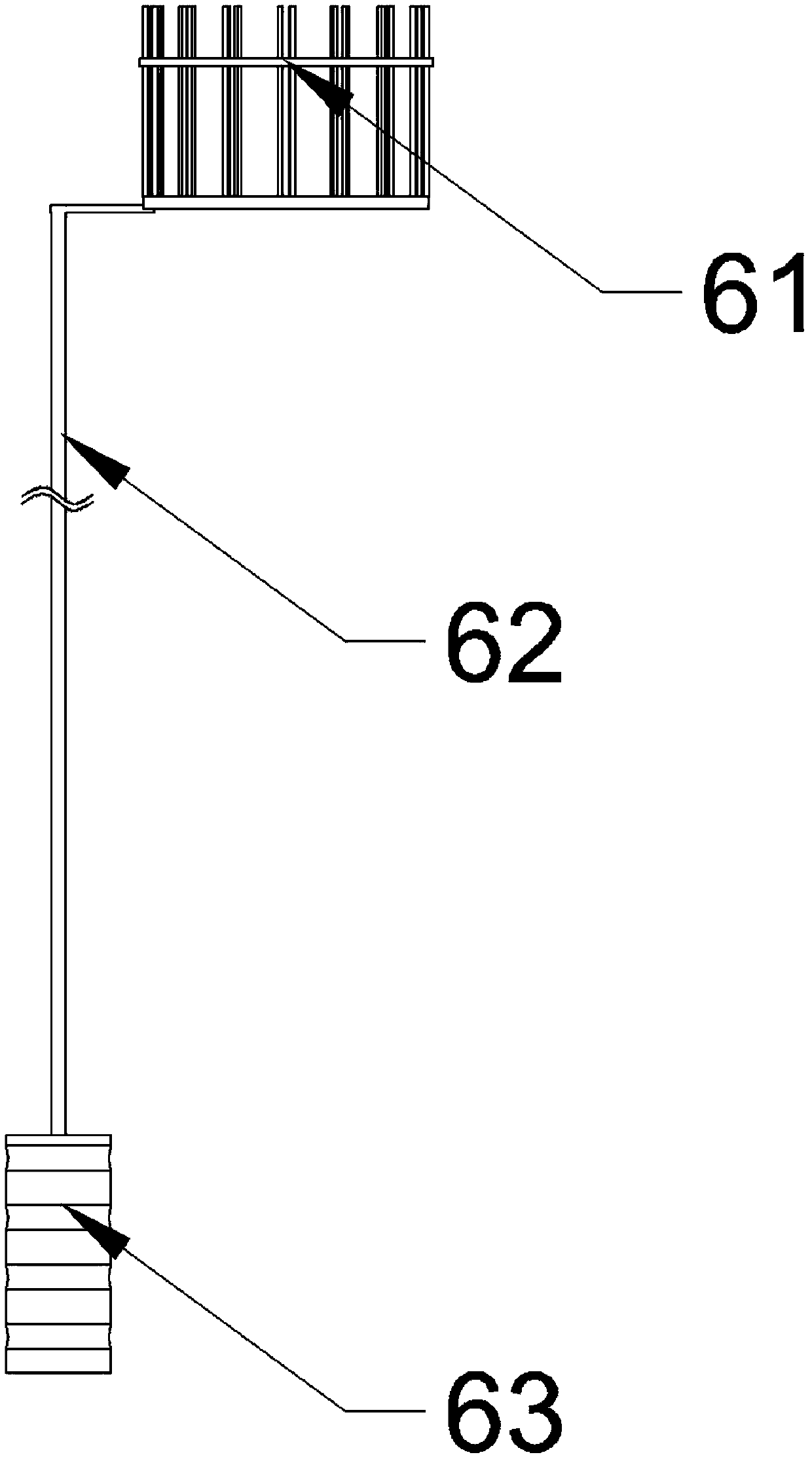

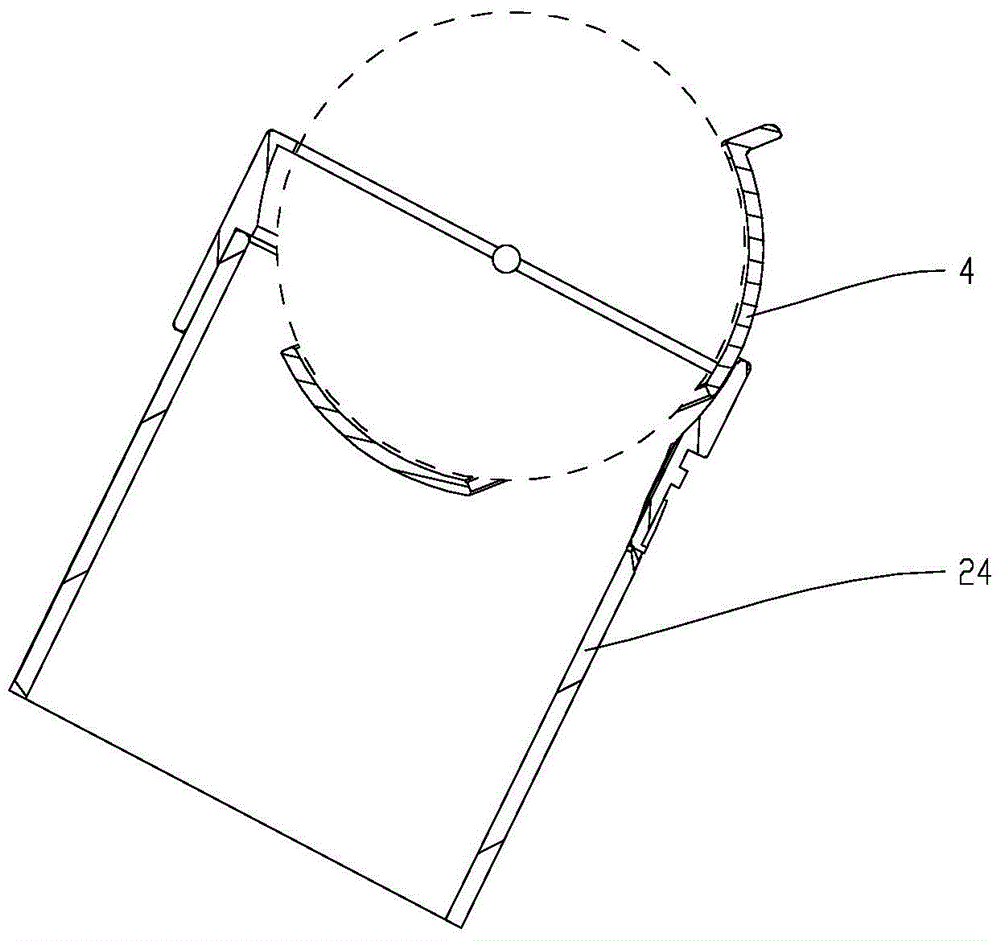

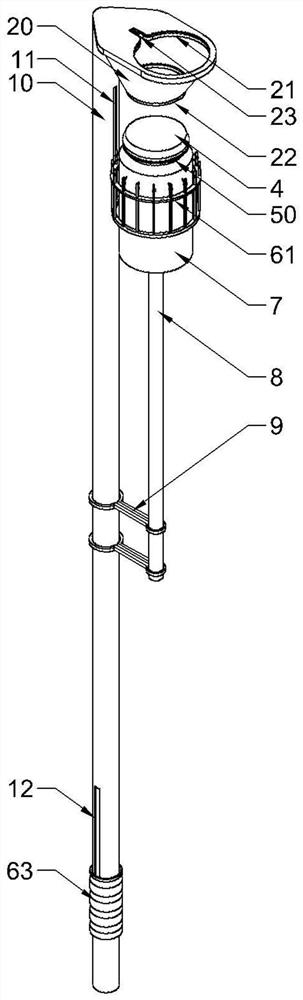

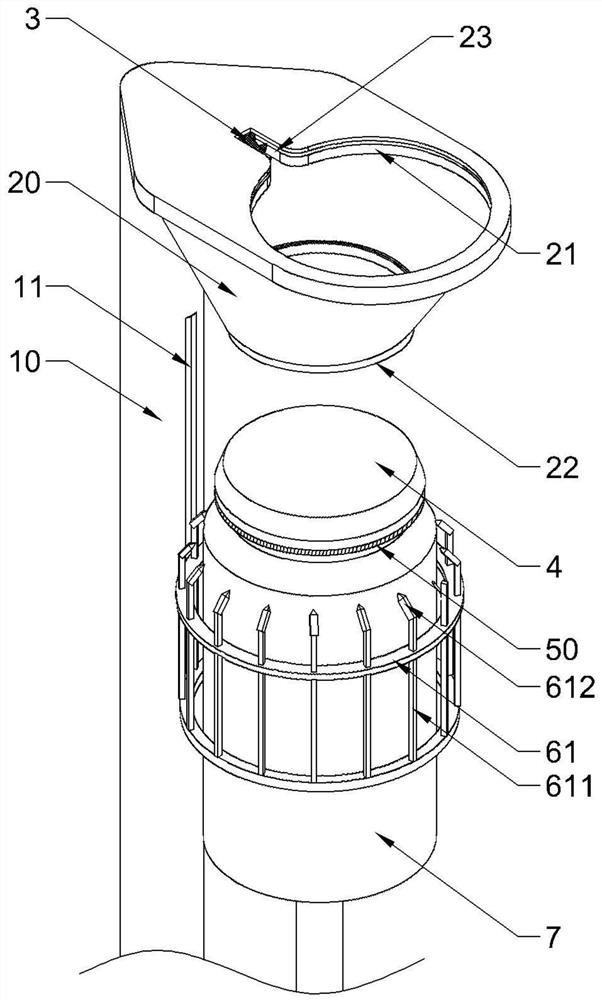

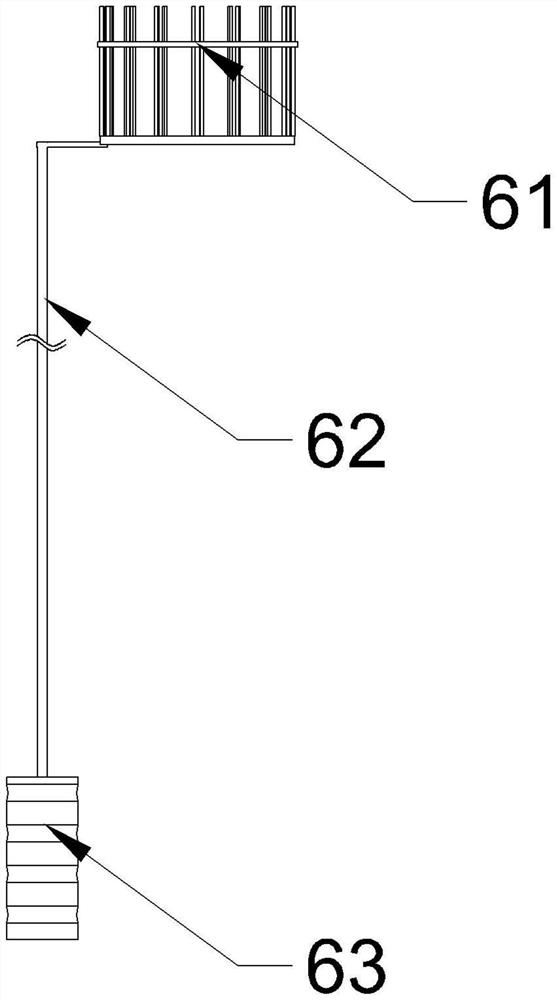

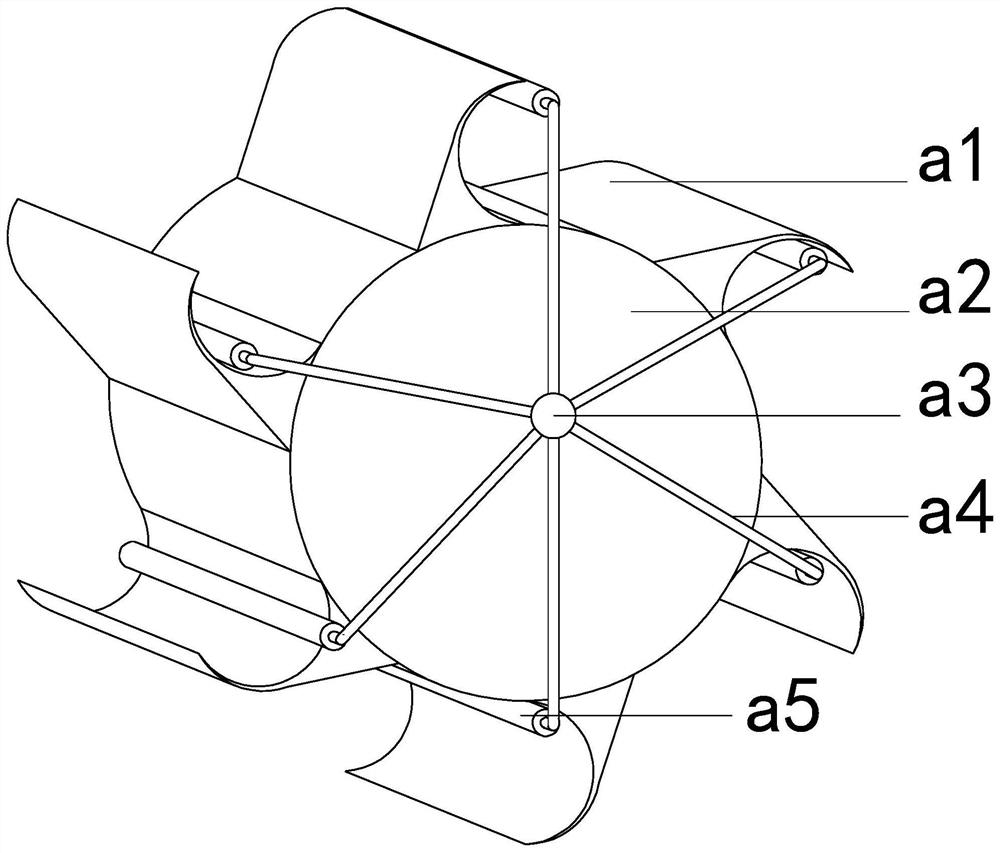

Packaging type fruit picker

ActiveCN109618662AEasy to fall intoFall into easyPackaging fruits/vegetablesPicking devicesPulp and paper industryEngineering

The invention provides a packable fruit picker, which comprises a picking mechanism and a packaging mechanism, wherein the picking mechanism comprises a main rod, a sleeve shell and a toothed blade, the toothed blade is arranged at the top side of the sleeve shell, and the sleeve shell is arranged at the top end of the main rod; the packaging mechanism comprises a tray, a rotary telescopic knife,a grabbing hook, a sleeve, an auxiliary rod and a net bag, wherein the tray is positioned under the sleeve shell, the tray, the rotary telescopic knife and the sleeve are sequentially overlapped fromtop to bottom, one end of the auxiliary rod is connected with the sleeve, and the other end of the auxiliary rod is fixed on the main rod through a connecting piece; the main rod is provided with a movable grappling hook, the net bag is sleeved on the sleeve and the auxiliary rod, and the top end hook of the net bag is clamped on the movable grappling hook; the movable grappling hook moves up anddown along the main rod. In the application, the fruit is sleeved by the sleeve shell, and then the fruit stems are cut by using the toothed blade, so that the fruit directly falls into the packagingmechanism. Meanwhile, the net bag is lifted by the grappling hook, so that the fallen fruits can be conveniently packaged; the redundant net bag is cut off by rotating the telescopic knife; and the fruit is supported and wrapped by the grappling hook which is not put down, so that the fruits are prevented from falling off before being taken away.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

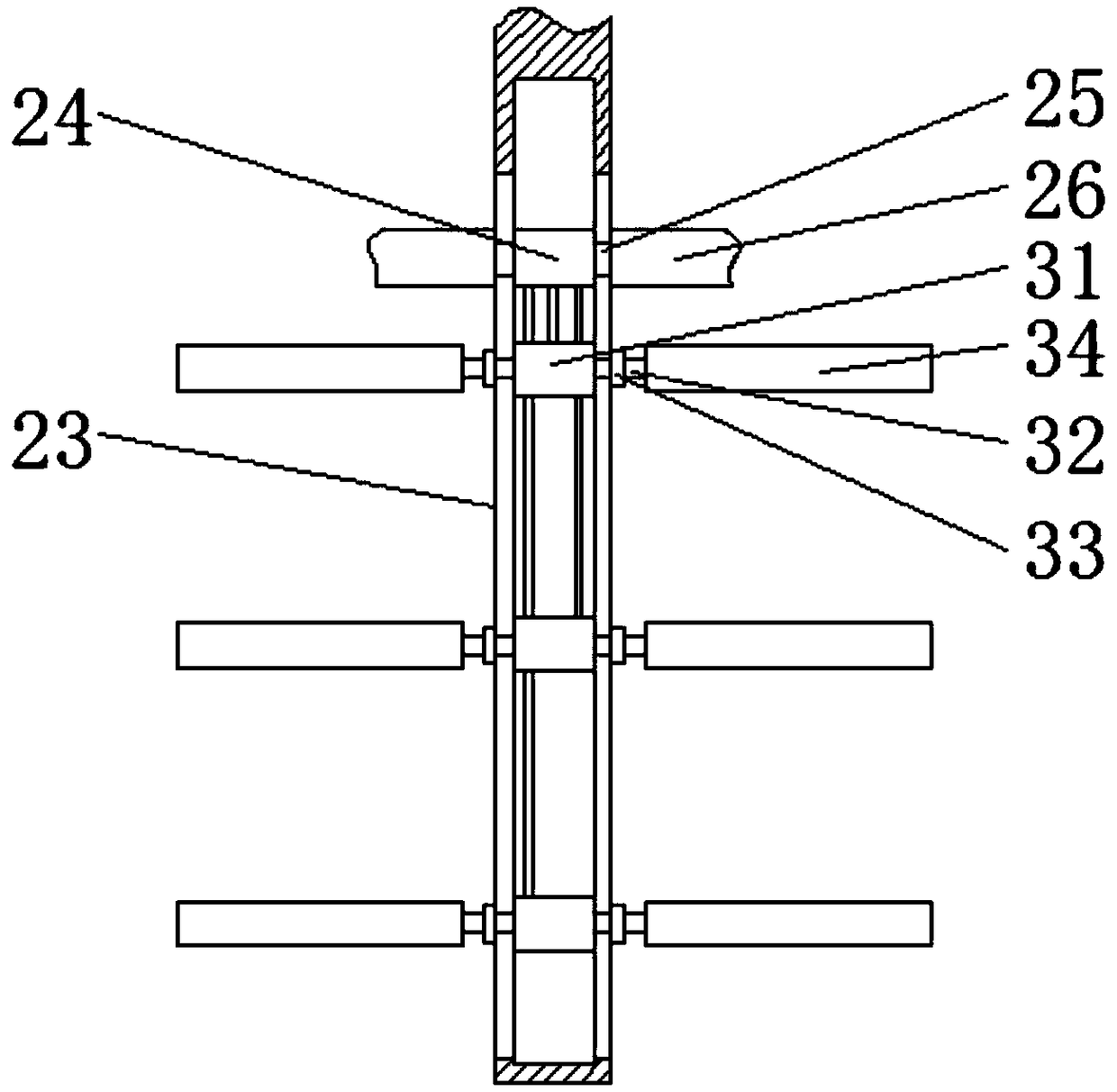

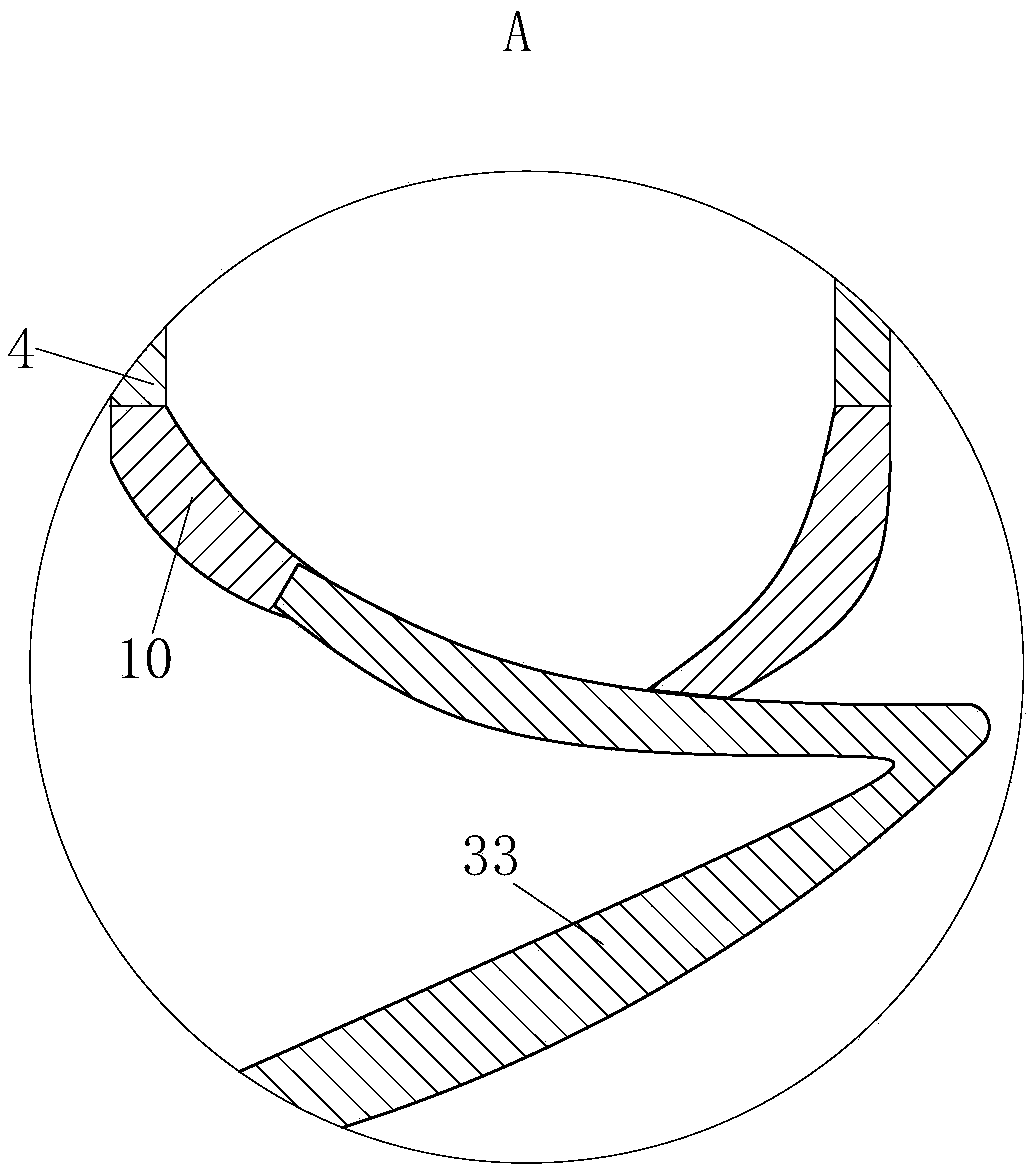

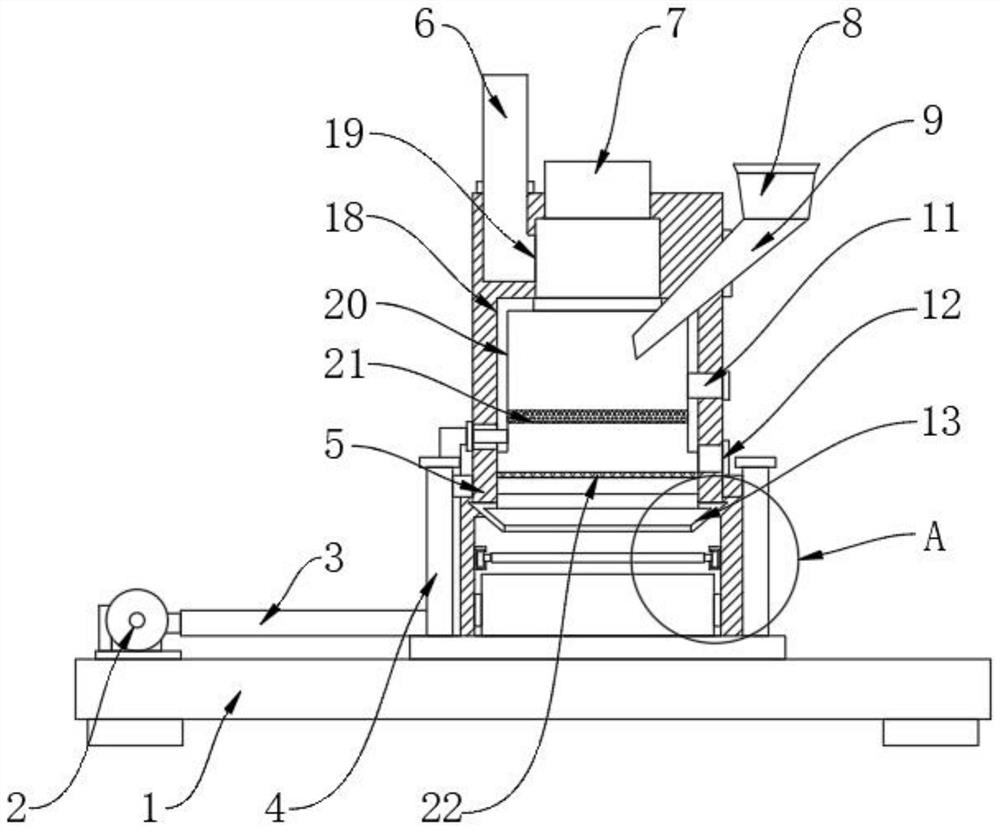

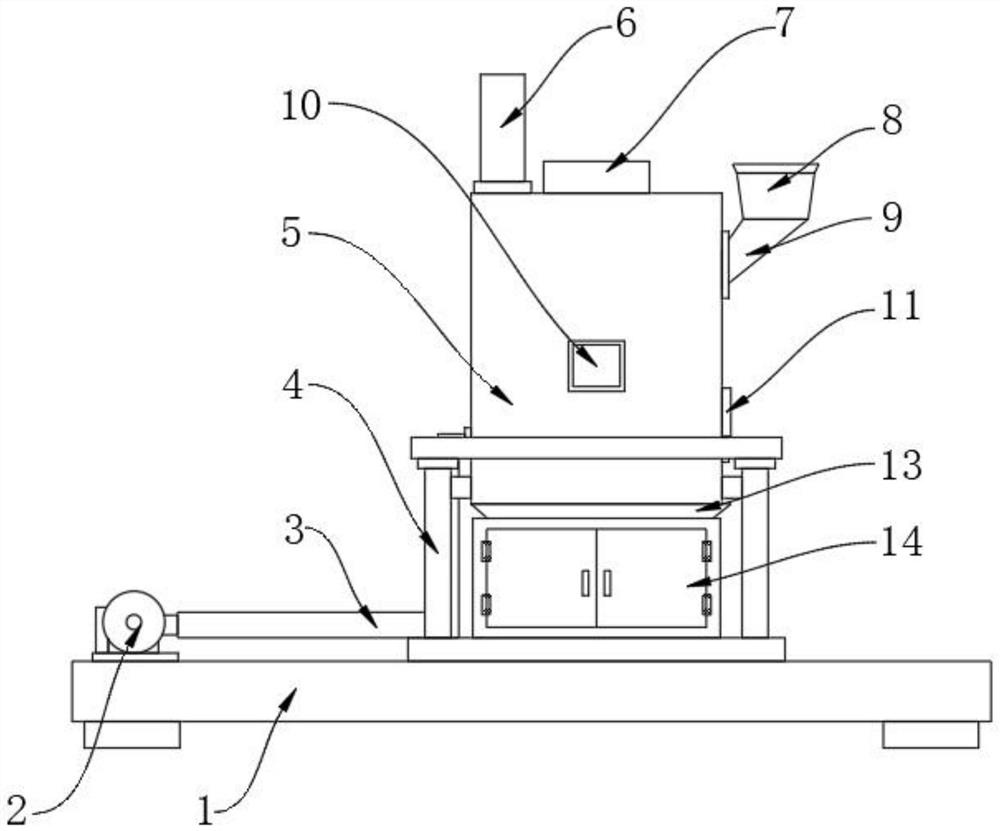

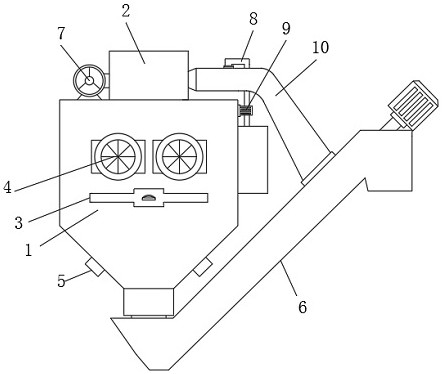

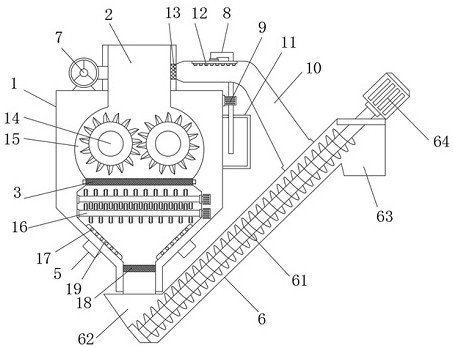

Wheat germ processing roller crushing machine

ActiveCN110420679AEasy to knock downQuick and efficient shot downGrain huskingGrain polishingWheat germEngineering

The invention relates to the technical field of wheat processing, in particular to a wheat germ processing roller crushing machine which comprises a base. An acquiring box and a stepping motor are mounted on the base, a connecting box is communicated with the upper portion of the acquiring box, at least one group of atomizers and a heater are mounted in a moisturizing and steaming box, a flow meter is arranged on a water conveying pipe, the other end of the water conveying pipe is connected onto a water pump, one side of a C-shaped sealing plate is connected with a pushing rod of a pushing rodmotor, a pressing and puncturing mechanism is mounted in the connecting box, a second motor is mounted at the top of the acquiring box, a beating and falling mechanism is mounted in the acquiring boxand connected with the stepping motor in a driven manner, and a filter portion is mounted at the bottom of the acquiring box. According to the crushing machine, wheat is moisturized by hot air, the moisturized wheat is punctured, so that germs are beaten and then fall off, the punctured wheat is 'flexibly' and integrally beaten by a high-speed rotation joint beating rod, and the wheat germs are rapidly and efficiently acquired.

Owner:BENGBU COLLEGE

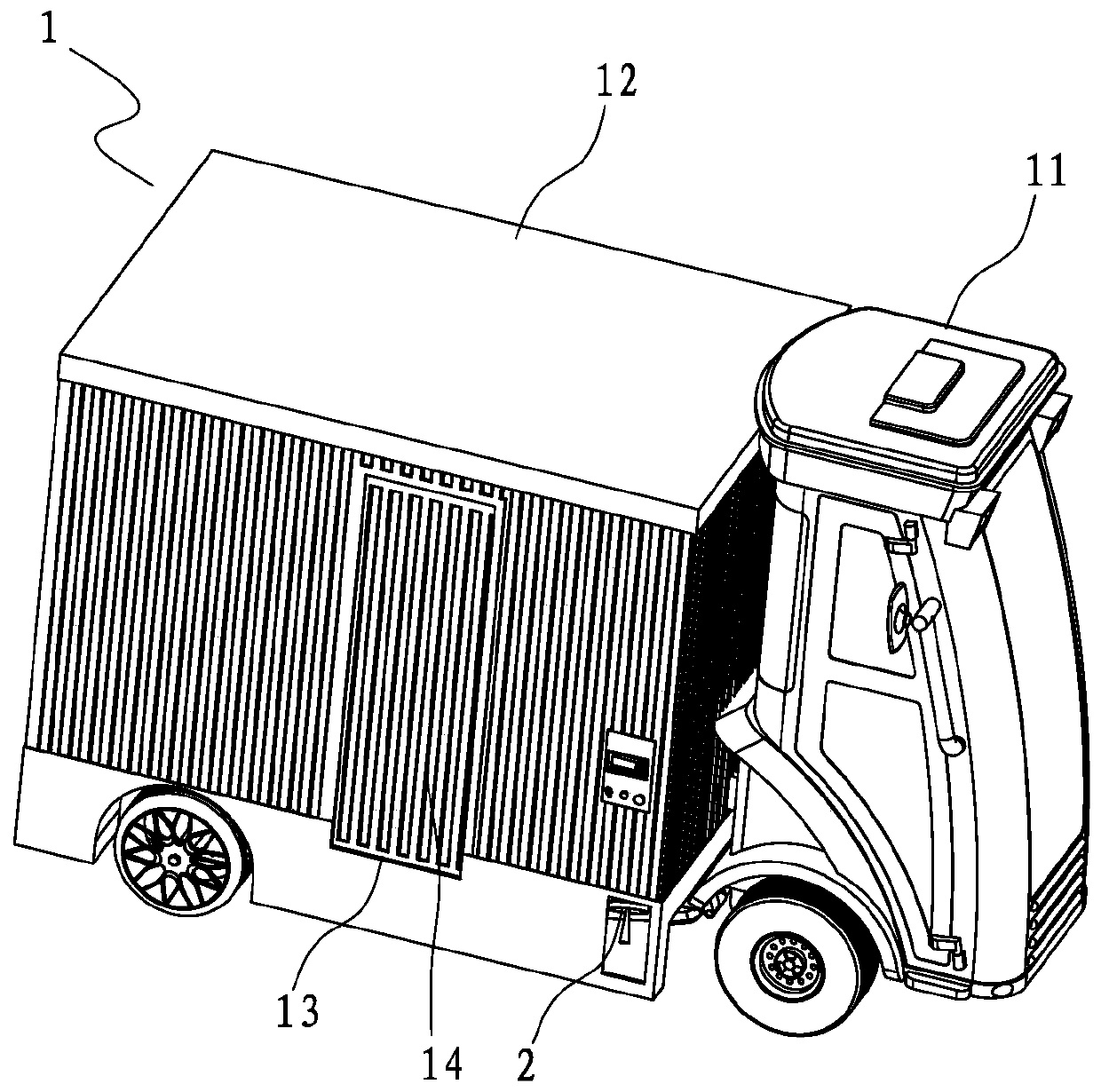

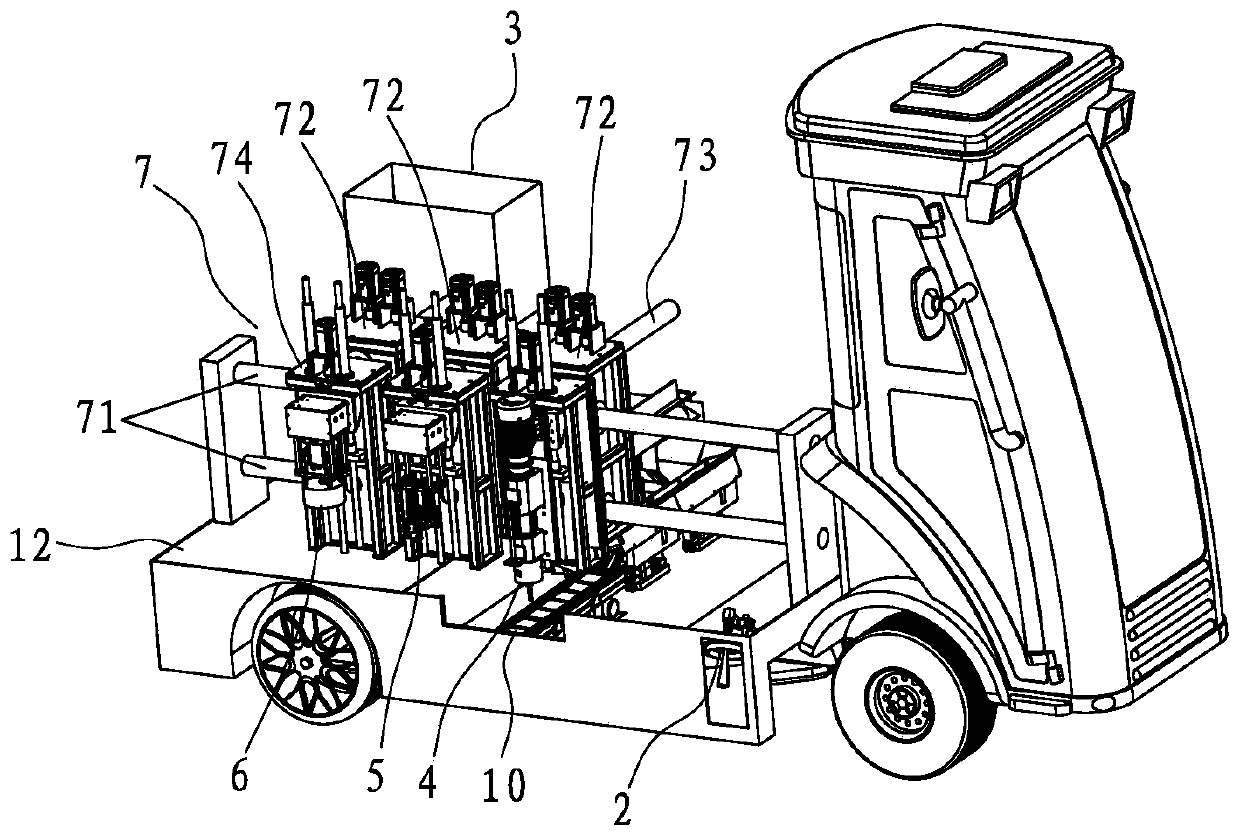

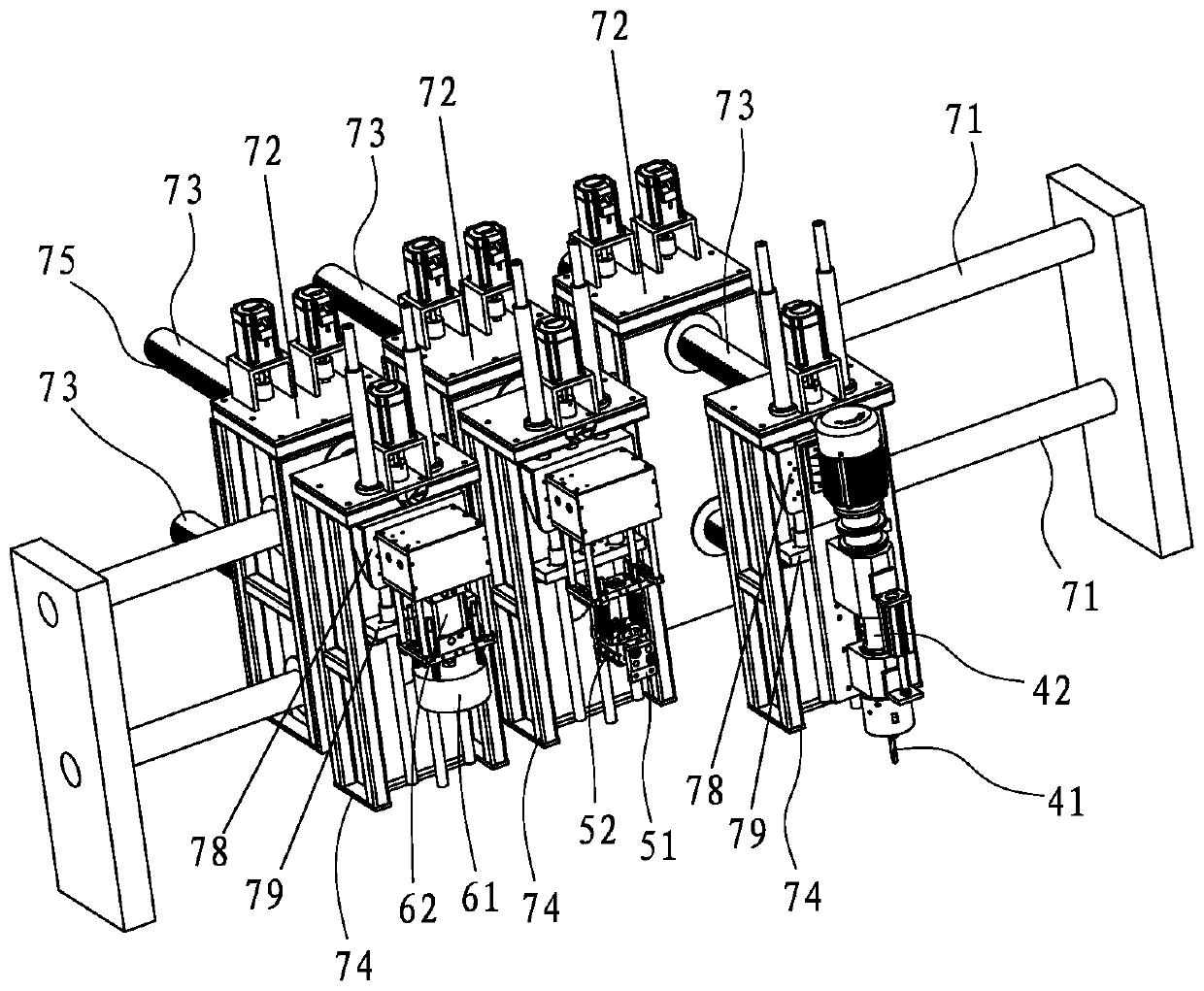

Full-automatic safety spike construction vehicle and safety spike construction method

PendingCN111172911ARealize automatic tracking and positioningImprove construction efficiencyTraffic signalsRoad signsControl systemRoad surface

The invention discloses a full-automatic safety spike construction vehicle. Vehicle body and control system, the vehicle body is provided with a camera used for shooting the position of a lane indication line on the road surface. The vehicle body is further provided with a sequencing conveying mechanism, a drilling mechanism, a nail taking mechanism and a hammering mechanism. The camera, the sequencing conveying mechanism, the drilling mechanism, the nail taking mechanism and the hammering mechanism are electrically connected with the control system. Wherein the drilling mechanism is used fordrilling holes in a road surface along a lane indication line, the sorting and conveying mechanism is used for sorting safety spikes and orderly supplying the safety spikes, the spike taking mechanismis used for grabbing the safety spikes from the sorting and conveying mechanism and inserting spike rods on the safety spikes into the drilled holes, and the hammering mechanism is used for hammeringthe safety spikes to stabilize the safety spikes on the road surface. The invention further discloses a construction method for the safety spikes by adopting the full-automatic safety spike construction vehicle. The construction method has the characteristics that the batch construction speed is high, the safety spike mounting distance is stable, manpower and material resources can be saved, andthe construction period is shortened.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA ZHONGSHAN INST

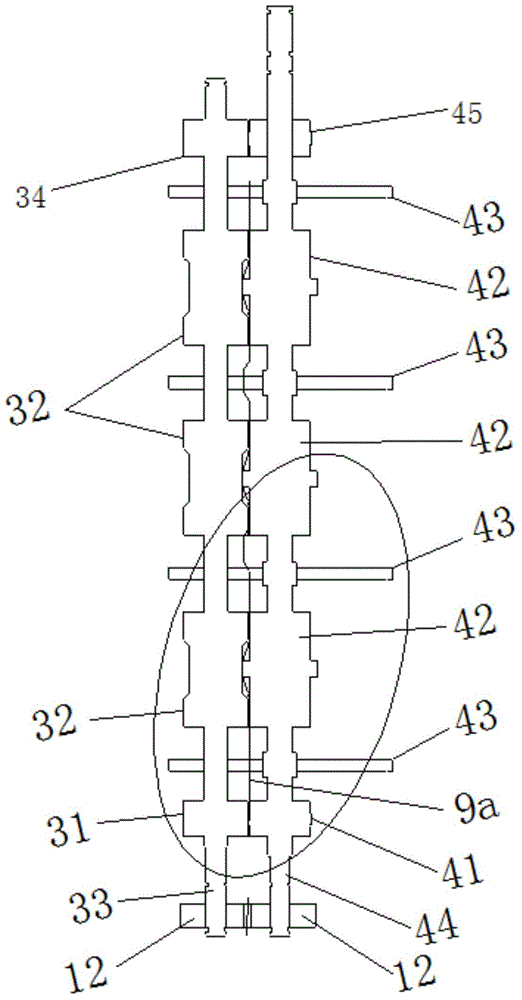

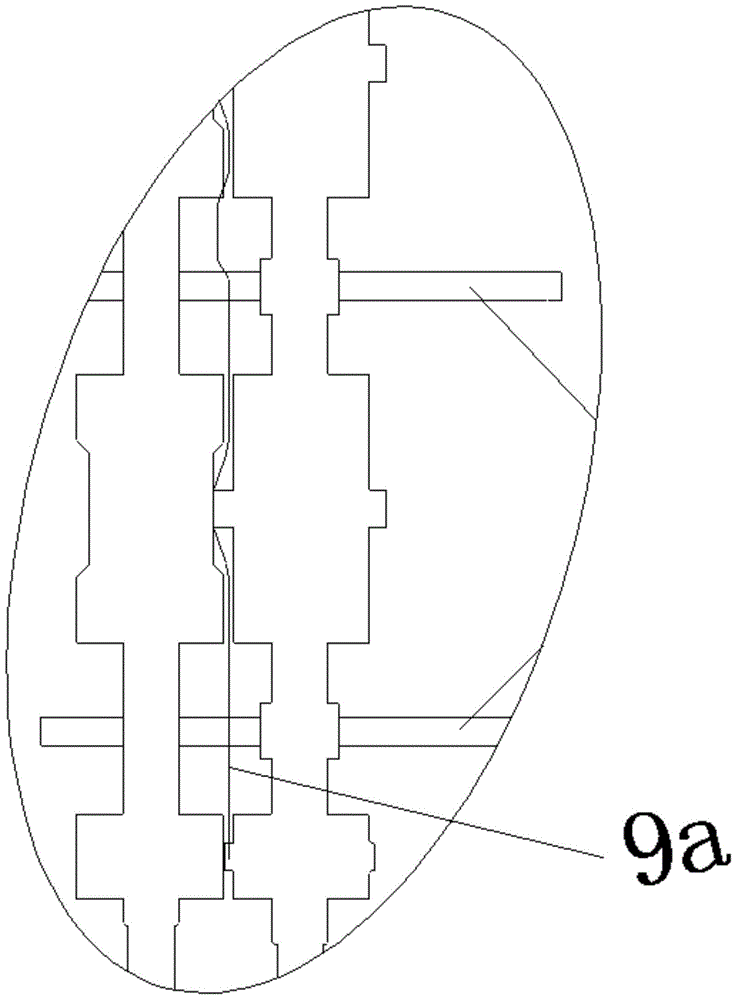

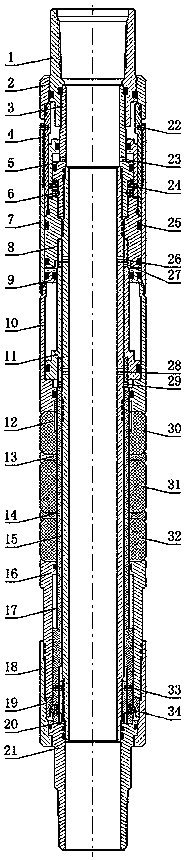

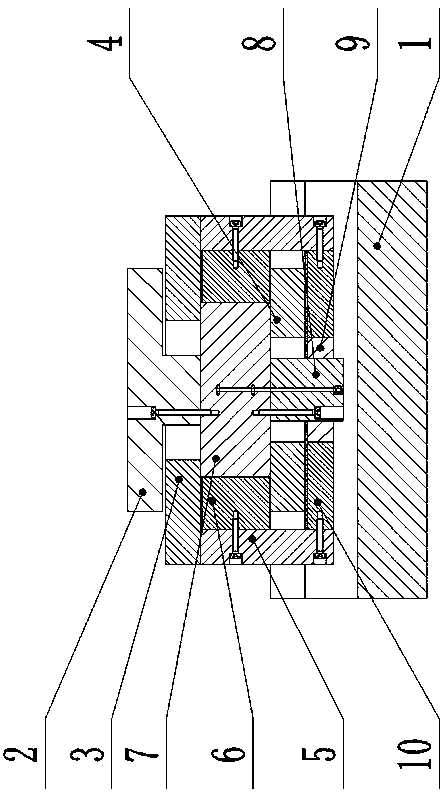

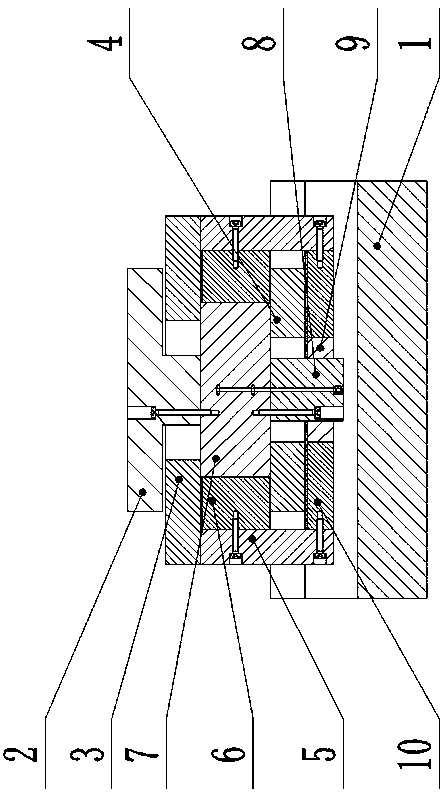

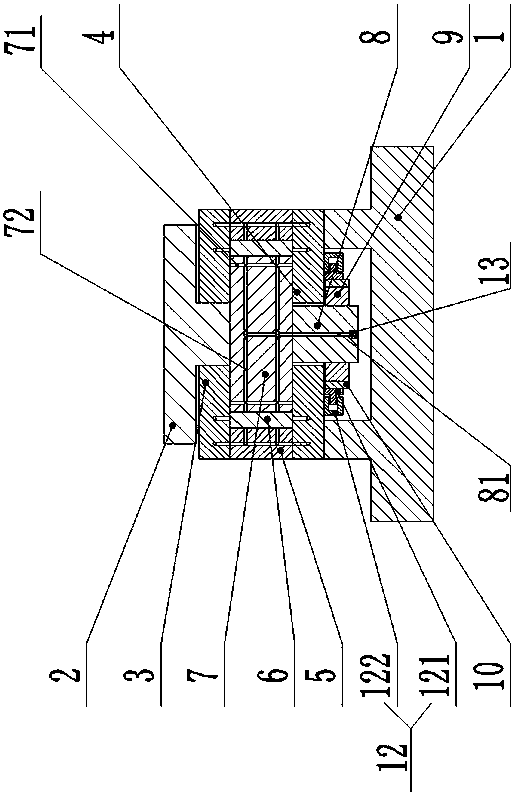

Packer with low-pressure setting and low-tension unsealing

The invention discloses a packer with low-pressure setting and low-tension unsealing. For a setting mechanism, an upper outer center pipe is connected with a ball locking seat in a threaded mode, theupper outer center pipe is connected with a lower outer center pipe in a threaded mode, an upper piston sleeve is arranged on the outer part of the upper outer center pipe in a sleeving mode, an upperouter sleeve is connected with a limiting sleeve in a threaded mode, and the upper outer sleeve and the limiting sleeve are arranged on the upper parts of the upper outer center pipe and the lower outer center pipe in a sleeving mode; an upper rubber cylinder, an upper separating ring, a middle rubber cylinder, a lower separating ring, a lower rubber cylinder and a lower pressing ring are arranged on the outer part of the lower outer center pipe; an annular groove is formed in the outer part of the upper outer center pipe, and the radian of the groove is the same as the radian of an upper steel ball; an annular hole is formed in the ball locking seat, and the center of the annular hole of the ball locking seat and the center of the annular groove of the upper outer center pipe are coincided; three quarters of the upper steel ball are placed in the annular hole of the ball locking seat, and the other quarter of the upper steel ball is placed in the annular groove of the upper outer center pipe; an upper center pipe is in locking fit with the ball locking seat through the upper steel ball; and a disjointing sleeve is arranged on the outer parts of the upper center pipe and the balllocking seat in a sleeving mode, and the disjointing sleeve and the ball locking seat are fixed with disjointing pins. The problem of well blocking due to the facts that for an existing packer, a stage-by-stage unsealing mechanism and an unsealing space are not located in a closed cavity and rubber cylinders cannot be completely recycled during unsealing is solved.

Owner:长春市恒大石油机械有限公司

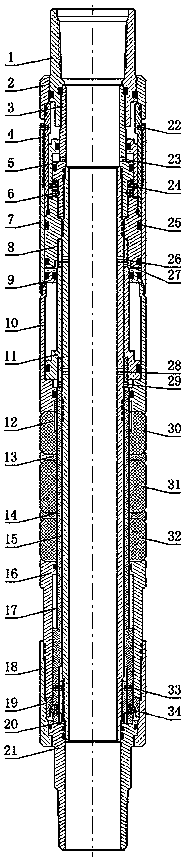

Dedusting device for roll forming machine

InactiveCN105057237AGood dust removal effectEffective dust removal effectCleaning using toolsCleaning using gasesTextileConveyor belt

Disclosed is a dedusting device for a roll forming machine. The dedusting device for the roll forming machine comprises a machine frame, a dedusting device body, a compression roller and a discharging roller. The dedusting device body is arranged under the compression roller. The dedusting device body comprises a suction ventilator, a feeding funnel, a discharging funnel, a conveyor belt and banister brushes. The suction ventilator is connected with the feeding funnel and the discharging funnel through a dust collecting bag. The feeding funnel is arranged under an upper conveyor belt body, and the discharging funnel is arranged under a lower conveyor belt body. The inclined banister brushes are arranged on the conveyor belt. The compression roller is arranged over the conveyor belt and makes physical contact with the banister brushes. The dedusting device for the roll forming machine has the advantaged that the dedusting effect is better due to the fact that the banister brushes make physical contact with textile; impurities can fall into the funnels more easily due to the appropriate gaps and inclination of the banister brushes; the dedusting effect is better due to the position arrangement of the suction ventilator, the feeding funnel, and the discharging funnel.

Owner:WUJIANG XINJIN TEXTILE

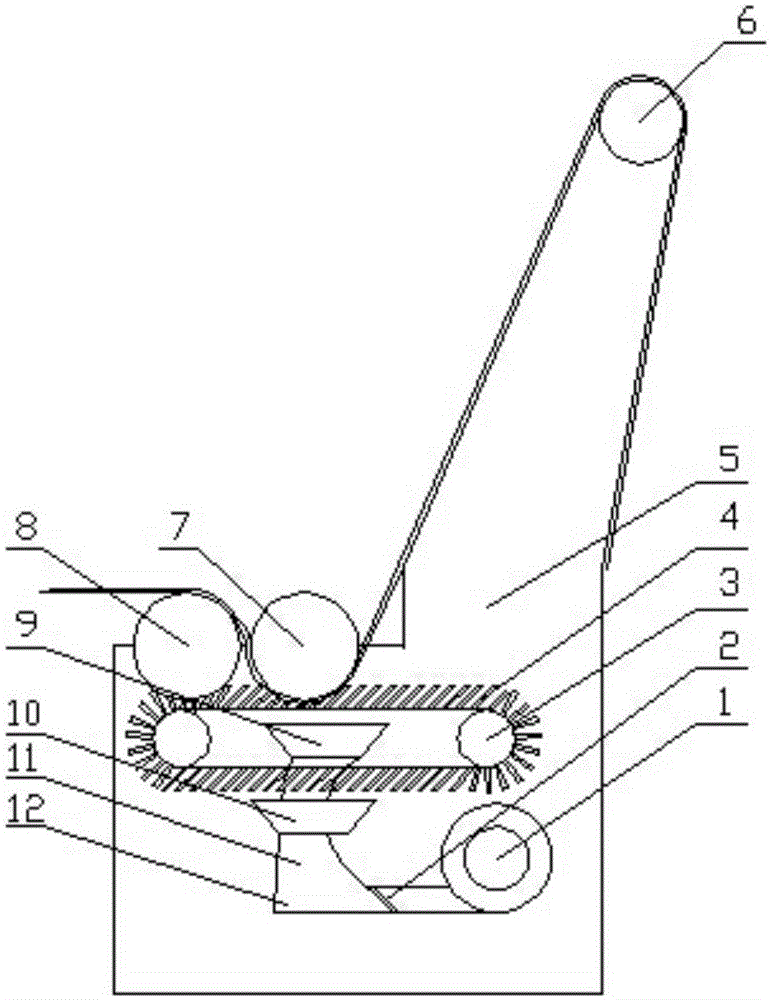

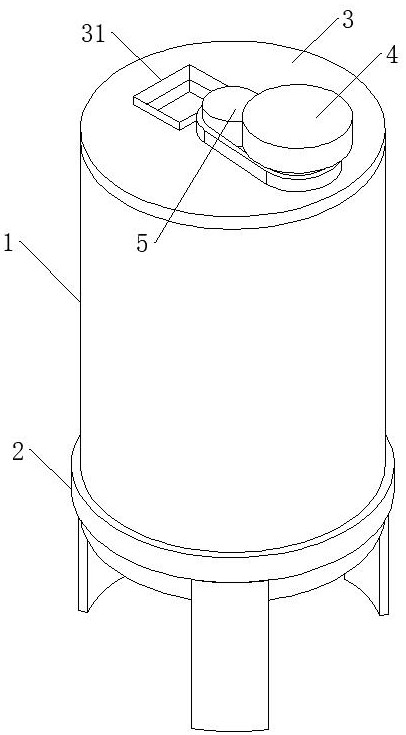

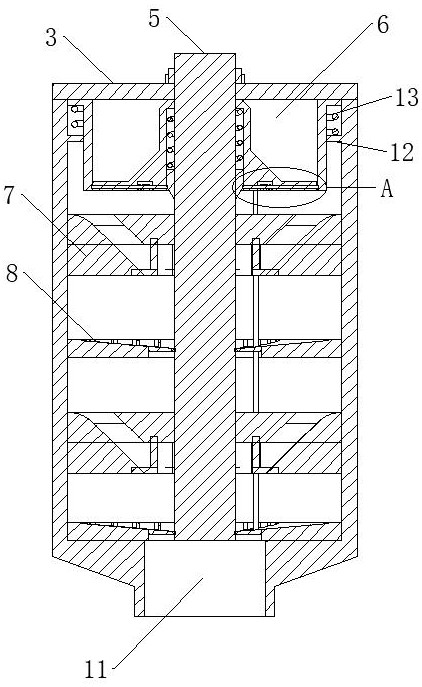

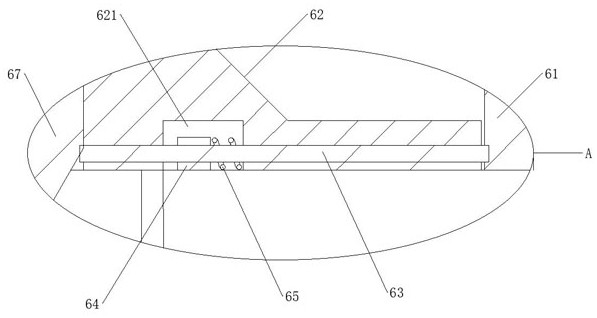

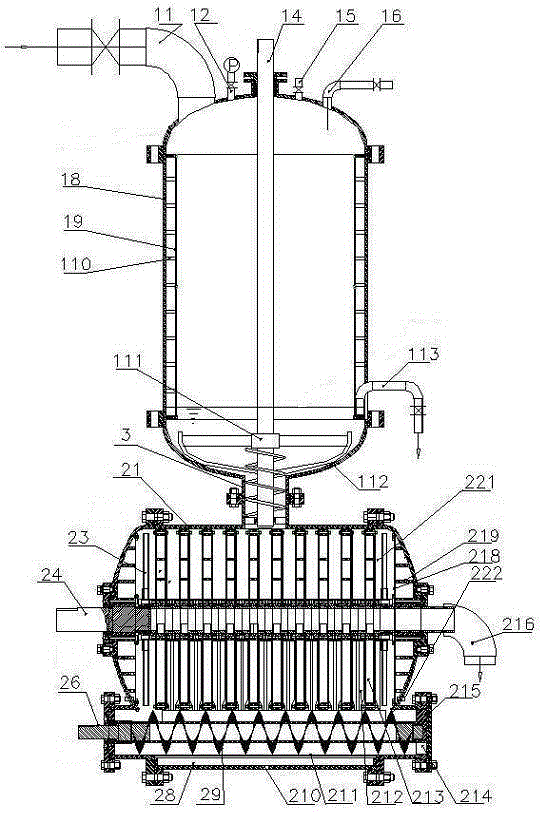

Disk type filter pressing device

ActiveCN104785002ASolve the problem that cannot be uninstalledSave pipesStationary filtering element filtersBiochemical engineeringFilter press

The invention discloses a disk type filter pressing device, which is composed of a grouting tank and a filter press, wherein the bottom end of a grouting tank shell is communicated with the top end of a filter press shell, a stirrer extending towards the filter press is arranged in the inner cavity of the grouting tank shell; a slewing shaft of the filter press horizontally penetrates through the filter press shell and is of a hollow structure; one end of the slewing shaft is communicated with a filtrate connector of the filter press; multiple disk type filter cores communicated with the inner cavity of the slewing shaft are coaxially arranged on the slewing shaft and in the inner cavity of the filter press shell; a fixed scraping plate fixed relative to the filter press shell is arranged between each two adjacent disk type filter cores; a filter press auger is arranged at the lower part of the inner cavity of the filter press shell. According to the disk type filter pressing device, the filter press auger is arranged at the lower part of the filter press, and a certain space is cleared out through the filter press auger when filter cakes are discharged; the grouting tank is directly arranged on the filter press, and thus pipelines are shortened; the stirrer is used for crushing the filter cakes in the grouting tank, so that the cakes fall into the filter press and the problem that filter cakes of an existing disk type filter pressing device cannot be discharged is solved.

Owner:江苏银鼎生物质科技有限公司

Raw material mixing device used before new material processing

PendingCN113769638AEasy to processAchieve separationRotary stirring mixersTransportation and packagingMaterials processingMechanical engineering

The invention discloses a raw material mixing device before new material processing, and relates to the technical field of new material processing. The device comprises a tank body with an opening, the tank body is vertically installed, an installation base is fixed to the bottom of the tank body, an end cover is installed on the opening in the top end of the tank body, a shaft body extending into the tank body is fixed to the end cover, and a power part driving the shaft body to rotate is installed on the end cover; a feeding port is formed in the end cover; and the shaft body is sleeved with a material collecting part, a grinding assembly and a mixing part, the material collecting part, the grinding assembly and the mixing part are all located in the tank body, the material collecting part is located on the lower side of the feeding port, and the grinding assembly and the mixing part are located on the lower side of the material collecting part. Raw materials to be mixed are added into the tank body through the feeding port, the raw materials to be mixed entering the pipe body are collected through the material collecting part and then sequentially pass through the grinding assembly and the mixing part, the raw materials to be mixed are ground and mixed through the grinding assembly and the mixing part, and later processing is facilitated.

Owner:SUZHOU SITRI WELDING TECH RES INST CO LTD

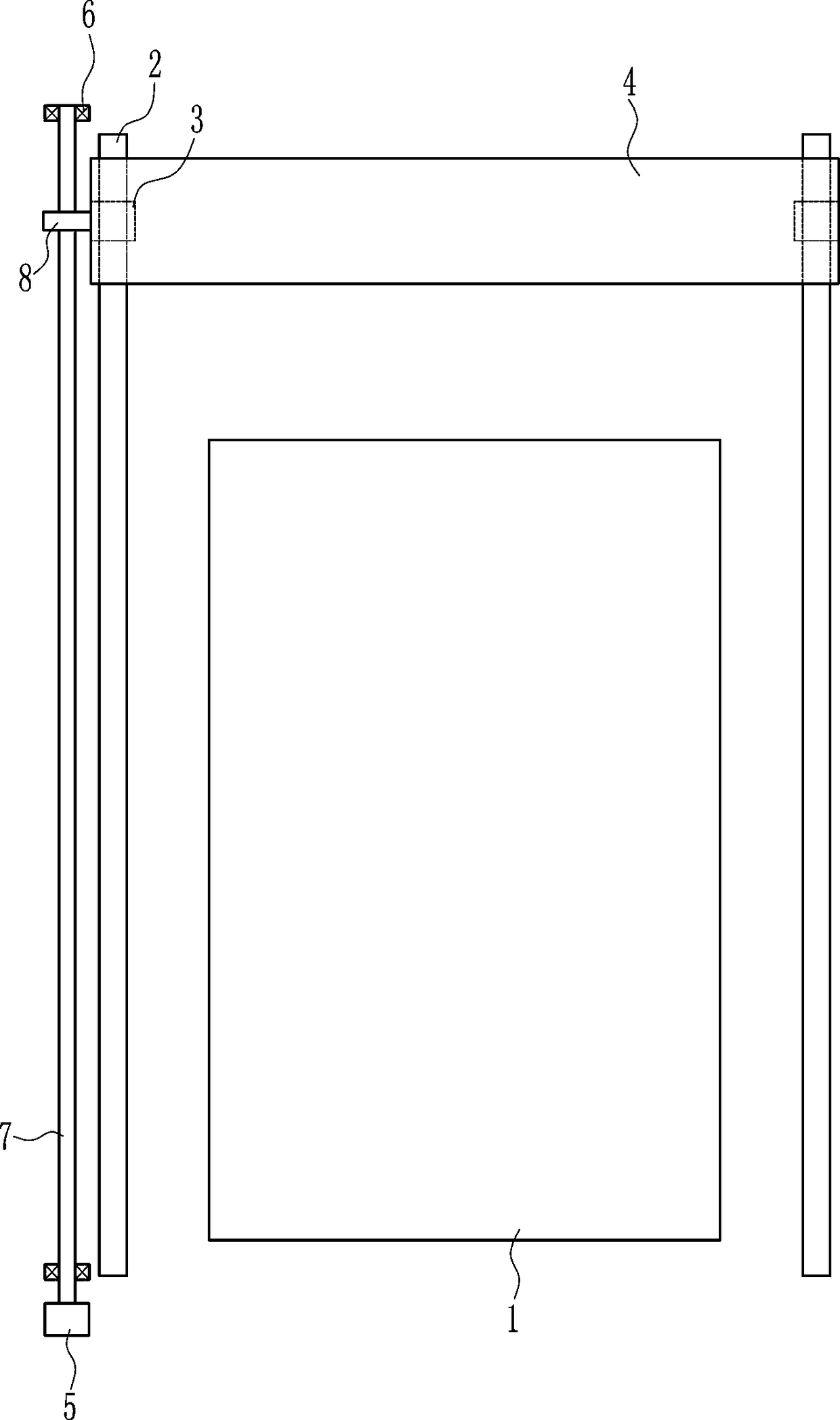

Visual chart cleaning equipment for ophthalmology

InactiveCN108636868AEasy to cleanAvoid cloggingDispersed particle filtrationDirt cleaningEngineeringVisual acuity

The invention relates to cleaning equipment, in particular to a visual chart cleaning equipment for ophthalmology. The technical problem to be solved is to provide clean and thorough cleaning, ophthalmic visual chart cleaning equipment with less operation cost of less labor. According to the technical scheme, the visual chart cleaning equipment for ophthalmology comprises a visual chart, a slide rail, a slide block , an n-shaped frame, a first motor and a first bearing seat and the like; sliding rails are arranged on the left portion and the right portion of the wall respectively, the visual chart is located between the sliding rails on the left side and the right side, sliding blocks are connected to the sliding rails in a sliding mode, an n-shaped frame is arranged between the sliding blocks on the left side and the right side, the upper part and the lower part of the left part of the wall are respectively provided with a first bearing seat, and a screw rod is connected between the first bearing seat on the upper side and the lower part of the wall. The cleaning equipment has the advantages of being thorough in cleaning, less operation cost of less labor, by arranging the n-typeframe and the brush roller, the n-type frame and the brush roller continuously move up and down, so that the effect of enabling the visual chart to be cleaned more completely and thoroughly is achieved.

Owner:班俊超

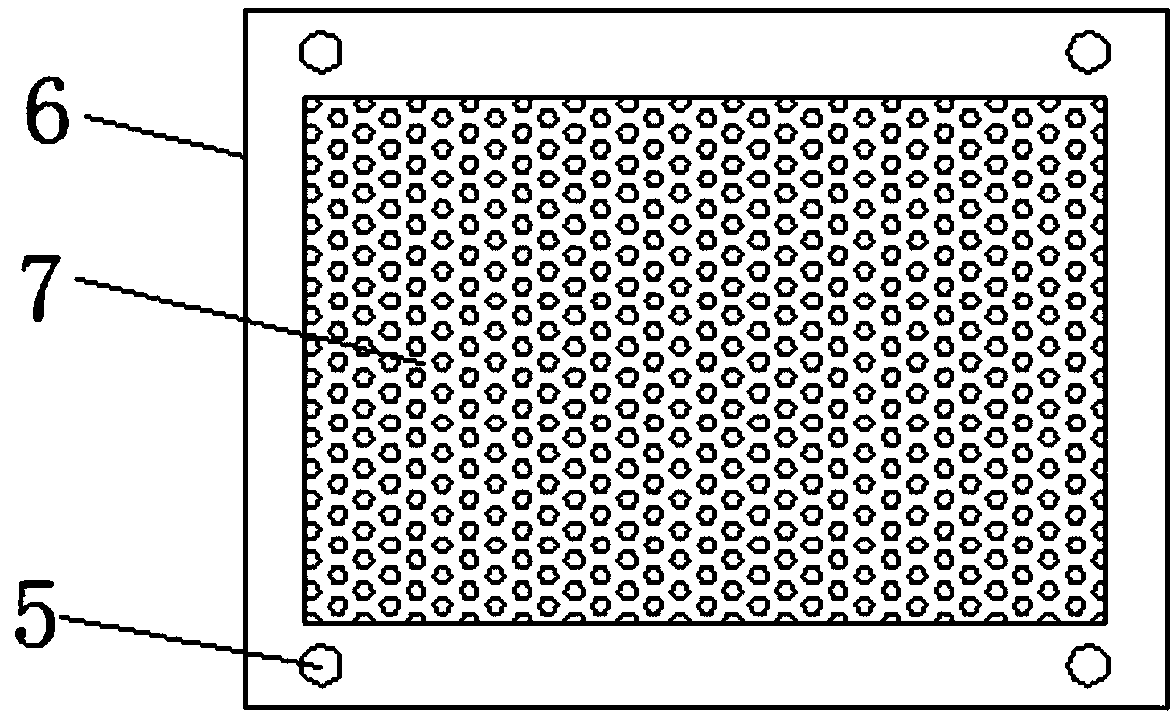

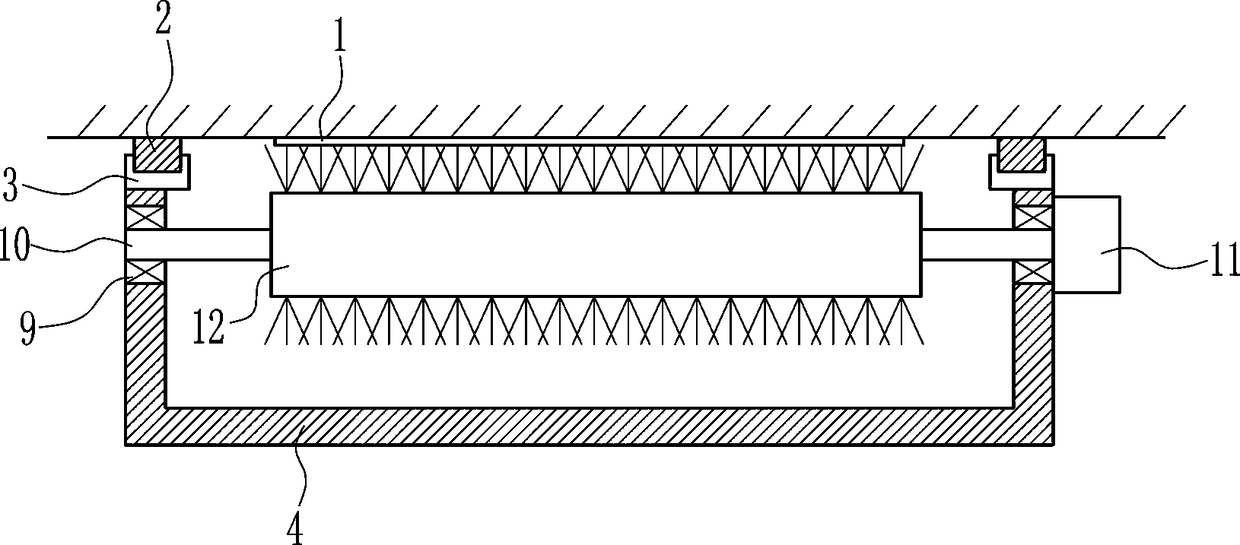

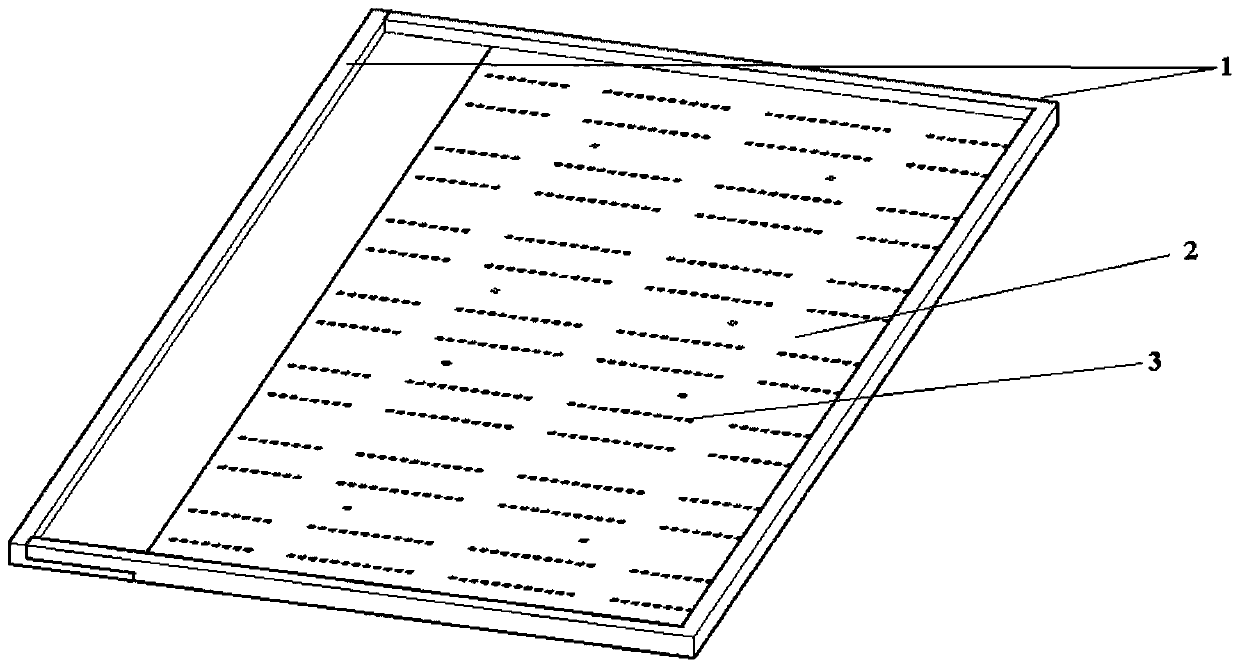

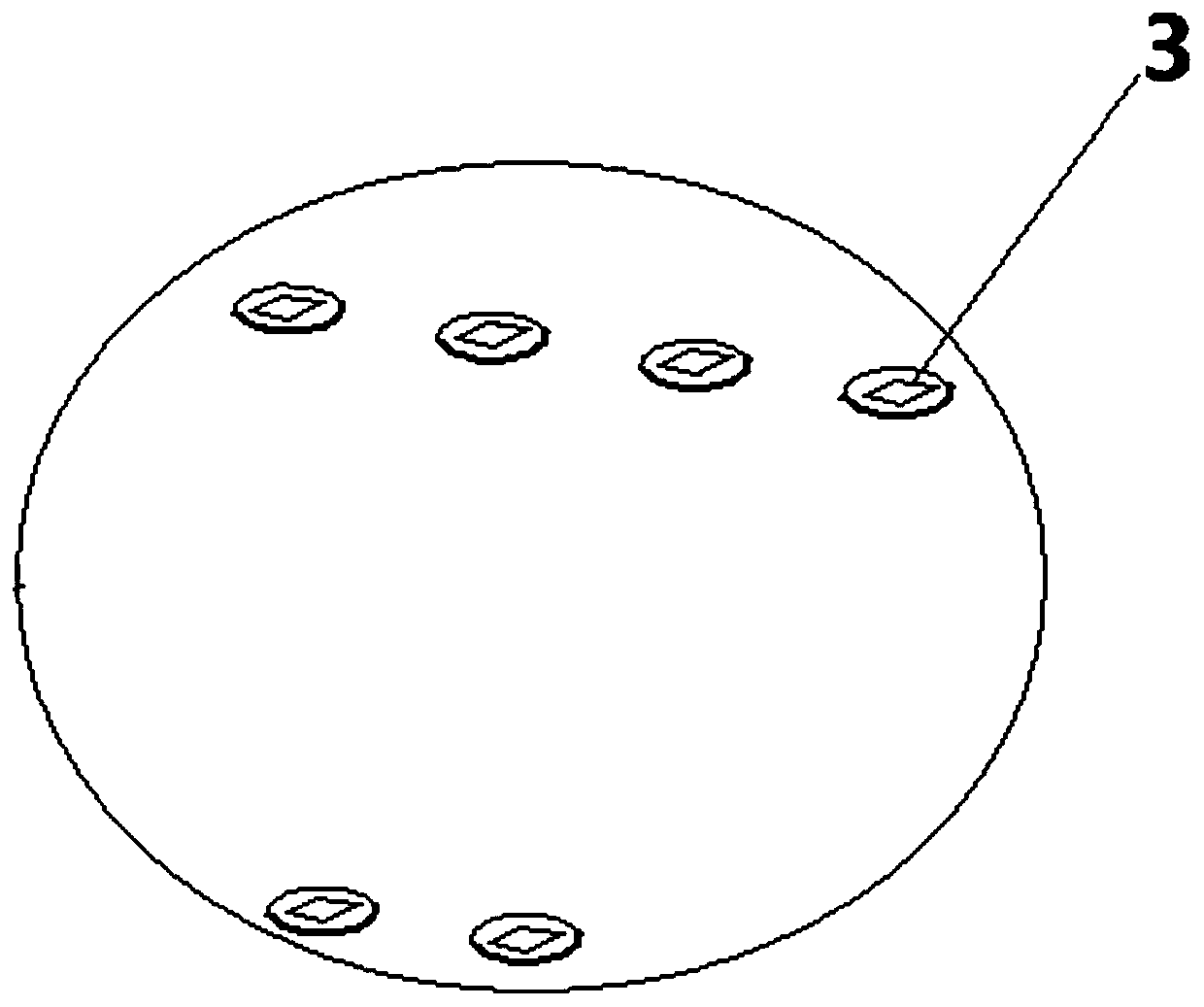

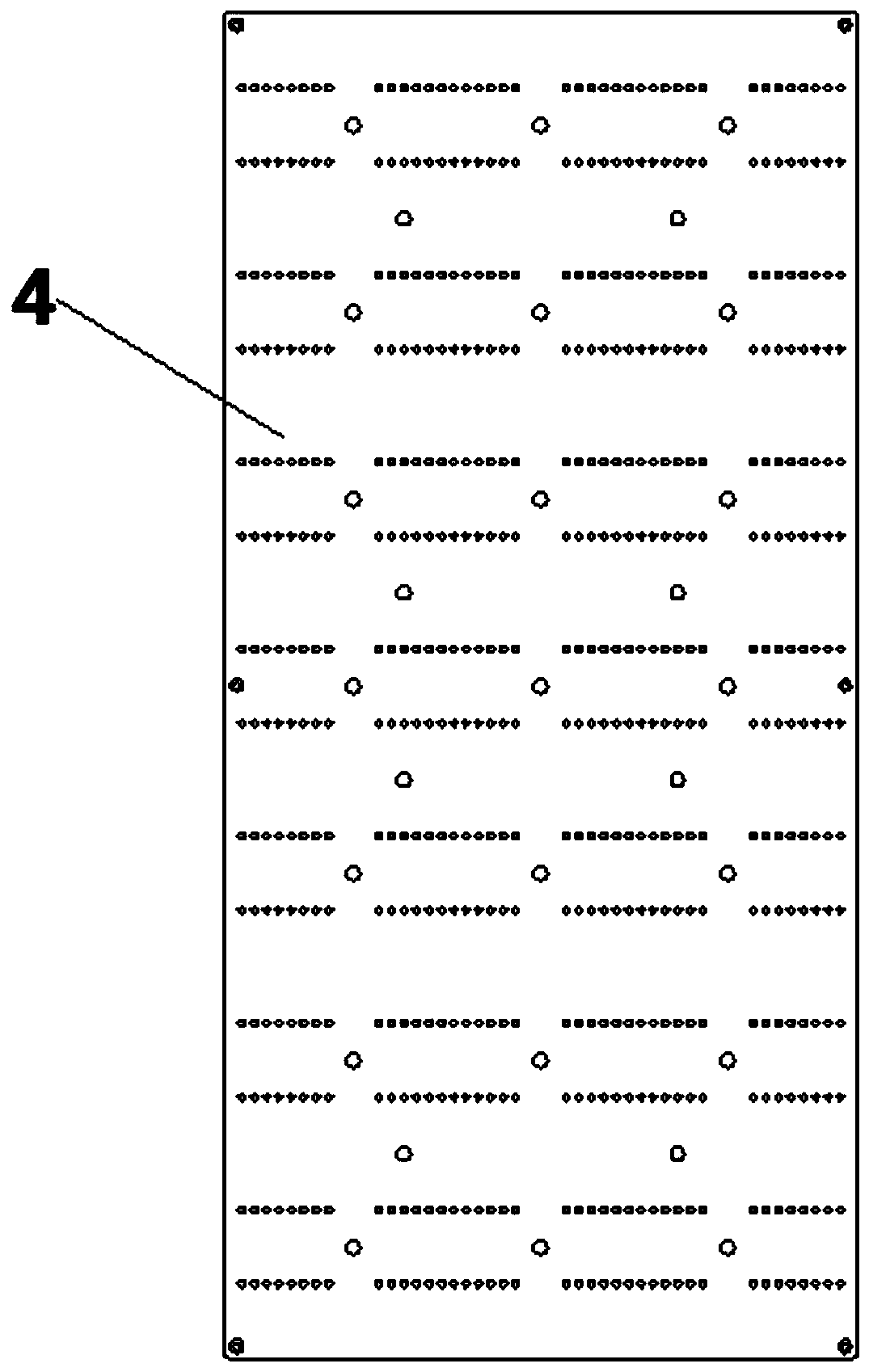

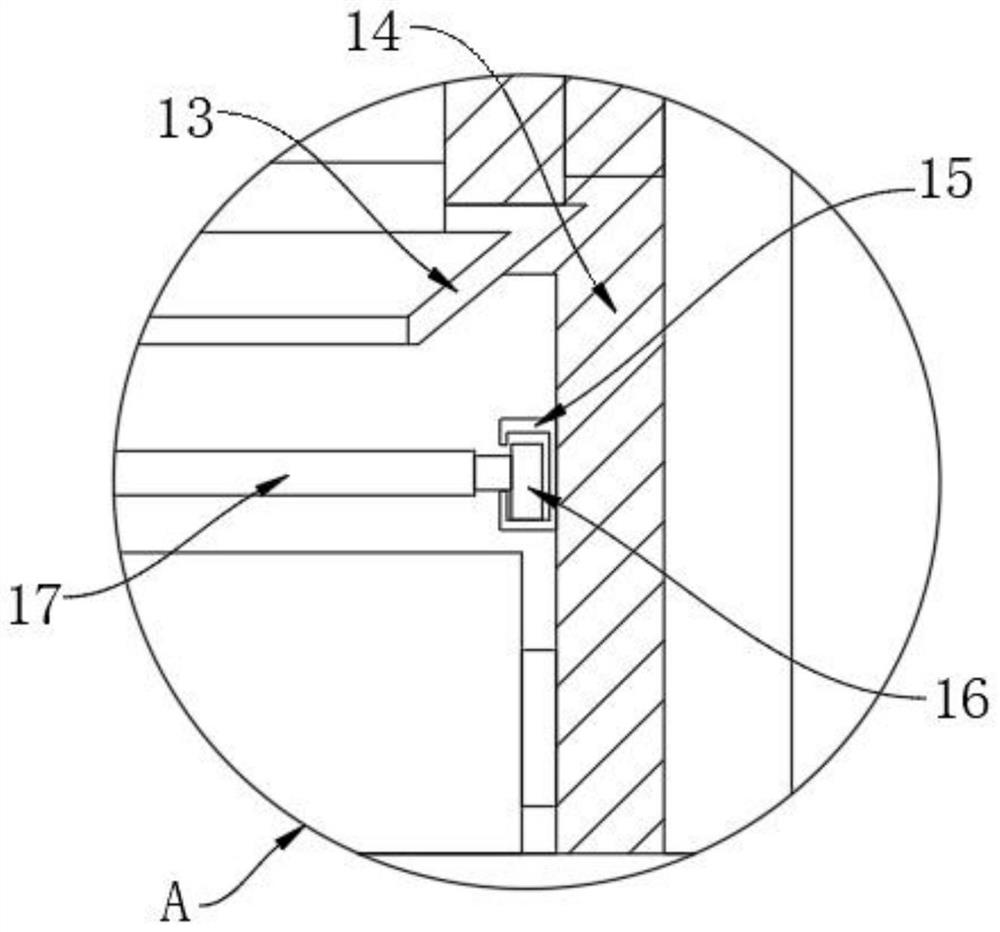

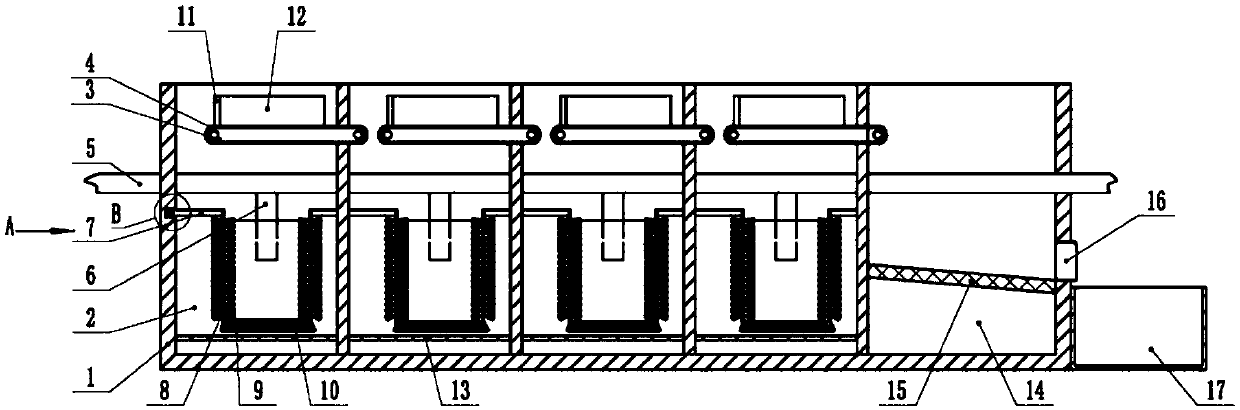

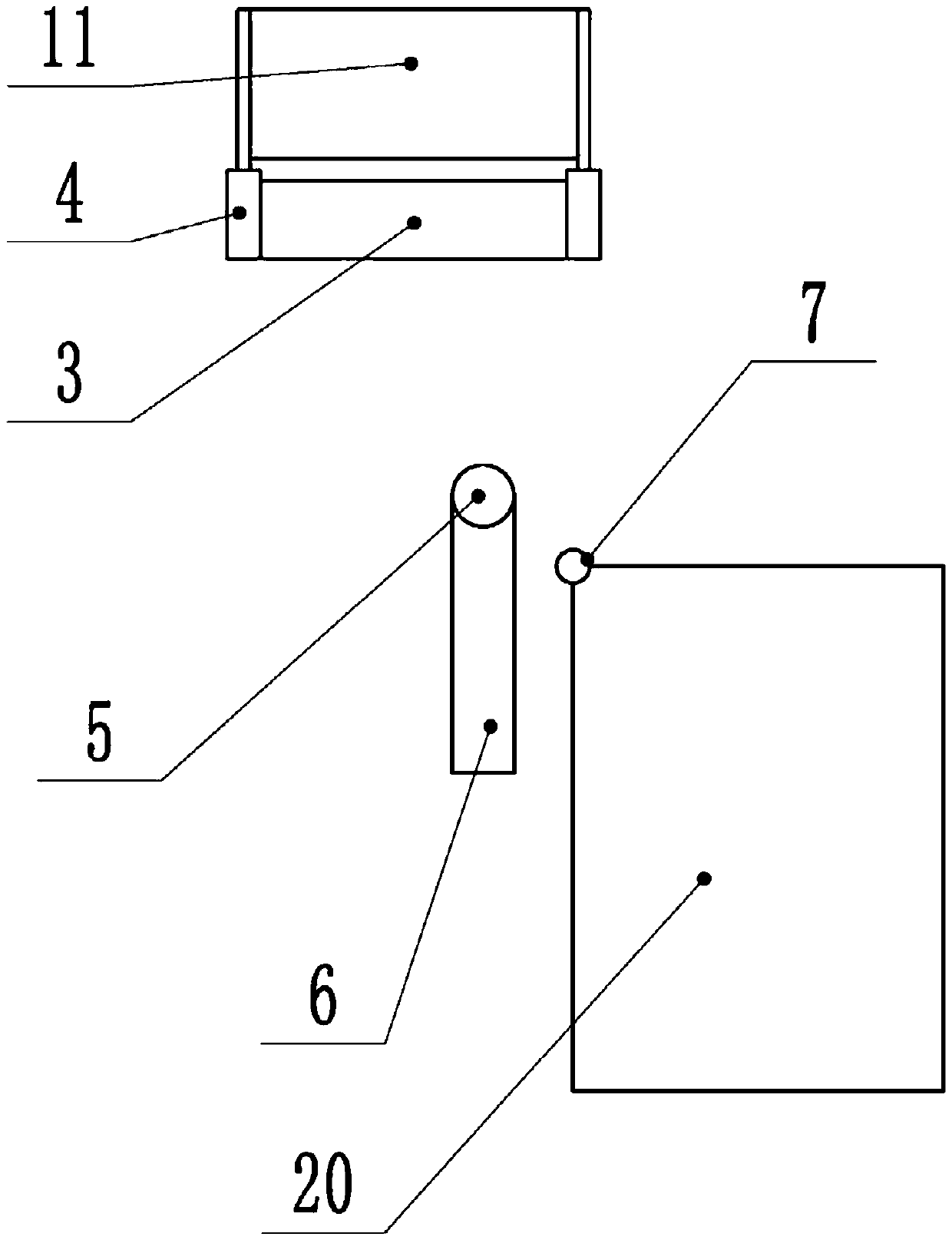

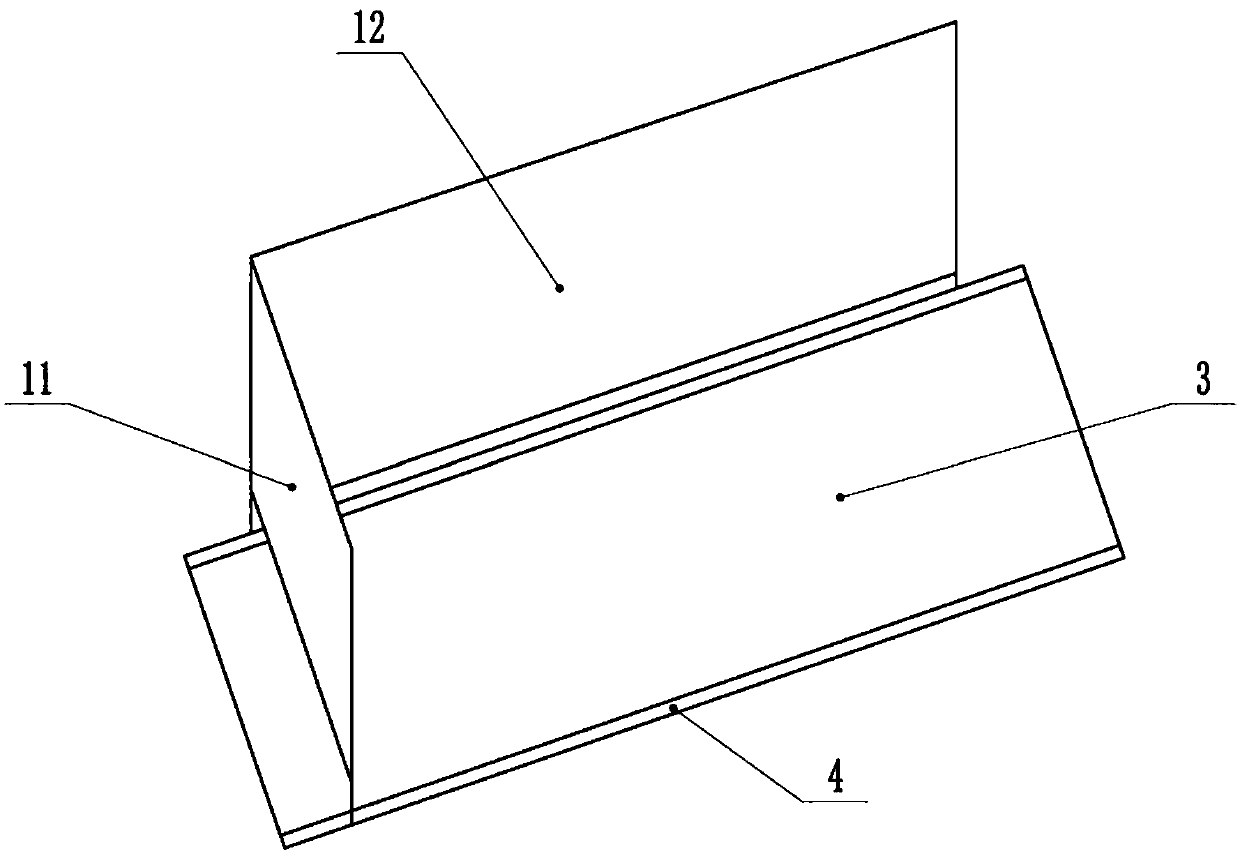

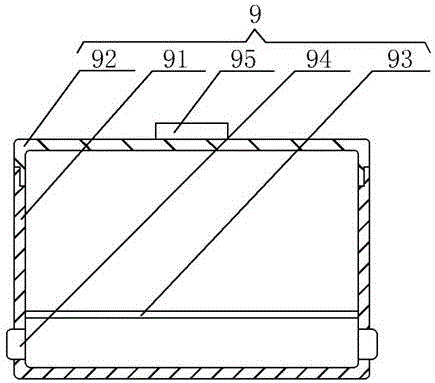

Surface-mounted leaded ceramic disc capacitor mounting burn-in device and method

ActiveCN110010377ASave operating timeImprove work efficiencyFixed capacitorsCapacitor manufactureCapacitancePower flow

The invention discloses a surface-mounted leaded ceramic disc capacitor mounting burn-in device and method. The device comprises a bushing and a burn-in plate, the bushing is provided with a pluralityof device leakage holes configured to contain devices, and the bushing is arranged on the burn-in plate and is configured to transfer the contained devices; the burn-in plate comprises a bottom plateand a pressing plate, the bottom plate is provided with burn-in holes corresponding to the device leakage holes, elastic current needles are arranged corresponding to the burn-in holes on the pressing plate, the burn-in holes on the bottom plate are connected with a negative pole, and the elastic current needles on the pressing plate are connected with the positive pole. The surface-mounted leaded ceramic disc capacitor mounting burn-in device and method are simple in operation, little in time consumption and safe and reliable in test, the number of devices which can be burnt in by a single board is not less than that of a conventional burn-in plate, the production efficiency is improved, and the cost is low.

Owner:西安太乙电子有限公司

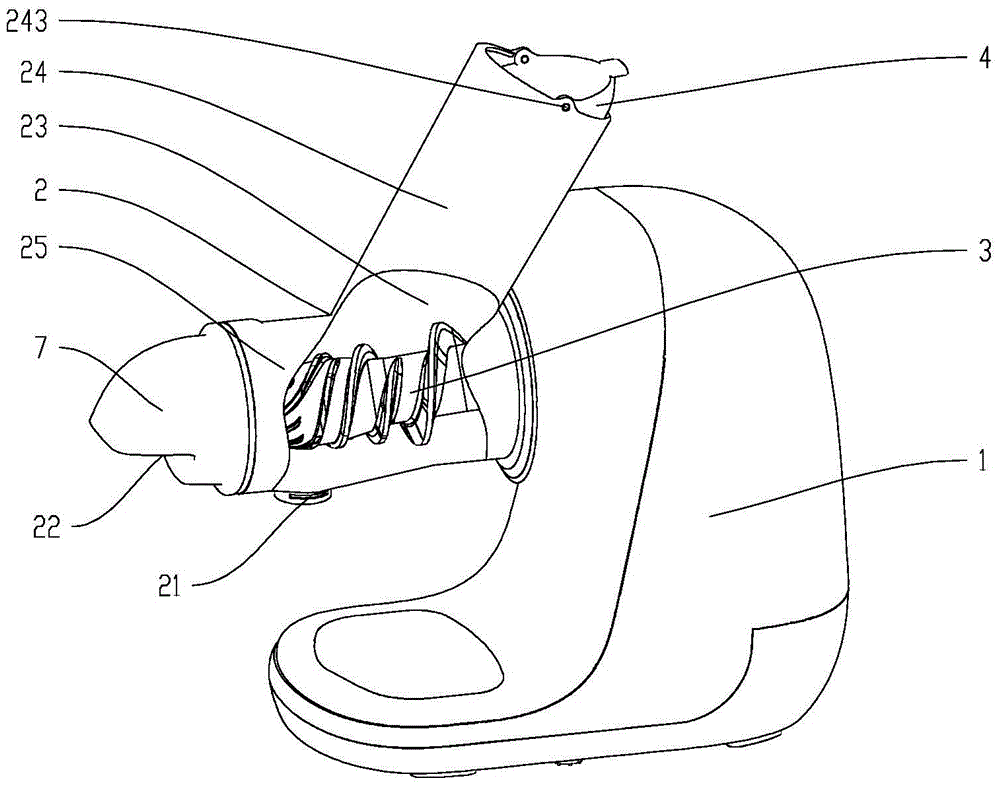

A Safe and Convenient Screw Squeeze Juicer

The invention discloses a safe and convenient screw extrusion juicer which comprises a machine base with a motor, a squeezing cavity mounted on the machine base and a screw placed in the squeezing cavity, wherein the squeezing cavity comprises a squeezing cavity body; a juice outlet and a residue outlet are formed in the squeezing cavity body; a feed inlet and a feeding channel connected with the feed inlet are formed in the squeezing cavity; the feeding channel comprises an upper end opening and a lower end opening connected with the feed inlet; a rotatable turnover object placement platform is movably arranged at the upper end opening; the rotating center of the turnover object placement platform penetrates through the upper end opening transversely; the turnover object placement platform is used for placement of materials and can rotate around the rotating center in any direction; and the materials are enabled to enter the feeding channel by rotating the turnover object placement platform by 60 degrees at least. Therefore, continuous juicing is realized, high safety in use is ensured, and accidental injury of a user is prevented; meanwhile, pretreatment of fruits and vegetables is not required, so that user operation is reduced, the user can use the juicer conveniently, and convenience for the user is increased; and the service life of the juicer is prolonged.

Owner:JOYOUNG CO LTD

A disc filter press device

ActiveCN104785002BSolve the problem that cannot be uninstalledSave pipesStationary filtering element filtersBiochemical engineeringFilter press

The invention discloses a disk type filter pressing device, which is composed of a grouting tank and a filter press, wherein the bottom end of a grouting tank shell is communicated with the top end of a filter press shell, a stirrer extending towards the filter press is arranged in the inner cavity of the grouting tank shell; a slewing shaft of the filter press horizontally penetrates through the filter press shell and is of a hollow structure; one end of the slewing shaft is communicated with a filtrate connector of the filter press; multiple disk type filter cores communicated with the inner cavity of the slewing shaft are coaxially arranged on the slewing shaft and in the inner cavity of the filter press shell; a fixed scraping plate fixed relative to the filter press shell is arranged between each two adjacent disk type filter cores; a filter press auger is arranged at the lower part of the inner cavity of the filter press shell. According to the disk type filter pressing device, the filter press auger is arranged at the lower part of the filter press, and a certain space is cleared out through the filter press auger when filter cakes are discharged; the grouting tank is directly arranged on the filter press, and thus pipelines are shortened; the stirrer is used for crushing the filter cakes in the grouting tank, so that the cakes fall into the filter press and the problem that filter cakes of an existing disk type filter pressing device cannot be discharged is solved.

Owner:江苏银鼎生物质科技有限公司

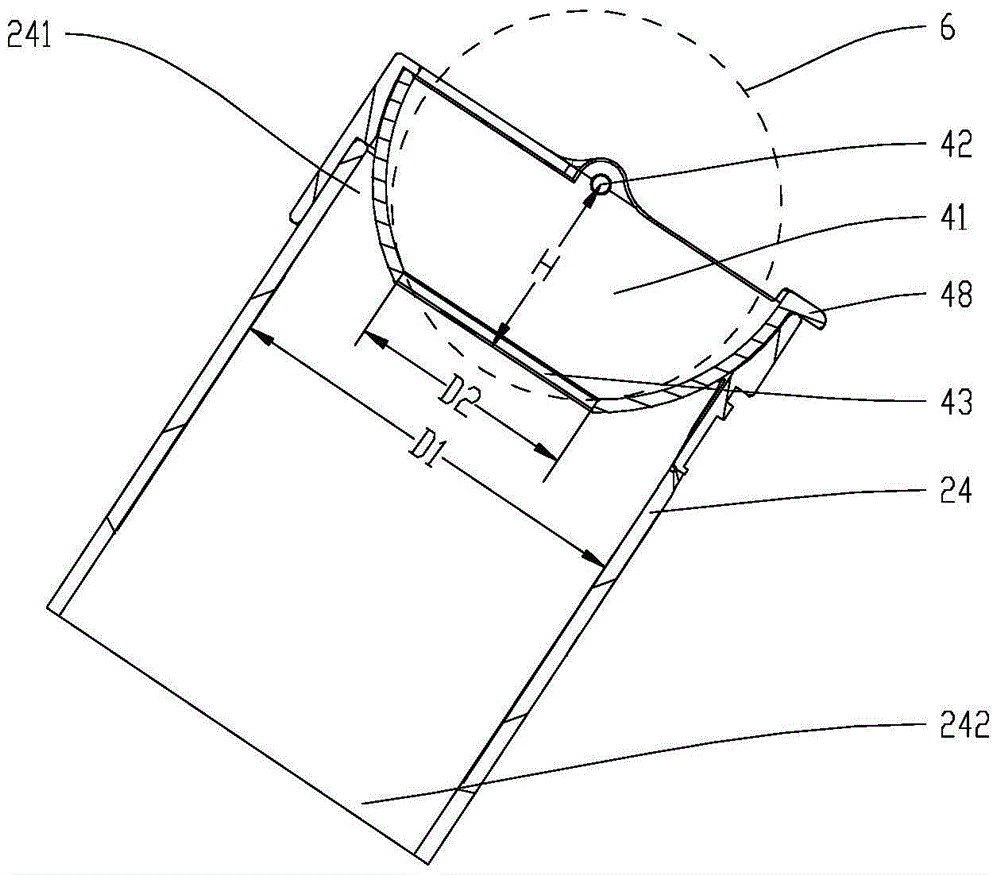

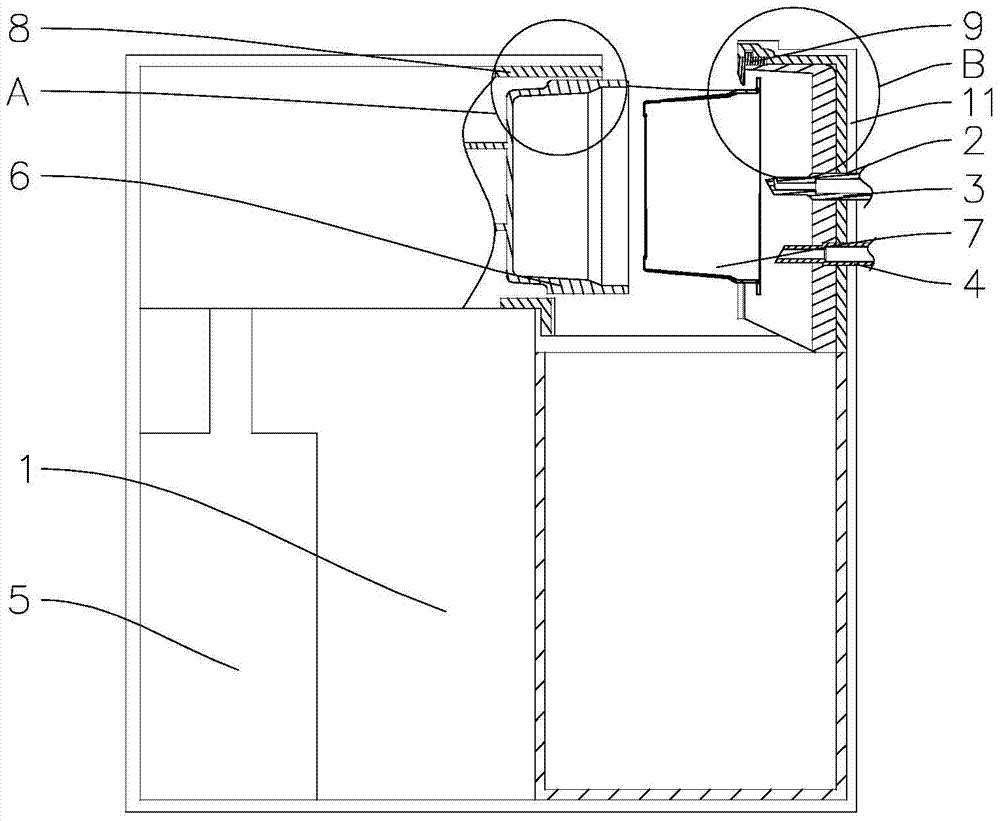

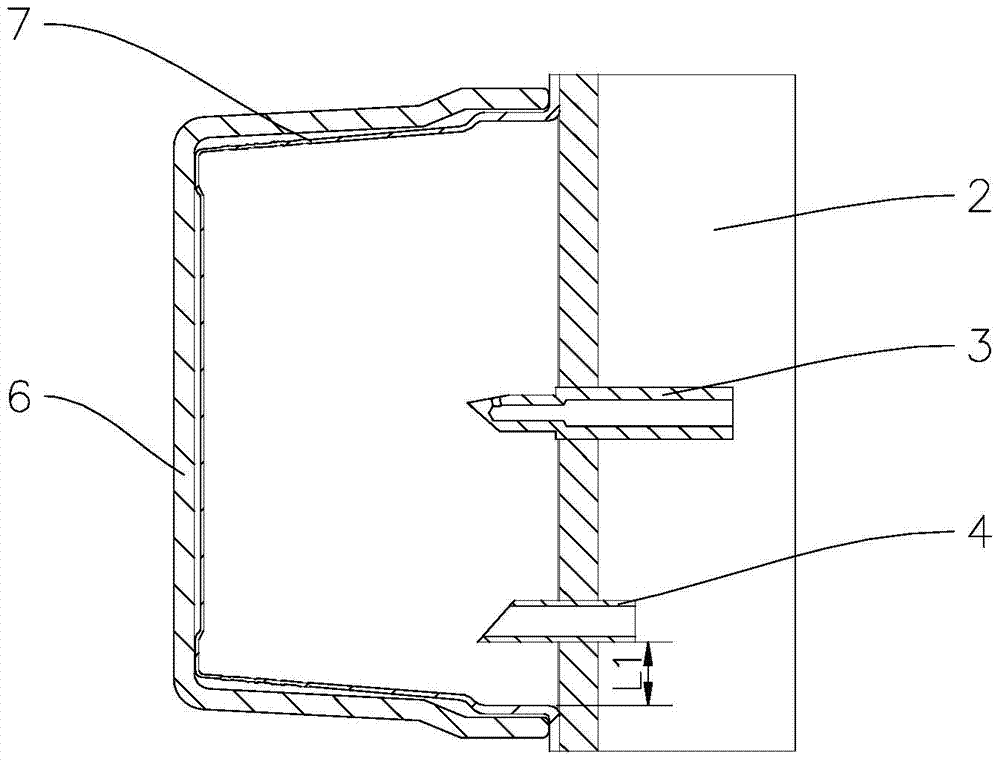

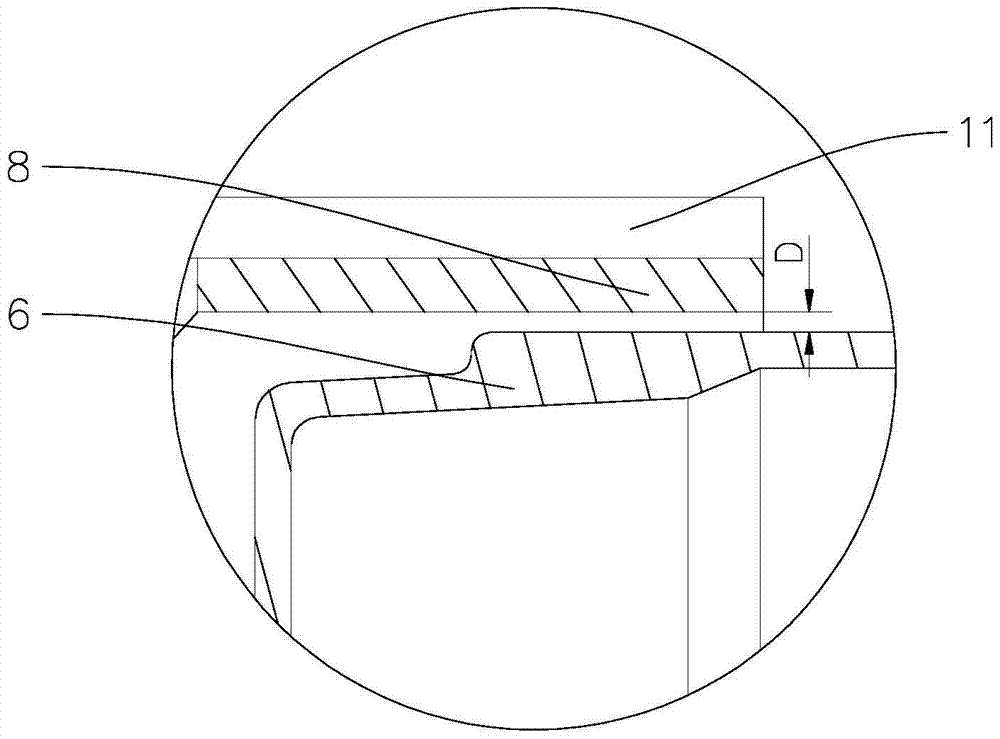

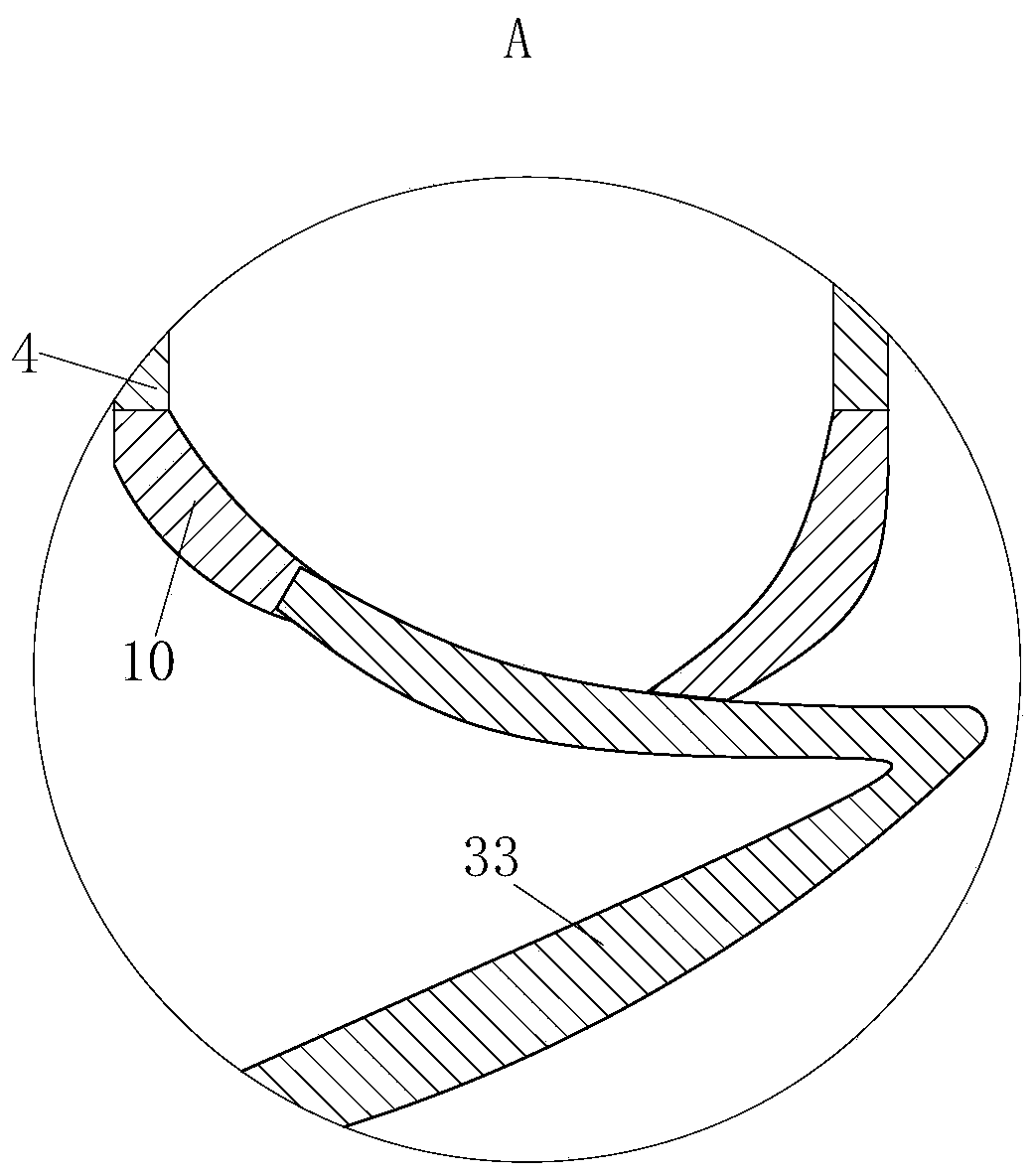

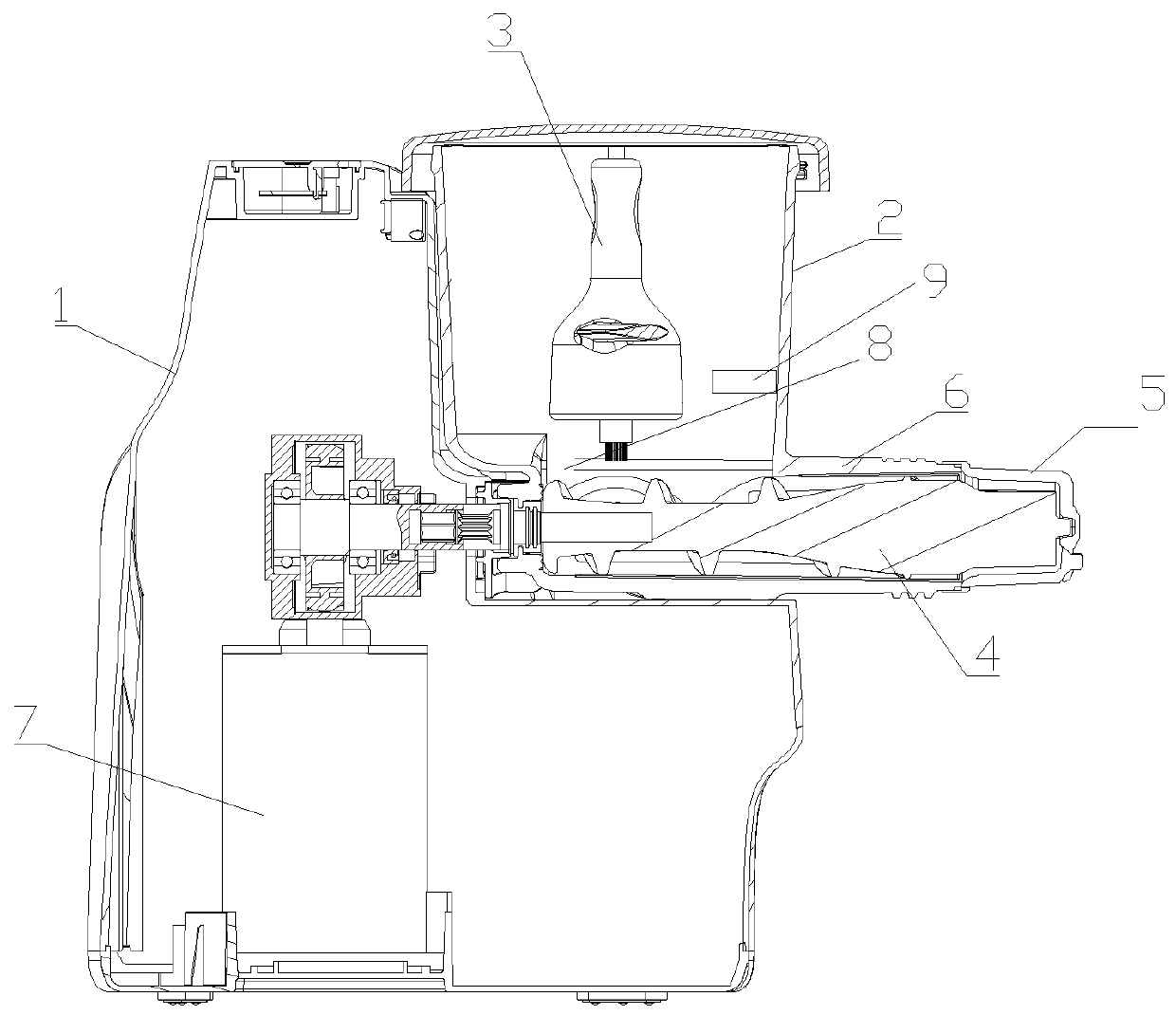

An easy-to-clean horizontal brewing beverage machine

The invention provides an easy-to-clean horizontal brewing beverage machine, which includes a machine base with a brewing chamber, a brewing head, a water inlet needle, an outlet needle, a liquid supply mechanism, and a brewing cup for accommodating a bag. The seat includes a casing, the upper surface of the casing is provided with a feeding port for feeding the material bag, and the casing is provided with a brewing rack and a driving device installed on the brewing rack, and the driving device drives the brewing cup in the brewing process. The brewing rack moves back and forth relative to the brewing head, and when the brewing cup moves to the brewing head, the brewing cup, the brewing head, and the brewing rack form a brewing cavity, and there is a seal between the brewing cup and the brewing rack. A gap is provided between the side wall of the brewing cup and the inner wall of the brewing frame, and the seal is used to prevent the slurry from spraying out from the gap, and the gap is D, 1mm≤D≤10mm. When there is spraying between the brewing head and the brewing cup, the seal prevents the slurry from spraying out from the gap, preventing the slurry from splashing into the inside of the machine base, which is not easy to clean, so as to avoid the problems of the slurry inside the machine base from smelling and breeding bacteria .

Owner:JOYOUNG CO LTD

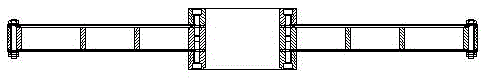

Steel wire welding device for fixed steel wire

ActiveCN113732473BIncrease production rateImprove welding qualityWelding/soldering/cutting articlesResistance welding apparatusButt weldingStructural engineering

The invention discloses a steel wire welding device applied to steel wire fixing, comprising a current control base, a welding mechanism is provided on the top of the current control base, a feeding mechanism is provided on one side of the welding mechanism, and the bottom of the feeding mechanism passes through The support rod is fixedly connected with the top of the current control base, and the side of the top of the current control base is fixedly connected with a discharge plate, and the discharge plate is located on one side of the welding mechanism. The welding mechanism includes a support seat, and the bottom of the support seat is connected to The top of the current control base is fixedly connected, and the invention relates to the technical field of steel wires. The steel wire welding device applied to steel wire fixing can effectively solve the problem that in the prior art, the existing small steel wire pair welding machine needs to be manually loaded for fixed welding during the welding process, and the efficiency is extremely low, and manual feeding is required. During the process, the centrality of the butt welding wire is not easy to adjust, which may easily cause the welding point to shift and affect the welding quality.

Owner:NANTONG SHENGYANG METAL PROD CO LTD

A duck shed cleaning device

ActiveCN105994009BEasy to separateEasy to dropSeparation devicesBird housingsEngineeringDrinking habits

The invention discloses a duck coop cleaning device, comprising a drinker and a separation plate for breeding; below the separation plate, a water receiving bucket is arranged by corresponding to the drinker, the bottom of the water receiving bucket is connected with one end of a drain pipe, the other end of the drain pipe is connected with a waste water collection device, the lower side of the water receiving bucket is connected with a support, and the upper side face of the water receiving bucket is connected with a filter plate; the bottom of the water receiving bucket is provided with a through hole, and the through hole is connected with the drain pipe. The duck coop cleaning device has the beneficial effects that sundries with bigger sizes are separated by the filter plate, and liquid falls into the water receiving bucket below, and is discharged through the drain pipe, so that the drain pipe can adopt a pipeline with a smaller pipe diameter, subsequent pipeline erection is facilitated, overall space is saved, and subsequent wastewater treatment difficulty is reduced; a shaking mechanism more facilitates the falling of the sundries, and an air drying mechanism contributes to the air drying of the sundries, so that the problem that in meat duck breeding, the environment is wet and gets worsened due to the drinking habit of meat ducks, and thus the bred ducks get ill is solved; the device is driven by one motor, and is low in overall power consumption.

Owner:NEW HOPE LIUHE

A concrete production device with automatic material control function

ActiveCN109624089BDust effectReduce the blanking distanceMixing operation control apparatusPretreatment controlStructural engineeringPipe

The invention belongs to the technical field of concrete production equipment, and particularly relates to a concrete production device with an automatic material control function. The concrete production device comprises an outer shell. A blanking hopper is arranged at the top end of the outer shell. A powder material control unit is arranged at the top end of the blanking hopper. A powder material input port is formed in the upper end of the powder material control unit. A powder material conveyor is connected to the top end of the powder material input port and is connected with a powder material storage bin. A material guiding pipe is arranged at the top end of the interior of the outer shell and is connected with the blanking hopper through a rubber hose. A water conveying pipe is arranged in the material guiding pipe. A stirring unit is arranged in the outer shell. A discharging hole is formed in the bottom end of the outer shell. The powder material control unit is used for controlling the usage amount of powder materials, so that the proportions of the balance weights of water and the powder materials can be accurately controlled, and the proportions of the materials for concrete are more uniform, and quality indexes such as concrete strength are better. The water conveying pipe is arranged in the material guiding pipe, so that the phenomenon that dust flies in the outer shell is avoided.

Owner:湖南郴建集团泰湘新型材料有限公司

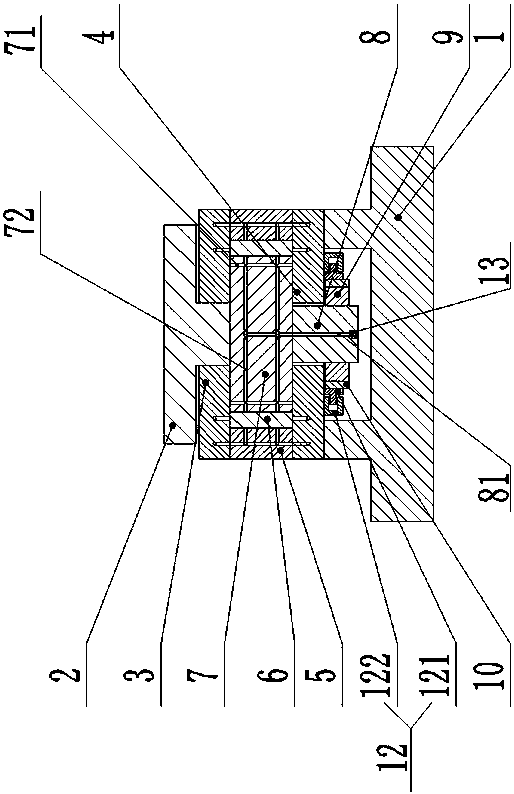

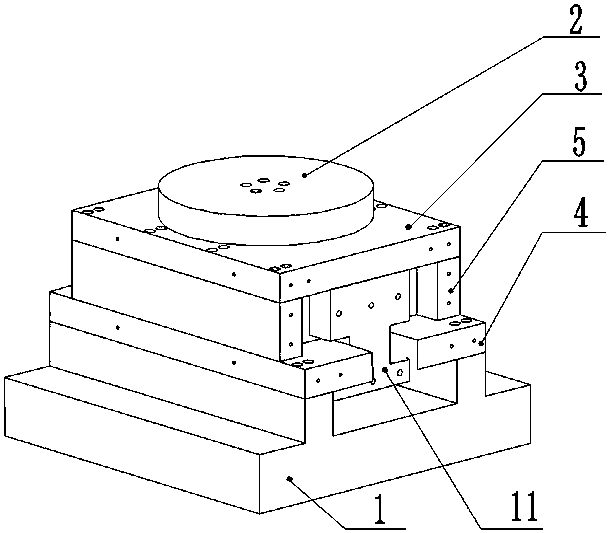

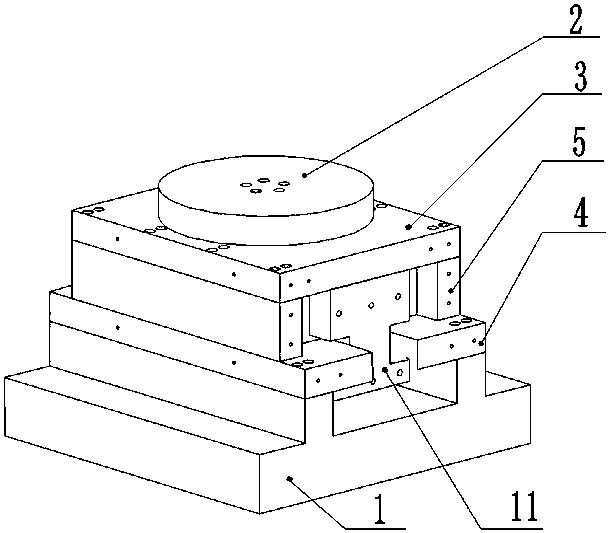

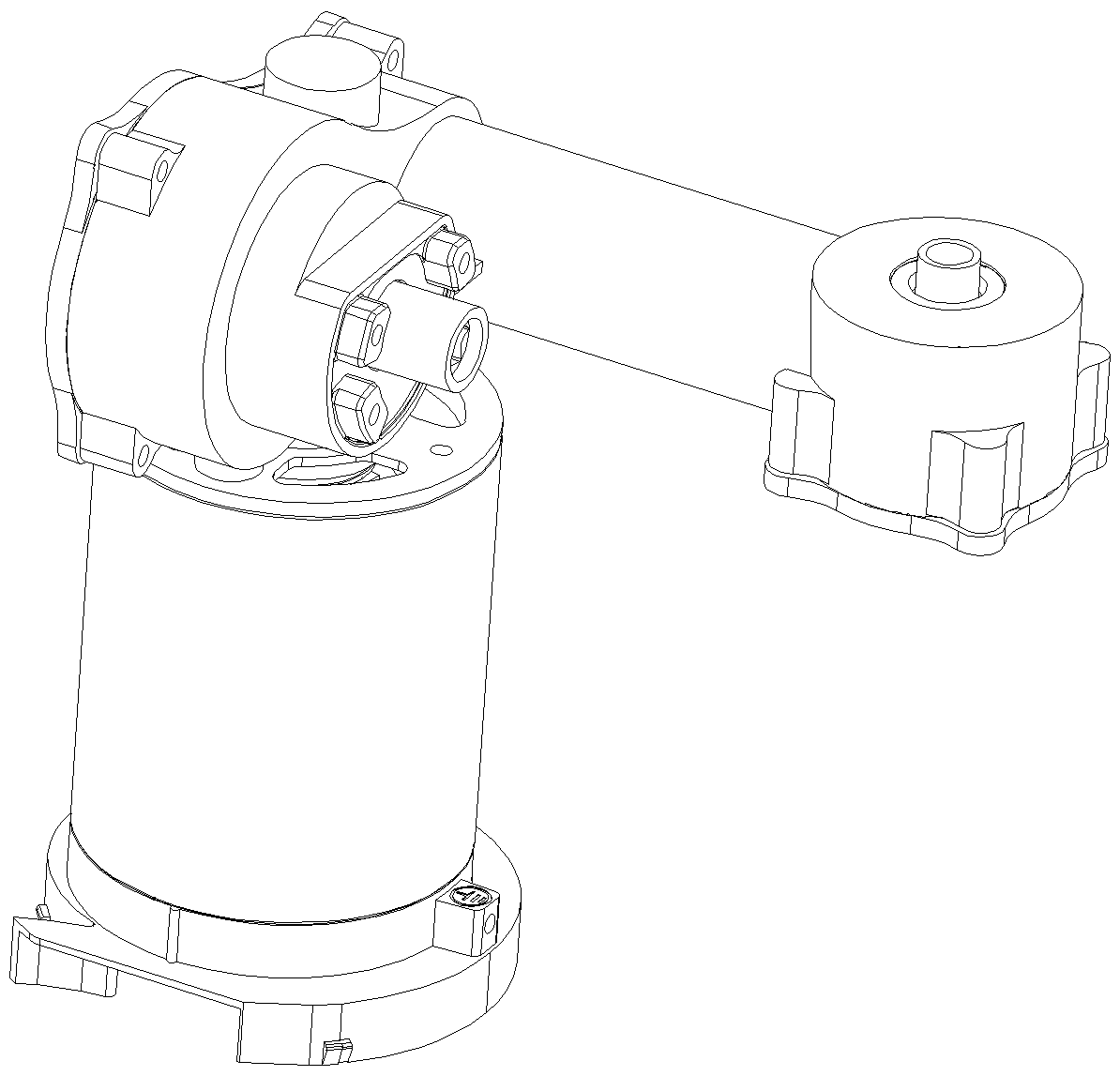

A high-precision two-dimensional hydrostatic motion system combined with a linear axis and a rotary axis

ActiveCN109163013BReduce mistakesHigh precisionGas cushion bearingsTorque motorPrecision engineering

Owner:HARBIN INST OF TECH

Biomass fuel hot-blast stove hearth structure

InactiveCN112460792AIncrease the burning areaAchieve complete combustionAir heatersHot air ovenProcess engineering

The invention discloses a biomass fuel hot-blast stove hearth structure. The structure comprises a base, wherein an air blower is fixedly connected to the upper surface of the base, an air supply pipeis fixedly connected to the side face of the air blower, a fixing frame is fixedly connected to the upper surface of the base, a hot-blast stove is arranged on the inner wall of the fixing frame, a smoke guide pipe is fixedly connected to the upper surface of the hot-blast stove, a hot air guide pipe is arranged on the upper surface of the hot-blast stove, and a fuel funnel is arranged on the side face of the hot-blast stove. According to the biomass fuel hot-blast stove hearth structure, air can be generated by arranging the air blower, the air blown by the air blower can be conveyed into amain hearth of the hot-blast stove by arranging the air supply pipe, then combustion air distribution of the main hearth is uniform, biomass fuel can be accumulated by arranging a material collectingnet, the main hearth and a sub hearth are arranged, a combustion area of the biomass fuel is increased, and the biomass fuel is combusted more sufficiently in the hearth, so that the effect that the fuel can be combusted completely is achieved.

Owner:铜陵美天新能源科技有限公司

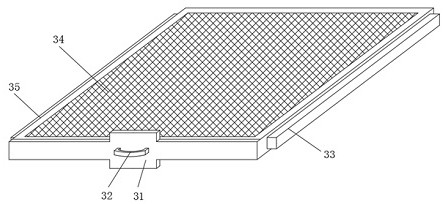

Processing device for pickled ginger

The invention belongs to the technical field of processing of pickled ginger, and particularly discloses a processing device for pickled ginger. The device comprises a motor and a cleaning box, the cleaning box is partitioned into several cleaning chambers, and a conveying mechanism used for conveying ginger to the next adjacent cleaning chamber is arranged between two adjacent cleaning chambers;a rotary shaft is arranged on the cleaning box and penetrates through all the cleaning chambers, an output shaft of the motor drives the rotary shaft to rotate, cleaning grooves used for scooping up ginger are rotatably connected with the side walls of the cleaning chambers, supporting bars used for pushing the cleaning grooves to be overturned to the conveying mechanisms and pouring ginger are fixedly connected with the rotary shaft, blocking doors are arranged at the ends, close to the supporting bars, of the cleaning grooves, and openings are formed in the ends, away from the cleaning grooves, of the supporting bars. The processing device is used for washing ginger in the ginger pickling process, the washing efficiency is improved, and ginger can be washed more cleanly.

Owner:贵州省桐梓县康利绿色食品有限公司

Garbage incinerator feeding device with multiple screening structures

PendingCN112344333ACompletely brokenThe filtering effect is thoroughIncinerator apparatusProcess engineeringIncineration

The invention provides a garbage incinerator feeding device with multiple screening structures. The garbage incinerator feeding device with the multiple screening structures comprises an incinerator body, a first crushing mechanism, a secondary crushing mechanism, an aeration mechanism and a conveying mechanism. A feeding pipe is arranged in the middle of the top of the incinerator body; a crushing bin is formed in the incinerator body; the first crushing mechanism is arranged at the upper position in the crushing bin; and a filtering mechanism is detachably arranged in the crushing bin and located below the first crushing mechanism. According to the garbage incinerator feeding device with the multiple screening structures provided by the invention, the first crushing mechanism and the secondary crushing mechanism are arranged, so that the first crushing mechanism and the secondary crushing mechanism can crush garbage; meanwhile, a second filter screen is arranged below the first crushing mechanism, and a third filter screen is arranged below the secondary crushing mechanism, so that the crushed garbage can be filtered through the second filter screen and the third filter screen; and the mesh diameter of the third filter screen is smaller than the mesh diameter of the second filter screen, so that the garbage subjected to multiple screening is ensured to be crushed and filteredmore thoroughly.

Owner:常德中联环保电力有限公司

A kind of wheat germ processing roller grinder

ActiveCN110420679BIncrease in sizeAvoid cloggingGrain huskingGrain polishingAgricultural scienceWheat germ

The invention relates to the technical field of wheat processing, in particular to a wheat germ processing roller crushing machine which comprises a base. An acquiring box and a stepping motor are mounted on the base, a connecting box is communicated with the upper portion of the acquiring box, at least one group of atomizers and a heater are mounted in a moisturizing and steaming box, a flow meter is arranged on a water conveying pipe, the other end of the water conveying pipe is connected onto a water pump, one side of a C-shaped sealing plate is connected with a pushing rod of a pushing rodmotor, a pressing and puncturing mechanism is mounted in the connecting box, a second motor is mounted at the top of the acquiring box, a beating and falling mechanism is mounted in the acquiring boxand connected with the stepping motor in a driven manner, and a filter portion is mounted at the bottom of the acquiring box. According to the crushing machine, wheat is moisturized by hot air, the moisturized wheat is punctured, so that germs are beaten and then fall off, the punctured wheat is 'flexibly' and integrally beaten by a high-speed rotation joint beating rod, and the wheat germs are rapidly and efficiently acquired.

Owner:BENGBU COLLEGE

High-precision two-dimensional static pressure movement system combining straight axle and revolving axle

In order to improve the assembly precision of a static pressure platform, the invention records a high-precision two-dimensional static pressure movement system combining a straight axle and a revolving axle. The high-precision two-dimensional static pressure movement system comprises a base, a workbench, an upper thrust plate, a lower thrust plate, a transition sliding block, a round sliding block and the like, wherein the transition sliding block is arranged between the upper thrust plate and the lower thrust plate; the upper end and the lower end of a side thrust plate are respectively fixed to two sides of the upper thrust plate and the lower thrust plate; the round sliding block is arranged in a central hole in the transition sliding block; the bulge of the workbench penetrates through the central hole of the upper thrust plate to be connected with the round sliding block; a torque motor connection column penetrates through the central hole of the lower thrust plate to be connected with the round sliding block; a torque motor is mounted on the torque motor connection column and is placed in the central hole of a connecting plate in a matching manner; the upper end and the lower end of an end surface connecting plate are respectively fixed to the transmission sliding block and the connecting plate; the connecting plate is connected with the lower thrust plate through a linear motor; the lower thrust plate is fixed to the base. The high-precision two-dimensional static pressure movement system disclosed by the invention belongs to the technical field of precision engineering, and has the advantages of being small in comprehensive error, high in precision, and low in mounting and adjusting difficulty.

Owner:HARBIN INST OF TECH

A packable fruit picker

ActiveCN109618662BEasy to fall intoFall into easyPackaging fruits/vegetablesPicking devicesStructural engineeringKnife blades

The invention proposes a packable fruit picking device, which includes a picking mechanism and a packaging mechanism. The picking mechanism includes a main rod, a casing and a toothed blade, the toothed blade is placed on the top side of the casing, and the casing is placed on the top of the main rod; The packaging mechanism includes a tray, a rotary telescopic knife, a movable grab hook, a sleeve, an auxiliary rod and a net bag. The sleeves are connected, and the other end is fixed on the main rod through a connecting piece; the main rod is provided with a movable grapple, the net bag is covered on the sleeve and the auxiliary rod, and the top hook of the net bag is stuck on the movable grapple; The main rod moves up and down. In the present application, after the casing covers the fruit, the fruit handle is cut with a toothed blade, and the fruit falls directly into the packaging mechanism. At the same time, the movable grapple lifts the net bag to facilitate packaging of the falling fruit, and the rotating telescopic knife cuts off the excess net bag, while the active grapple that has not been put down wraps the fruit support to prevent the fruit from falling before being taken away.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

A sweeping robot with a device for cleaning chewing gum

The invention discloses a floor-sweeping robot with a device for cleaning chewing gum. The structure includes a floor-sweeping robot, a counterweight, a boom, a telescopic cylinder, and a scraper. One end of the sweeping robot is connected to a boom, and the tail of the boom is connected to the telescopic cylinder Vertical welding, a scraper is connected to the bottom of the telescopic cylinder, and a counterweight is provided at the end of the sweeping robot opposite the boom. , Sponge roller, the inside of the shell is equipped with a rotary scraper, a collection tank, and a sponge roller in sequence from front to back, a floor cleaner tank is provided on the rear side of the sponge roller, and a liquid transfer roller is provided above the floor cleaner tank. The invention is beneficial The effect is: the chewing gum is scraped off by the wave-shaped scraper, and the chewing gum can be smoothly pushed out of the scraper for collection with the gradual introduction of the push roller. Clean up and get smarter.

Owner:山东海拓天宇智能机器人有限公司

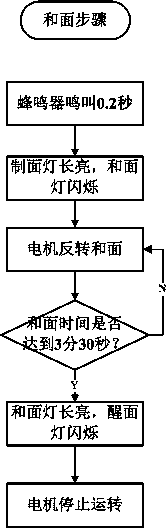

An intelligent noodle making method for a household noodle machine

ActiveCN104920527BStable Rotational Inertial ForceAvoid idlingMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsMotor driveResidual method

An intelligent noodle making method for a home noodle machine. The invention discloses a noodle making method which is convenient for the dough to fall quickly, has high noodle making efficiency and has no residue on the dough. The method for making noodles includes at least the following steps: kneading step: the motor drives the stirring rod to rotate in the opposite direction, the stirring rod stirs the flour and water, and mixes them into dough; extrusion molding step: the motor drives the stirring rod to rotate in the forward direction , the dough is driven by the stirring rod to enter the extruding cylinder from the noodle inlet, and the extruding screw rotates forwardly under the drive of the motor, and pushes the dough into the extruding cylinder forward to the die head, thereby extruding into noodles; During the extrusion molding step, the stirring rod rotates at different speeds.

Owner:JOYOUNG CO LTD

Electronic automatic toilet bowl seat defecation treating device

The invention provides an electronic automatic toilet bowl seat defecation treating device which comprises frameworks, handrails, large wheels, small wheels, a seat plate, a defecation opening, a controller, a toilet bowl device, a toilet bowl shell, a gypsum filling body, a spray head, a discharge outlet, a treating device, a box body, a cover body, a liquid filter plate, a sucking opening, a feed inlet and deodorant solution storage pots. The handrails are fixedly installed on the two sides of the frameworks. The large wheels are arranged on the outer sides of the handrails. The frameworks are further provided with small wheels. The seat plate is installed between the frameworks and provided with the defecation opening. The bottom of the defecation opening is fixedly connected with the toilet bowl device. The two sides of the toilet bowl device are provided with the deodorant solution storage pots. A treating device is installed at the bottom of the toilet bowl device. The framework on the left is further provided with a controller. By arranging the toilet bowl device, the odor removal and cleaning can be automatically carried out after the device is used, so that no odor is left when a user uses the device for the second time, and the heavy psychological burden of the user is reduced.

Owner:史慧亮

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com