Packer with low-pressure setting and low-tension unsealing

A packer and pulling force technology, which is applied in sealing/isolation, wellbore/well components, earthwork drilling and production, etc., can solve the problem that the rubber cartridge cannot be recovered, the packer unsealing mechanism step by step and the unsealing space are not in a closed state Intracavity, stuck well and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

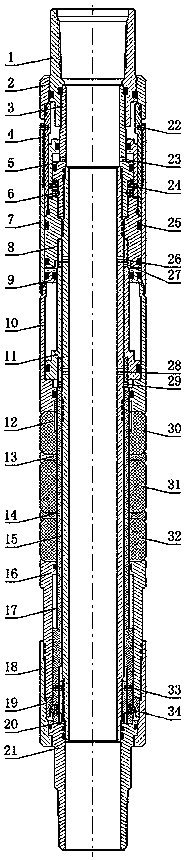

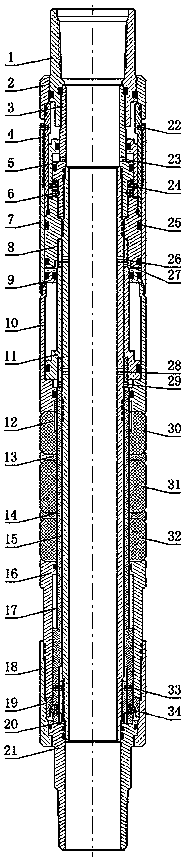

[0025] The implementation process of the present invention is further described through the following drawings, but the technical solution of the present invention is not limited.

[0026] Such as figure 1 As shown, in the present invention, the upper joint 1 and the upper core pipe 3 are connected by threads, and the upper core pipe 3 and the center pipe 15 are connected by threads; Inside the lock ball seat 8, the disconnecting piston 5 is sleeved on the upper core tube 3 and the lock ball seat 8, and the disconnection sleeve 4 and the lock ball seat 8 are threaded; the jumper 25 is sleeved in the lock ball seat 8 groove, Circlip 25 is provided with outer clamping teeth, and lock sleeve 7 covers are located at disjoint sleeve 4, clamp spring 25, lock ball seat 8, upper piston 9 outside, lock sleeve 7 tops have inner clamping teeth, lock sleeve 7 bottoms and upper overcoat 10 The upper part is connected by thread; the upper piston 9 is sleeved on the outside of the upper out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com