Dedusting device for roll forming machine

A technology of dust removal device and roll forming machine, applied in cleaning methods and tools, cleaning methods using tools, chemical instruments and methods, etc., can solve problems affecting production efficiency, equipment failure, production stagnation, etc., and achieve better dust removal effect , Dust removal effect is effective

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

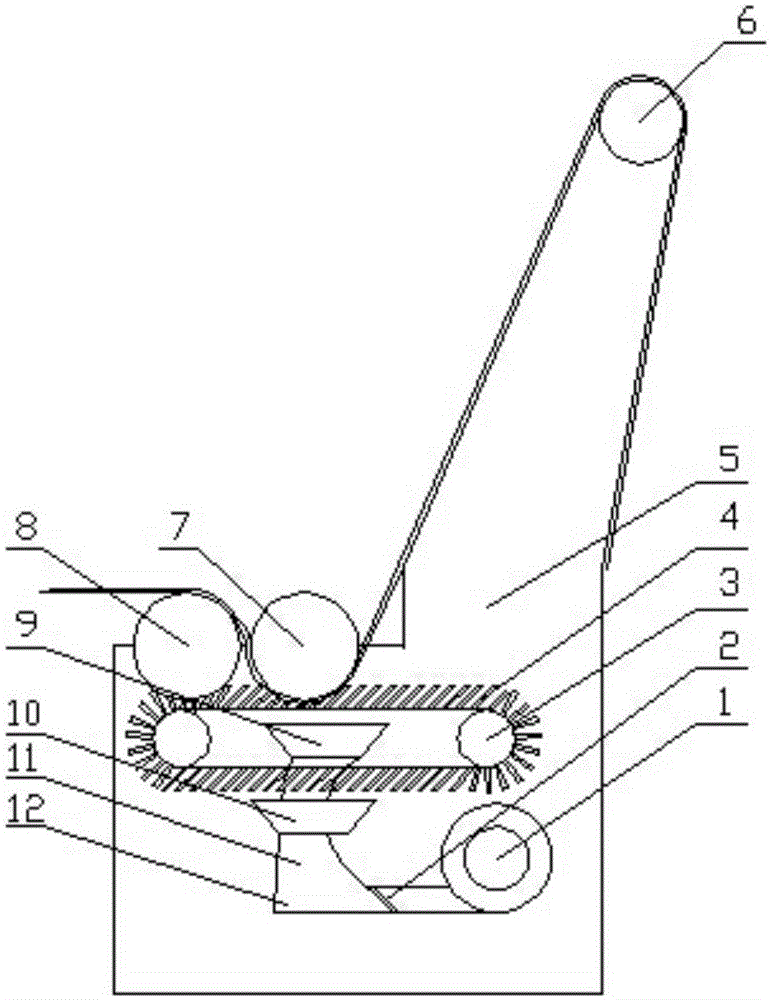

[0013] like figure 1 As shown, a lapping machine dust removal device includes a frame 5, a dust removal device 12, a pressure roller 7, a discharge roller 8, and a feed roller 6. The dust removal device 12 is located directly below the pressure roller 7. The dust removal device 12 includes a suction fan 1, an upper hopper 9, a lower hopper 10, a conveyor belt 3, and a soft brush 4; Connected; dust suction bag 11 is located directly below upper hopper 9 and lower hopper 10; upper hopper 9 is located directly below the upper conveyor belt, and lower hopper 10 is located directly below the lower conveyor belt, and an inclined soft brush 4 is installed on the conveyor belt 3; The roller 7 is located directly above the conveyor belt 3 and is in physical contact with the soft brush 4; the soft brush 4 is inclined at a certain angle, and there is a gap between the soft brush 4, and impurities can pass through the gap from the inclined soft brush 4 Slide into the upper and lower hopp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com