Steel wire welding device for fixed steel wire

A welding device and steel wire fixing technology, applied in welding equipment, welding/welding/cutting items, resistance welding equipment, etc., can solve the problems of difficult adjustment of welding steel wire centrality, influence on welding quality, welding point offset, etc., and achieve improvement Welding quality, consistent centrality, and the effect of preventing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

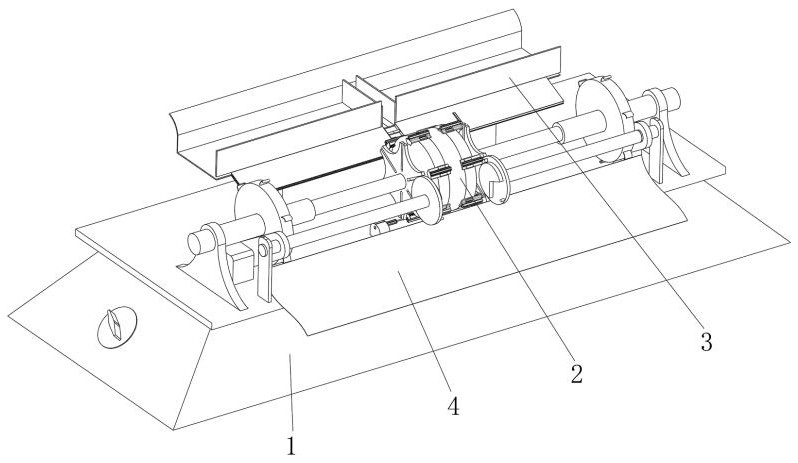

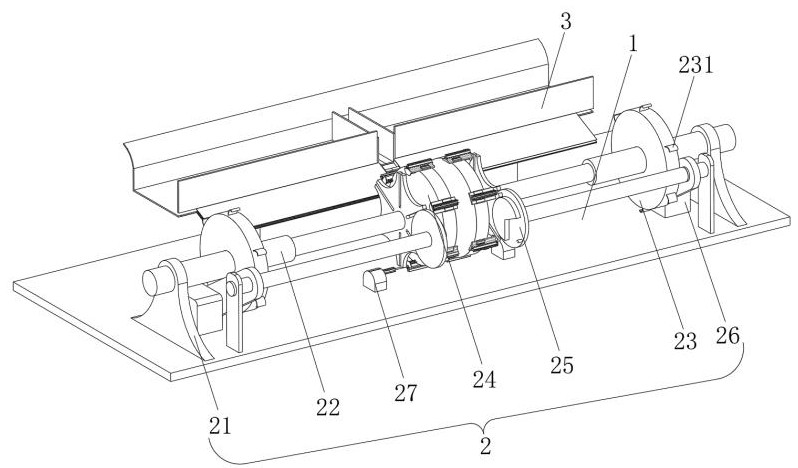

[0033] see Figure 1-7 , the present invention provides a technical solution: a steel wire welding device applied to steel wire fixing, comprising a current control base 1, a welding mechanism 2 is provided on the top of the current control base 1, a feeding mechanism 3 is provided on one side of the welding mechanism 2, and the upper The bottom of the feeding mechanism 3 is fixedly connected with the top of the current control base 1 through the support rod, and the side of the top of the current control base 1 is fixedly connected with a discharging plate 4, and the discharging plate 4 is located on the side of the welding mechanism 2;

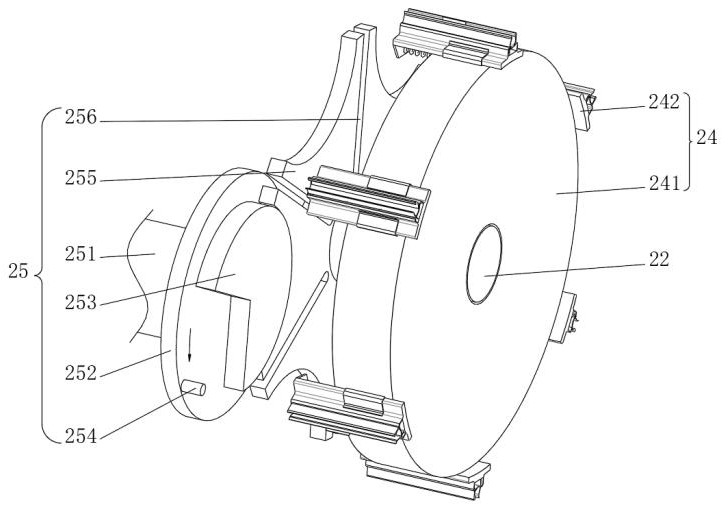

[0034] The welding mechanism 2 includes a support base 21, the bottom of the support base 21 is fixedly connected with the top of the current control base 1, the support base 21 is rotatably connected with an adjustable rotating rod 22, and one end of the rotating rod 22 is fixedly connected with a disengagement prevention wheel 23, which pre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com