A disc filter press device

A disc type, filter press technology, applied in the direction of fixed filter element filter, filtration separation, chemical instruments and methods, etc., can solve the problems of unloading filter cake, filter cake clogging, etc., to avoid clogging and accelerate pressure The effect of filtering speed and improving work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

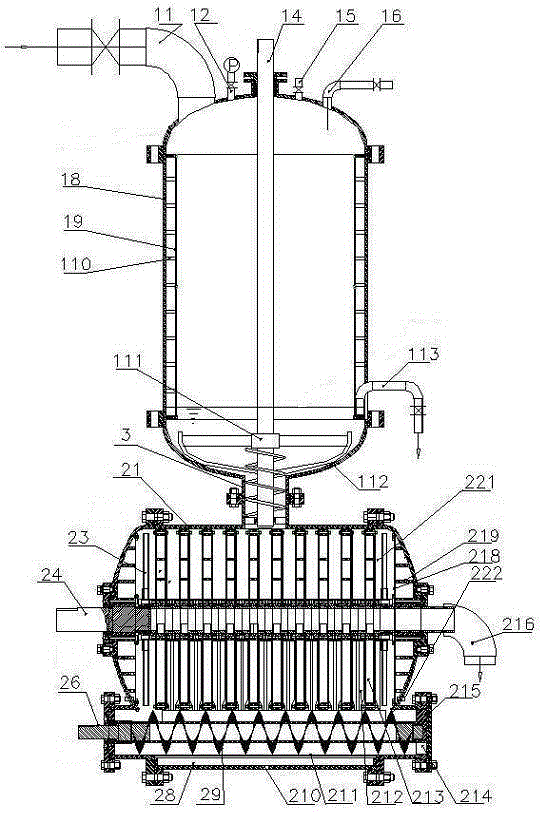

[0023] like figure 1 A kind of disc filter press device shown is made up of a slurry tank and a filter press, and the bottom end of the slurry tank housing 18 communicates with the top of the filter press housing 21 through a transition pipe 3; The inner chamber of the housing 18 is provided with an agitator 111 extending to the filter press, and the stirring shaft 14 of the agitator 111 vertically penetrates the grouting tank housing 18, which is located at the bottom of the grouting tank housing 18 and is connected with a Stirring paddle, the bottom end of which is inserted into the transition pipe 3 is connected with a vertically arranged auger; the rotary shaft 24 of the filter press runs through the filter press housing 21 horizontally, and the rotary shaft 24 is a hollow structure, and one end of the rotary shaft Connected to the filter press filtrate interface 216, a plurality of disc filter elements 213 connected to the cavity are coaxially installed on the rotary shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com