Pump system and ink path system of small character inkjet printer

A technology of inkjet printer and pump system, which is applied in the field of inkjet printers, can solve the problems of high production and maintenance costs, large space occupation, and large wear of mechanical parts, so as to reduce the difficulty of assembly and maintenance and reduce the occupied space , the effect of preventing ink precipitation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be described in further detail below in conjunction with the accompanying drawings and working principles, but it is not intended to limit the protection scope of the present invention.

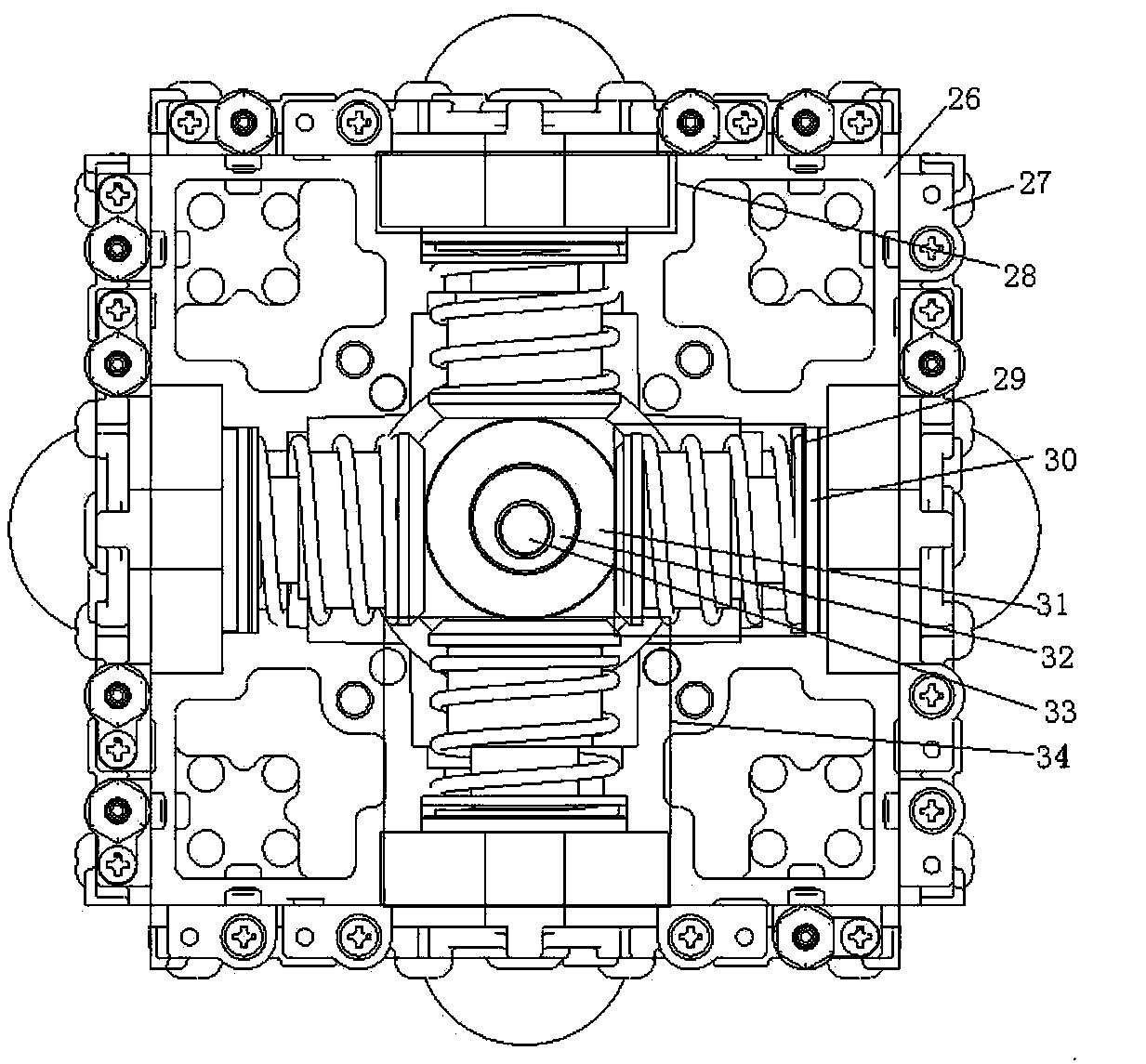

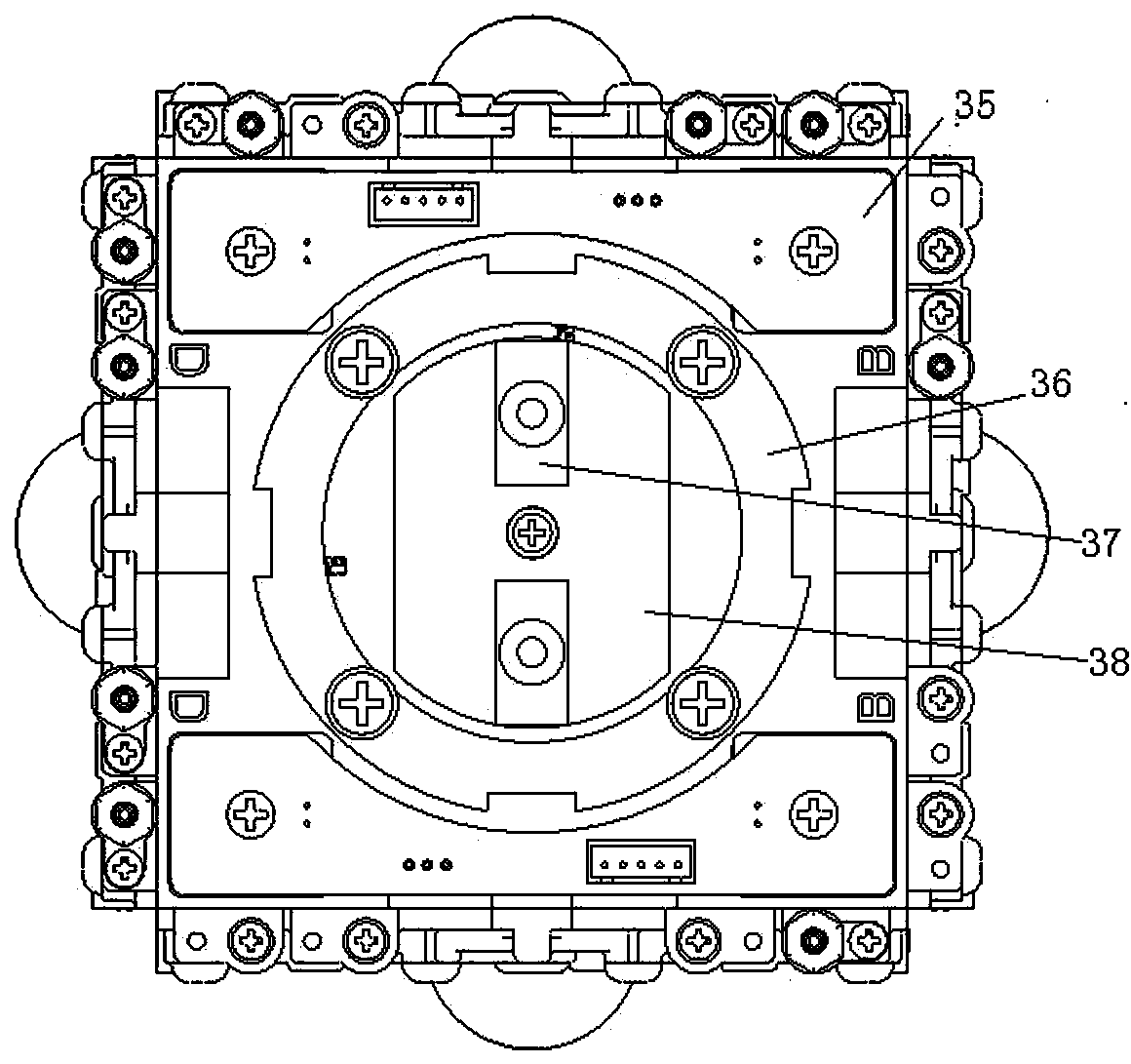

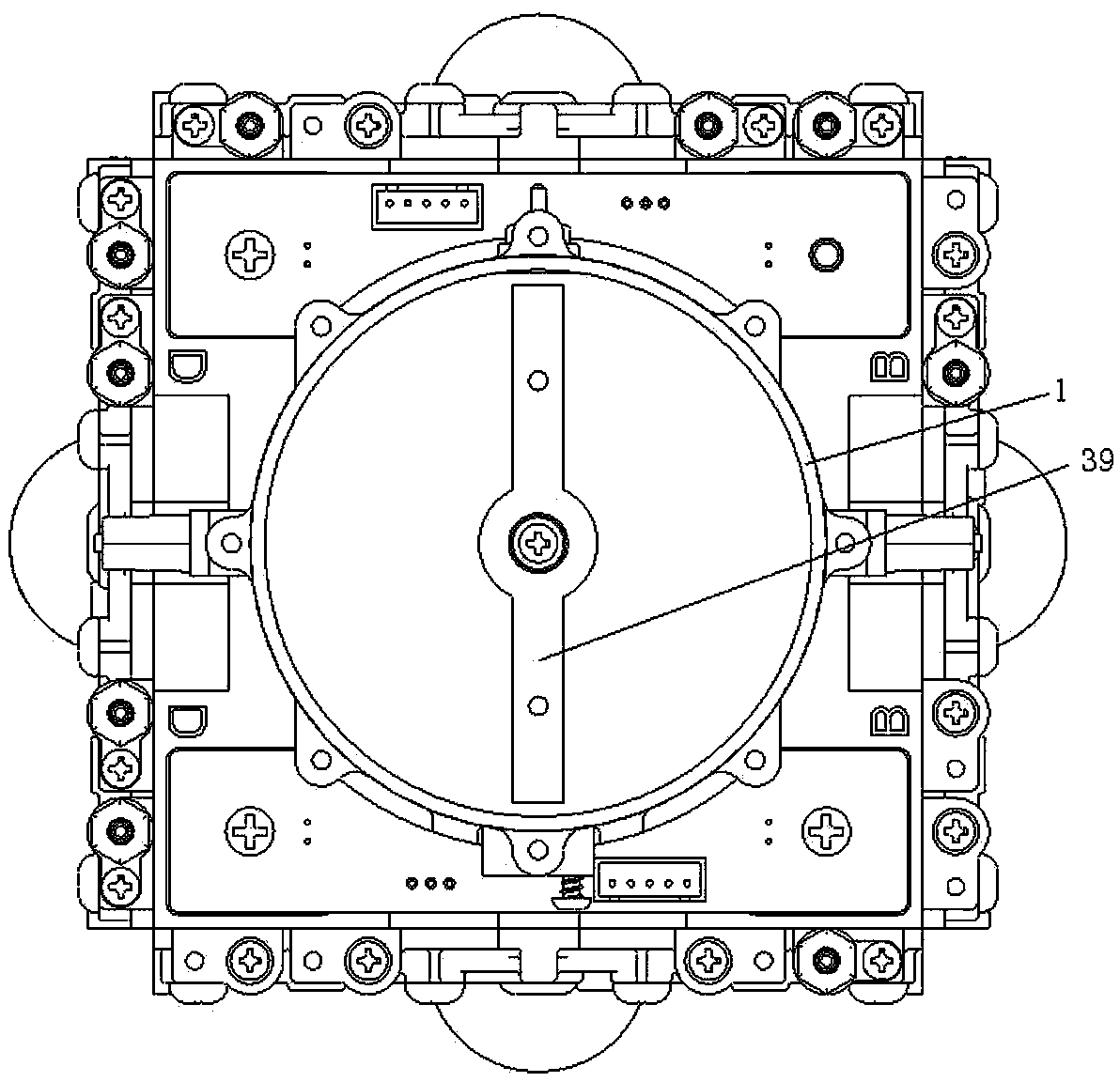

[0033] Such as Figure 1-4 As shown, a small character inkjet printer pump system includes two pump frames 26 assembled symmetrically up and down with a square horizontal plane, and four pump bodies 34 are installed in the horizontal direction in the hollow position between the two pump frames 26, which are respectively Main ink pump, recovery pump, thinning pump, ink replenishing pump, four pump bodies 34 facing east, west, north, south, four directions in pairs, pump body 34 is provided with push-pull buffer assembly 29, diaphragm 30, valve 28, on the pump frame Transmission system is installed below 26, and transmission system includes motor 41, transmission shaft 33, eccentric wheel 32, and transmission shaft 33 is installed on the motor 41, and eccen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com