Non-equant distribution type microporous aeration pipe system for sewage treatment

A microporous aeration and sewage treatment technology, applied in water/sludge/sewage treatment, water aeration, aerobic process treatment, etc., can solve the problem of dense pipelines, uneven distribution of dissolved oxygen in water, and turbulent diffusion of bubbles Weakness and other problems, to achieve the effects of enhanced turbulent diffusion, enhanced aeration and mass transfer efficiency, and uniform distribution of dissolved oxygen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Now further illustrate how the present invention is implemented in conjunction with accompanying drawings:

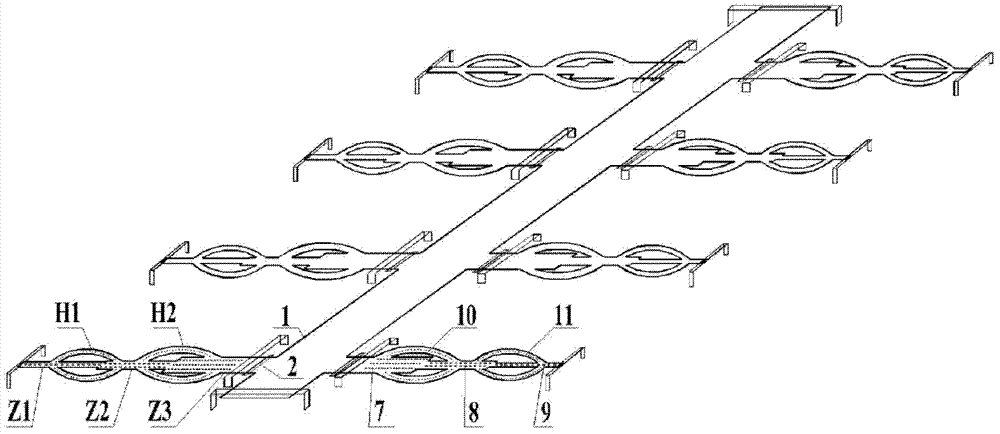

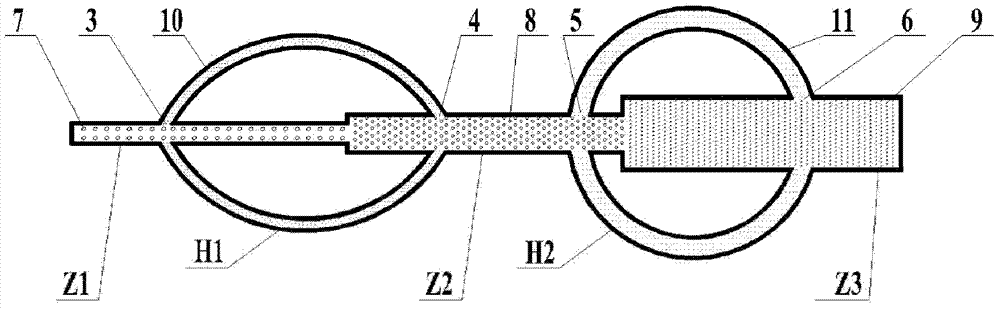

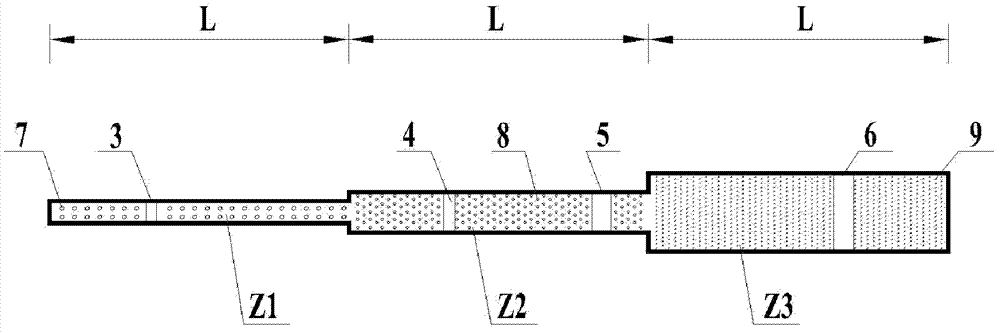

[0017] The microporous aeration main pipe is composed of three sections of microporous aeration straight pipes with the same length and different inner diameters, which are connected as microporous aeration straight pipes according to their inner diameters from small to large in order of Z1, Z2, and Z3. Microporous aeration branch pipes are respectively Two microporous aeration ring pipes H1 and H2 are symmetrically connected between the microporous aeration straight pipes Z1 and Z2, Z2 and Z3, and the microporous aeration ring pipe H1 and the microporous aeration straight pipes Z1 and Z2 are respectively There are connecting holes 3 and 4, the microporous aeration ring pipe H2 and the microporous aeration straight pipes Z2 and Z3 respectively have communicating holes 5 and 6, and four rows of microporous aeration main pipes are arranged in parallel at intervals w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com