An intelligent noodle making method for a household noodle machine

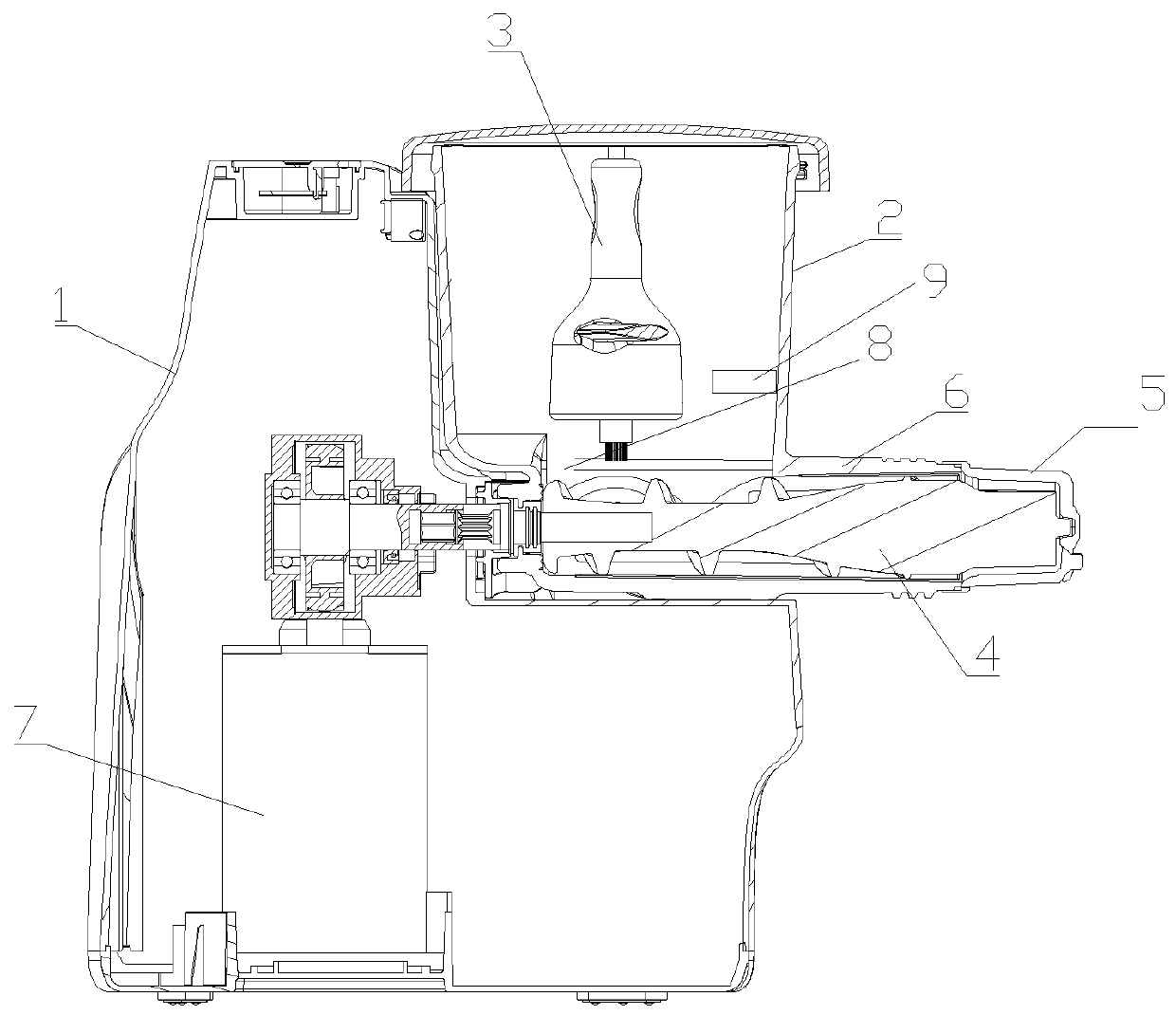

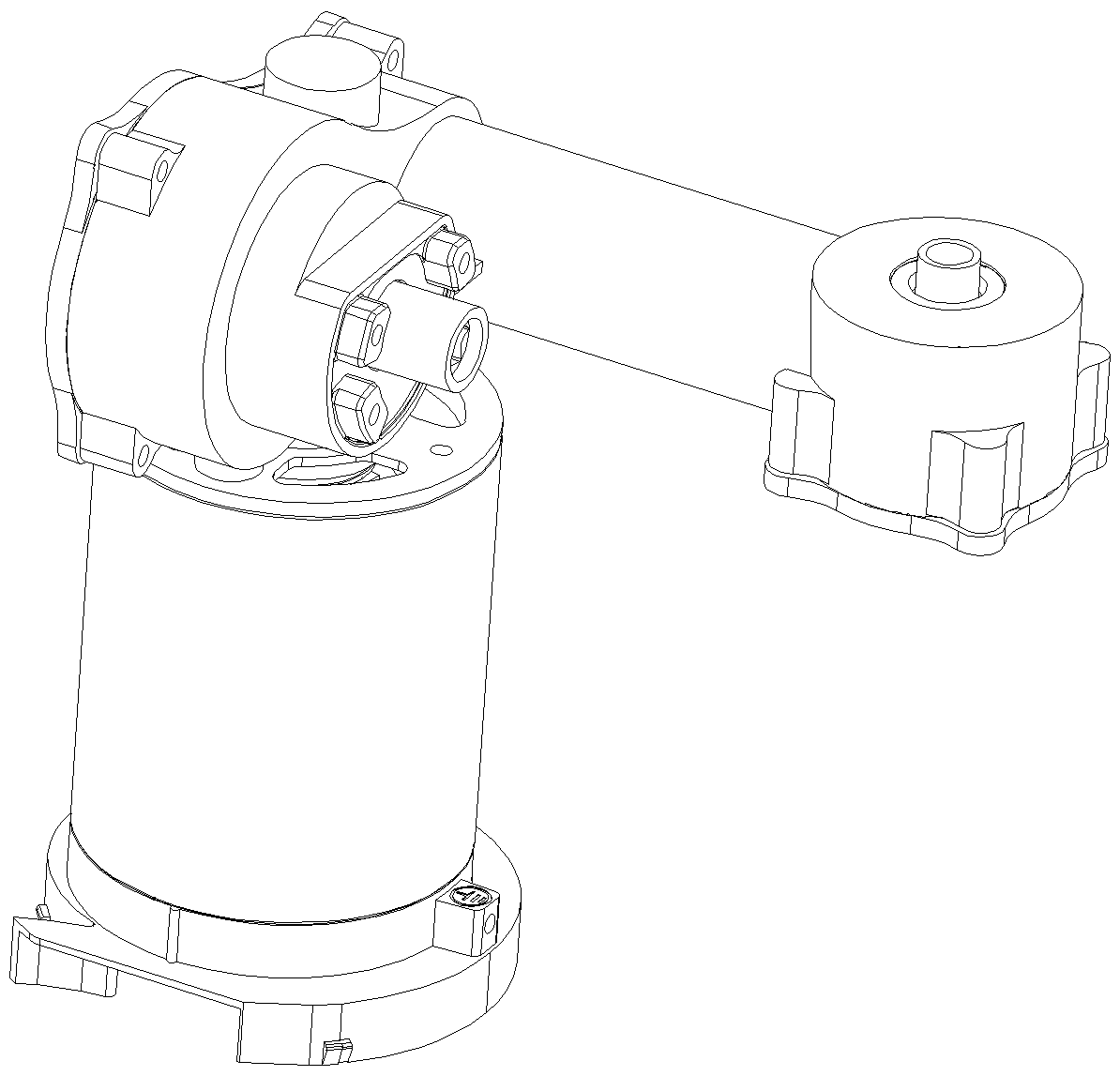

A noodle machine, household technology, applied in dough extruders, structural components of mixing/kneading machines, mixing/kneading with vertical installation tools, etc., can solve problems such as inconvenient operation for users and lack of intelligence , to achieve a good mixing effect, improve the efficiency of noodle extrusion, and thoroughly enter the noodle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0043] The noodle making method of the present embodiment, its specific technological process is as follows:

[0044] (1) The customer adds flour and water into the mixing cup of the noodle machine, presses the start button, and the buzzer of the noodle machine sounds for 0.2 seconds to remind the customer that the machine starts to run. start working;

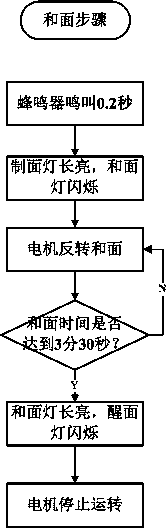

[0045] (2) Kneading steps: such as image 3 As shown, the first output shaft drives the stirring rod to rotate in reverse, and the second output shaft drives the screw to rotate in reverse. The stirring rod stirs flour and water. When flour and water are mixed into dough, does the reversal time reach 3 minutes and 30 minutes? Seconds, when it reaches 3 minutes and 30 seconds, the kneading process is completed, the kneading light is always on, the motor stops running, and the kneading step is completed.

[0046] (3) Waking up steps: such as Figure 4 As shown, this step and the dough light continue to stay on, the wake-up li...

Embodiment 2

[0058] Such as Figure 6 As mentioned above, the rest of the steps in this embodiment are the same as those in Embodiment 1. On the basis of the first step in Embodiment 1, a passive reverse process is added in the extrusion molding step: during forward extrusion of the screw, the control unit judges Whether the motor current load value is higher than the set value I, if it is higher than the set value, the motor will continue to rotate forward after reversing for a period of time, where 1.3A≤I≤1.9A. The specific process is as follows:

[0059] The forward rotation of the motor drives the screw to extrude the noodles, and the control unit judges whether the motor current load value is higher than the set value I. In this embodiment, I is 1.6A. If it is not higher than 1.6A, then it is judged that the extruded noodles are normal, and the forward rotation is continued. If it is higher than 1.6A, it is judged that the load of the motor is heavy, and the control unit controls the...

Embodiment 3

[0062] Such as Figure 7 As shown, the remaining steps of this embodiment are the same as those of Embodiment 1. On the basis of the first step of Embodiment 1, a current clamping process is added in the extrusion molding step: the control unit judges whether the motor current load value is higher than the first A set value I1, if it is higher than the first set value I1, the motor current load value is controlled within the first set value, and it is judged whether the motor current load value is higher than the second set value I2, the second set value The fixed value I2 is less than the first set value I1, if it is higher than the second set value I2, the motor will be controlled to reverse once, where 1.7A≤I1≤2.0A, 1.5A≤I2≤1.7A.

[0063] The specific process is as follows:

[0064] The motor rotates forward to drive the screw to extrude the noodles. The control unit judges whether the motor current load value is higher than the first set value I1. In this embodiment, I1 i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com