A Safe and Convenient Screw Squeeze Juicer

A technology of screw extrusion and juicer, which is applied in household machinery for filtering food, household appliances, applications, etc. It can solve problems that affect customer experience, shorten the service life of the machine, and increase machine loss, so as to improve convenience, The effect of continuous juice extraction and reduced loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

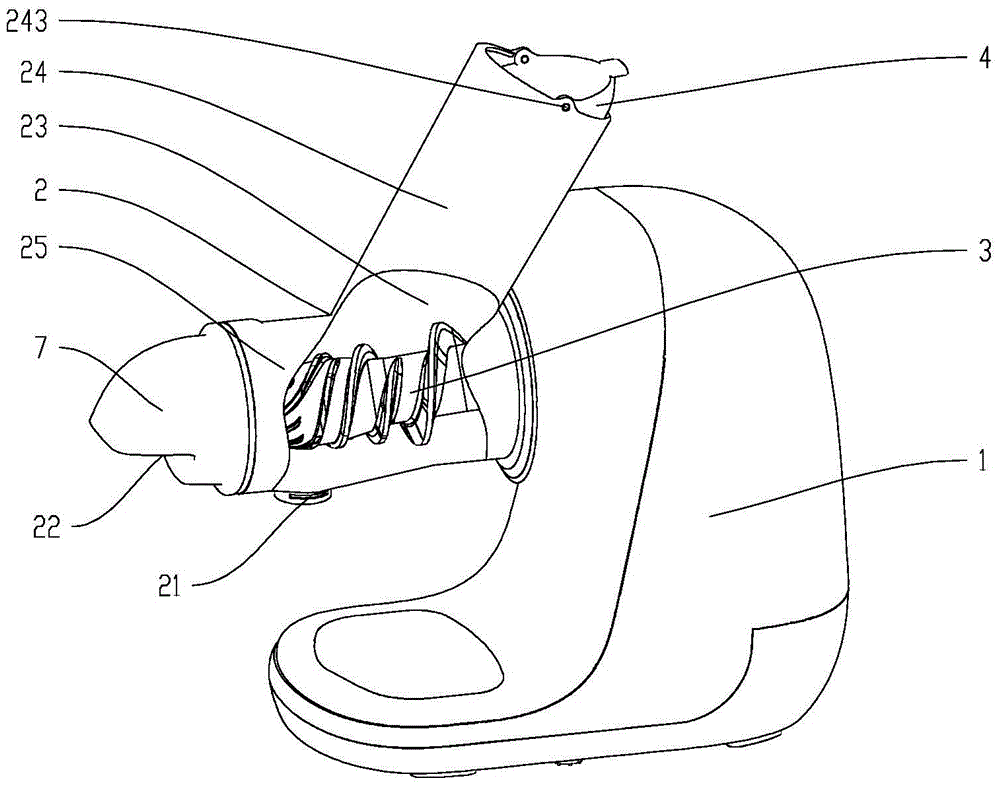

[0052] Such as figure 1 -4, the safe and convenient screw extrusion juice extractor of the present invention includes a machine base with a motor, a squeezing cavity mounted on one side of the base 1, 2, and an squeezing chamber horizontally arranged in the squeezing cavity 2. The extruding screw 3 is provided with an extruding screw on the outer surface, and the inner surface of the pressing cavity 2 is provided with an extruding rib that cooperates with the extruding screw for extruding the crushed material, the extruding rib There are multiple strips, and the extrusion ribs are integrally formed with the pressing cavity 2. The squeezing cavity 2 includes a squeezing cavity body 25 and an end cover 7 sleeved on the end of the squeezing cavity body 25. The end cover 7 is connected to the squeezing cavity body 25 by a screw connection, and the squeezing cavity body 25 is provided with a juice outlet 21. The slag outlet 22, the feed port 23 and the feed channel 24 connected with...

Embodiment 2

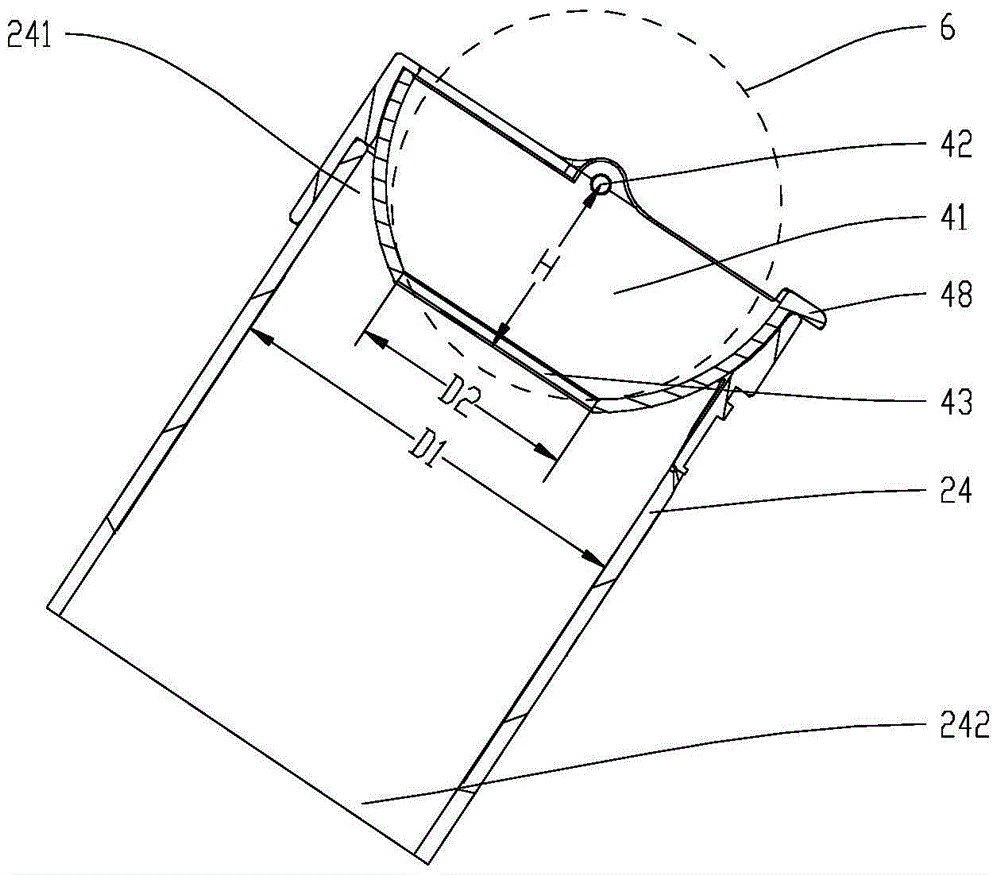

[0069] The difference between this embodiment and the first embodiment lies in: Figure 7 , 8 As shown, the turning table 4 is inserted into the upper end of the feed channel 24 through the mounting seat 5 and is located at the upper port 241, the mounting seat 5 is annular, and the side wall of the mounting seat 5 is provided with a rotating hole 51, The side wall of the turning table 4 is provided with a rotating shaft 42, and the turning table 4 is hinged to the mounting seat 5 through the cooperation of the rotating shaft 42 and the rotating hole 51.

[0070] The mounting base 5 is provided with a button buckle 52, the side wall of the feed channel 24 is provided with protrusions that cooperate with the button buckle 52, and a magnetic control switch is provided in the base 1 at a position corresponding to the mounting seat 5, The mounting base 5 is correspondingly provided with a magnet 53 for triggering a magnetic control switch, the mounting base 5 is provided with a mounti...

Embodiment 3

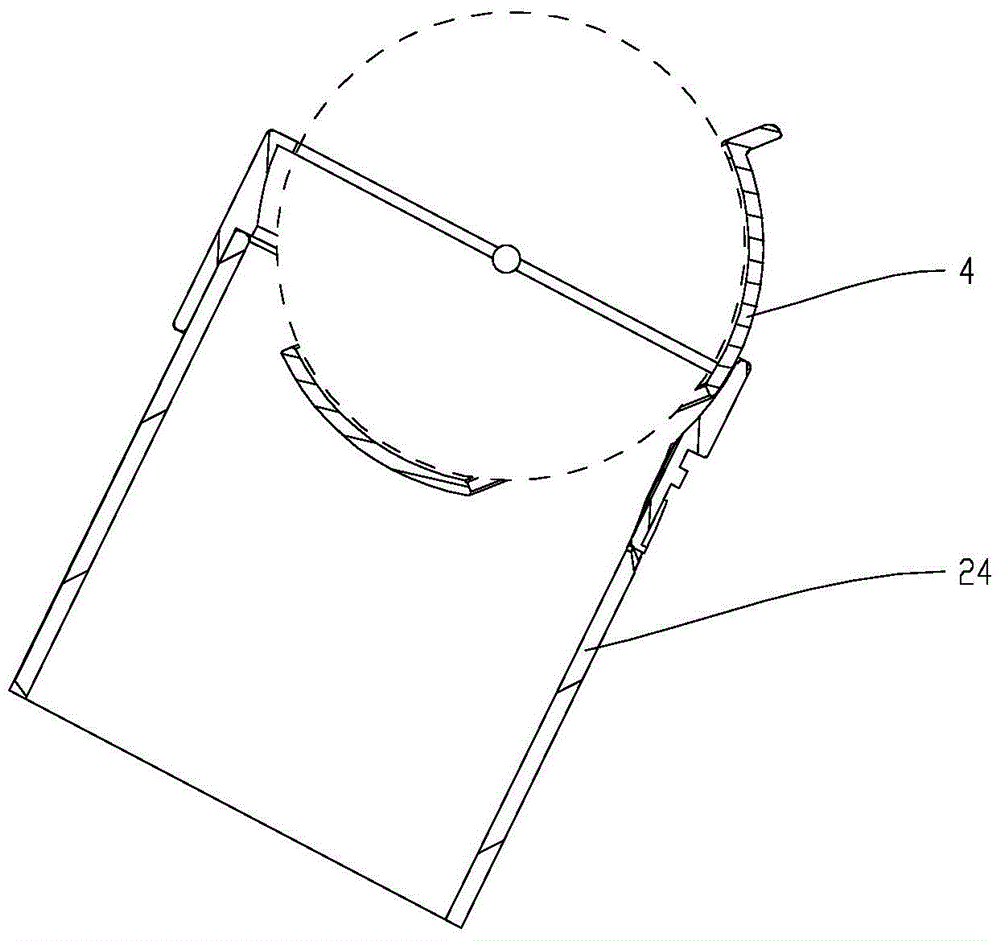

[0072] The difference between this embodiment and the first embodiment lies in: Picture 9 As shown in —12, the turning table 4 includes a first table 44 and a second table 45. The first table 44 and the second table 45 cooperate with each other to form a holding chamber 41. The table 44 and the second placing table 45 are separated and the materials placed in the material holding chamber 41 fall into the feeding channel 24. The first placing table 44 and the second placing table 45 are respectively provided with side walls and bottom walls, so The upper ends of the side walls of the first holding table 44 and the second holding table 45 are provided with a connected rotating hole, the side wall of the feeding channel 24 is provided with a rotating shaft, and the rotating shaft passes through the first holding table 44 and the second The rotation holes on the side walls of the second placing table 45 enable the first placing table 44 and the second placing table 45 to rotate aro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com