Surface-mounted leaded ceramic disc capacitor mounting burn-in device and method

A technology of aging and ceramics, applied in the field of capacitors, can solve the problems of time-consuming and labor-intensive, limiting the aging capacity, etc., achieve the effect of less time-consuming, simplify aging plates, and improve work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

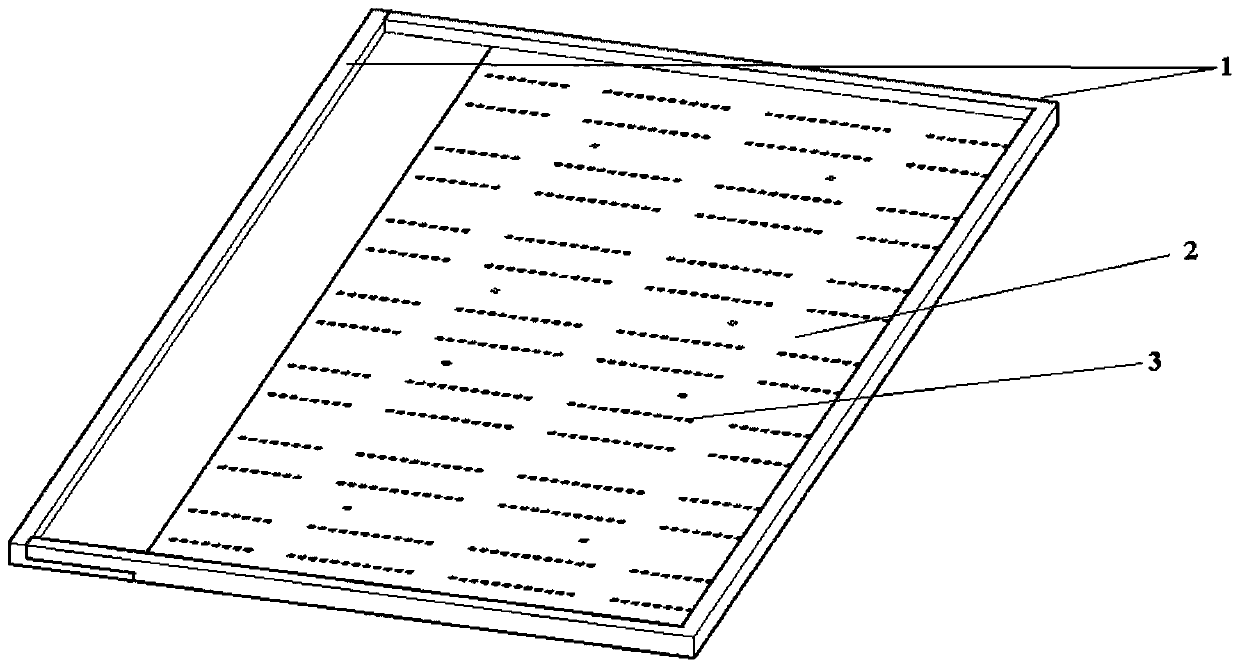

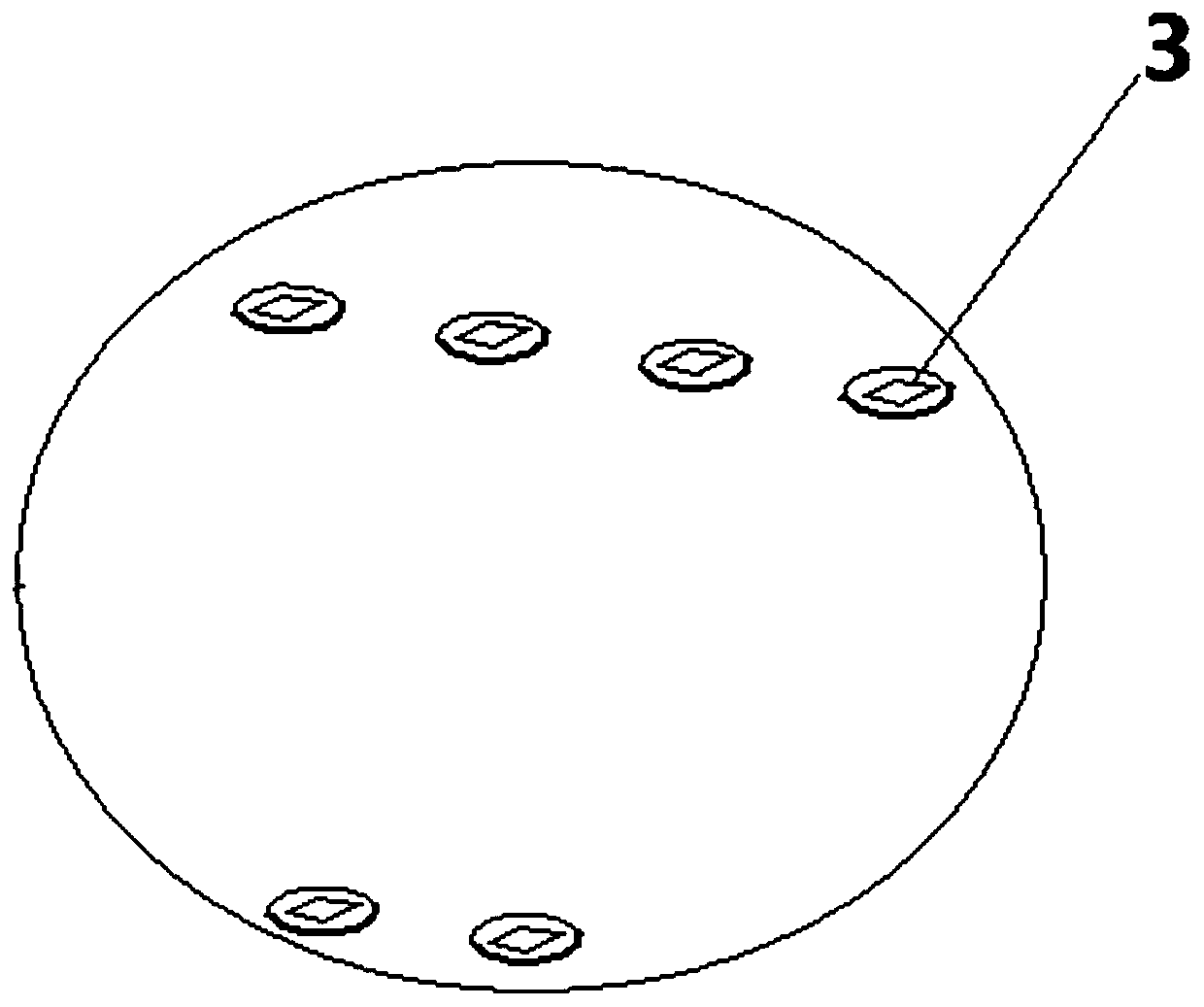

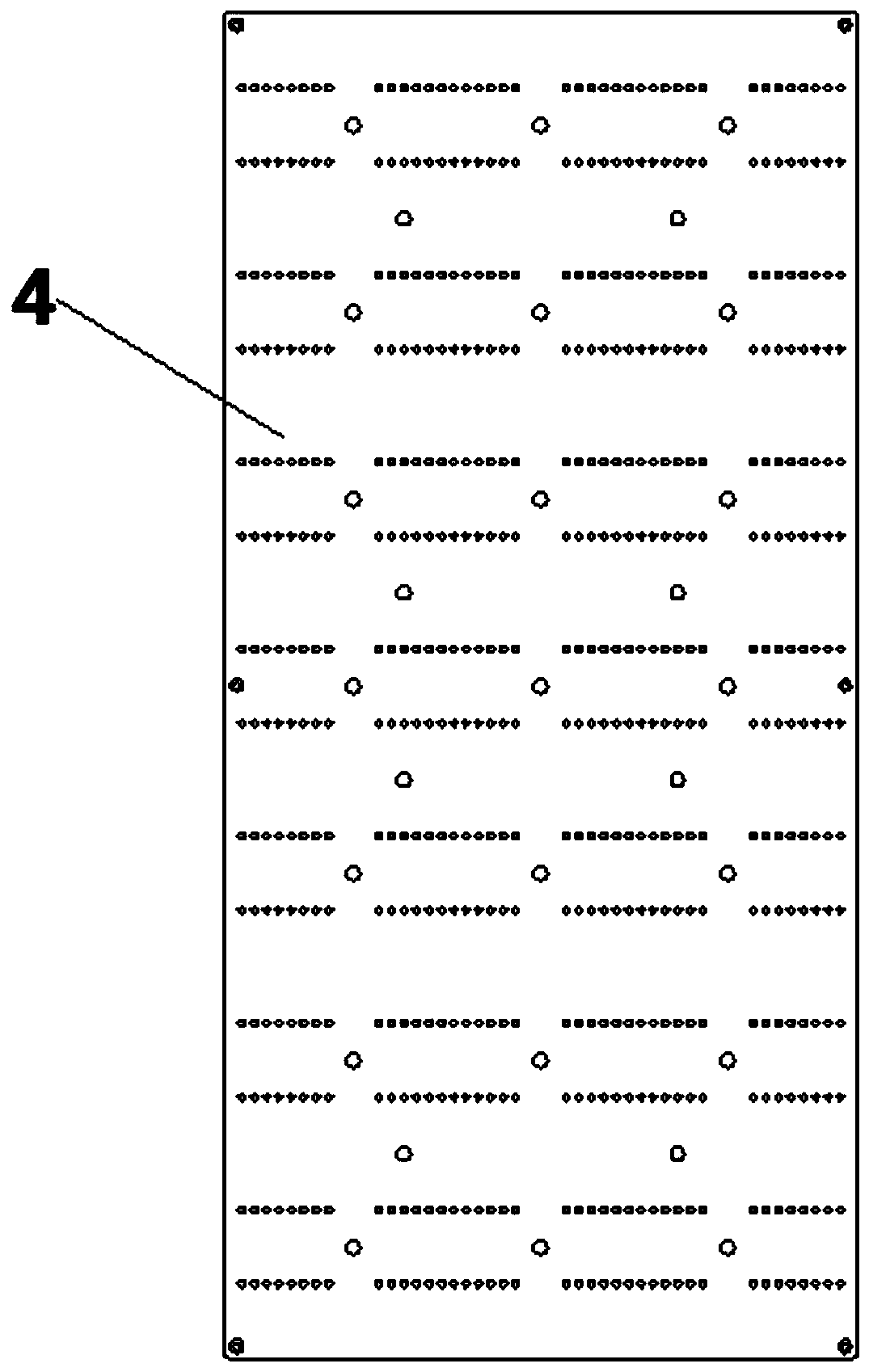

[0033] see figure 1 , a surface-mounted ceramic capacitor installation aging device of the present invention, including an aging plate, a shaker tank 1 and a drain plate 2, the shaker tank 1 and the drain plate 2 are combined to form a closed space for storing and transferring devices, and the old The refining plate includes a bottom plate 4 and a pressing plate 6. Several device leakage holes 3 are arranged at intervals on the leaking plate 2. Burning holes are arranged on the bottom plate 4 corresponding to the device leakage holes 3. Elastic current needles are arranged on the pressing plate 6 corresponding to the aging holes. The aging hole on the bottom plate 4 is connected to the cathode, and the elastic current needle is connected to the anode.

[0034] Shaking trough 1 is arranged around and above the bushing plate 2, multiple device leak holes 3 are arranged in a group horizontally, multiple sets of device leak holes 3 are arranged in parallel on the bushing plate 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com