Duck coop cleaning device

A technology for cleaning devices and duck sheds, applied in separation devices, poultry cages or houses, mobile filter element filters, etc., can solve problems such as frequent disease of ducks, flooding of drugs, poor solid-liquid separation, etc., to reduce bacteria The possibility of breeding, the solution to the deterioration of environmental humidity, and the effect of saving overall space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

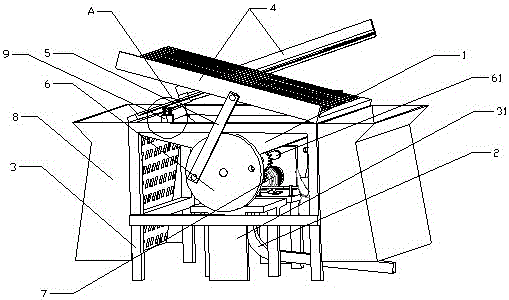

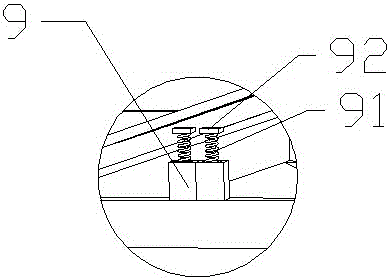

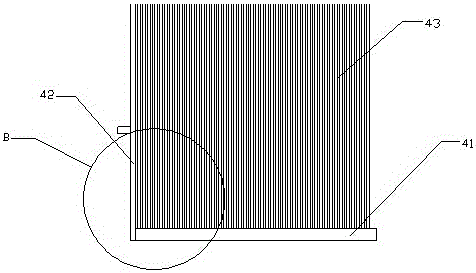

[0034] see Figure 1 to Figure 9 , the present invention is a duck shed cleaning device, comprising a drinking fountain, a partition for breeding, and below the partition, a water receiving bucket 1 is arranged corresponding to the drinking fountain, the bottom of the water receiving bucket 1 is connected to one end of a drain pipe 2, and the drain pipe 2 The other end of the water receiving bucket 1 is connected to the waste water collection device, the lower side of the water receiving bucket 1 is connected to the bracket 3, and the upper side of the water receiving bucket 1 is provided with a filter plate 4; A through hole is provided at the bottom, and the through hole is connected to the drain pipe 2;

[0035] The partitions for breeding are mesh partitions used in duck sheds, the drinking fountains are commonly used sink type or nipple drinking fountains, and the waste water collection device can be collected directly with buckets or other related sewage treatment method...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com