Full-automatic safety spike construction vehicle and safety spike construction method

A fully automatic, construction vehicle technology, applied in the direction of roads, roads, road signs, etc., can solve the problems of requiring a large amount of manpower, low construction efficiency, and long construction time of road construction, achieving huge engineering value, short construction period, and high construction efficiency high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention will be further described below in conjunction with accompanying drawing:

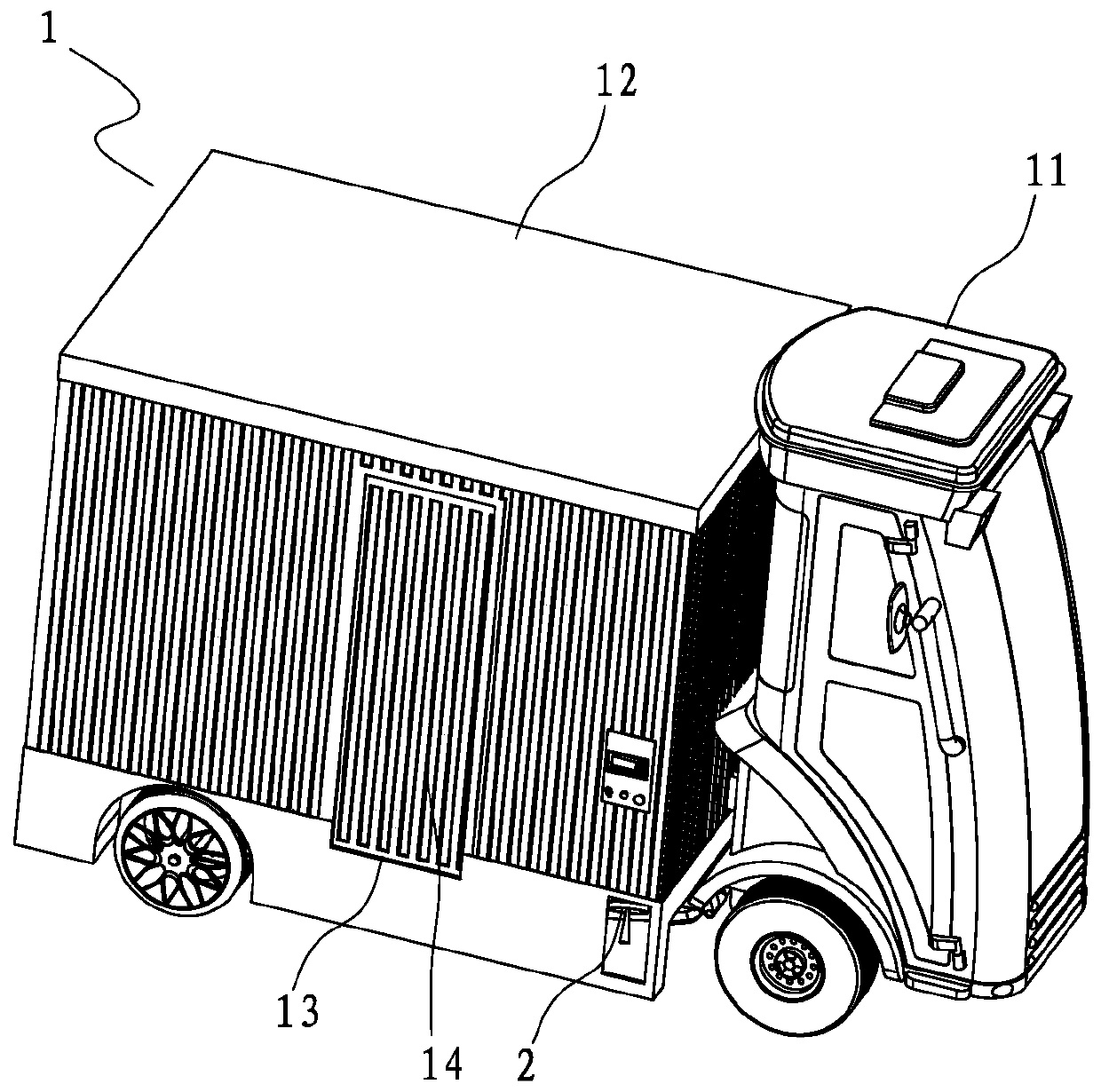

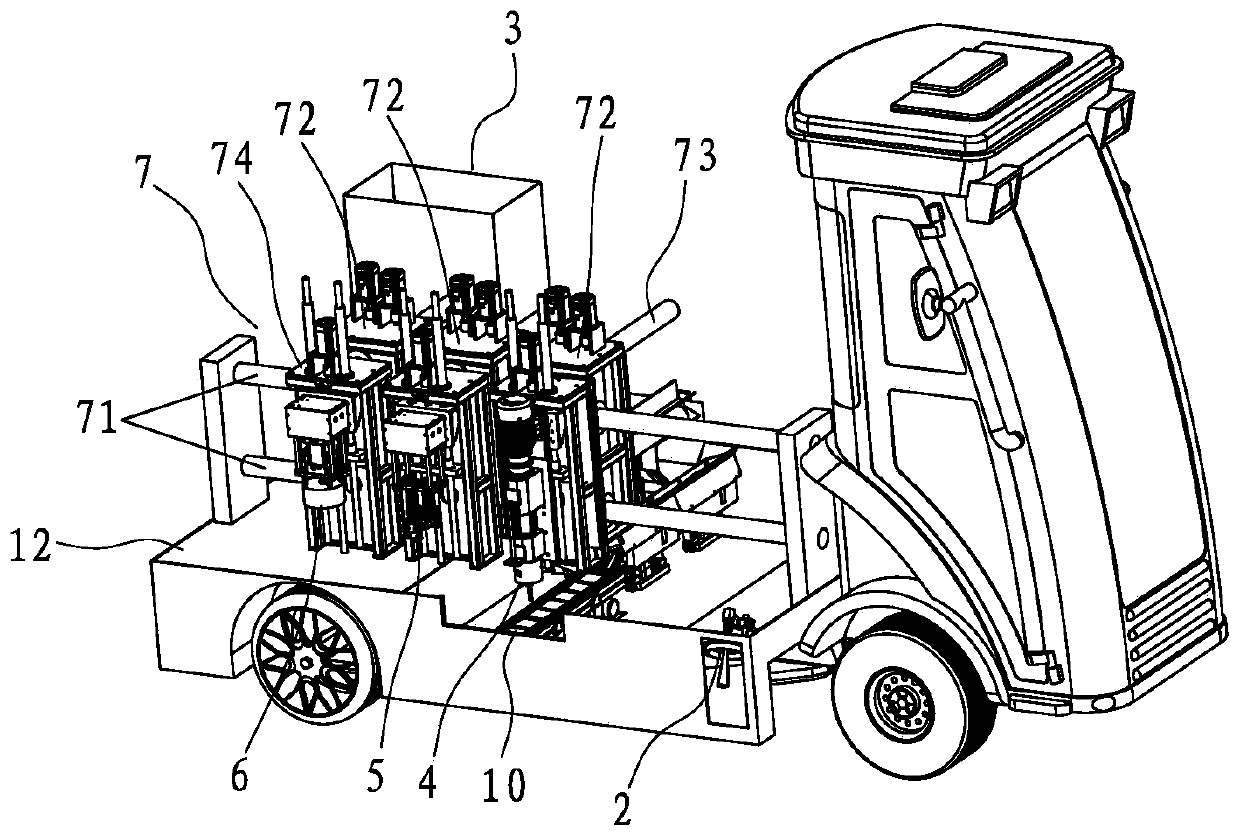

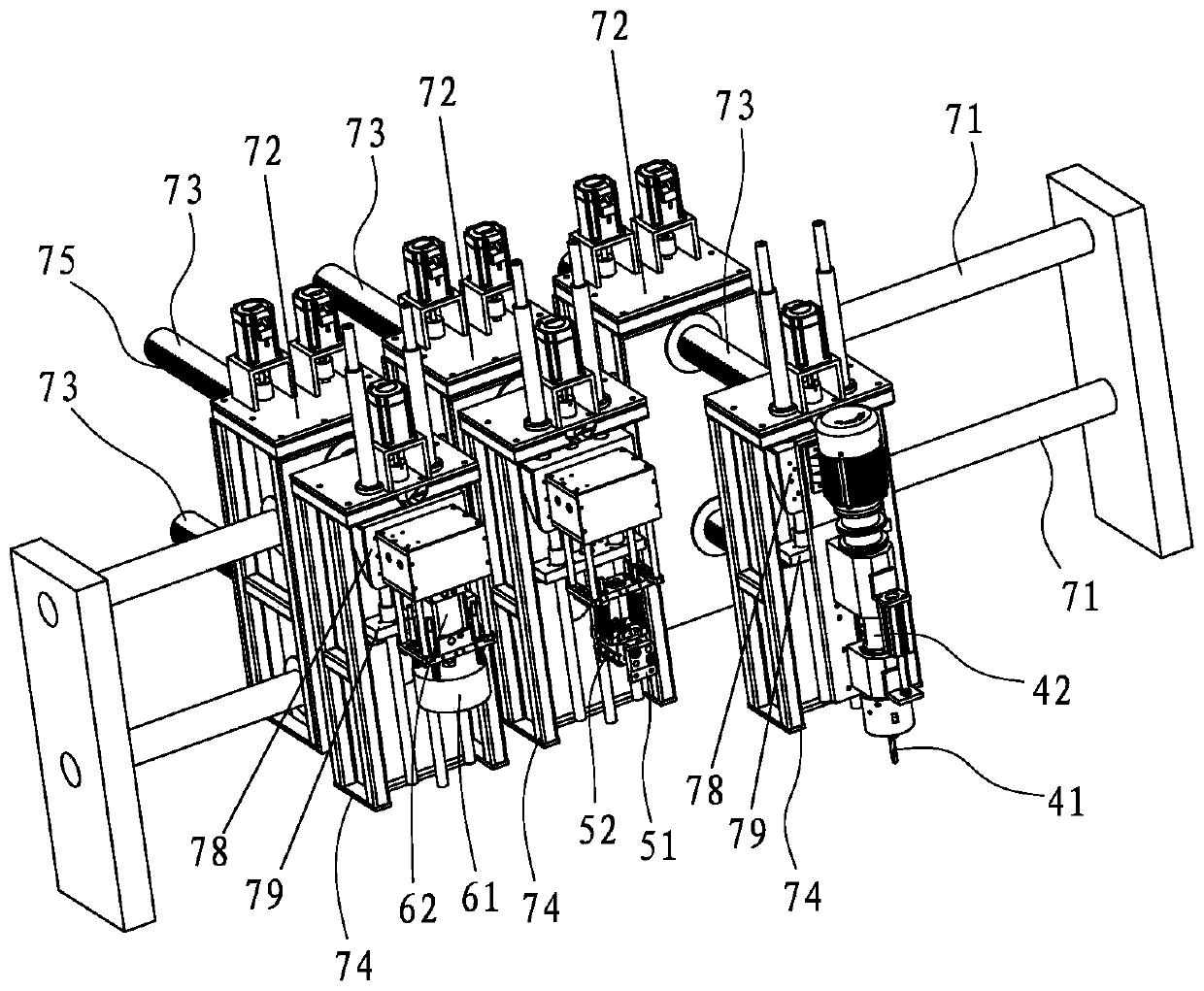

[0043] Such as Figure 1 to Figure 12 A full-automatic safety road stud construction vehicle shown includes a vehicle body 1 capable of driving and moving and a control system. The vehicle body 1 is provided with a camera 2 for photographing the position of the lane indicator line on the road surface. The body 1 is also provided with a sorting and conveying mechanism 3, a drilling mechanism, a nail-taking mechanism and a hammering mechanism, and the camera 2, the sorting and conveying mechanism 3, the drilling mechanism, the nail-taking mechanism and the hammering mechanism are respectively electrically connected to the control system , the way of electrical connection can be connected by cables, the drilling mechanism is used to drill holes on the road surface along the lane indicator line, and the sorting and conveying mechanism 3 is used to sort the safety road studs 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com