Loader with water mist dust suppressor

A loader, water mist technology, applied in the direction of injection device, liquid injection device, mechanically driven excavator/dredger, etc., can solve the problem of silicosis or other occupational diseases, affecting the health of employees, toxic and harmful loading materials, etc. problem, achieve the effect of reducing dust phenomenon, simple structure and increasing weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

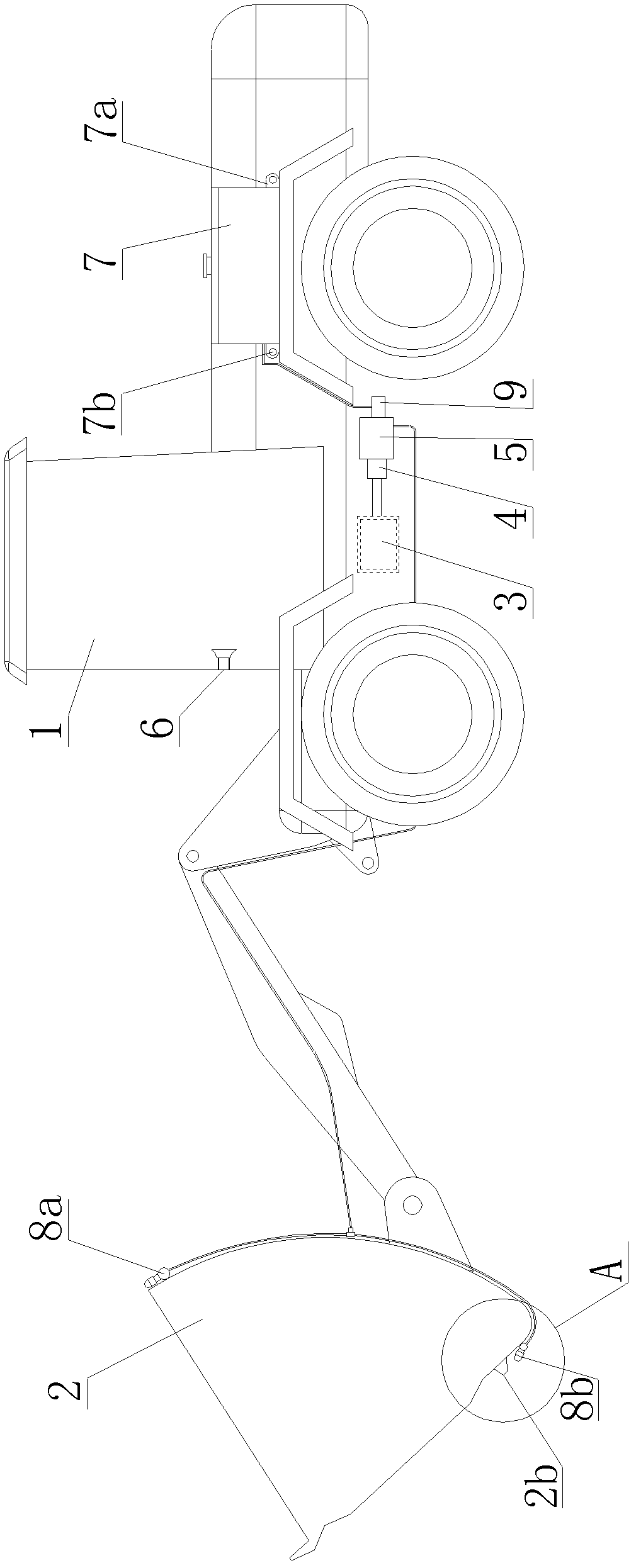

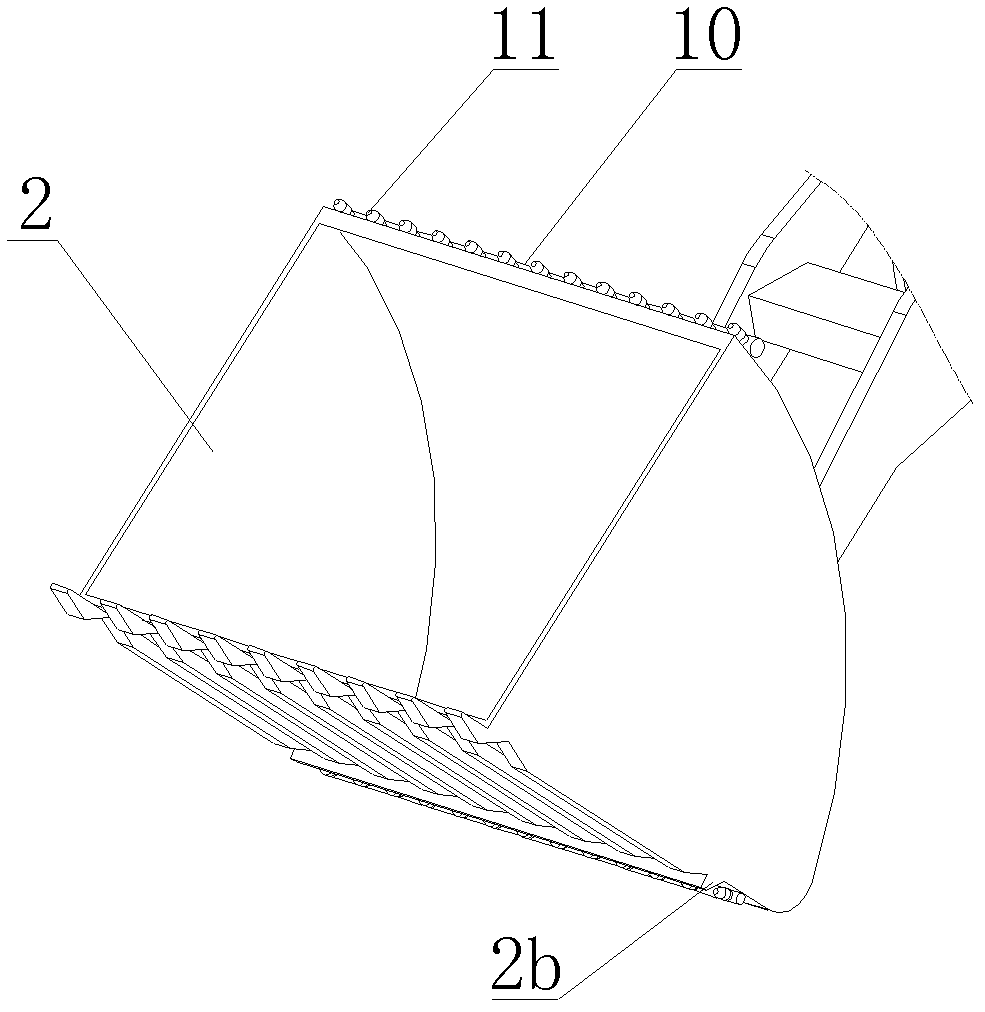

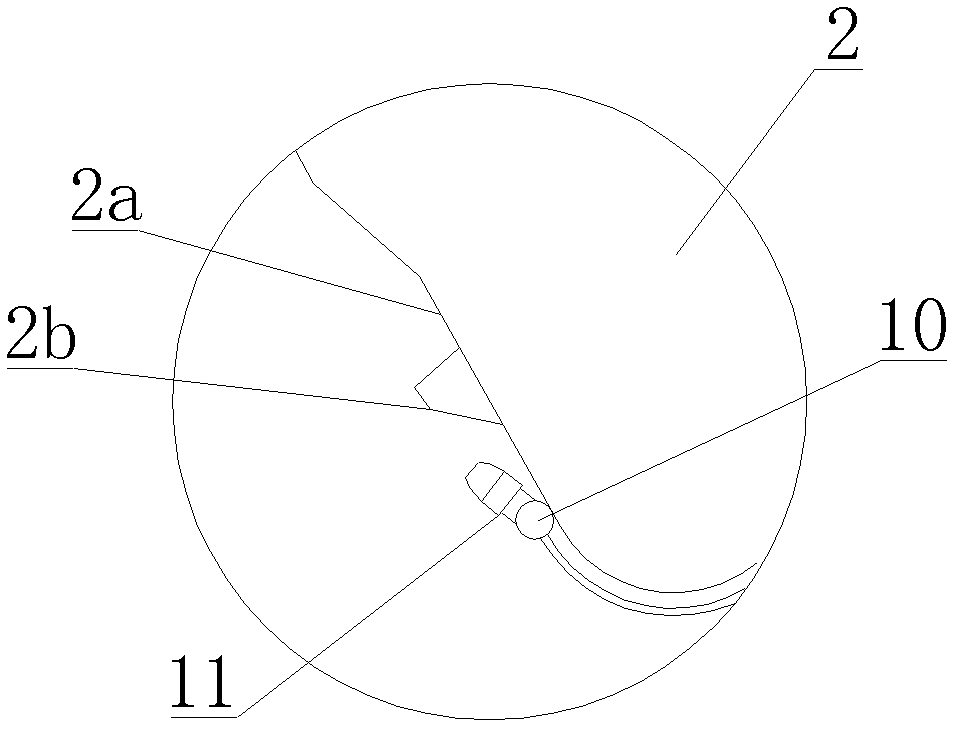

[0022] refer to Figure 1 to Figure 7 As shown, a loader with a water mist dust suppression device of the present invention includes a car body 1, a hopper 2 is provided at the front of the car body 1, a power transmission box is provided at the bottom of the car body 1, and a power transmission box is provided at the bottom of the car body 1. The pipeline is connected with hydraulic distributor 3, and the pipeline of hydraulic distributor 3 is connected with hydraulic motor 4, and the power output shaft of hydraulic motor 4 is connected with high-pressure liquid pump 5; the circuit of hydraulic distributor 3 is connected with hydraulic motor control button 6, high-pressure hydraulic pump The water inlet pipeline of 5 is connected with a water tank 7, and a filter 9 is arranged on the pipeline between the high-pressure liquid pump 5 and the water tank 7, and the filter 9 can prevent the water tank 7 from being sucked into the pump by the high-pressure liquid pump 5 when debris ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com