Preparation method of silicon-based negative electrode slurry

A technology of silicon-based negative electrode and silicon-based composite material, which is applied in electrode manufacturing, battery electrodes, structural parts, etc., can solve the problems of increasing the difficulty of increasing the surface wetting of silicon-based particles, long slurry preparation period, and poor dispersion effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

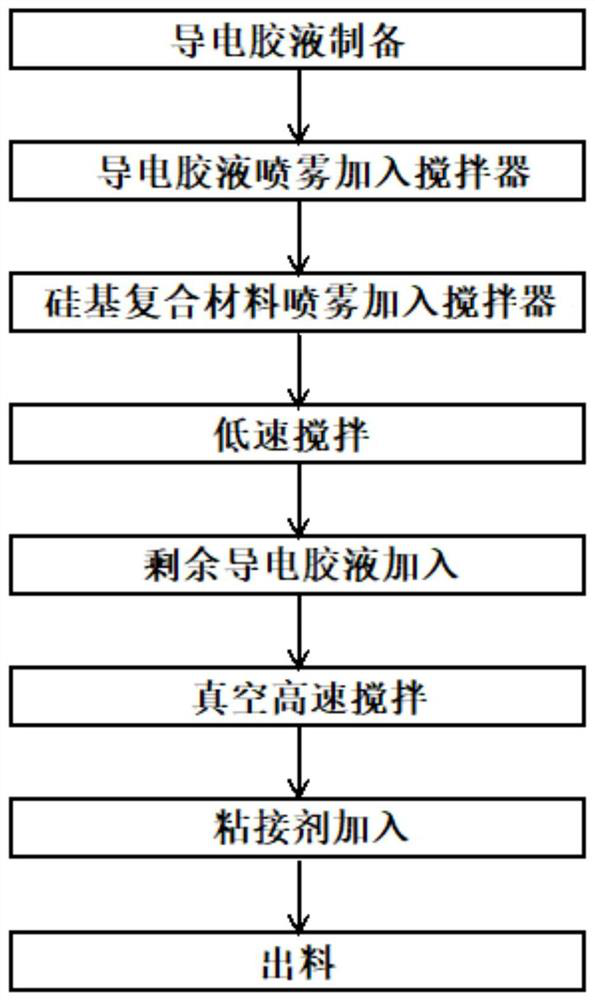

[0028] Such as figure 1 As shown, the specific embodiment of the present invention is a method for preparing a silicon-based negative electrode slurry, and the specific steps are as follows:

[0029] S1. Stir the solvent, thickener and conductive agent in the glue tank at low speed to obtain conductive glue; the solvent is water, the thickener is anionic surfactant or nonionic surfactant, and the conductive agent is conductive carbon Material. The mass ratio of solvent, thickener and conductive agent in the conductive glue is 100:(1.0-2.5):(1.0-3.0).

[0030] The solvent is water, and the thickener is one or more of sodium carboxymethylcellulose, hypromellose, hydroxymethylcellulose, or hydroxyethylcellulose;

[0031] The conductive agent is one or more of single-walled carbon nanotubes, furnace black, acetylene black, multi-walled carbon nanotubes, graphene or carbon fibers. Due to its high aspect ratio and good flexibility, single-walled carbon nanotubes can also play a g...

Embodiment 1

[0044] The proportion of the negative electrode in Example 1 is silicon-based composite material: sodium carboxymethyl cellulose: single-walled carbon nanotubes: carbon black: styrene-butadiene rubber = 95:2:0.2:1:1.8. Wherein, single-walled carbon nanotubes are slurry with a solid content of 0.3%; carbon black is sp conductive carbon black; styrene-butadiene rubber (adhesive) has a solid content of 48%; and the weight of the silicon-based composite material is 190kg.

[0045] First prepare the conductive glue, add single-wall carbon nanotube slurry, carbon black and water to the glue tank, stir for 10min-30min, then add carboxymethylcellulose sodium continuously, and continue stirring for 2h-4h to prepare the conductive glue. Set aside. The conductive glue can be prepared in advance. In this embodiment, the total weight of the conductive adhesive is 195kg.

[0046] Next, the agitator starts stirring at a low speed, the stirring revolution is 15rpm, and the rotation is 80rpm...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com