Downhole drilling anti-dust device

A technology of dust-proof device and spray device, applied in construction and other directions, can solve the problems of wasting water, test of waterproof performance of electrical appliances, explosion, etc., and achieve the effect of reducing dust and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

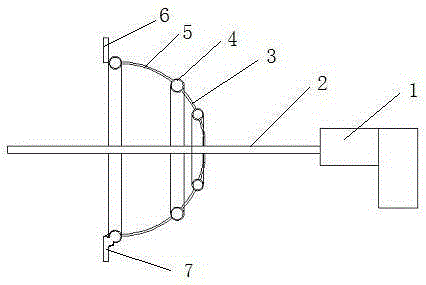

[0008] In order to further illustrate the technical solution of the present invention, the specific implementation manner of the present invention is now described in conjunction with the accompanying drawings, as figure 1 , the dust-proof device that adopts in this example adopts outer ring diameter 500 millimeters, inner hole diameter 100 millimeters, the profile of hemispherical radius 250 millimeters, spray water pipe 4 adopts the thin-walled seamless steel pipe of diameter 14 millimeters; Make a water spray hole less than 1 mm on the top as a spray device; select the same thin-walled steel pipe as the connector 2, 5, and connect the three spray water pipes 4 together; at the same time, the connector 2 and 5 are located on the inside of the hemisphere and also set the spray device ; Connectors 2 and 5 are multiple, select 15 to be evenly arranged on the surface of the hemisphere in this example; select the steel plate with thickness 8 millimeters as the hook device 6 in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com