A kind of manufacture method of large particle size melamine cyanurate

A technology of melamine cyanurate and its manufacturing method, which is applied in the field of manufacturing melamine cyanurate with large particle size, can solve the problems of affecting the quality of MCA, yellowing of nylon during high-temperature processing, and low heat resistance of additives, etc., and achieve reduction Dust phenomenon, simple production process, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

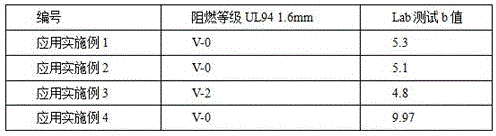

Examples

Embodiment 1

[0039] 1) Put 5Kg of melamine and 5.115Kg of cyanuric acid into the kneader reactor, turn on the normal rotation and knead for 20 minutes, add 2 Kg of pure water, turn on the heating to 90°C and knead at a constant temperature for 2 hours, turn on the vacuum to dry the remaining water;

[0040] 2) Add 300g of caprolactam into a 2L flask, heat to 85°C, add 1.5g of sodium hydroxide after the dissolution is complete, turn on the vacuum to -0.05MPa for 5 minutes, then add 1.5g of hexamethylene diisocyanate, and stir well;

[0041] 3) Add the intermediate obtained in step 2) into the kneader, turn on the heating to 160°C while maintaining a vacuum of -0.05MPa, react for 1 hour and then cool to 80°C to discharge;

[0042] 4) Test bulk density: 0.7g / mL, particle size D50=10.2μm, TGA 1% thermal decomposition weight loss temperature of 305℃ in nitrogen atmosphere;

Embodiment 2

[0044] 1) Put 5Kg of melamine and 5.115kg of cyanuric acid into the kneader reaction kettle, turn on the normal rotation and knead for 20 minutes, add 2Kg of pure water, turn on the heating to 100°C and knead at a constant temperature for 2 hours, turn on the vacuum to dry the remaining water;

[0045] 2) Add 200g of caprolactam into a 2L flask, heat to 85°C, add 1 g of sodium hydroxide after the dissolution is complete, turn on the vacuum at -0.05MPa for 5 minutes, then add 1 g of N-acetyl caprolactam, and stir well;

[0046] 3) Add the intermediate obtained in step 2) into the kneader, turn on the heating to 170°C while maintaining a vacuum of -0.05MPa, react for 1 hour and then cool to 80°C to discharge;

[0047] 4) Test bulk density: 0.61g / mL particle size D50=9.3μm nitrogen atmosphere TGA 1% thermal decomposition weight loss temperature 303℃;

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com