Tobacco high-pressure micro fog humidification system

A humidification system and high-pressure technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of damp walls, low economic benefits of manufacturers, and shedding, so as to reduce humidity conditions, improve tobacco quality and production efficiency, and humidify effect uniform effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

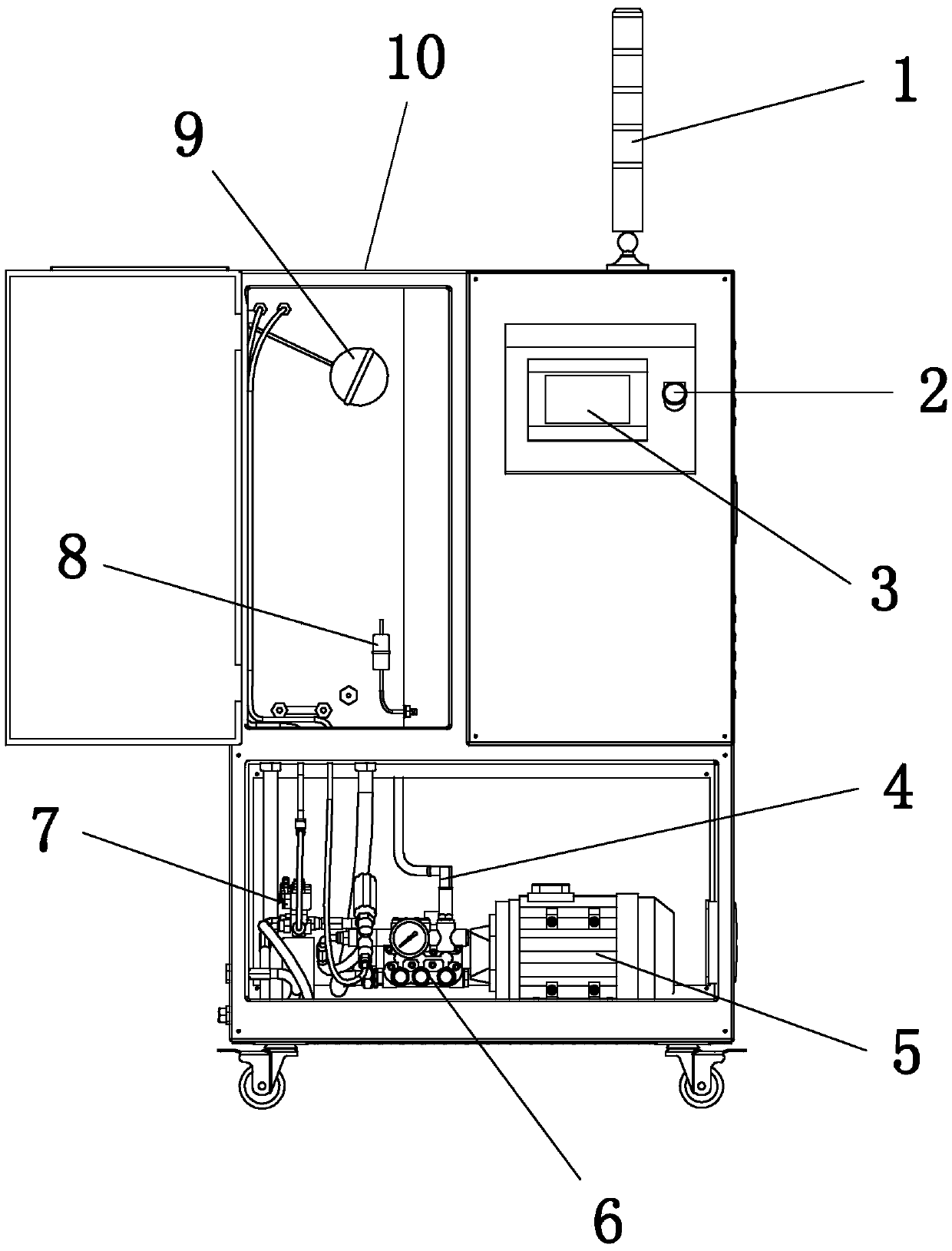

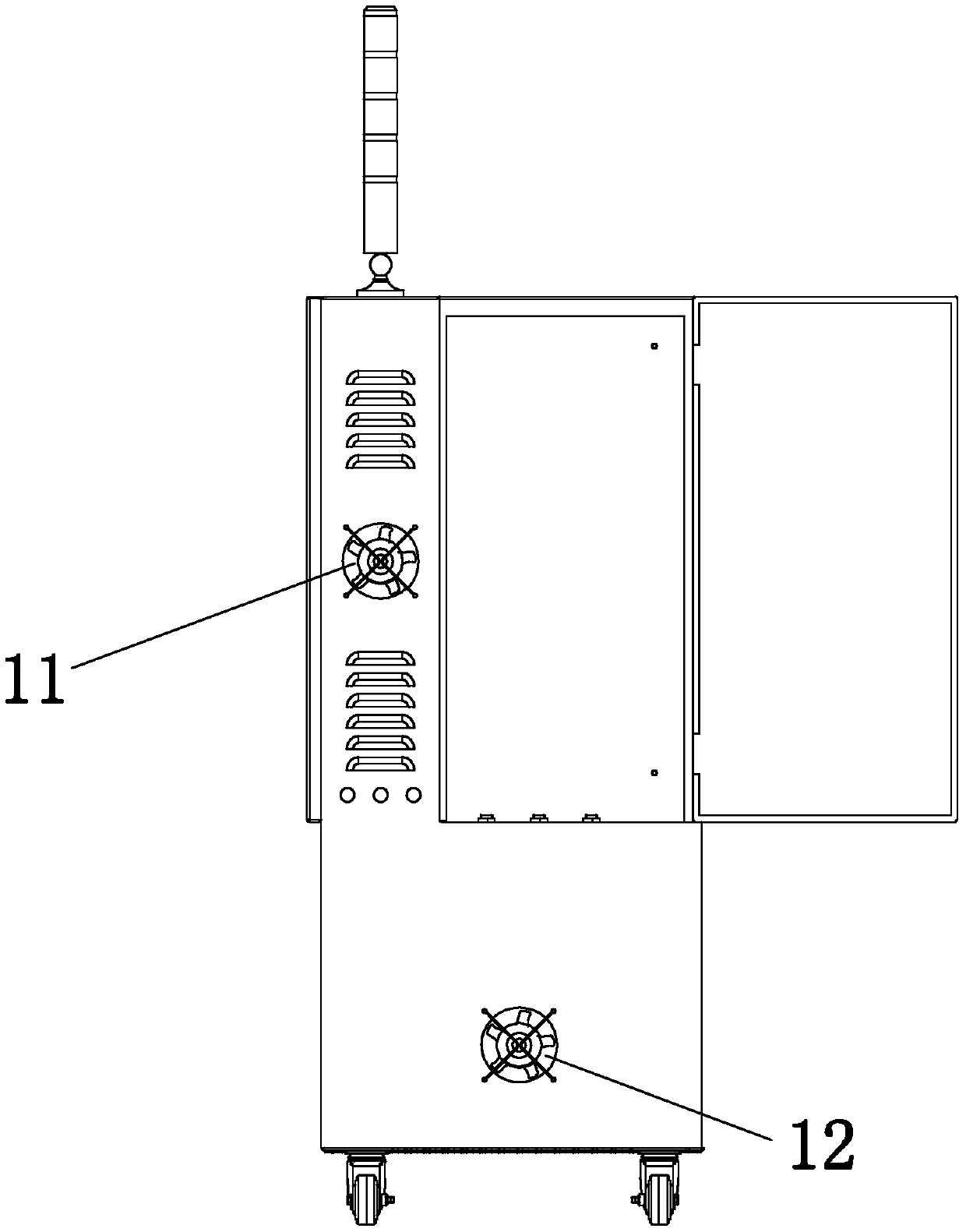

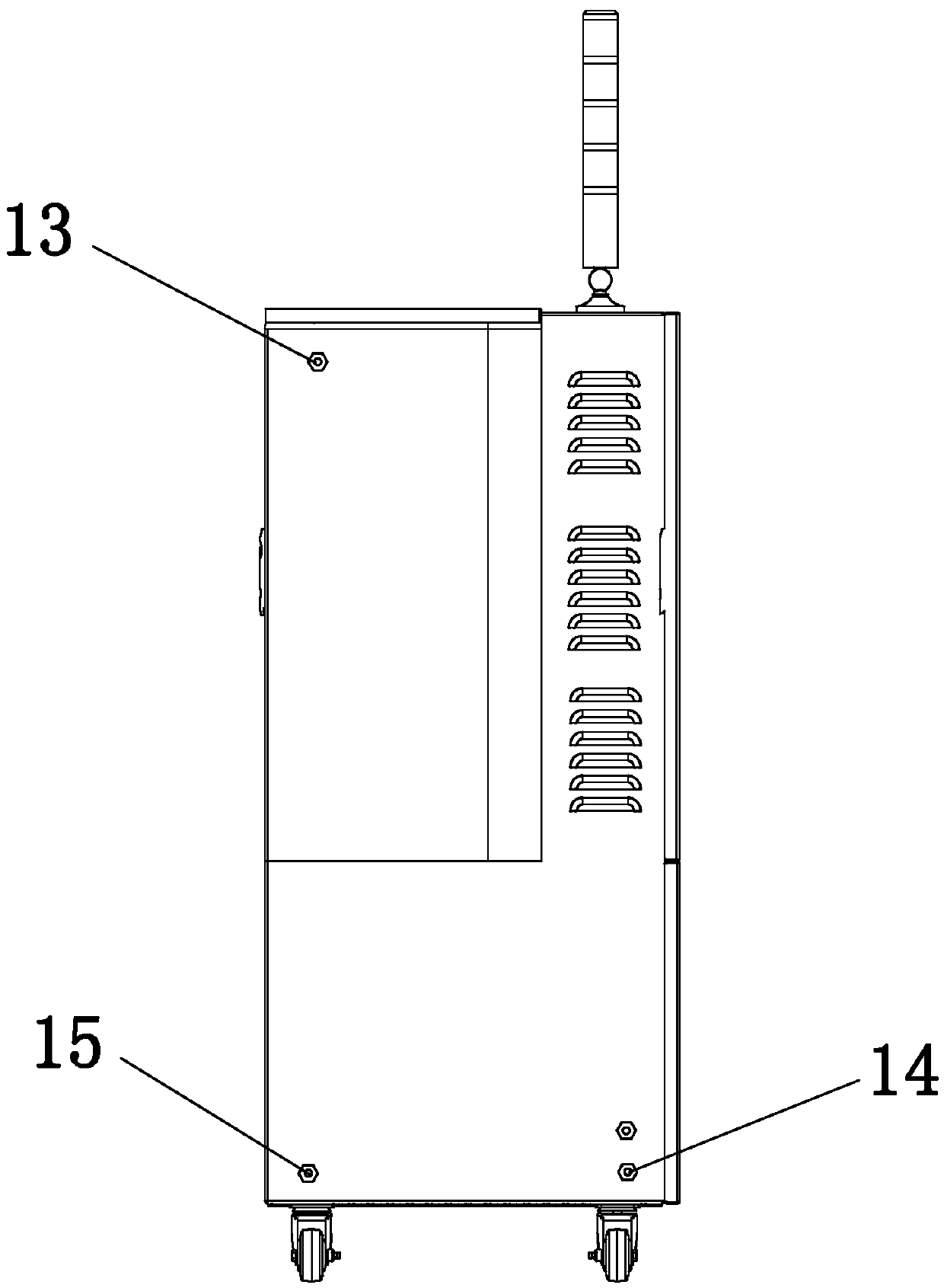

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0016] Such as Figure 1-4 As shown, the present invention includes a housing 10, which also includes a PLC control system, a pressure transmitter 4, and a heating device 16; the housing 10 includes a left cavity, a right cavity and a lower cavity; The water inlet float valve 9 is arranged on the side; the water inlet float valve 9 can effectively play the role of delaying water intake, and avoid mixing the hot water spray liquid in the left cavity with the external cold water; the lower right of the front of the left cavity is provided with Float limit switch 8; the float limit switch 8 rises / falls synchronously with the liquid level, when it rises / falls to the set position, the float limit switch 8 will trigger the travel switch at the set position, so that the travel switch will send The electric signal is transmitted to the elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com