Dust suppression system for dust silo

An ash storage and dust technology, which is applied in the field of dust control system for dust storage in power plants, can solve the problems of lack of supporting dust collection system, ground pollution of carriages and ash storage, dust pollution, etc., so as to facilitate forklifts to enter the operation and avoid a large number of The effect of dust generation and high degree of mechanization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] All features disclosed in this specification, or steps in all methods or processes disclosed, may be combined in any manner, except for mutually exclusive features and / or steps.

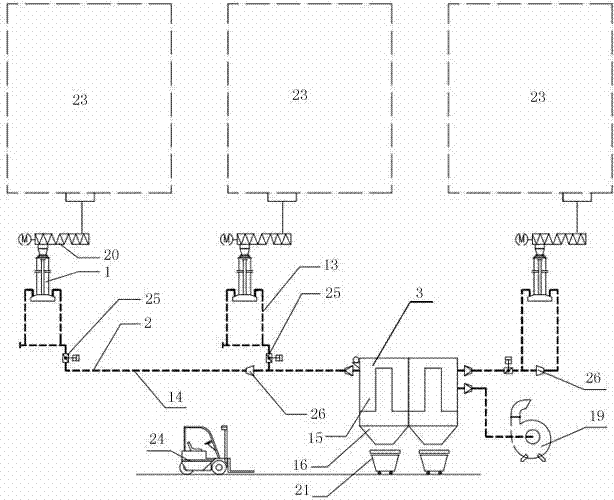

[0044] The dust suppression system of the ash store in the present invention includes: a retractable dust suction hood device, a negative pressure pipe network system, a dust capture and collection device, and an ash store decompression cone. figure 1 This is the flow chart of the dust suppression system of the ash storehouse. According to actual needs and specific on-site operations, the number of the dust collection hood devices 1 can be set to 1, 2 or more than 2.

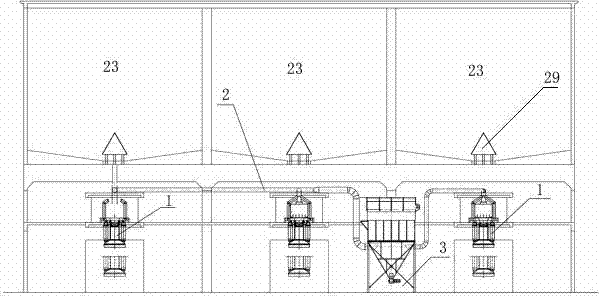

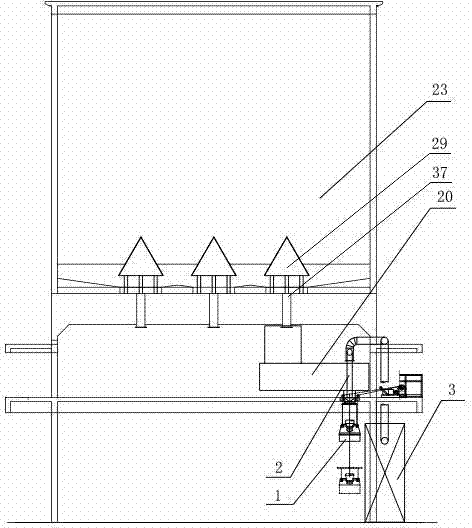

[0045] like figure 2 , image 3 As shown, a dust suppression system for an ash store includes a dust collection hood device 1, a negative pressure pipe network system 2, and a dust collection device 3. The dust collection hood device 1 is configured as a retractable structure, and the negative pressure pipe network One end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com