Slag skimming machine with automatic water mist dust suppression device

A slag removal machine and water mist technology, applied in spraying devices, safety devices, liquid spraying devices, etc., can solve problems such as difficulty in eliminating the impact of operating dust, silicosis of workers, affecting work efficiency and safety production, etc., to reduce dust. Phenomena, the effect of simple structure and convenient connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

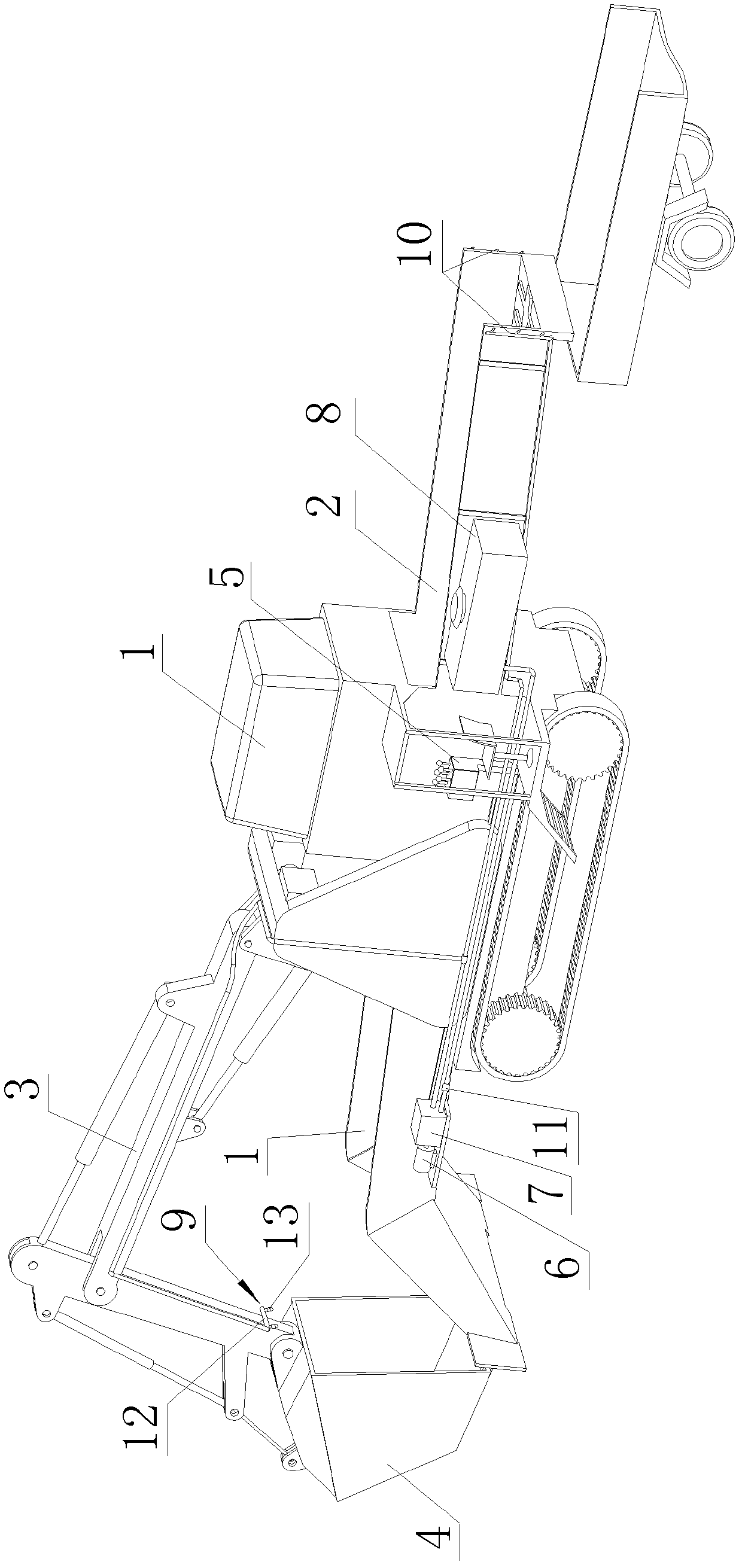

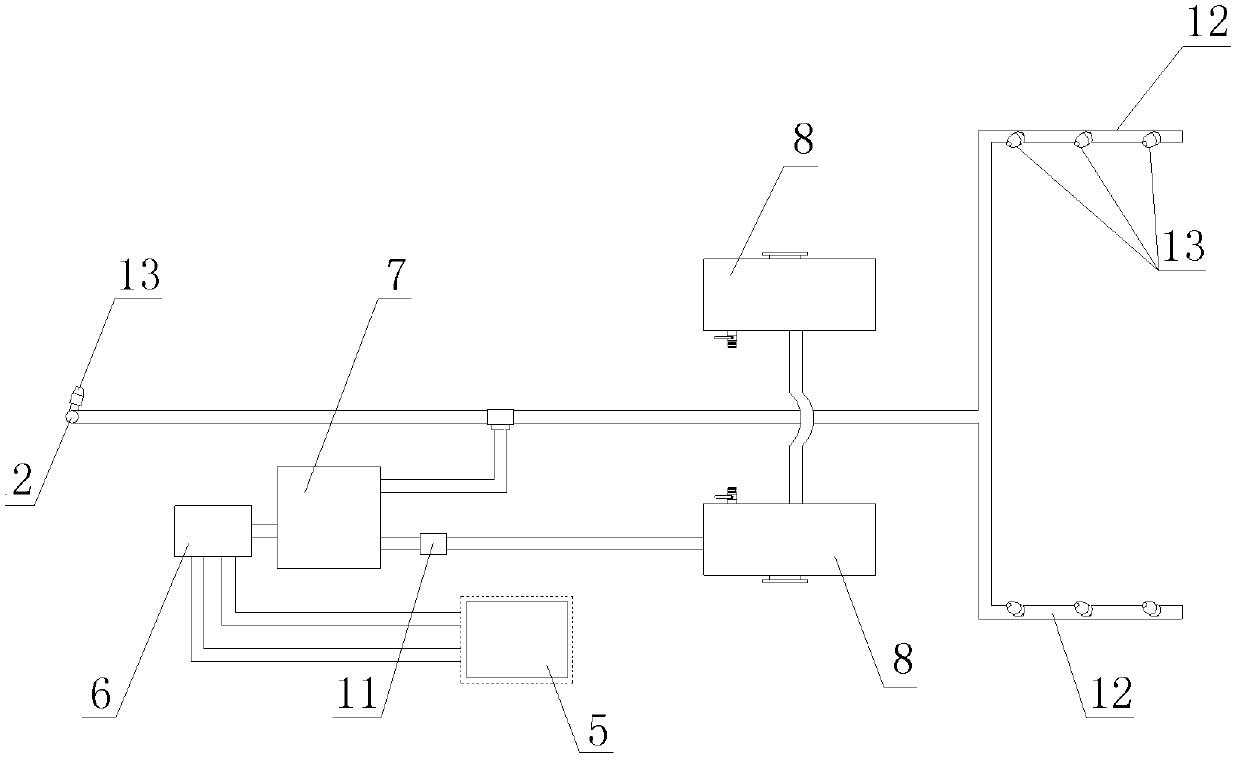

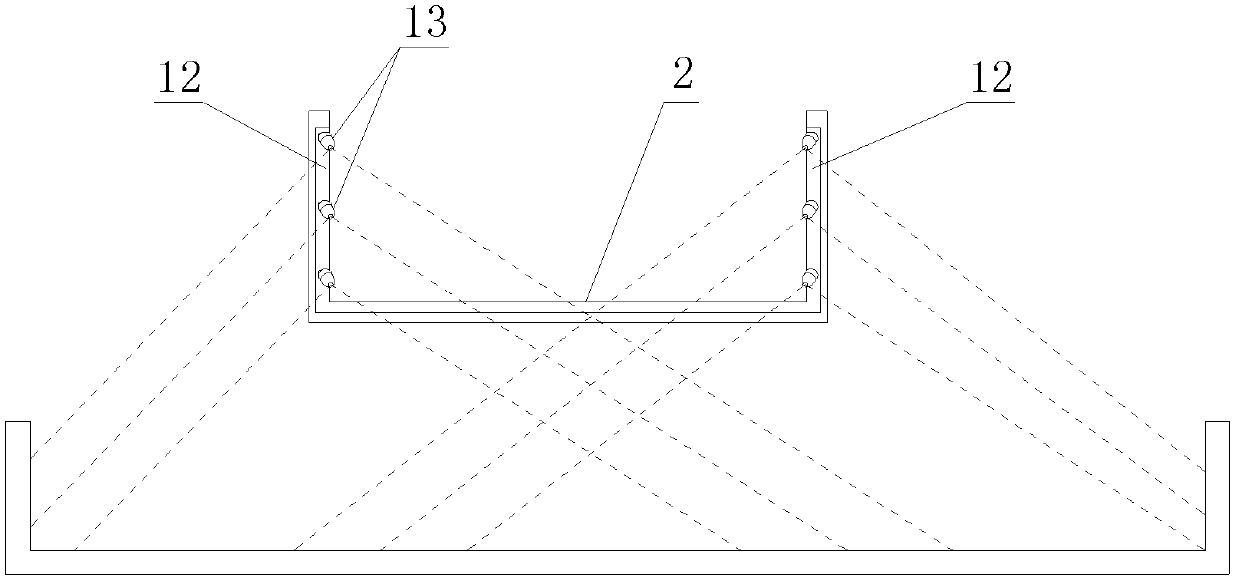

[0015] refer to Figure 1 to Figure 4 As shown, a slag removal machine with an automatic water mist dust suppression device of the present invention includes a body 1, a chain conveying trough 2 is provided on the body 1, a slag removal arm 3 is provided at the front of the body 1, and a slag removal arm 3 is arranged on the body 1. The free end of the slag arm 3 is provided with a scraping hopper 4 corresponding to the feed port of the chain conveyor trough 2, and a hydraulic distributor 5 is provided on the body 1, and the hydraulic distributor 5 and the hydraulic cylinder pipeline on the slag scraper arm 3 connection, the hydraulic distributor 5 is set in the cab to control the slag removal work of the entire slag removal machine; the hydraulic distributor 5 is also connected to the hydraulic motor 6, and the power output shaft of the hydraulic motor 6 is connected to the high-pressure liquid pump 7, The water inlet pipeline of the high-pressure liquid pump 7 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com