Multi-angle multi-directional down suction device for down jacket

A down jacket, multi-directional technology, applied in textile and papermaking, mechanical cleaning, high-pressure cleaning, etc., to achieve the effect of reducing accumulation and cleaning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

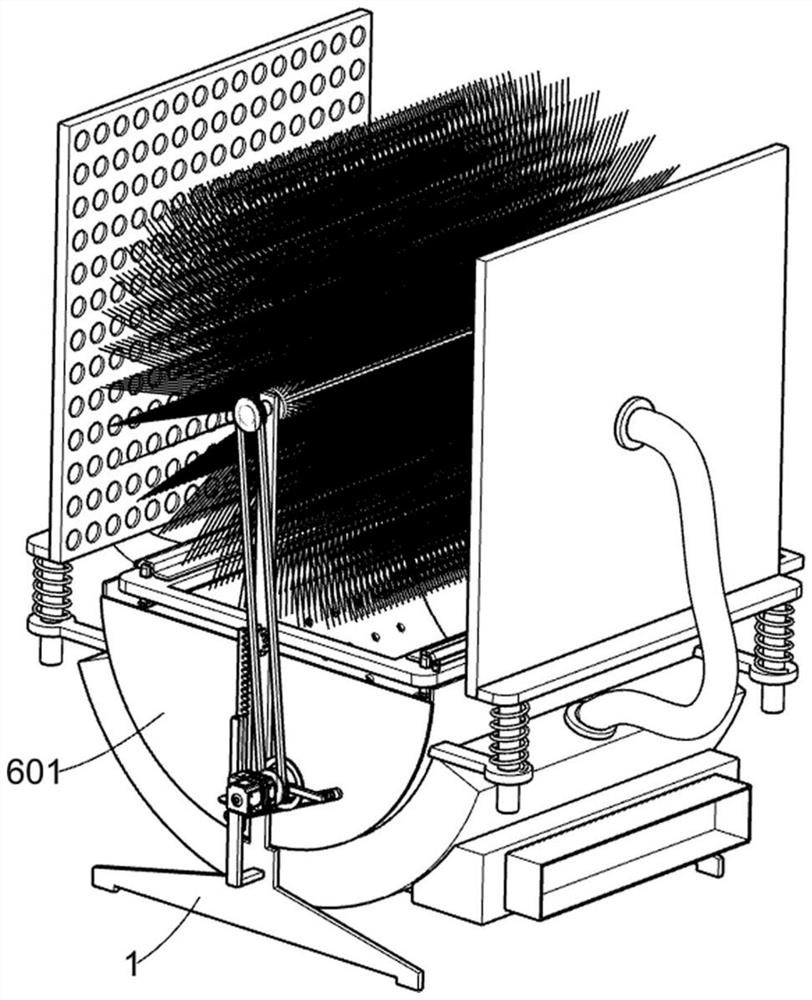

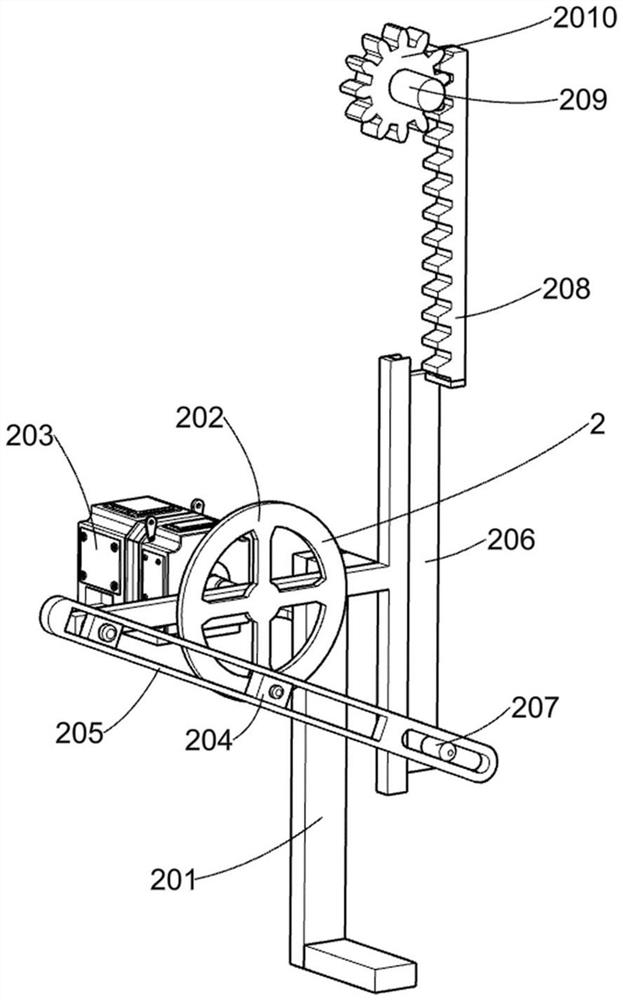

[0023] A device capable of absorbing down jackets from multiple angles and directions, such as Figure 1-8 As shown, it includes a support frame 1, a reciprocating rotation mechanism 2 for a placing plate, a down rolling brush mechanism 3, a placing plate body 4, a down jacket clamping mechanism 5, a eiderdown suction mechanism 6 and a discharge frame 7, and the placing plate reciprocates and rotates Mechanism 2 is arranged on one of the support frames 1, and the down roller brush mechanism 3 for carrying out the roller brush operation to the down fiber is arranged on the two support frames 1 and is connected with the reciprocating rotation mechanism 2 of the placement plate. The placing plate body 4 for placing the down jacket is arranged on the placing plate reciprocating rotation mechanism 2, and the down jacket clamping mechanism 5 for clamping the down jacket on the placing plate body 4 is arranged on the upper side of the placing plate body 4. The down suction mechanism ...

Embodiment 2

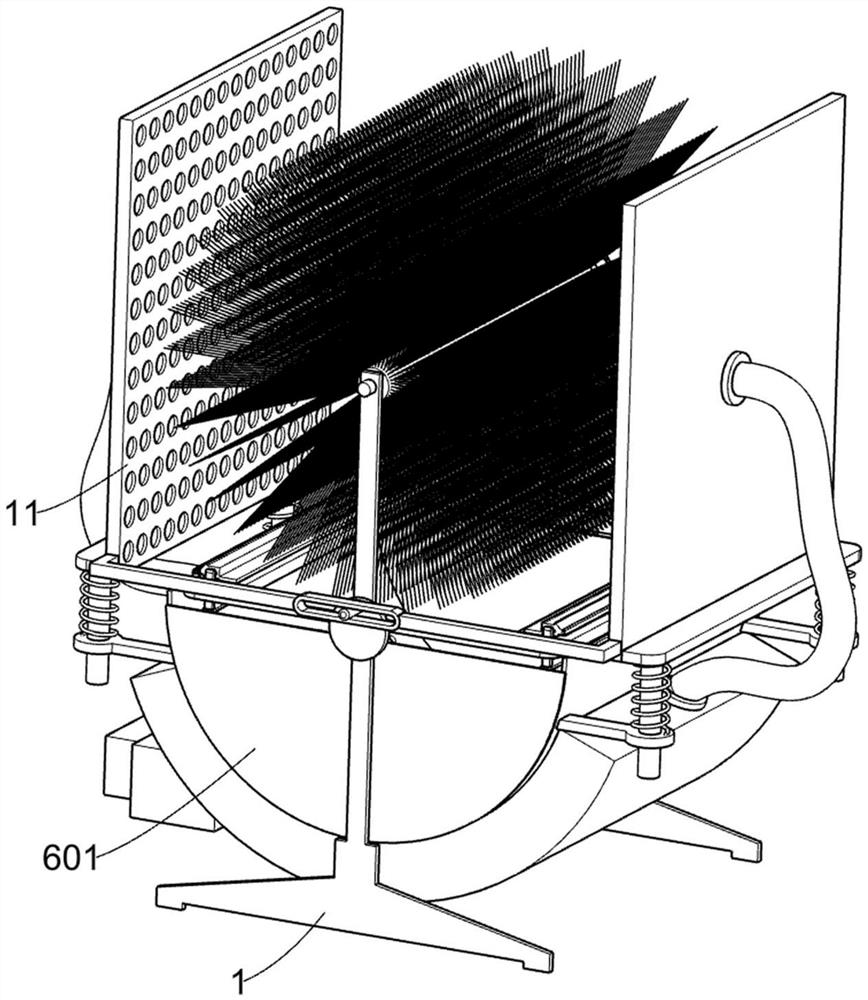

[0032] On the basis of Example 1, such as figure 2 and Figure 8 As shown, it also includes a guide sleeve 8, a movable frame 9, a second compression spring 10, a suction plate 11, a delivery hose 12, a slotted connecting rod 13, a push rotating disc 14 and a pin rod 15, and the semicircle frame 601 Two symmetrical guide sleeves 8 are fixedly provided on both sides of the two groups of guide sleeves 8, and a movable frame 9 is slidably provided in the guide sleeves 8 of the two groups, and a second compression spring 10 is arranged between the movable frame 9 and the guide sleeve 8, Described suction plate 11 is fixedly arranged on the upper side of movable frame 9 and is evenly distributed with suction holes on the suction plate 11, and two described suction plates 11 can be on the down fiber on both sides of down jacket and the hair roller brush 302. The down fibers are adsorbed, and the two suction plates 11 and the arc-shaped frame 603 are connected with a delivery hose ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com