An automatic adjustment system for automobile fuel filler door production

A technology for automatic adjustment and refueling, which can be used in motor vehicles, power units, metal processing, etc., and can solve problems such as great influence.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

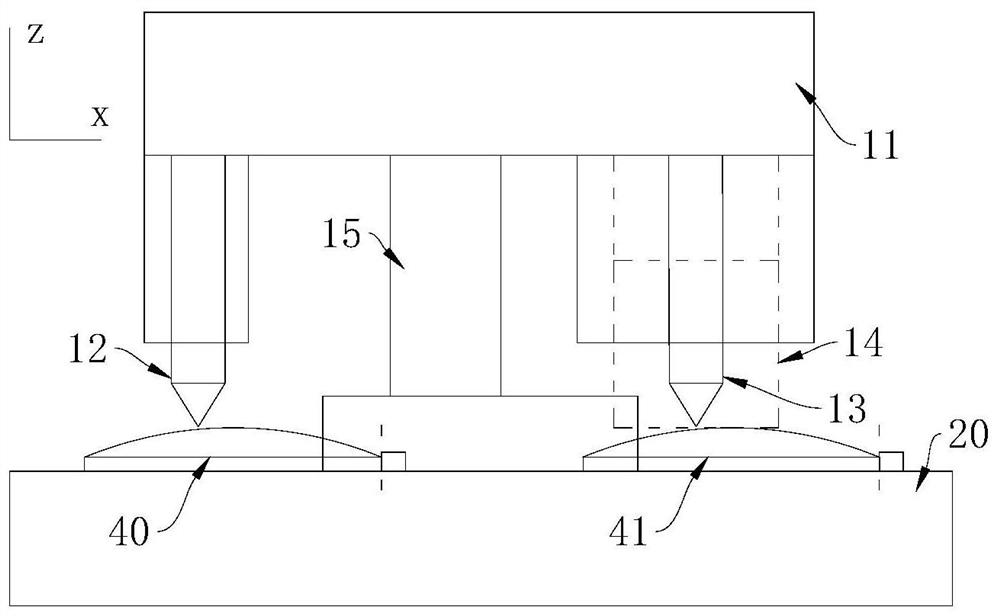

[0038] see Figure 1-Figure 3 , a kind of auto fuel filler door production automatic adjustment system of the present embodiment, comprises the following contents:

[0039] Configuration unit: it is used to set the fuel filler door standard part and the tested part on the base of the workbench, and configure the calibration parameters; among them, the reference blocks are respectively arranged on the base to fix the reference side of the standard part and the tested part, so that The standard part and the tested part are fixed on the base with a certain distance h;

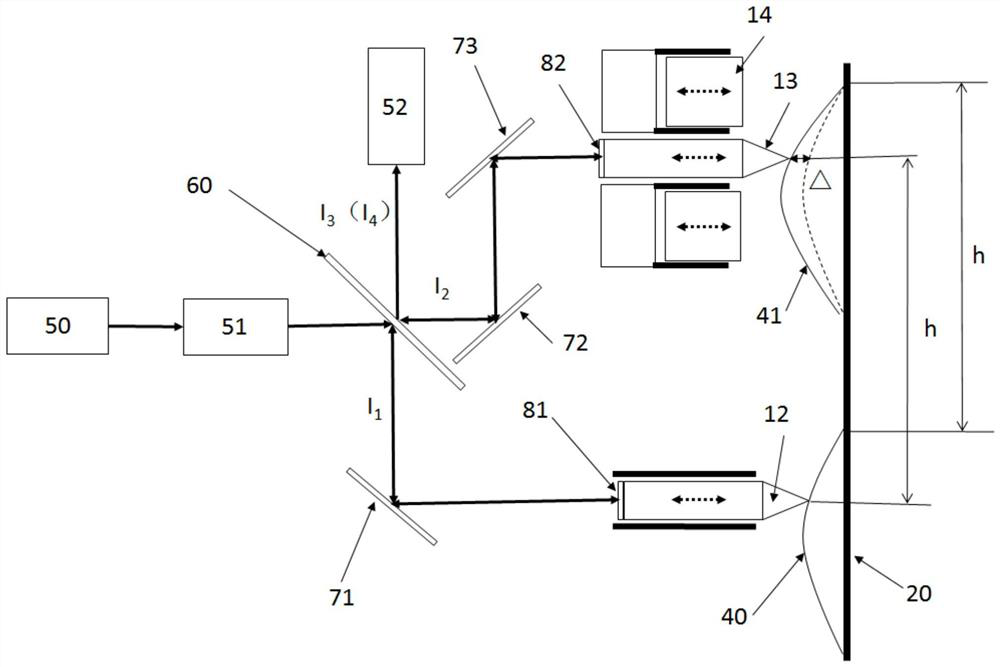

[0040] Laser calibration unit: used to compare the surface of the standard part and the tested part by using the Michelson interference system, use the calibration block to push the deformation of the tested part surface to perform the calibration operation, and verify the verification operation of the comparison operation and the calibration operation;

[0041] The comparison operation includes: adjusting the di...

Embodiment 2

[0057] see Figure 4-Figure 6 , on the basis of embodiment 1, a kind of automatic adjustment system for the production of automobile fuel filler door of the present embodiment also includes an image verification unit, and the image verification unit includes a smoothness verification module, an opening angle verification module, and a gap verification module And surface difference calibration module;

[0058] The configuration unit is also used to install the test piece of the fuel filler door on the simulation base for preset detection, and configure the calibration parameters; wherein, the center of the simulation base is provided with a reserved opening for installing the fuel filler door, and There is a simulation board for the side wall of the body on the periphery, and the fuel filler door can be locked or opened;

[0059] Smoothness verification module: used to illuminate the simulation board and the test piece in the closed position, and then use the camera component ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com