Multifunctional automatic carrying device

A handling device and multi-functional technology, which is applied in the field of multi-functional automatic handling devices, can solve the problems of single structure of the handling device, poor handling capacity, inability to telescopically lift or fold, etc., to achieve convenient construction, convenient handling operations, and reduced occupancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

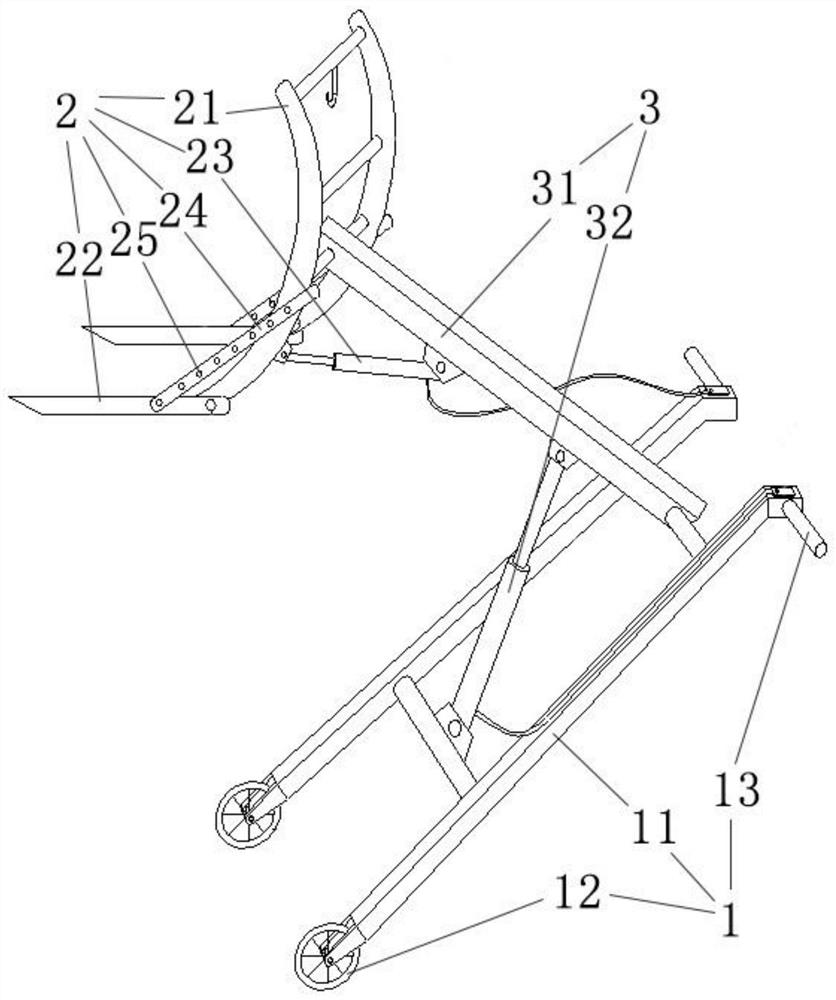

[0024] As shown in the figure, a multifunctional automatic handling device includes:

[0025] The walking part 1, the walking part 1 includes a vehicle frame 11, the bottom of the vehicle frame 11 is provided with a number of wheels 12 for walking, and the vehicle frame 11 is welded by two vertical bars and two horizontal bars to form a rectangular frame structure;

[0026] The cargo support part 2 is used to carry the articles to be transported. The cargo support part 2 includes a shelf 21, and the front side of the bottom of the shelf 21 is provided with a fork 22. The shelf includes two arc-shaped support rods, and the two arc-shaped support rods pass through multiple The root connecting beam is fixedly connected, and the connecting beam at the top is provided with a hook for hanging items;

[0027] The lifting part 3 is used to realize the lifting of the cargo supporting part 2, the bottom of the lifting part 3 is connected with the vehicle frame 11, the lifting end of the...

Embodiment 2

[0035] As shown in the figure, a multifunctional automatic handling device includes:

[0036] The walking part 1, the walking part 1 includes a vehicle frame 11, the bottom of the vehicle frame 11 is provided with a number of wheels 12 for walking, and the vehicle frame 11 is welded by two vertical bars and two horizontal bars to form a rectangular frame structure;

[0037] The cargo support part 2 is used to carry the articles to be transported. The cargo support part 2 includes a shelf 21, and the front side of the bottom of the shelf 21 is provided with a fork 22. The shelf includes two arc-shaped support rods, and the two arc-shaped support rods pass through multiple The root connecting beam is fixedly connected, and the connecting beam at the top is provided with a hook for hanging items;

[0038] The lifting part 3 is used to realize the lifting of the cargo supporting part 2, the bottom of the lifting part 3 is connected with the vehicle frame 11, the lifting end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com