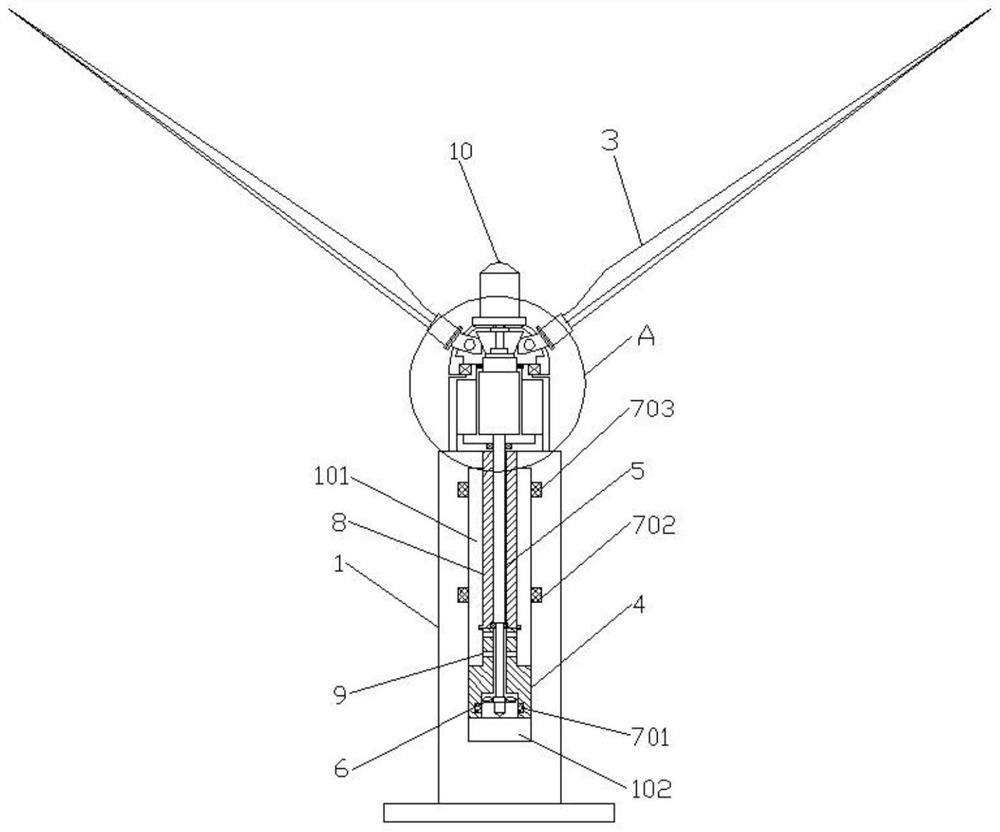

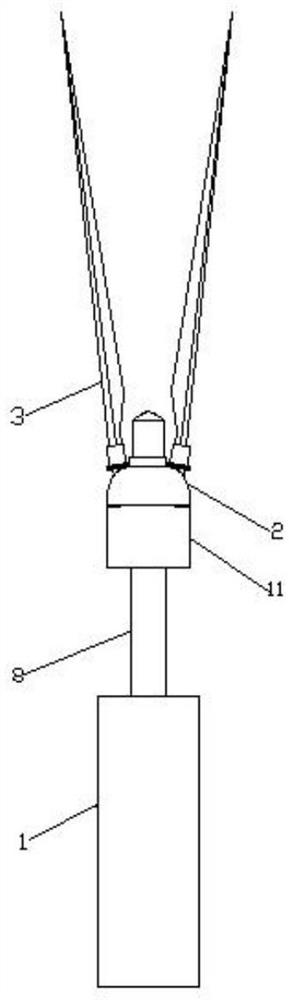

Vertical axis wind turbine based on magnetic damping technology

A wind turbine, vertical axis technology, applied to wind turbines, wind turbines at right angles to the wind direction, wind turbine combinations, etc., can solve the problem that the pitch pitch technology stays in the theoretical stage, the vertical axis wind turbine is slow, and it is unfavorable for power generation. It can improve the utilization rate of wind energy, reduce the cost of the whole machine, and attenuate vibration.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

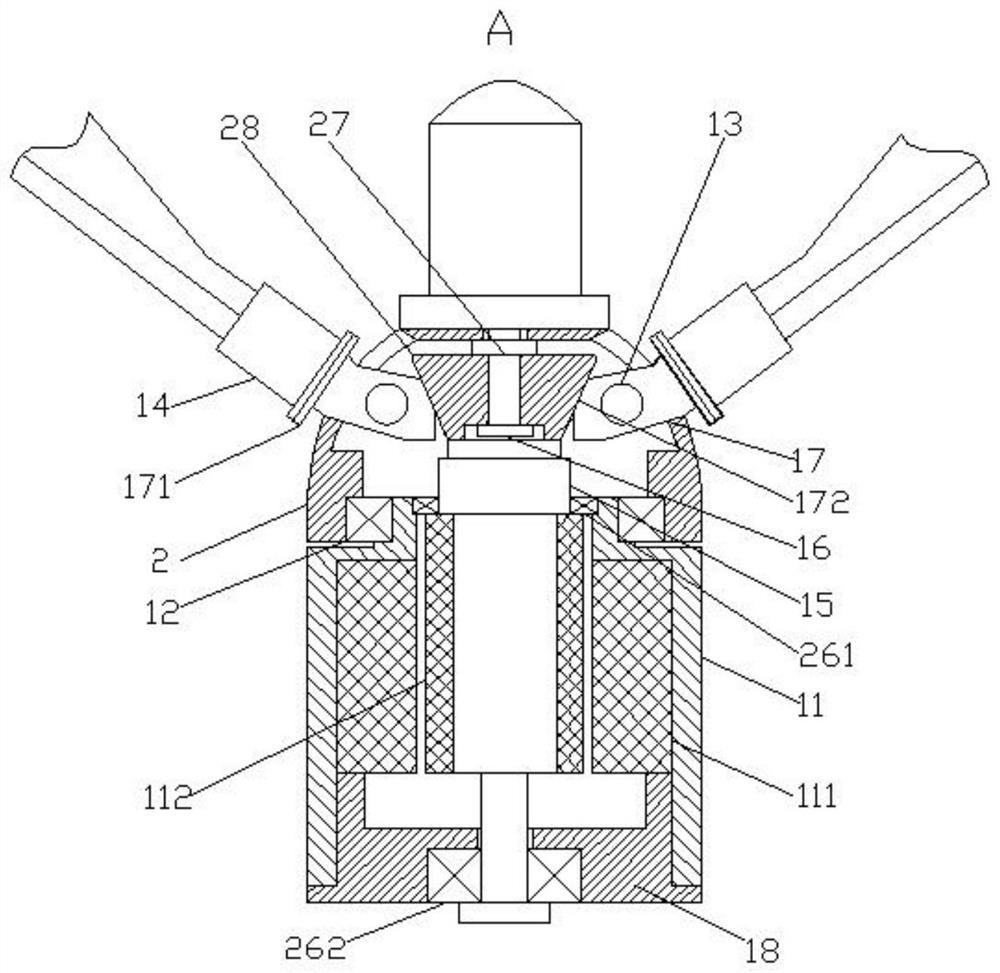

[0027] In the following, the embodiments of the present invention will be described in detail in conjunction with the accompanying drawings.

[0028] A vertical axis wind power generator based on magnetic damping technology, including a hub 2, the hub 2 is a hemispherical shell structure, the surface of the spherical shell has a first guide groove 201, a second guide groove 202 and a third guide groove 203, the first One guide groove 201, the second guide groove 202 and the third guide groove 203 process shaft hole 204 in the direction perpendicular to the groove surface, the paddle shaft 13 is installed in the shaft hole 204, the swing arm 17 is installed on the paddle shaft 13, and one end of the swing arm 17 is welded The swing arm flange 171 has a wedge surface 172 processed at the other end. The pitch control assembly 14 is installed on the swing arm flange 171. The blade 3 is installed in the pitch control assembly 14. The wedge surface 172 is pressed against the first st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com