Method for producing a decorative surface, in particular of a wood workpiece

A decorative, wood surface technology, applied in the field of equipment for implementing the method, can solve problems such as a large number of manual operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

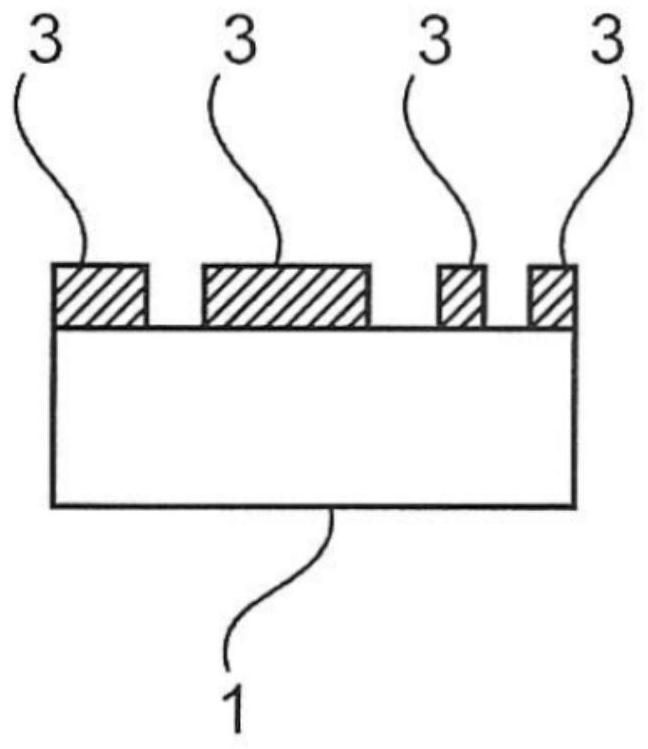

[0054] exist Figure 1a The workpiece 1 is shown in a side view, which is designed here as a plate-shaped workpiece 1 . The workpiece 1 contains solid wood or wood fibers at least in partial regions of the surface.

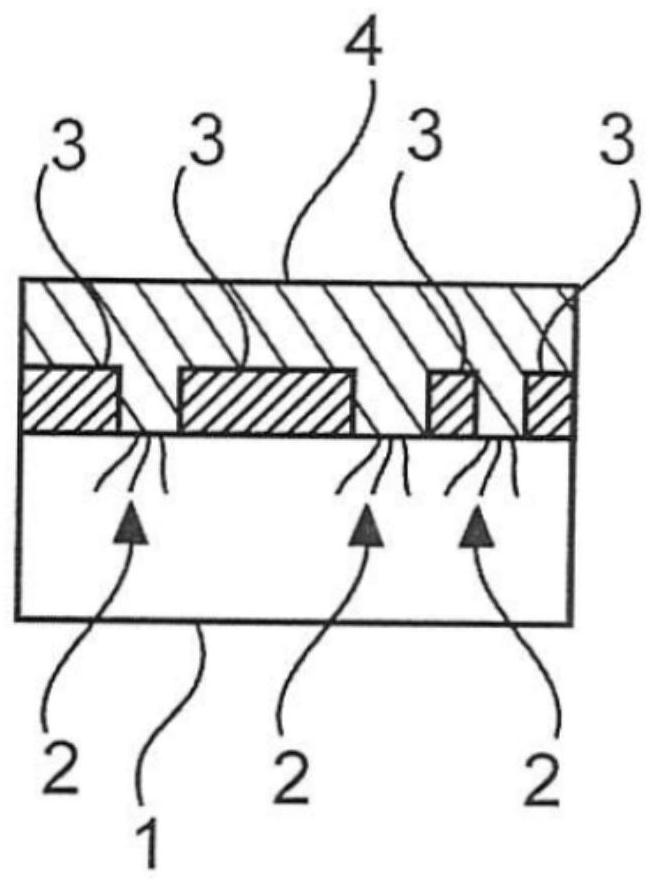

[0055] A covering 3 is applied to the upward facing surface of the workpiece 1 . The covering 3 is applied in such a way that at least some parts of the surface of the workpiece 1 are covered by the covering 3 . The result of this imposition is in Figure 1b shown in . The covering 3 is used for sealing on the surface of the workpiece 1 so that the area of the surface of the workpiece 1 to which the covering 3 is applied is sealed. Thus, the surface is masked for the next step, ie sub-regions of the surface of the workpiece 1 are no longer exposed as before.

[0056] In a further step, a liquid 4 is applied to the surface of the masked workpiece 1 . The liquid 4 here only comes into contact with exposed (ie uncovered) areas of the surface of the workpiece ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com