Formed reinforced complex phase steel and preparation method thereof

A technology of complex phase steel and chemical composition, applied in the field of cold-rolled ultra-high-strength steel production and manufacturing, can solve the problems of poor forming ability of complex phase steel, and achieve the effect of good hole expansion performance and formability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

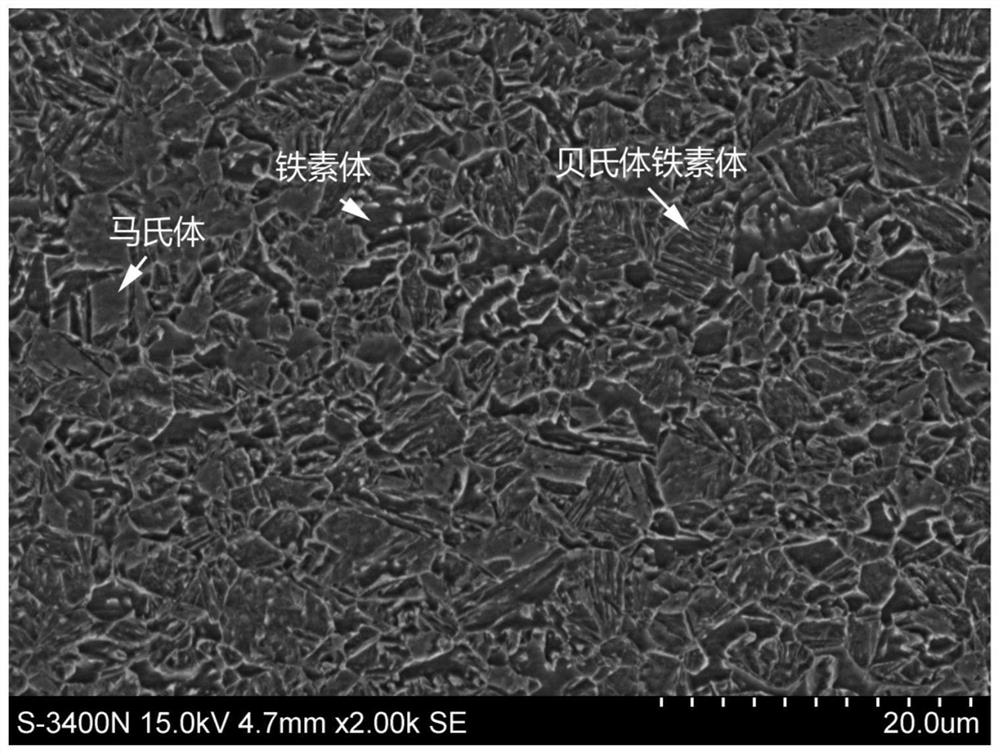

Image

Examples

Embodiment

[0064]The chemical composition of the formed reinforced composite phase steel according to the mass fraction of the present invention is as follows:

[0065]C: 0.17%~0.21%, Si: 0.2~0.7%, Mn: 1.8~2.5%, P: ≤0.01%, S: ≤0.005%, Al: 0.4~0.8%, Cr: 0.1~0.39%, Nb: 0.02~0.04%;

[0066]And contains at least one of the following elements:

[0067]Ti: 0.01 to 0.04%, Cu: 0.03 to 0.1%; the balance is Fe.

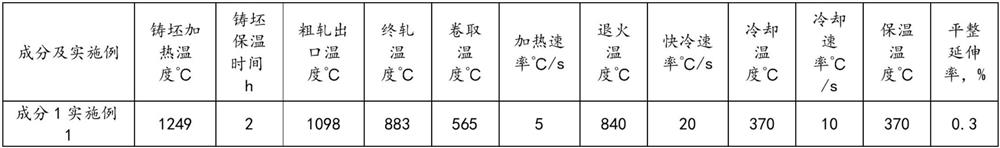

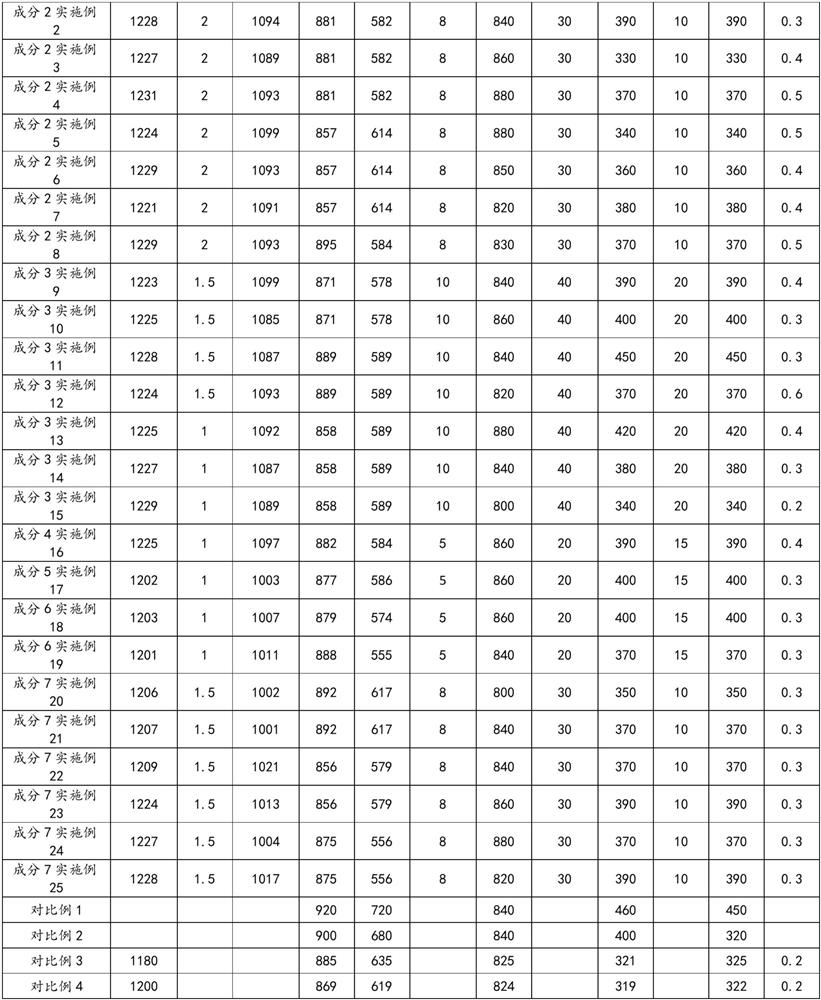

[0068]The present invention has 25 examples and 4 comparative examples. In the 25 examples, the forming reinforced multiphase steel has a total of 7 different chemical compositions, named as compositions 1-7, compositions 1-7, and the chemical compositions of the comparative examples. Table 1 shows.

[0069]Table 1 Chemical composition of ingredients 1-7 and comparative examples 1-4 (mass fraction%)

[0070] CSi Mn PSAlNb CrMo Ti Cu Ingredient 1 0.170.662.060.0050.0030.530.0310.38-0.0380.009 Ingredient 2 0.180.332.110.0070.0030.750.0220.25-0.040.012 Ingredient 3 0.190.572.320.0070.0020.570.0280.31-0.0320.012...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com