Steel box girder mounting method

An installation method and technology of steel box girder, applied in bridges, bridge materials, bridge construction and other directions, can solve the problems of unfavorable and smooth closing of steel box girder inclination, unable to meet the actual use, etc., to achieve convenient closing, good use effect, and guarantee stability. effect of marching

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

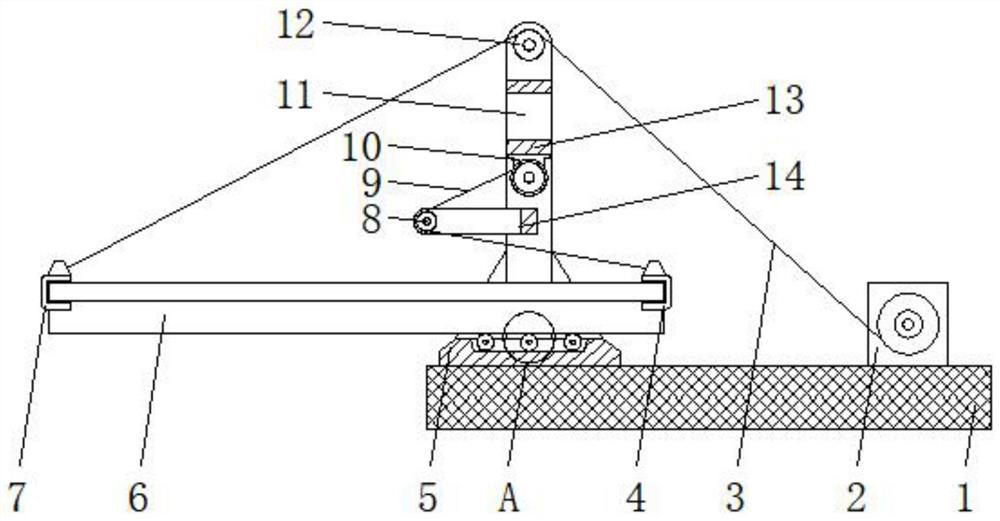

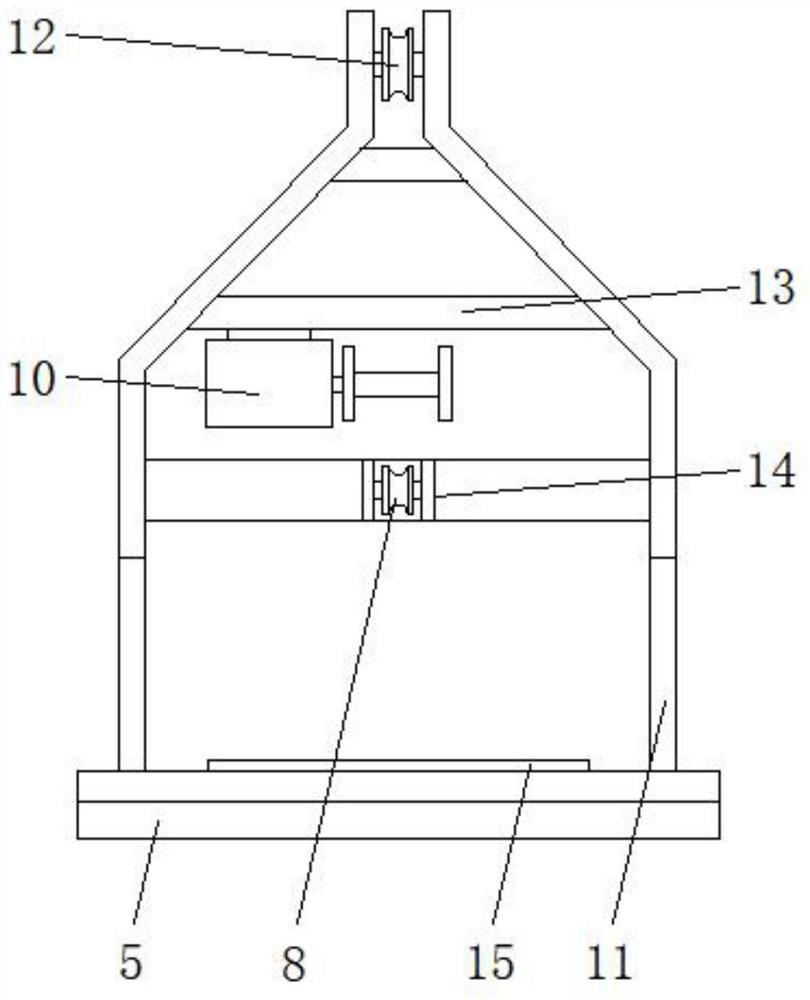

[0027] A steel box girder installation structure, comprising a bridge body 1, a base 5 and a bracket 11, the upper surface of the bridge body 1 is equipped with a base 5, the upper surface of the base 5 is welded with a bracket 11, and one side of the base 5 is provided with a second A hoist 2, a second hoist 10 is installed inside the bracket 11, the first hoist 2 is fixed on the completed section of the bridge body 1, and the first hoist 2 and the surface of the bridge body 1 are reinforced by bolts to avoid loosening. The base 5 is also a completed section fixed on the bridge body 1, reinforced by bolts, and can be disassembled and installed flexibly for continuous use.

[0028] The inner wall of the lower end of the support 11 is welded with an extension frame 14, and the extension frame 14 is equipped with a first pulley 8 inside the end away from the support 11, and the second hoist 10 is located at the upper end of the extension frame 14. The steel cable 9 is sleeved on...

Embodiment 2

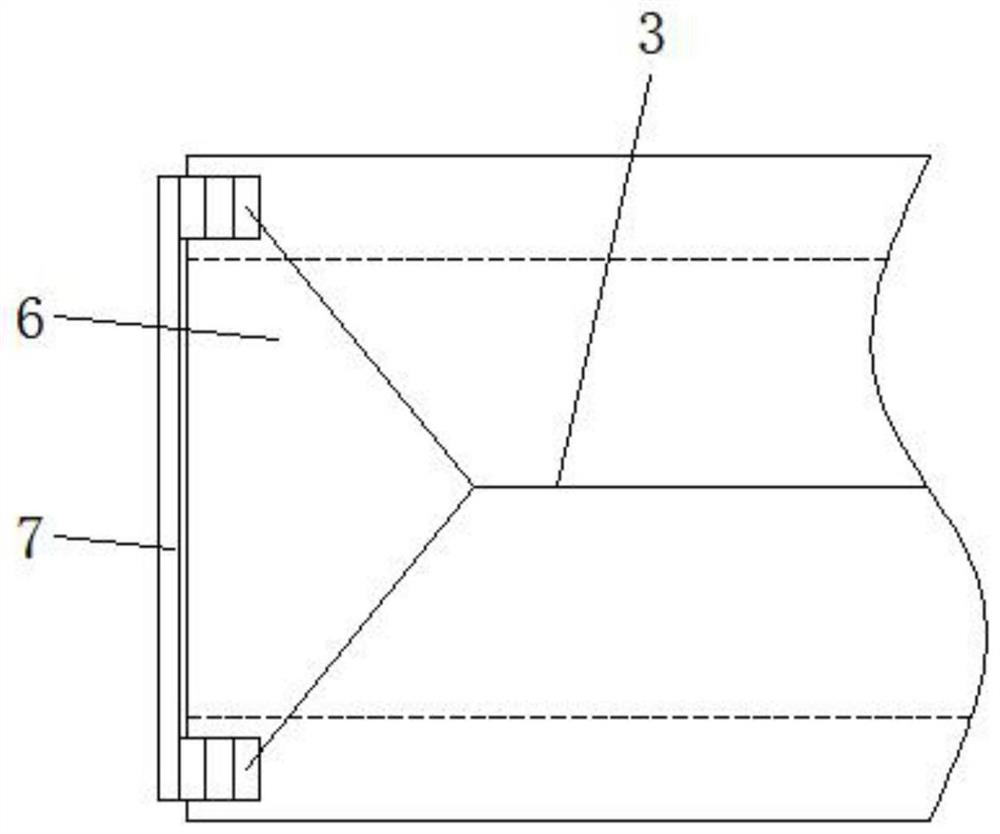

[0033] A method for installing a steel box girder, comprising a first hoist 2 and a second hoist 10, characterized in that the first hoist 2 pulls the second ferrule 7 through the first steel cable 3 to move, and the second hoist 10 moves through the second steel The cable 9 pulls the first ferrule 4 to move.

[0034]The first hoist 2 can tighten and release the first steel cable 3 slowly. When one end of the steel box girder body 6 is sleeved on the second ferrule 7, the first steel cable 3 connected to the second ferrule 7 is subjected to the first The traction of the winch 2, when the steel box girder body 6 is advancing, the first steel cable 3 can lift the front end of the steel box girder body 6, and the forward end of the steel box girder body 6 remains horizontal to facilitate docking, and the second pulley 12 can increase the hoisting moment of the first wire rope 3.

[0035] When the second hoist 10 is rewinding the second steel cable 9, the second steel cable 9 wil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com