Fabricated inorganic mineral plate leveling and mounting structure

A technology for installing structures and inorganic substances, which is applied in building structures, floors, buildings, etc. It can solve the problems that the leveling feet cannot form stable supports, the installation process of the feet is complicated, and the structural stability is poor, so as to achieve a good decorative effect , The effect of simple construction process and strong bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

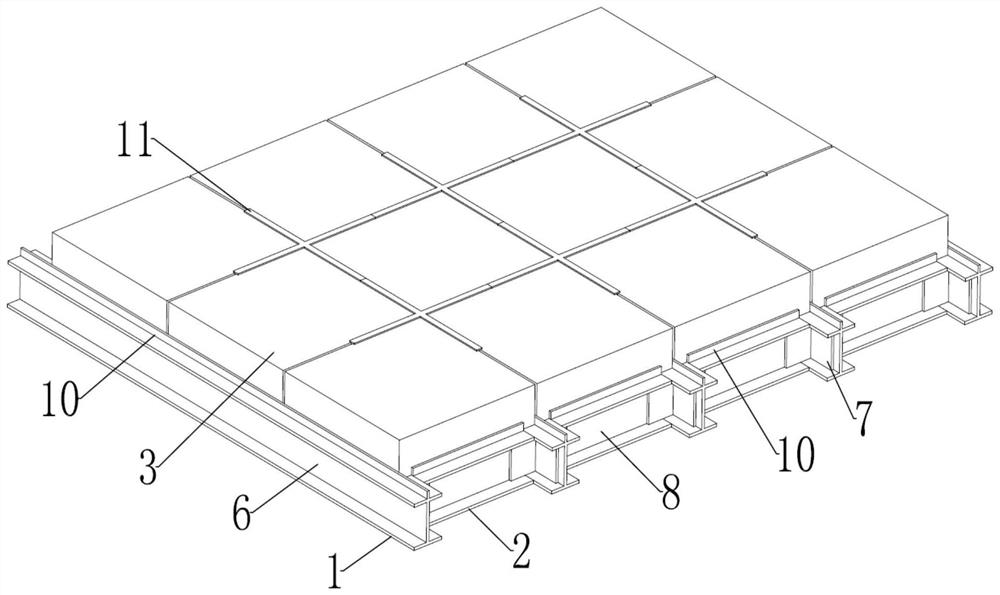

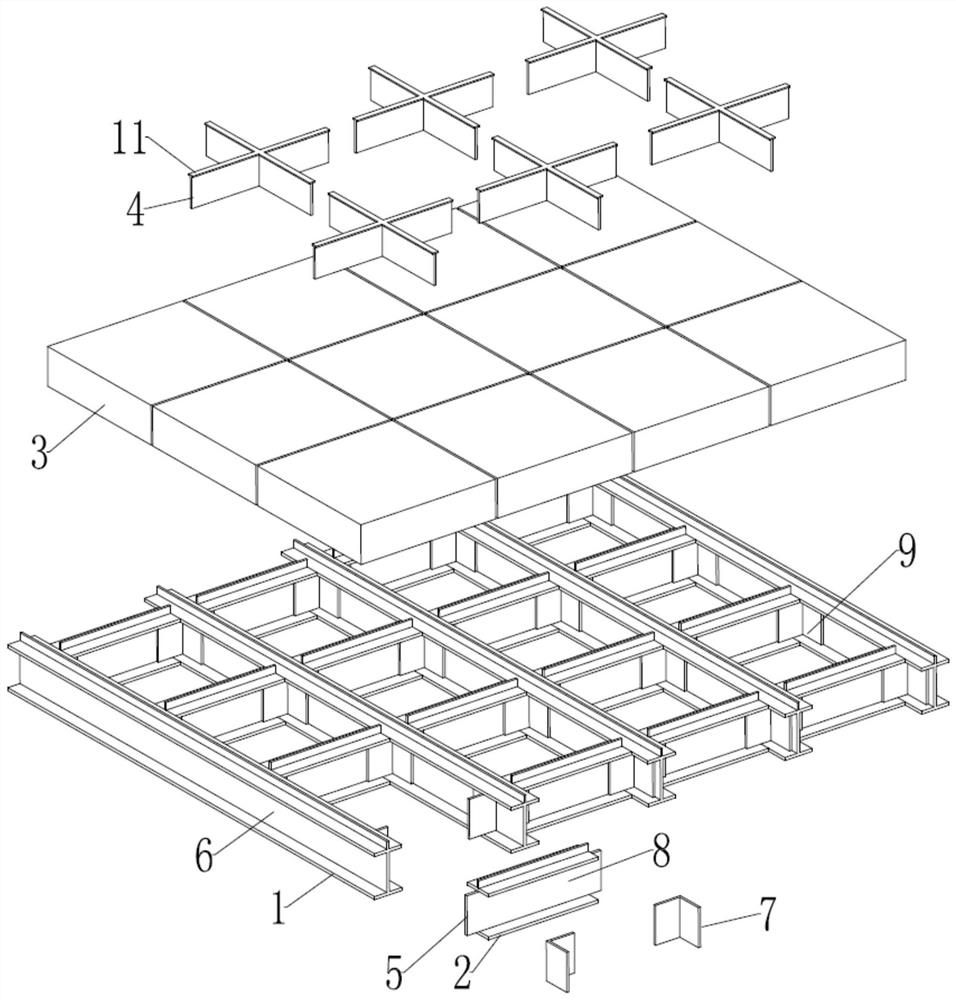

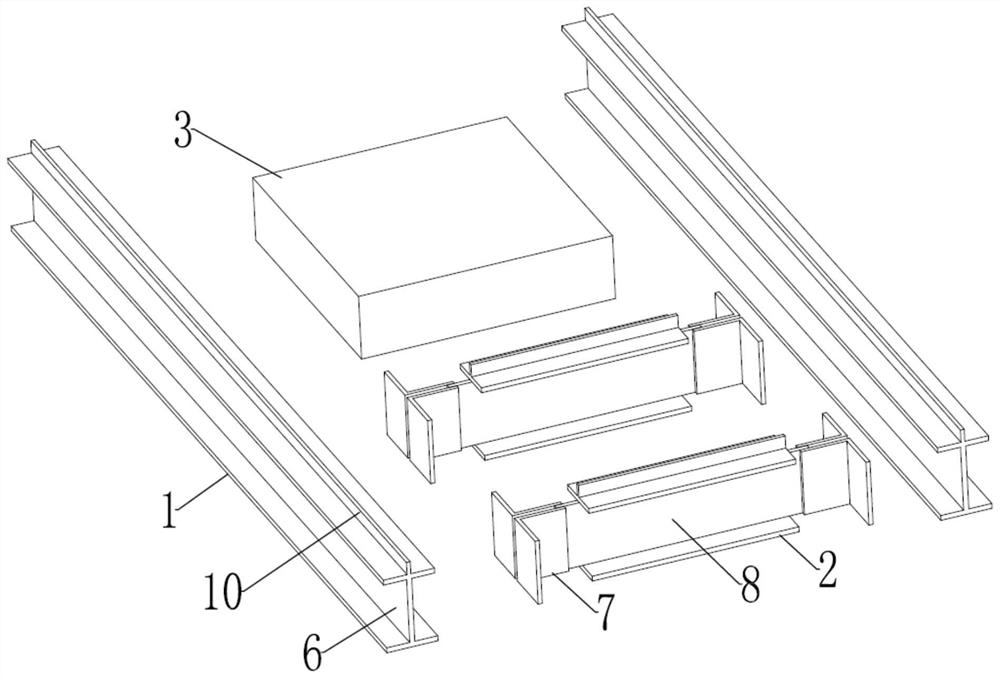

[0030]SeeFigure 1 to Figure 7This embodiment provides an assembly type inorganic mineral board leveling installation structure, in which, first, the main keel 1, the auxiliary keel 2, the floor body 3 and the edge strip 4 are set, and the main keel 1 is fixedly connected to On the ground base, multiple main keels 1 are arranged parallel to each other, and auxiliary keels 2 are arranged perpendicular to the main keel 1, and the auxiliary keels 2 are located between two adjacent main keels 1, and the two ends of the auxiliary keels 2 are provided with bosses 5 , The boss 5 is clamped into the first slot 6 of the side wall of the main keel 1, the boss 5 is fixedly connected to the bottom of the first slot 6 through the corner code 7, and the boss 5 extends to the second side wall of the auxiliary keel 2. In the clamping groove 8, two adjacent main keels 1 and two adjacent auxiliary keels 2 are enclosed to form an installation groove 9. The floor body 3 is clamped in the installation gr...

Embodiment 2

[0039]SeeFigure 1 to Figure 7, The figure shows a prefabricated inorganic mineral plate leveling installation structure provided by the second embodiment of the present invention. On the basis of the above embodiment, this embodiment further makes the following as an improved technical solution: The main keel 1 and the auxiliary keel 2 are both steel rail structures with a "earth" cross section, and the cross-sections of the main keel 1 and the auxiliary keel 2 have the same dimensions.

[0040]Effective strength support is provided by the I-shaped bottom structure, and the upward limit plate 10 serves as the edge of the installation slot 9 to limit the floor body 3. The structure is ingeniously designed to ensure the structural strength and functional requirements while making the main The auxiliary keel 2 is lightweight, saves material, and is easy to install.

Embodiment 3

[0042]SeeFigure 1 to Figure 7, The figure shows a prefabricated inorganic mineral plate leveling installation structure provided in the third embodiment of the present invention. On the basis of the above-mentioned embodiment, this embodiment further makes the following technical solutions as an improvement: The edge strip 4 has a cross-shaped structure, and the end surfaces of two adjacent edge receiving strips 4 are attached together, and the thickness of the edge receiving strip 4 is equal to the width of the limiting plate 10.

[0043]Specifically, seeFigure 1 to Figure 7, The top surface of the edge receiving strip 4 coincides with the top surface of the floor body 3, and the top surface of the edge receiving strip 4 is provided with a decorative noodle strip 11, which has a cross-shaped strip structure.

[0044]Specifically, see Figure 1 to Figure 7 , The decorative noodle 11 is made of rubber.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com