Cooling and shaping device for PVC film production

A technology of cooling and shaping and cooling box, which is applied in the field of cooling and shaping devices for PVC film production, can solve the problems of unguaranteed cooling of PVC film, uneven cooling of PVC film, wrinkling of PVC film, etc., to achieve flexible adjustment of cooling time, uniform cooling, The effect of uniform cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

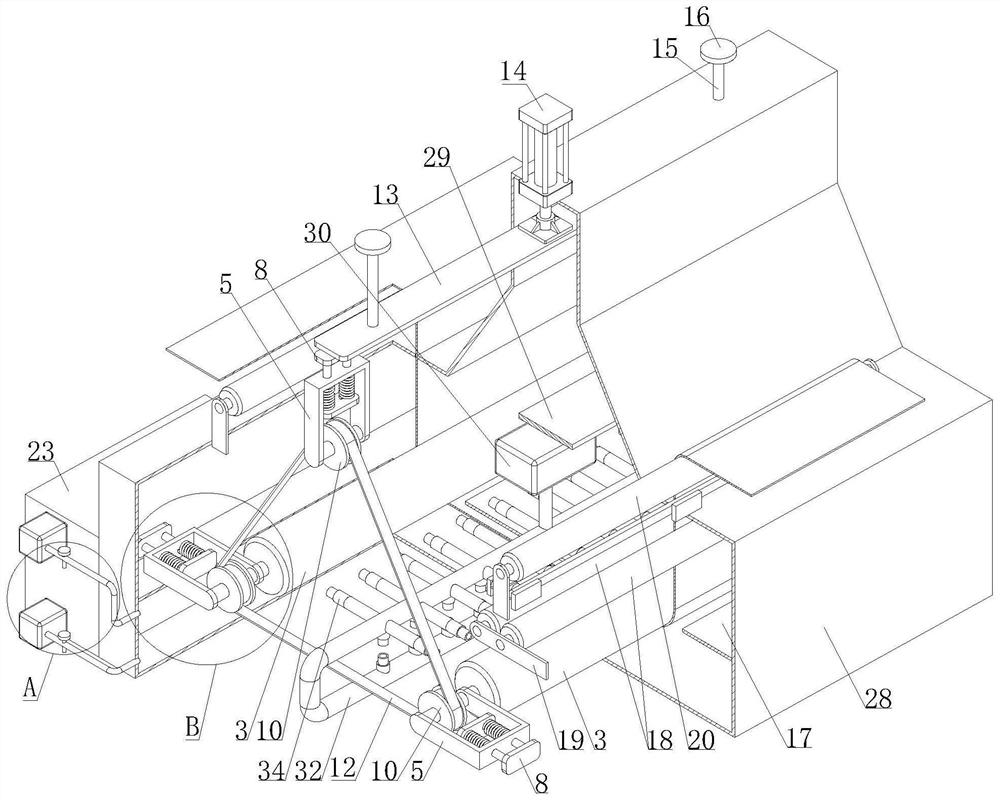

[0026] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in combination with specific embodiments and with reference to the accompanying drawings. It should be understood that these descriptions are exemplary only, and are not intended to limit the scope of the present invention. Also, in the following description, descriptions of well-known structures and techniques are omitted to avoid unnecessarily obscuring the concept of the present invention.

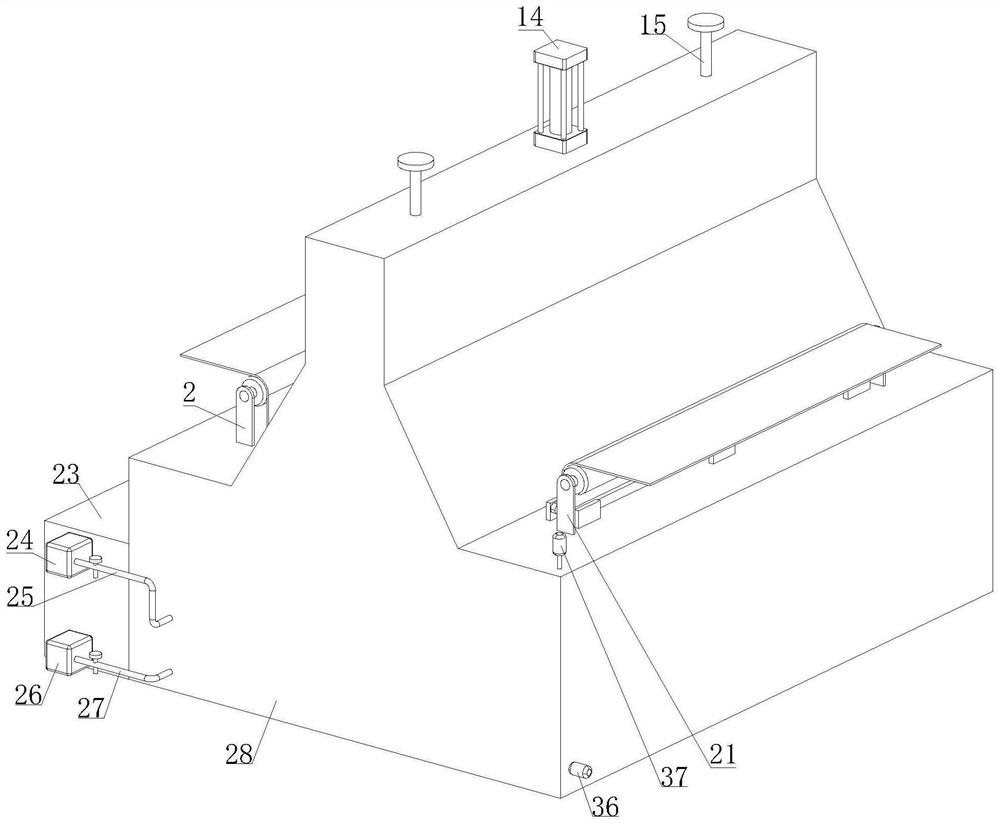

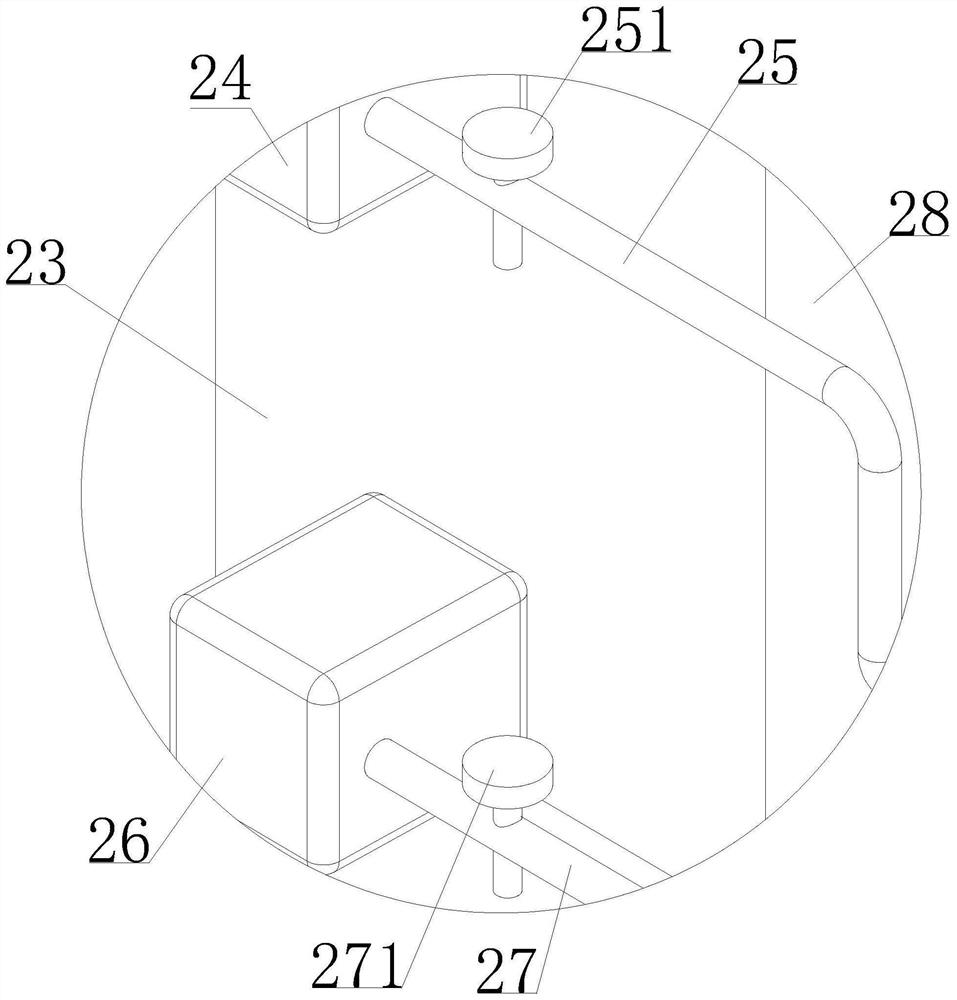

[0027] Such as Figure 1-5 As shown, a kind of PVC film production cooling setting device that the present invention proposes, comprises cooling roll 3, elastic adjustment assembly, transmission mechanism, moving plate 13 and cooling box 28;

[0028] The film inlet hole and the film outlet hole are respectively arranged on the top lateral sides of the cooling box 28; the cooling roller 3 and the elastic adjustment assemb...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap