Simple multi-angle mechanical assembly accurate installation fastener

A multi-angle, simple technology, applied in the direction of mechanical equipment, fixing devices, etc., can solve the problems of reducing the safety of mechanical parts, the tightness of mechanical parts cannot meet the requirements, and the assembly requirements cannot be met, so as to ensure the installation accuracy and use cost Low, the effect of reducing the overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

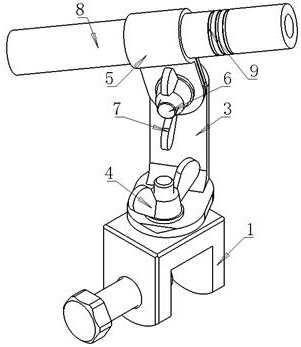

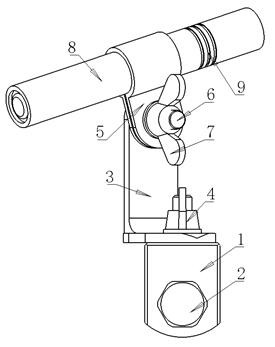

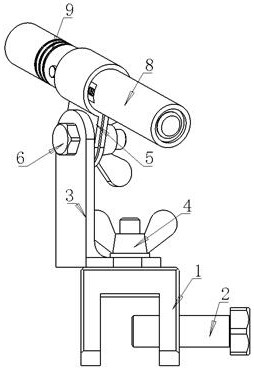

[0020] like Figure 1 to Figure 7 As shown, a simple multi-angle mechanical assembly for precise installation of fasteners has a simple overall structure and is more flexible and convenient to use. When in use, the installation position can be calibrated according to the installation needs of mechanical fasteners to ensure that the mechanical The installation accuracy of fasteners during installation can effectively improve the efficiency of installation and reduce the overall cost of mechanical parts during installation, so that it can meet the requirements of high-precision mechanical products such as aviation for the assembly accuracy of mechanical fasteners , to ensure the overall safety of the mechanical parts during use. The fastener can be adjusted to multiple positions in different directions according to the needs during use, and it can have a wider adjustment range during use, so that the whole The application range is wider, the overall cost of the installation fast...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com