Target mode position measurement method and system, storage medium and equipment

A measurement method and target technology, applied in character and pattern recognition, image analysis, image enhancement, etc., can solve problems affecting positioning accuracy, hidden safety hazards, blurred boundaries of target objects, etc., and achieve rapid 3D modeling and wide application space Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

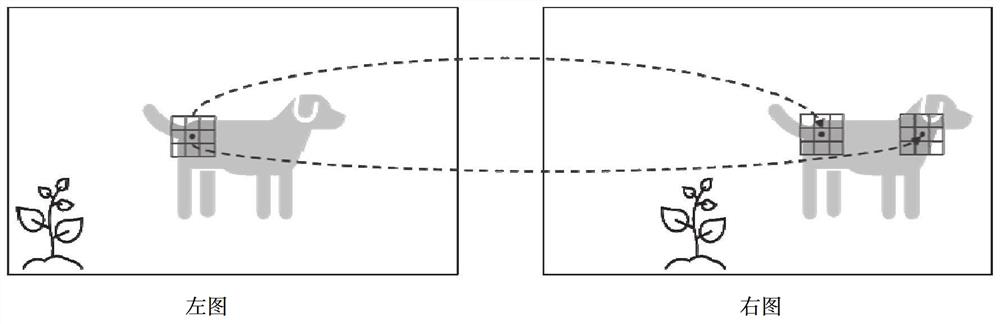

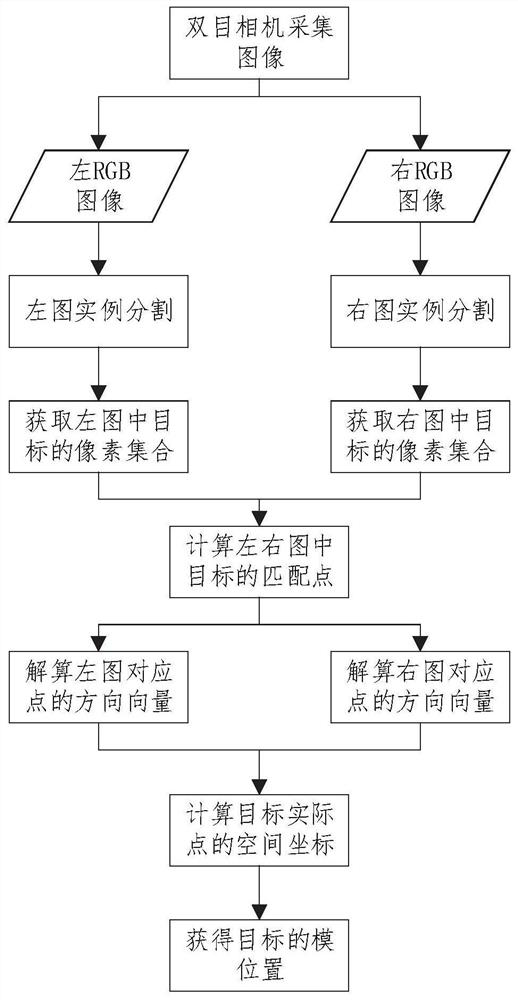

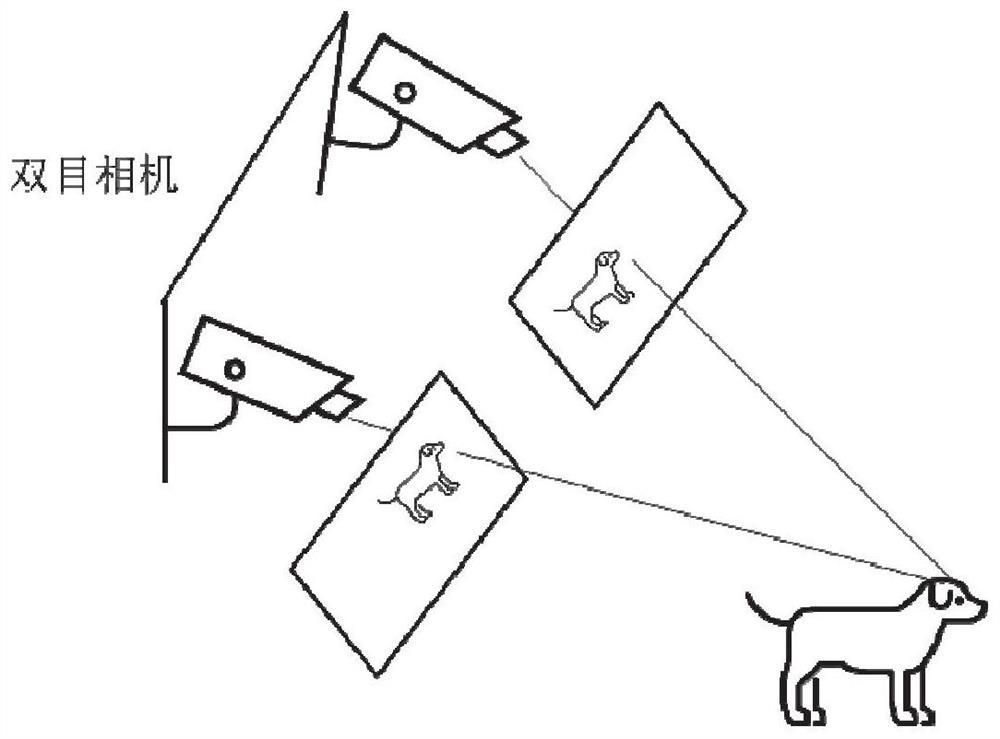

[0048] This embodiment proposes a method for measuring the position of a target module based on a binocular camera. Such as figure 1 As shown in Fig. 1, the left and right images of the target entity are first collected by a binocular camera. Instance segmentation is performed on the left and right images respectively to obtain the target entity to be measured in the image, and the pixel set of the target to be measured in the left and right images is obtained. Taking the left image as the reference image, the pixel points of the target in the two images are matched to obtain the one-to-one correspondence between the target pixel points in the left and right images.

[0049] Solve the poses of the two cameras using the pixel and world coordinates of the known reference fiducials. Based on the camera pose and the pixel coordinates of the target to be measured, the spatial direction vector of the target point is calculated. After obtaining the spatial direction vectors of the...

Embodiment 2

[0073] Utilize the method of embodiment 1 to the positioning of the packing box (such as a cube box) in the industrial automation production workshop: by measuring the mold position of the cube box in an industrial automation production scene, the position and occupied space of the cube box in the scene can be obtained, and the manipulator According to the mold position of the box, it can be accurately grasped.

Embodiment 3

[0075] The method of Embodiment 1 is used to locate each electric device in the substation, determine the boundary of the electric device, and mark the above-mentioned boundary in the patrol inspection task, so as to control the robot to avoid obstacles.

[0076] In addition, the following product examples are provided:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com