Bayonet lock fixing mode and fixing method for air respirator back plate device

A fixed method and respirator technology, applied in the direction of respiratory protection devices, life-saving equipment, etc., can solve the problems of changing the size and sliding of the main backplane and movable backplane

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

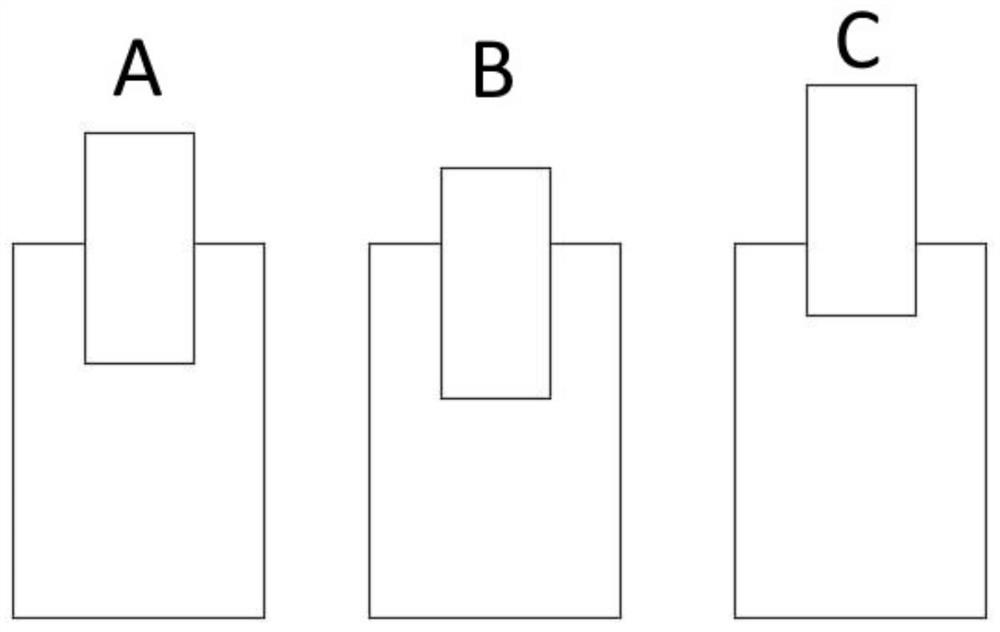

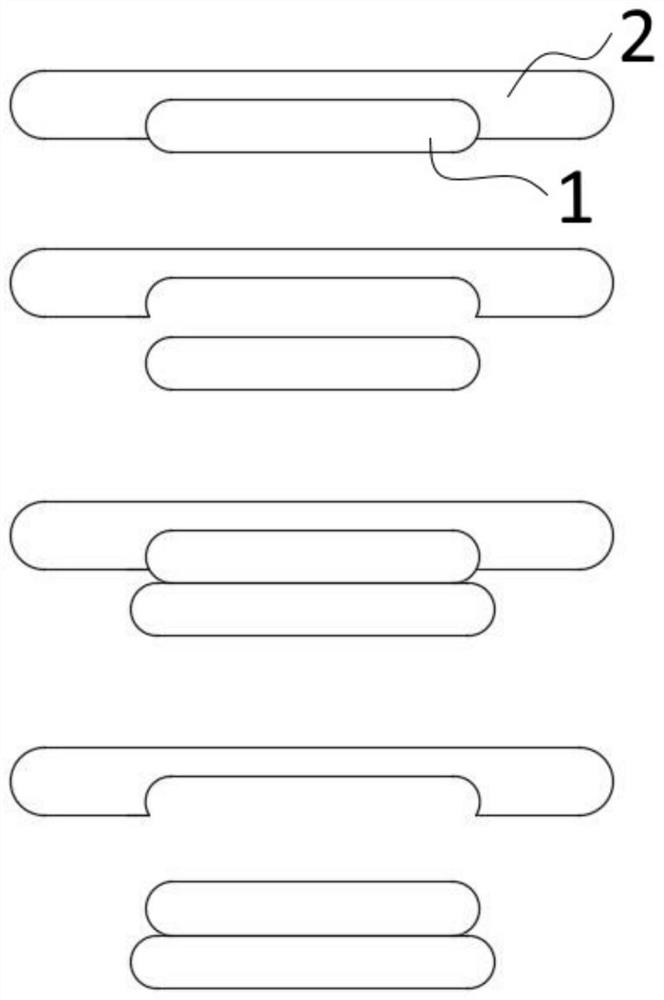

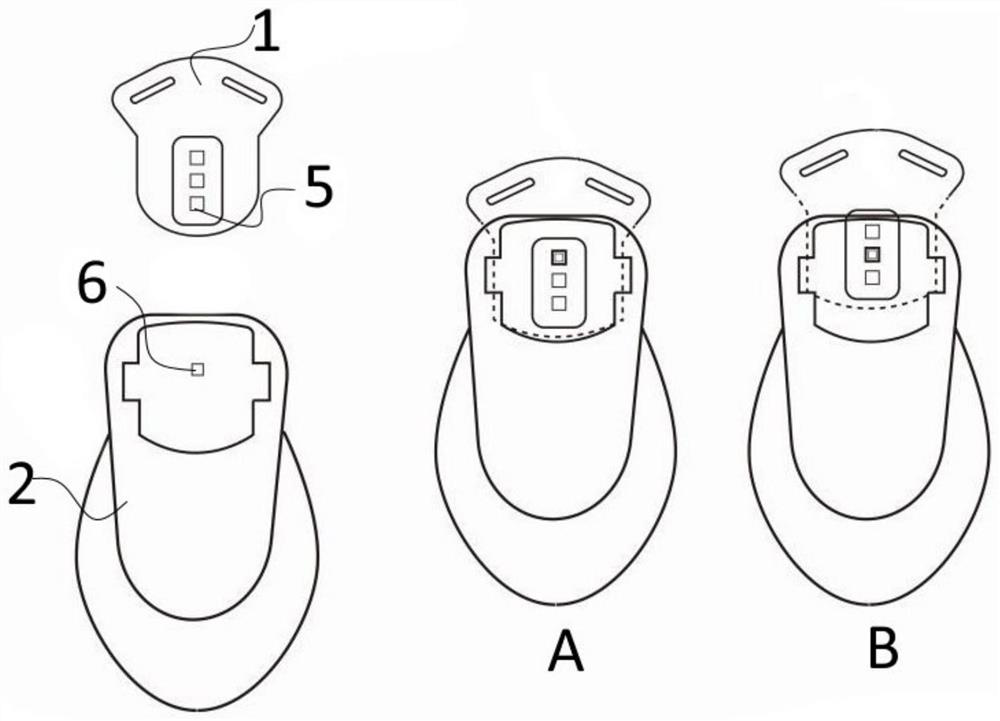

[0035] Embodiment 1: The single-hole bayonet fixing method includes setting a single limit hole 5 on the main backplane 2, and the movable backplane 1 is provided with a single row of limit holes 6; the single row of limit holes 6 The direction is parallel to the moving direction of the movable backplane 1, image 3 Accompanying drawings A and B are the expansion and contraction state diagrams of the expansion device of this embodiment.

specific Embodiment approach 2

[0036] Embodiment 2: The single-hole bayonet fixing method can also be provided with a single row of limiting holes 6 on the main backplane 2, and the movable backplane 1 is provided with a single limiting hole 5; the single row of limiting holes 6 The direction is parallel to the moving direction of the movable backplane 1, Figure 4 Accompanying drawings A and B are the expansion and contraction state diagrams of the expansion device of this embodiment.

[0037] Specific Embodiments 1 and 2: When the lengths of the two backplanes are adjusted in the U-shaped groove, at a certain position, the limit holes between the main backplane 2 and the movable backplane 1 will overlap. Use the bayonet to pass through the two overlapping holes. At this time, the two backplanes will not be able to slide in the U-shaped slot. The bayonet has an anti-falling function. It can be a pin, a screw, or an elastic buckle. The buckle is removed from the hole of either the main backplane 2 or the r...

specific Embodiment approach 3

[0038]Specific embodiment three: the double-hole bayonet fixing includes a single row of limiting holes 6 on both sides of the main backplane 2, and a single row of limiting holes 5 on both sides of the movable backplane 1; The direction of the row of limiting holes 6 is parallel to the moving direction of the movable backplane 1; the single limiting hole 5 is arranged at least three quarters of the movable backplane 1, and two limiting holes are used to align the main backplane. 2 The fixation with the movable backplane 1 can reduce the shaking phenomenon of the movable backplane 1 compared with the single-hole bayonet fixing method, Figure 5 Accompanying drawings A and B are the expansion and contraction state diagrams of the expansion device of this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com